Professional Documents

Culture Documents

HS 027 Competence, Training and Awareness

HS 027 Competence, Training and Awareness

Uploaded by

grantCopyright:

Available Formats

You might also like

- Kyocera EcosysM6230cidn-M6630cidn-M6235cidn-M6635cidnENSMR3-ASSCDocument964 pagesKyocera EcosysM6230cidn-M6630cidn-M6235cidn-M6635cidnENSMR3-ASSCDoug83% (6)

- SITXFSA002 Assessment 1 - AssignmentDocument6 pagesSITXFSA002 Assessment 1 - AssignmentJunio Braga0% (1)

- Internal Auditing and Inspection ProcedureDocument2 pagesInternal Auditing and Inspection ProcedurednmuleNo ratings yet

- (ISO 9001) Procedure For TrainingDocument3 pages(ISO 9001) Procedure For TrainingTuan AnhNo ratings yet

- Installation Manual: Technical Service Provided byDocument48 pagesInstallation Manual: Technical Service Provided byAlezsander RguezArNo ratings yet

- Msds Coladet Heb-PlusDocument3 pagesMsds Coladet Heb-PlusmndmattNo ratings yet

- SK 600 Service ManualDocument48 pagesSK 600 Service Manualahsani100% (2)

- HS 028 Continious Ris AssessmentDocument14 pagesHS 028 Continious Ris AssessmentgrantNo ratings yet

- HS 060 Evaluation of ComplianceDocument12 pagesHS 060 Evaluation of CompliancegrantNo ratings yet

- HS 069 Operational ControlDocument15 pagesHS 069 Operational ControlgrantNo ratings yet

- HSP05 Employee Competence rv4Document2 pagesHSP05 Employee Competence rv4john osullivanNo ratings yet

- Audit Summary ReportDocument2 pagesAudit Summary Reportas rginorNo ratings yet

- ASMI-OSHMS-PR-03 - Legal Compliance and Evaluation ProcedureDocument13 pagesASMI-OSHMS-PR-03 - Legal Compliance and Evaluation ProcedureJHUPEL ABARIALNo ratings yet

- Internal Quality Audit: Ogive Technology LLP Quality System ProcedureDocument2 pagesInternal Quality Audit: Ogive Technology LLP Quality System Proceduretrivesh100% (1)

- Can You Provide Some Examples of Quality Objectives For An Organization?Document1 pageCan You Provide Some Examples of Quality Objectives For An Organization?balusandeep20No ratings yet

- 15.1 Appendix 1 Internal Audit Checklist Preview ENDocument2 pages15.1 Appendix 1 Internal Audit Checklist Preview ENgheoda8926No ratings yet

- BCG-TM-PRO-13-13 HSE Performance & Calibration ProcedureDocument2 pagesBCG-TM-PRO-13-13 HSE Performance & Calibration ProcedureYousaf RichuNo ratings yet

- PR Training & CompetencyDocument9 pagesPR Training & CompetencyMuhammad ImranNo ratings yet

- ESCL-SOP-017, Procedure For Control of Workshop-Project OperationsDocument8 pagesESCL-SOP-017, Procedure For Control of Workshop-Project Operationsadiqualityconsult100% (1)

- OCP For Machine SafetyDocument1 pageOCP For Machine SafetyTigor Gurning100% (1)

- Training, Awareness & CompetenceDocument3 pagesTraining, Awareness & CompetencevladNo ratings yet

- RP-IMS-P-17 Internal AuditDocument5 pagesRP-IMS-P-17 Internal AuditArul Prasaad100% (1)

- Sample - 2 Procedure For Management ReviewDocument6 pagesSample - 2 Procedure For Management ReviewKauser Kazmi100% (1)

- Emergency Preparedness and ResponseDocument7 pagesEmergency Preparedness and Responseusq venture100% (1)

- 014 IITS Internal AuditDocument5 pages014 IITS Internal AuditSirajul IslamNo ratings yet

- 07 Procedure For Communication Participation and ConsultationDocument8 pages07 Procedure For Communication Participation and ConsultationBhuvanesh WaranNo ratings yet

- GP3101 ISO 14001 - 2004 ChecklistDocument5 pagesGP3101 ISO 14001 - 2004 ChecklistMagalyNo ratings yet

- FSMS-stage 02Document15 pagesFSMS-stage 02Arpita TripathiNo ratings yet

- Internal Audit Checklist PDFDocument18 pagesInternal Audit Checklist PDFKingsley PhangNo ratings yet

- Management Review ReportDocument11 pagesManagement Review ReportBrian Rasco100% (1)

- GEANT Anti-Slavery PolicyDocument3 pagesGEANT Anti-Slavery PolicyManel GuitartNo ratings yet

- HSEMS Management Review ProcedureDocument6 pagesHSEMS Management Review ProcedurebaselNo ratings yet

- Integrated Management System (IMS) QMS/EMS/OHSDocument17 pagesIntegrated Management System (IMS) QMS/EMS/OHSamitbanerjee51No ratings yet

- Monitoring of OHS Objectives & Targets v-0.1Document2 pagesMonitoring of OHS Objectives & Targets v-0.1Nomaan MalikNo ratings yet

- Sample SOP For Legal and Other Requirements PDFDocument2 pagesSample SOP For Legal and Other Requirements PDFanoushia alviNo ratings yet

- 10 Audit and Management Review Procedure FINALDocument3 pages10 Audit and Management Review Procedure FINALDayne Ocampo-SolimanNo ratings yet

- 10.1 Internal Audit Report App 1Document6 pages10.1 Internal Audit Report App 1SethNo ratings yet

- Bosch Code of Business ConductDocument20 pagesBosch Code of Business ConductParikshit DavateNo ratings yet

- EOHSP 07 Communication Consultation Participation PDFDocument5 pagesEOHSP 07 Communication Consultation Participation PDFSyafiq KhalilNo ratings yet

- Integrated Audit ReportDocument15 pagesIntegrated Audit ReportfeeNo ratings yet

- Internal Audit ChecklistDocument14 pagesInternal Audit ChecklistRamesh KumarNo ratings yet

- Environmental Goals ObjectivesDocument2 pagesEnvironmental Goals ObjectivesSujanto WidjajaNo ratings yet

- Health and Safety Manual 2023Document36 pagesHealth and Safety Manual 2023habiba rais100% (1)

- Journey Management ReviewDocument3 pagesJourney Management Reviewhamid123456789No ratings yet

- Management ReviewDocument3 pagesManagement ReviewAfrizal Ramadhan50% (2)

- Procedure For Management ReviewDocument2 pagesProcedure For Management ReviewSAKTHIVEL ANo ratings yet

- C-SMS-4.4.2. - Competence, Training and AwarenessDocument7 pagesC-SMS-4.4.2. - Competence, Training and Awarenesscontrax8No ratings yet

- SOP - For - HygieneDocument1 pageSOP - For - HygieneELITE INDUSTRIAL CONSULTNo ratings yet

- OHSAS Objectives and Targets PA Rev2Document3 pagesOHSAS Objectives and Targets PA Rev2ShirleyNo ratings yet

- Example Audit Report - ISO14001 2015Document19 pagesExample Audit Report - ISO14001 2015Shezi BhattiNo ratings yet

- Operational Control ProcedureDocument28 pagesOperational Control ProcedureS'peed50% (2)

- Audit Schedule - Department WiseDocument10 pagesAudit Schedule - Department WiseashishvaidNo ratings yet

- HSE-P-07 Work Permit Procedure Issue 2.1Document30 pagesHSE-P-07 Work Permit Procedure Issue 2.1eng20072007100% (1)

- 06 - Procedure For Performance Measurement MonitoringDocument5 pages06 - Procedure For Performance Measurement Monitoringbelhareth seifeddineNo ratings yet

- Procedure For Objectives and TargetsDocument2 pagesProcedure For Objectives and TargetsSAKTHIVEL A100% (1)

- OSH AuditDocument44 pagesOSH Auditsdtseurdiu8f9No ratings yet

- SHE-ECP-09-013 Portable Electrical Equipment Procedure Rev02Document5 pagesSHE-ECP-09-013 Portable Electrical Equipment Procedure Rev02grantNo ratings yet

- PPEA-WI-012 - B Consultation and Communication at SiteDocument6 pagesPPEA-WI-012 - B Consultation and Communication at SiteDeepakNo ratings yet

- Non Conformity ReportDocument1 pageNon Conformity ReportaikqualityNo ratings yet

- HSE-P-06 Monitoring and Measurement Issue 2.1Document4 pagesHSE-P-06 Monitoring and Measurement Issue 2.1eng20072007No ratings yet

- FRM-MR-01 Management Review Sept 03Document6 pagesFRM-MR-01 Management Review Sept 03Ranjit RoyNo ratings yet

- HS 071 HS PolicyDocument12 pagesHS 071 HS PolicygrantNo ratings yet

- IMS-PRO-004-VER-00 - Training Management ProcedureDocument12 pagesIMS-PRO-004-VER-00 - Training Management ProcedureDINESH KUMARNo ratings yet

- 216 Fire PreventionDocument12 pages216 Fire PreventiongrantNo ratings yet

- 217 Confined Space LaminatingDocument11 pages217 Confined Space LaminatinggrantNo ratings yet

- Accident Investigation 3Document33 pagesAccident Investigation 3grantNo ratings yet

- 218 Site EstablishmentDocument14 pages218 Site EstablishmentgrantNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)grantNo ratings yet

- 213 Laminating of GRPDocument11 pages213 Laminating of GRPgrantNo ratings yet

- Handtool Safe UsageDocument42 pagesHandtool Safe UsagegrantNo ratings yet

- 2 PM PROJ 06 - Major Design Change Register - REVISED JHLDocument2 pages2 PM PROJ 06 - Major Design Change Register - REVISED JHLgrantNo ratings yet

- 1 PM Proj 06 - Major Design Change Report - Revised JHLDocument4 pages1 PM Proj 06 - Major Design Change Report - Revised JHLgrantNo ratings yet

- Prj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundDocument2 pagesPrj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundgrantNo ratings yet

- PM Site 15b - Site Materials Control - REVISED JHLDocument2 pagesPM Site 15b - Site Materials Control - REVISED JHLgrantNo ratings yet

- 1 Osha 2Document19 pages1 Osha 2grantNo ratings yet

- ISO Training List - ConstructionDocument2 pagesISO Training List - ConstructiongrantNo ratings yet

- BSA - Safe Working at Height On SteelworkDocument95 pagesBSA - Safe Working at Height On SteelworkgrantNo ratings yet

- 6 PM PROJ 06 - Change of Scope FormDocument2 pages6 PM PROJ 06 - Change of Scope FormgrantNo ratings yet

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDocument1 pagePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNo ratings yet

- Section 4 - Index - Revised JHLDocument1 pageSection 4 - Index - Revised JHLgrantNo ratings yet

- PM Site 07a - Revised JHLDocument1 pagePM Site 07a - Revised JHLgrantNo ratings yet

- PM Proj 01 Wi-Method Statement - Revised JHLDocument11 pagesPM Proj 01 Wi-Method Statement - Revised JHLgrantNo ratings yet

- PM PROJ 01-Project Execution Procedure - REVISED JHL XXDocument1 pagePM PROJ 01-Project Execution Procedure - REVISED JHL XXgrantNo ratings yet

- PM Site 02b - Revised JHL #Document1 pagePM Site 02b - Revised JHL #grantNo ratings yet

- 1.conveyors Risk AssessmentDocument19 pages1.conveyors Risk AssessmentgrantNo ratings yet

- Section 9 - Check Out - Test & Acceptance Certificates - REVISED JHLDocument3 pagesSection 9 - Check Out - Test & Acceptance Certificates - REVISED JHLgrantNo ratings yet

- Sectiion 8 - Index - Quality Forms - Revised JHLDocument1 pageSectiion 8 - Index - Quality Forms - Revised JHLgrantNo ratings yet

- Section 6 - Index - Revised JHLDocument1 pageSection 6 - Index - Revised JHLgrantNo ratings yet

- Section 2 - Index - Revised JHLDocument1 pageSection 2 - Index - Revised JHLgrantNo ratings yet

- Section 1 Index - Revised JHLDocument1 pageSection 1 Index - Revised JHLgrantNo ratings yet

- Section 7 - Index - Revised JHLDocument1 pageSection 7 - Index - Revised JHLgrantNo ratings yet

- Section 2 - Execution Plan - REVISED JHLDocument1 pageSection 2 - Execution Plan - REVISED JHLgrantNo ratings yet

- 4.RAMS Machine Installations 2023Document14 pages4.RAMS Machine Installations 2023grantNo ratings yet

- Weekly Mass Toolbox Talk - 23rd Feb' 20Document3 pagesWeekly Mass Toolbox Talk - 23rd Feb' 20AnwarulNo ratings yet

- Strontium ChromateDocument5 pagesStrontium ChromateErika WidiariniNo ratings yet

- FR 003 Work-at-Height-ChecklistDocument1 pageFR 003 Work-at-Height-Checklistum erNo ratings yet

- Standards and Quality in EthiopiaDocument39 pagesStandards and Quality in EthiopiaEDEN2203No ratings yet

- Rachel B. Magistrado Tle Teacher Hinigaran National High SchoolDocument5 pagesRachel B. Magistrado Tle Teacher Hinigaran National High SchoolRachel MagistradoNo ratings yet

- Nebosh International Diploma For Occupational Health and Safety Management ProfessionalsDocument2 pagesNebosh International Diploma For Occupational Health and Safety Management ProfessionalsAftab Qadir100% (1)

- LA7958NDocument7 pagesLA7958NDurgesh SinghNo ratings yet

- Hazard Communication Safety Data Sheet Quick CardDocument2 pagesHazard Communication Safety Data Sheet Quick CardjoesuhreNo ratings yet

- Dimension of The DevelopmentDocument29 pagesDimension of The DevelopmentNoritz SantiagoNo ratings yet

- Final TLE 7-8 Hairdressing Q1 M5 PDFDocument16 pagesFinal TLE 7-8 Hairdressing Q1 M5 PDFLorena Espedillon EscuadroNo ratings yet

- 6213 Schnellbach Adam 2016Document185 pages6213 Schnellbach Adam 2016abdul haNo ratings yet

- SDRRMC Action Plan 2019Document5 pagesSDRRMC Action Plan 2019Vincent Librea100% (4)

- FINAL MARET 22 - TGI-MN-07-10 Emergency Response Plan (Rev-02) 23 Mar 2022 - Review by RMCGDocument69 pagesFINAL MARET 22 - TGI-MN-07-10 Emergency Response Plan (Rev-02) 23 Mar 2022 - Review by RMCGfarid akbarNo ratings yet

- Functional Safety Report (V1.01)Document16 pagesFunctional Safety Report (V1.01)boyu wangNo ratings yet

- 29 CFR 1910-101 Compressed Gases - General RequirementsDocument2 pages29 CFR 1910-101 Compressed Gases - General RequirementsgbogboiweNo ratings yet

- OSHAD-SF-TG-Laboratory Safety - V3.0 - EnglishDocument44 pagesOSHAD-SF-TG-Laboratory Safety - V3.0 - EnglishNiel Brian Villarazo0% (1)

- Operation & Maintenance: Paver Finisher F 121 W/D F 141 W/DDocument232 pagesOperation & Maintenance: Paver Finisher F 121 W/D F 141 W/DAliTronic1972No ratings yet

- DNV Wave Energy Converter RegsDocument217 pagesDNV Wave Energy Converter RegsBob ShelmerdineNo ratings yet

- 22 Haydon Allen Emergency Evacuation Area - 2Document1 page22 Haydon Allen Emergency Evacuation Area - 2johndoeNo ratings yet

- RA - Slips Trips & FallsDocument1 pageRA - Slips Trips & FallsDjole GeorgeNo ratings yet

- Legel Requirment ISO 45001Document2 pagesLegel Requirment ISO 45001sudhir sharmaNo ratings yet

- Application Note 6 ChecklistDocument35 pagesApplication Note 6 ChecklistHeresiarch100No ratings yet

- Equipment Training Policy and ProcedureDocument13 pagesEquipment Training Policy and Proceduremonir61100% (1)

- Iso 19443 2018Document15 pagesIso 19443 2018Musadik IkramNo ratings yet

- Val-Tex Grease Valve FlushDocument1 pageVal-Tex Grease Valve Flushpichet33No ratings yet

HS 027 Competence, Training and Awareness

HS 027 Competence, Training and Awareness

Uploaded by

grantOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HS 027 Competence, Training and Awareness

HS 027 Competence, Training and Awareness

Uploaded by

grantCopyright:

Available Formats

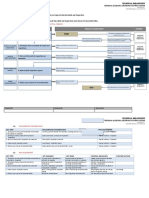

SOUTH AFRICA REGION REFERENCE REVISION PAGE

SERVICES H&S 027 5 1 OF 13

HEALTH & SAFETY SYSTEM OPERATIONAL ORIGINATOR H&S MANAGER

PROCEDURE

COMPETENCE, TRAINING AND AWARENESS

DESIGNATION PRINT NAME SIGNATURE DATE

COMPILED BY H&S OFFICER S THERON Original Signed 10/03/2011

REVIEWED BY H&S OFFICER JSD CRONJE Original Signed 10/03/2011

AUTHORISED BY H&S MANAGER J SODEN Original Signed 10/03/2011

TABLE OF CONTENTS PAGE ADDENDA PAGE

1. PURPOSE 2 ANNEXURE “X” – DEFINITIONS AND ABBREVIATIONS 7 - 11

2. SCOPE 2 ANNEXURE “XX” - REFERENCES 12

3. DEFINITIONS AND

2 RECORD OF AMENDMENTS 13

ABBREVIATIONS

4. REFERENCES 2

5. RESPONSIBILITY /

2

ACCOUNTABILITIES

6. REQUIREMENTS 3

7. FORMAL TRAINING 3

8. REVIEW TRAINING 4

9. COMPETENCY TRAINING 4

10. H&S MANAGEMENT SYSTEM

5

TRAINING

11. EDUCATION 5

12. H&S MANAGEMENT SYSTEM

6

NEEDS ANALYSIS

REVISION DESCRIPTION OF REVISION DATE

5 REVISION DUE TO NAME CHANGES 10 MARCH 2011

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 1 of 13

1. PURPOSE

The purpose and objective of this document is to provide guidance to South Africa Region Services for

harmonisation and common understanding in terms of the competence, training and awareness

process.

The management of South Africa Region Services is devoted in creating an enabling environment for

the employees to work in and that starts with planning. The next step is now to implement this plan

and have employees competent and trained to perform their work safely.

2. SCOPE

The scope of this procedure is to train all employees and contractors at South Africa Region Services

whose work directly or indirectly impacts on the safety health and environment so as to enable them to

conduct their work and manage the activities in a responsible manner by demonstrating that they have

the requisite competence and/or appropriate training as depicted in the training needs analysis matrix.

Management determine the level of experience, competence and training necessary to ensure the

capability of personnel and contractors which includes specialized OHS activities.

3. DEFINITIONS AND ABBREVIATIONS

Refer to Annexure “X”

4. REFERENCES

Refer to Annexure “XX”

5. RESPONSIBILITY / ACCOUNTABILITIES

Designation Responsibilities and accountabilities

HOD ATDS • Ensure availability of resources for training and competency assessments

as identified in the training needs analysis matrix.

HOD’s • Ensure that roles and responsibilities are set.

• Ensure that only trained and competent employees are selected to

perform work.

H&S Manager • Ensure that the competency of workers is monitored.

• Ensure changes as determined in the risk assessment process is fed

back to the training dept.

Supervisor / Foreman • Ensure that all employees in your area of responsibility are trained and

competent.

Snr Training & • Manage the training system and ensure that all employees are trained

Development Officer and competent as per the training needs analysis matrix.

• Ensure that lesson plans stay relevant / up to standard.

Moderator • Moderate assessment of learners found competent by a registered

assessor.

Training Officer • Manage the competency assessment system.

• Give update info to line to ensure the people are trained, refreshed and

found competent.

Assistant Training • Report to Training Officers.

Officer • Identify training needs with follow up visits.

• Refresher training.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 2 of 13

Line supervisors / • Ensure that employees that have received training are found competent

workplace assessors on the job.

Management • Ensure availability of resources to implement the OH&S programme

Representative • Ensure that analysis is made of information pertinent to OH&S

• Compare information with objectives, evaluate effectiveness of controls

and where targets are not met change controls to achieve desired results

• Ensure information is distributed and communicated to employees

relevant to the work they perform

• Ensure that personnel are aware of applicable legal and other

requirements

• Ensure H&S Officer (Systems) keep and maintain records

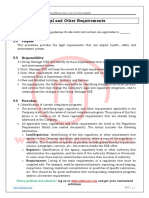

6. LEGAL AND OTHER REQUIREMENTS

• South Africa Region Services shall ensure that any person(s) under it’s control performing tasks

that can impact on OH&S is (are) competent on the basis of appropriate education, training or

experience. Associated records shall be retained.

• South Africa Region Services shall identify training needs associated with it’s OH&S risks and

OH&S management system. It shall provide training to meet these needs, evaluate the

effectiveness of the training and retain associated records.

• Awareness programmes / procedures must take account of OH&S risks and individual capabilities,

e.g. literacy and language skills.

• Awareness programmes must be provided for contractors / temporary workers / visitors according

to the level of risk to which they are exposed.

7. FORMAL TRAINING

This consists of compulsory initial training for all new individuals into South Africa Region Services, but

can also include existing employees that are scheduled for refresher training i.e. ex leave employees.

All training will ensure sufficient knowledge of the:

• consequences of their actions and behaviour in relation to OH&S risks

• benefits of improved OH&S performance

• need to conform to OH&S policies and procedures

• other aspects that might impact on OH&S.

What Training or Assessment is given By whom

First Aid Certificate St. John’s

Certificate of Fitness Occupational Health Centre

Human Resources Orientation Human Resources Department

Hazard Identification and Risk Assessment VR Gateway Training Centre / WW Learning

Centre (ATDS)

H&S Management System H&S Department

AngloGold Ashanti Overview / South Africa Training Department / VR Gateway / South Africa

Region Services Induction (HR Training) Region Services HR Department

South Africa Region Services Overview Training Department / VR Gateway / South Africa

Region Services HR Training Department

Technical Screening Engineering Training Department

Assessment Training Department and/or Accredited Assessor

Job Induction – (Site Specific) Line Managers

Specialised Training i.e. Weapons handling, Accredited Training Provider / Accepted Training

Driving of company vehicles Provider

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 3 of 13

On the Job Induction – Site Specific (Refer to H&S 066 – Annexure 1)

No employee is to receive any instruction to perform work without having gone through the specific site

induction. The following employees require induction:

• All new employees

• Employees transferred from other Business Units i.e. an Underground Fitter transferred to the

Surface workshop

• Internal transfers from one Geographical area to another i.e. an employee transferred from Vaal

River Kopanang Residence to West Wits Numbawani Residence

• All Contactors / temporary workers / visitors

The purpose of site inductions is to properly acquaint the employee with his area of work, the nature of

his tasks and his responsibility towards health and safety. The following issues must be broadly

discussed during a site induction process:

• Critical hazards and risks and how it relates to the work environment

• Control measures in places to deal with these hazards and risks.

• Work standards

• Employee responsibilities

• Emergency procedures

• Managerial Instructions and other Safety Rules

• Incident and Injury reporting requirements

8. REVIEW TRAINING

This is refresher training provided to all employees on an annual basis (birth month) as the need

arises. The training is provided by the HR training section and consists of the following:

• Training on legal requirements

• H&S Induction

• Work site specific induction

9. COMPETENCY TRAINING

Competence shall be defined in terms of appropriate education, training and experience. This training

is therefore focussed on equipping the employee with the knowledge and skill base to perform work in

a proper and safe manner.

How do we ensure competency?

Prior to commencing any work all South Africa Region Services employees are formally trained and

equipped with the required technical skills and knowledge, to perform the activities and related tasks

as required for a specific job. An employee is then found capable on the job by a registered internal or

external Training provider. The employee then returns to his/her area of work and performs the tasks

that he/she has been trained for. Although the employee has been trained and found capable of

performing specified tasks, he/she does so under constant or at least close supervision. Within in

a period of 60 days the employee must be found competent by a qualified assessor.

A process of continuous follow-ups by Line Supervisors to ensure that the employee adheres to

trained standards and continually improves on his/her skills to perform work properly. This is done

through scheduled planned personal contacts, planned inspections, planned task observations and

performance ratings. Any deviations identified during a PTO for example from the objectives of a

specific task, must be addressed by the Line Supervisor through on the job coaching. An agreement

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 4 of 13

must be reached between the parties concerned that a deviation or problem area has been identified

and a commitment must be made to remedy the situation.

If the on the job coaching sessions remain unsuccessful, the employee(s) is scheduled for re-training

through ATDS.

Further to this certain competencies i.e. Drivers, Weapon handlers, Overhead crane operators, will be

required to undergo regular screening by an accredited outside authority. The Materials Handling Act

for example stipulates that all employees working with Lifting equipment i.e. Forklift, Overhead crane,

Truck mounted crane, will undergo formal review training every 18 months and be re-assessed.

Specific competency requirements for the following employees:

• top management appointee, employees performing risk assessments, performing audits and

conducting incident investigations

10. SARSSS TRAINING

This training addresses Health & Safety principles and techniques.

Purpose of this training

• To provide knowledge and skill for preventing and controlling accidental loss.

• To enable employees to manage the H&S system within their work areas.

Content

• Hazard Identification and Risk Assessment

• Stop, Think and Go

• OHSAS 18OO1:2007

• Conduction and analysis of PTO’s, Planned Inspection, Green Area Meetings and Pre Use

Inspections, CRA System.

• Occupational Health and Hygiene issues

• Environment – General

• It’s OK Principles

This type of training is conducted on a formal and informal level. It is formally conducted during the

SDP course for all supervisors between Paterson grading B Lower to C Upper.

The other form of training is informally conducted through continuous coaching by H&S Officials during

work site inspections. Attendance registers will be kept of this kind of training as well.

11. EDUCATION

This is training in addition to formal training, to further develop and improve an employee’s

performance.

• ABET Training

• College /Technicon / University and other educational institutions

• E – Learning

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 5 of 13

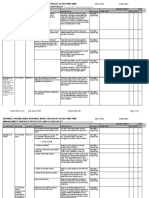

12. SARSSS NEEDS ANALYSIS

The Senior Training and Development Officer will compare the existing Health and Safety Training

available, with the Performance Standard requirements by means of a systematic team approach, to

establish and review the SARSSS Training needs for all levels of employees by considering the

following: (Annexure 2 - Example)

a) Risk Assessment Training

b) Inspections

c) Observations

d) Task Analysis and Procedures

e) Investigations

f) Emergency Preparedness

g) Signs and Colour Coding

h) First Aid

i) Communications

⇒ Proper job instructions

⇒ Coaching and Counselling

⇒ Group Meetings

⇒ Visibility Tours

j) Induction

k) Health and Hygiene

l) P.P.E

⇒ Fitting

⇒ Limitations

⇒ Maintenance

⇒ Storage

m) Critical Rules and Regulations

n) Permit and Licenses

o) Audits

The Health and Safety Committee must be consulted on the final document. The needs analysis will

be revised on inclusion of new occupations, when significant changes in the SARSSS occurs, or at

least annually.

Effectiveness of training will be evaluated to identify whether the training given is effective and

addresses hazards and reduce consequence.

Contractors will be dealt with the same as all other employees at all levels of competency.

ure 2

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 6 of 13

Annexure X

DEFINITIONS AND ABBREVIATIONS

DEFINITIONS:

DOCUMENT

Information and its supporting medium (The medium can be paper, magnetic, electronic or optical computer

disc, photograph or master sample, or a combination thereof.)

RECORD

Document stating results achieved or providing evidence of activities performed

CONTROLLED DOCUMENT

Any document that needs to be controlled in terms of its distribution and use, such as the Policy and

documented procedures. These documents are either signed in original ink and/or signed for on a

distribution list. These documents will be signed off after evaluation has been done to determine that they

are adequate for purpose. The document will be signed off by the relevant members as depicted on the

distribution list.

Once copies are printed of the database, they are considered to be “uncontrolled”.

OBSOLETE DOCUMENTS

Documents that have been replaced by later revisions or those that is no longer relevant or valid, and has

been cancelled from the system. These documents will be identified either by crossing them out and writing

obsolete or rubber stamp obsolete document.

UNCONTROLLED DOCUMENTS

Any documents that have not been issued under the circumstances under “controlled documents” are

categorised as uncontrolled. This includes, but may not be limited to:

Documents that do not need to be controlled such as the monthly safety topic.

Documents not distributed by the authorised person as per the procedures “authority and

responsibility” table and signed for by the recipient.

Documents printed from the electronic database. (Watermarked “uncontrolled document”)

Documents duplicated or photocopied from controlled documents.

Photocopies of the Occupational Health and Safety policy as issued to the public or other

Interested and Affected Parties

It is not possible to judge from an uncontrolled copy whether it is the latest version. It is the responsibility of

the person holding the documentation to ensure that (s) he has the latest version.

INJURY

Physical harm or damage

OCCUPATIONAL HEALTH AND SAFETY

Conditions and factors that affect, or could affect the health and safety of employees or other workers

(including temporary workers and contractor personnel), visitors, or any other person in the workplace

OH&S MANAGEMENT SYSTEM

Part of an organization’s management system used to develop and implement its OH&S policy and manage

its OH&S risks

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 7 of 13

SEVERITY / CONSEQUENCE

Outcome of an event. There may be one or more consequences from an event. May be expressed

qualitatively or quantitatively may range from positive to negative (Speculative).

FREQUENCY

Occurrence per unit time, (May be expressed qualitatively or quantitatively).

EXPOSURE

How often and for how long employees are exposed to a hazard/s.

LIKELIHOOD

Means the chance of an event occurring.

DUE DILIGENCE

Taking reasonable care to protect the health and safety of all employees. Provide equipment, maintain the

equipment, use equipment as prescribed, provide information relating to the equipment, and provide

competent supervision.

INCIDENT

An undesired event which under slightly different circumstances could result in harm to people. Damage to

property or loss to process or an undesired event that could or does result in a loss.

RISK MATRIX

A Risk index can be determined by plotting likelihood and severity indices on the y and x-axis respectively

and then using them to obtain a risk ranking.

HIRA

Process of recognizing that a hazard exists and defining its characteristics

• H = HAZARD

Anything around us that we can see as well as those energy sources we cannot see e.g. Gas and

radiation that can cause harm

• I = IDENTIFICATION

Identify the significant hazards (Process and recognition)

• R = RISK

Risk imagining (Likelihood and consequence if risk materializes)

• A = ASSESSMENT

Determine the magnitude of the risk if materialized

ROUTINE ACTIVITY

An activity which is performed on a regular basis (day to day)

NON ROUTINE

An activity performed on an adhoc basis

ACCOUNTABILITY

Principle that, individuals, organizations, and the community are responsible for their actions and may be

required to explain them to others.

RESPONSIBLE

Liable to be called to respond to a person for issues to be done.

ILL HEALTH

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 8 of 13

Identifiable adverse physical or mental condition arising from and/or made worse by a work activity and/or

work-related situation.

INTERESTED PARTIES

Person or group, inside or outside the workplace, concerned with or affected by the SARSSS performance.

NONCONFORMITY

Non-fulfilment of a requirement – can be any deviation from:

Relevant work standards, practices, procedures, legal requirements.

SARSSS OBJECTIVES

SARSSS goals, in terms of OHS performance, that SA Region Services sets itself to achieve. Objectives are

quantified wherever practical.

SARSSS PERFORMANCE

Measurable results of SA Region Services management of its risks.

Note: Performance measurement includes measurement the effectiveness of controls.

OHS POLICY

Overall intention and direction which will be followed for the management of health and safety.

RECORD

Document stating results achieved or providing evidence of activities performed

HAZARD

A condition or practice with the potential to cause harm, or exposure to danger. (Immediate Causes,

Substandard Act or Substandard Condition)

RISK ASSESSMENT

Process of evaluating the risk(s) arising from a hazard(s), taking into account the adequacy of any existing

controls, and deciding whether or not the risk(s) is acceptable

PREVENTATIVE ACTION

Action to eliminate the cause of a potential nonconformity or other undesirable potential situation.

CORRECTIVE ACTION

Action taken to rectify a non-conformance or deviation

CONTINUAL IMPROVEMENT

To constantly improve on current Health and Safety standards

PROCEDURE

Specified way to carry out an activity or a process.

RISK ASSESSMENT

Process of evaluating the risk arising from a hazard, taking into account the adequacy of any existing

controls, and deciding whether or not the risk is acceptable.

WORKPLACE

Any physical location in which work related activities are performed under the control of SA Region

Services.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 9 of 13

AUDIT

Independent and documented process for obtaining “audit evidence” and evaluating it objectively to

determine the extent to which “audit criteria” are fulfilled.

SAFETY MONTH

Period from the 20th of a particular month up to the 19th of the following month.

EFFORT BASED OBJECTIVES

Objectives set to improve program related issues

EFFECT BASED OBJECTIVES

Objectives set to improve severity or injury rates

MANCOM

Management Committee

EXCO

Executive Committee

SUPERVISOR

Within SA Region Services – One who supervise or has charge and direction of i.e. Foreman, Clerk of

works, Training Officer, Residence Manager, Security Officer etc.

EMPLOYEE

Person working under the control of the organisation and includes contractors.

MANAGEMENT REPRESENTATIVE

A Person appointed in writing ensuring that the OH&S management system is established, implemented

and maintained in accordance with this OHSAS Standard;

and ensuring that reports on the performance of the OH&S management system are presented to top

management for review and used as a basis for improvement of the OH&S management system.

VISITOR

Any person who enters the premises of the mine who is not a full time employee or Contractor paid by the

mine

CONTRACTOR

Any person who perform work for the mine and is paid for his/her service.

ACCEPTABLE RISK

Risk that has been reduced to a level that can be tolerated by the organization having regard to its legal

obligations and its own

HEALTH AND SAFETY COMMITTEE

A committee as required by law M H & S Act Section 25(2)

VERIFICATION

Verification is the act of reviewing, inspecting, testing, etc. to establish and document that a product, service,

or system meets the regulatory, standard, or specification requirements.

VALIDATION

Validation refers to meeting the needs of the intended end-user or customer to

prove the truth or to determine or test the accuracy. Also, validation is the process of checking if something

satisfies a certain criterion.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 10 of 13

ABBREVIATIONS:

M H & S Act - Mine Health & Safety Act

MA&R - Mineral Act & Regulations

OHASA - Occupational Health and Safety Act

DMR - Department of Mineral Resources

DOL - Department of Labour

SARS - South Africa Region Services

ESW - Engineering Services Workshops

WITW - Wellness in the Workplace

H&S - Health and Safety

LTIFPD - Loss Time Injury Free Production Days

IFPD - Injury Free Production Days

AGAH - AngloGold Ashanti Health

TMM - Trackless Mobile Machinery

COP - Code of Practice

ATDS - AngloGold Ashanti Training and Development Services

CRA - Continuous Risk Assessment

SARSSS - South Africa Region Services Safety System

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 11 of 13

Annexure XX

REFERENCES

• Roles and responsibilities are depicted in each system procedure and updated as and when

required in table format

• OHSAS 18001:2007 (Occupational Health and Assessment Series)

• The Mine Health and Safety Act 29 of 1996

• The Minerals Act 50 of 1991

• Occupational Health and Safety Act (Act 86 of 1993)

• COIDA

• AGA Strategic Objectives

• Implex Legal Register

• ATDS Training Matrix

• AGA RCAT

• Corporate Procedure Directive

• Health and Safety Agreement

• SAR/OESH/P/A/001.01 – AGA Incident reporting

• H&S 004 – Incident investigation

• H&S 006 – Emergency preparedness and response

• H&S 014 – Issue based risk assessment

• H&S 018 – Baseline risk assessment H&S 019 – Control of records

• H&S 023 – Control of documents

• H&S 027 – Competence, training and awareness

• H&S 028 – Continuous risk assessment

• H&S 029 – Communication, participation and consultation

• H&S 030 – Management review

• H&S 031 – Internal audit

• H&S 037 – Management of change

• H&S 055 – SA Region Services Scope

• H&S 058 – Legal and other requirements

• H&S 059 – Performance measurement and monitoring

• H&S 060 – Evaluation of compliance

• H&S 061 – Nonconformity, corrective and preventative action

• H&S 065 – Objectives and programme(s)

• H&S 067 – Resources, roles, responsibility, accountability and authority

• H&S 069 – Operational control

• H&S 070 – Documentation

• H&S 071 – H&S Policy

• H&S 066 – Contractor H&S Requirements SARS

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 12 of 13

RECORDS OF AMENDMENTS

PROCEDURE DATE OF

CHANGES TO PROCEDURE

REVISION NUMBER APPROVAL

Purpose, Scope, Training needs, Definitions

and abbreviations, References, Body Fluids

add to Annexure 1, Responsibility and

literacy, other requirements, training and

H&S 027 – Revision 03 2 June 2009

effectiveness, competency requirements,

consequences, benefits and need to comply

with occupational health & safety standards

and procedures

Training requirement matrix (Annexure 2 P6

point 12)

Attendance register for informal training (P5

H&S 027 – Revision 04 1 October 2009

point 10)

SARS Induction added (P3 point 7)

Added annexure 2 (P12)

H&S 027 – Revision 05 Annexure 1 & 2 removed 10 March 2011

SADS changed to SARS

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Competence, Training and REVISION EFFECTIVE DATE PRINT DATE PAGE

Awareness

H&S 027 05 October 2009 10 March 2011 Page 13 of 13

You might also like

- Kyocera EcosysM6230cidn-M6630cidn-M6235cidn-M6635cidnENSMR3-ASSCDocument964 pagesKyocera EcosysM6230cidn-M6630cidn-M6235cidn-M6635cidnENSMR3-ASSCDoug83% (6)

- SITXFSA002 Assessment 1 - AssignmentDocument6 pagesSITXFSA002 Assessment 1 - AssignmentJunio Braga0% (1)

- Internal Auditing and Inspection ProcedureDocument2 pagesInternal Auditing and Inspection ProcedurednmuleNo ratings yet

- (ISO 9001) Procedure For TrainingDocument3 pages(ISO 9001) Procedure For TrainingTuan AnhNo ratings yet

- Installation Manual: Technical Service Provided byDocument48 pagesInstallation Manual: Technical Service Provided byAlezsander RguezArNo ratings yet

- Msds Coladet Heb-PlusDocument3 pagesMsds Coladet Heb-PlusmndmattNo ratings yet

- SK 600 Service ManualDocument48 pagesSK 600 Service Manualahsani100% (2)

- HS 028 Continious Ris AssessmentDocument14 pagesHS 028 Continious Ris AssessmentgrantNo ratings yet

- HS 060 Evaluation of ComplianceDocument12 pagesHS 060 Evaluation of CompliancegrantNo ratings yet

- HS 069 Operational ControlDocument15 pagesHS 069 Operational ControlgrantNo ratings yet

- HSP05 Employee Competence rv4Document2 pagesHSP05 Employee Competence rv4john osullivanNo ratings yet

- Audit Summary ReportDocument2 pagesAudit Summary Reportas rginorNo ratings yet

- ASMI-OSHMS-PR-03 - Legal Compliance and Evaluation ProcedureDocument13 pagesASMI-OSHMS-PR-03 - Legal Compliance and Evaluation ProcedureJHUPEL ABARIALNo ratings yet

- Internal Quality Audit: Ogive Technology LLP Quality System ProcedureDocument2 pagesInternal Quality Audit: Ogive Technology LLP Quality System Proceduretrivesh100% (1)

- Can You Provide Some Examples of Quality Objectives For An Organization?Document1 pageCan You Provide Some Examples of Quality Objectives For An Organization?balusandeep20No ratings yet

- 15.1 Appendix 1 Internal Audit Checklist Preview ENDocument2 pages15.1 Appendix 1 Internal Audit Checklist Preview ENgheoda8926No ratings yet

- BCG-TM-PRO-13-13 HSE Performance & Calibration ProcedureDocument2 pagesBCG-TM-PRO-13-13 HSE Performance & Calibration ProcedureYousaf RichuNo ratings yet

- PR Training & CompetencyDocument9 pagesPR Training & CompetencyMuhammad ImranNo ratings yet

- ESCL-SOP-017, Procedure For Control of Workshop-Project OperationsDocument8 pagesESCL-SOP-017, Procedure For Control of Workshop-Project Operationsadiqualityconsult100% (1)

- OCP For Machine SafetyDocument1 pageOCP For Machine SafetyTigor Gurning100% (1)

- Training, Awareness & CompetenceDocument3 pagesTraining, Awareness & CompetencevladNo ratings yet

- RP-IMS-P-17 Internal AuditDocument5 pagesRP-IMS-P-17 Internal AuditArul Prasaad100% (1)

- Sample - 2 Procedure For Management ReviewDocument6 pagesSample - 2 Procedure For Management ReviewKauser Kazmi100% (1)

- Emergency Preparedness and ResponseDocument7 pagesEmergency Preparedness and Responseusq venture100% (1)

- 014 IITS Internal AuditDocument5 pages014 IITS Internal AuditSirajul IslamNo ratings yet

- 07 Procedure For Communication Participation and ConsultationDocument8 pages07 Procedure For Communication Participation and ConsultationBhuvanesh WaranNo ratings yet

- GP3101 ISO 14001 - 2004 ChecklistDocument5 pagesGP3101 ISO 14001 - 2004 ChecklistMagalyNo ratings yet

- FSMS-stage 02Document15 pagesFSMS-stage 02Arpita TripathiNo ratings yet

- Internal Audit Checklist PDFDocument18 pagesInternal Audit Checklist PDFKingsley PhangNo ratings yet

- Management Review ReportDocument11 pagesManagement Review ReportBrian Rasco100% (1)

- GEANT Anti-Slavery PolicyDocument3 pagesGEANT Anti-Slavery PolicyManel GuitartNo ratings yet

- HSEMS Management Review ProcedureDocument6 pagesHSEMS Management Review ProcedurebaselNo ratings yet

- Integrated Management System (IMS) QMS/EMS/OHSDocument17 pagesIntegrated Management System (IMS) QMS/EMS/OHSamitbanerjee51No ratings yet

- Monitoring of OHS Objectives & Targets v-0.1Document2 pagesMonitoring of OHS Objectives & Targets v-0.1Nomaan MalikNo ratings yet

- Sample SOP For Legal and Other Requirements PDFDocument2 pagesSample SOP For Legal and Other Requirements PDFanoushia alviNo ratings yet

- 10 Audit and Management Review Procedure FINALDocument3 pages10 Audit and Management Review Procedure FINALDayne Ocampo-SolimanNo ratings yet

- 10.1 Internal Audit Report App 1Document6 pages10.1 Internal Audit Report App 1SethNo ratings yet

- Bosch Code of Business ConductDocument20 pagesBosch Code of Business ConductParikshit DavateNo ratings yet

- EOHSP 07 Communication Consultation Participation PDFDocument5 pagesEOHSP 07 Communication Consultation Participation PDFSyafiq KhalilNo ratings yet

- Integrated Audit ReportDocument15 pagesIntegrated Audit ReportfeeNo ratings yet

- Internal Audit ChecklistDocument14 pagesInternal Audit ChecklistRamesh KumarNo ratings yet

- Environmental Goals ObjectivesDocument2 pagesEnvironmental Goals ObjectivesSujanto WidjajaNo ratings yet

- Health and Safety Manual 2023Document36 pagesHealth and Safety Manual 2023habiba rais100% (1)

- Journey Management ReviewDocument3 pagesJourney Management Reviewhamid123456789No ratings yet

- Management ReviewDocument3 pagesManagement ReviewAfrizal Ramadhan50% (2)

- Procedure For Management ReviewDocument2 pagesProcedure For Management ReviewSAKTHIVEL ANo ratings yet

- C-SMS-4.4.2. - Competence, Training and AwarenessDocument7 pagesC-SMS-4.4.2. - Competence, Training and Awarenesscontrax8No ratings yet

- SOP - For - HygieneDocument1 pageSOP - For - HygieneELITE INDUSTRIAL CONSULTNo ratings yet

- OHSAS Objectives and Targets PA Rev2Document3 pagesOHSAS Objectives and Targets PA Rev2ShirleyNo ratings yet

- Example Audit Report - ISO14001 2015Document19 pagesExample Audit Report - ISO14001 2015Shezi BhattiNo ratings yet

- Operational Control ProcedureDocument28 pagesOperational Control ProcedureS'peed50% (2)

- Audit Schedule - Department WiseDocument10 pagesAudit Schedule - Department WiseashishvaidNo ratings yet

- HSE-P-07 Work Permit Procedure Issue 2.1Document30 pagesHSE-P-07 Work Permit Procedure Issue 2.1eng20072007100% (1)

- 06 - Procedure For Performance Measurement MonitoringDocument5 pages06 - Procedure For Performance Measurement Monitoringbelhareth seifeddineNo ratings yet

- Procedure For Objectives and TargetsDocument2 pagesProcedure For Objectives and TargetsSAKTHIVEL A100% (1)

- OSH AuditDocument44 pagesOSH Auditsdtseurdiu8f9No ratings yet

- SHE-ECP-09-013 Portable Electrical Equipment Procedure Rev02Document5 pagesSHE-ECP-09-013 Portable Electrical Equipment Procedure Rev02grantNo ratings yet

- PPEA-WI-012 - B Consultation and Communication at SiteDocument6 pagesPPEA-WI-012 - B Consultation and Communication at SiteDeepakNo ratings yet

- Non Conformity ReportDocument1 pageNon Conformity ReportaikqualityNo ratings yet

- HSE-P-06 Monitoring and Measurement Issue 2.1Document4 pagesHSE-P-06 Monitoring and Measurement Issue 2.1eng20072007No ratings yet

- FRM-MR-01 Management Review Sept 03Document6 pagesFRM-MR-01 Management Review Sept 03Ranjit RoyNo ratings yet

- HS 071 HS PolicyDocument12 pagesHS 071 HS PolicygrantNo ratings yet

- IMS-PRO-004-VER-00 - Training Management ProcedureDocument12 pagesIMS-PRO-004-VER-00 - Training Management ProcedureDINESH KUMARNo ratings yet

- 216 Fire PreventionDocument12 pages216 Fire PreventiongrantNo ratings yet

- 217 Confined Space LaminatingDocument11 pages217 Confined Space LaminatinggrantNo ratings yet

- Accident Investigation 3Document33 pagesAccident Investigation 3grantNo ratings yet

- 218 Site EstablishmentDocument14 pages218 Site EstablishmentgrantNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)grantNo ratings yet

- 213 Laminating of GRPDocument11 pages213 Laminating of GRPgrantNo ratings yet

- Handtool Safe UsageDocument42 pagesHandtool Safe UsagegrantNo ratings yet

- 2 PM PROJ 06 - Major Design Change Register - REVISED JHLDocument2 pages2 PM PROJ 06 - Major Design Change Register - REVISED JHLgrantNo ratings yet

- 1 PM Proj 06 - Major Design Change Report - Revised JHLDocument4 pages1 PM Proj 06 - Major Design Change Report - Revised JHLgrantNo ratings yet

- Prj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundDocument2 pagesPrj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundgrantNo ratings yet

- PM Site 15b - Site Materials Control - REVISED JHLDocument2 pagesPM Site 15b - Site Materials Control - REVISED JHLgrantNo ratings yet

- 1 Osha 2Document19 pages1 Osha 2grantNo ratings yet

- ISO Training List - ConstructionDocument2 pagesISO Training List - ConstructiongrantNo ratings yet

- BSA - Safe Working at Height On SteelworkDocument95 pagesBSA - Safe Working at Height On SteelworkgrantNo ratings yet

- 6 PM PROJ 06 - Change of Scope FormDocument2 pages6 PM PROJ 06 - Change of Scope FormgrantNo ratings yet

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDocument1 pagePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNo ratings yet

- Section 4 - Index - Revised JHLDocument1 pageSection 4 - Index - Revised JHLgrantNo ratings yet

- PM Site 07a - Revised JHLDocument1 pagePM Site 07a - Revised JHLgrantNo ratings yet

- PM Proj 01 Wi-Method Statement - Revised JHLDocument11 pagesPM Proj 01 Wi-Method Statement - Revised JHLgrantNo ratings yet

- PM PROJ 01-Project Execution Procedure - REVISED JHL XXDocument1 pagePM PROJ 01-Project Execution Procedure - REVISED JHL XXgrantNo ratings yet

- PM Site 02b - Revised JHL #Document1 pagePM Site 02b - Revised JHL #grantNo ratings yet

- 1.conveyors Risk AssessmentDocument19 pages1.conveyors Risk AssessmentgrantNo ratings yet

- Section 9 - Check Out - Test & Acceptance Certificates - REVISED JHLDocument3 pagesSection 9 - Check Out - Test & Acceptance Certificates - REVISED JHLgrantNo ratings yet

- Sectiion 8 - Index - Quality Forms - Revised JHLDocument1 pageSectiion 8 - Index - Quality Forms - Revised JHLgrantNo ratings yet

- Section 6 - Index - Revised JHLDocument1 pageSection 6 - Index - Revised JHLgrantNo ratings yet

- Section 2 - Index - Revised JHLDocument1 pageSection 2 - Index - Revised JHLgrantNo ratings yet

- Section 1 Index - Revised JHLDocument1 pageSection 1 Index - Revised JHLgrantNo ratings yet

- Section 7 - Index - Revised JHLDocument1 pageSection 7 - Index - Revised JHLgrantNo ratings yet

- Section 2 - Execution Plan - REVISED JHLDocument1 pageSection 2 - Execution Plan - REVISED JHLgrantNo ratings yet

- 4.RAMS Machine Installations 2023Document14 pages4.RAMS Machine Installations 2023grantNo ratings yet

- Weekly Mass Toolbox Talk - 23rd Feb' 20Document3 pagesWeekly Mass Toolbox Talk - 23rd Feb' 20AnwarulNo ratings yet

- Strontium ChromateDocument5 pagesStrontium ChromateErika WidiariniNo ratings yet

- FR 003 Work-at-Height-ChecklistDocument1 pageFR 003 Work-at-Height-Checklistum erNo ratings yet

- Standards and Quality in EthiopiaDocument39 pagesStandards and Quality in EthiopiaEDEN2203No ratings yet

- Rachel B. Magistrado Tle Teacher Hinigaran National High SchoolDocument5 pagesRachel B. Magistrado Tle Teacher Hinigaran National High SchoolRachel MagistradoNo ratings yet

- Nebosh International Diploma For Occupational Health and Safety Management ProfessionalsDocument2 pagesNebosh International Diploma For Occupational Health and Safety Management ProfessionalsAftab Qadir100% (1)

- LA7958NDocument7 pagesLA7958NDurgesh SinghNo ratings yet

- Hazard Communication Safety Data Sheet Quick CardDocument2 pagesHazard Communication Safety Data Sheet Quick CardjoesuhreNo ratings yet

- Dimension of The DevelopmentDocument29 pagesDimension of The DevelopmentNoritz SantiagoNo ratings yet

- Final TLE 7-8 Hairdressing Q1 M5 PDFDocument16 pagesFinal TLE 7-8 Hairdressing Q1 M5 PDFLorena Espedillon EscuadroNo ratings yet

- 6213 Schnellbach Adam 2016Document185 pages6213 Schnellbach Adam 2016abdul haNo ratings yet

- SDRRMC Action Plan 2019Document5 pagesSDRRMC Action Plan 2019Vincent Librea100% (4)

- FINAL MARET 22 - TGI-MN-07-10 Emergency Response Plan (Rev-02) 23 Mar 2022 - Review by RMCGDocument69 pagesFINAL MARET 22 - TGI-MN-07-10 Emergency Response Plan (Rev-02) 23 Mar 2022 - Review by RMCGfarid akbarNo ratings yet

- Functional Safety Report (V1.01)Document16 pagesFunctional Safety Report (V1.01)boyu wangNo ratings yet

- 29 CFR 1910-101 Compressed Gases - General RequirementsDocument2 pages29 CFR 1910-101 Compressed Gases - General RequirementsgbogboiweNo ratings yet

- OSHAD-SF-TG-Laboratory Safety - V3.0 - EnglishDocument44 pagesOSHAD-SF-TG-Laboratory Safety - V3.0 - EnglishNiel Brian Villarazo0% (1)

- Operation & Maintenance: Paver Finisher F 121 W/D F 141 W/DDocument232 pagesOperation & Maintenance: Paver Finisher F 121 W/D F 141 W/DAliTronic1972No ratings yet

- DNV Wave Energy Converter RegsDocument217 pagesDNV Wave Energy Converter RegsBob ShelmerdineNo ratings yet

- 22 Haydon Allen Emergency Evacuation Area - 2Document1 page22 Haydon Allen Emergency Evacuation Area - 2johndoeNo ratings yet

- RA - Slips Trips & FallsDocument1 pageRA - Slips Trips & FallsDjole GeorgeNo ratings yet

- Legel Requirment ISO 45001Document2 pagesLegel Requirment ISO 45001sudhir sharmaNo ratings yet

- Application Note 6 ChecklistDocument35 pagesApplication Note 6 ChecklistHeresiarch100No ratings yet

- Equipment Training Policy and ProcedureDocument13 pagesEquipment Training Policy and Proceduremonir61100% (1)

- Iso 19443 2018Document15 pagesIso 19443 2018Musadik IkramNo ratings yet

- Val-Tex Grease Valve FlushDocument1 pageVal-Tex Grease Valve Flushpichet33No ratings yet