Professional Documents

Culture Documents

90 160kW EG Screw Compressor PDF

90 160kW EG Screw Compressor PDF

Uploaded by

Suresh Nath0 ratings0% found this document useful (0 votes)

22 views6 pagesOriginal Title

90-160kW-EG-Screw-Compressor.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

22 views6 pages90 160kW EG Screw Compressor PDF

90 160kW EG Screw Compressor PDF

Uploaded by

Suresh NathCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

90 - 160 kw

EG Series

<> Screw Air Compressors

“N | Life source of industries

UPTIME”

Kas

RELIABILITY

ELGi, established in 1960, designs and manufactures a wide range of compressors The

company has gained its reputation for design and manufacture of screw compressors

through strategie partnerships and continuous research and development. Over the years i

‘emerged 5 2 multiproduct, mut-market enterprise providing total compressed ai in all

Segments, ELGi's design capabilities translated into a wide range of products ranging from

ciblubticated and oil-free rotary screwr compressors, reciprocating compressors and

‘entifugal compressors, ELGi has ts own manufacturing operations in China France, India

and italy with subsidiaries in Australia, Braz, Indonesia, UAE and USA. The company is fast

expanding ts global footprint atractng distributors and customers witits latest generation

products

EG Series

‘The ew EG Series electric powered screw compressors stands as proof of ELGI spirit of continuous development. Combining reliability with energy

efficiency, ELGis new EG Series compressor systems designed with improved feature ik space-saving, significant reduction in noise level, ficient

moisture separator, low ol-cary over and user-friendly controll. Moreover, low power and reduced maintenance needs ensure that operating costs

‘will remain ow throughout the compressor ie. The compressor s manufacture in compliance with applicable international standards (UL, ASME,

(CEand others) and designed as per the international quality standards

MAXIMIZE

RELIABILITY

EFFICIENCY

PERFORMANCE

TECHNOLOGY EG MINIMIZE

Series # NOISE LEVEL

DOWN TIME

‘Vie MAINTENANCE

OIL CARRY OVER

Screw compression elements are manufactured in-house using state-of-the-art machining centres for rotor grinding and machining castings

of various sizes. Elg’s exclusive Axis arends ensure energy-eficient compressed air supply forall demanding applications.

+ Axis arend is powered by Elg’seffiient profile rotors

+ Axis airend is internally lubricated to eliminate cil leakage

+ Axis airend with 4x5 ground rotor combination lobes results in optimum efficiency at 100 -115 psi g (7-8 bar g) and reduced compression

losses provide better spectic power consumption per KW

+ Axis aired has high volumetric efficiency and high isentropic efficiency

Global Series - The Technology Edge =

™\ MAXIMUM Energy Efficiency

Optimal Flow Control

+ The new generation intake valve with integrated blow down uni, solenoid

switch and actuator is designed for low losses

+ The intake valve i optimized for dual mode operations

* Large size ofthe intake vale minimizes pressure drop and suction losses

* Modulation unit ensures effective contol of inet airflow and maximizes

power savings

+ Auto dual contol operates on madulation meade from 100-60% in lading

andin oad-unload mode for loads below 60%

* Constant pressure due to gradual opening or closing of suction valve with

respect to demand (multi-point) contol

* Option for selecting load-unload/modulation auto dual made for all large 100

Screw compressor models as a standard feature

* Smooth operation by modulation ensures longer ife of airend, valves and

all mechanical components. It also ensures no sudden spikes or dp in

line pressure

* Lowest power consumption in its lass of compressor controls, even with

fluctuating loads

apt Romer

of ess

conte

0 3% © 30 6 7 wm $0 10

os

xX‘ MAXIMUM Reliability

Efficient Air Filter System

* Use of prefilters ensure clean ar suction unit and enhances air filter ile cycle

* Heavy duty dry type air fier ensure two ways of tration by centrifugal action and by

paper fitercarridge with 99.9% efficiency

* Optimally sized high efficiency filter provides maximum filter ifeand clean intake air

+ Air iter with visual condition indicator and silencer for easy maintenance of the sytem

+ Automatic cleaning of ai filter for every cycle of upload operations

High Efficiency Drive System

+ Heavy duty EFC squitrel cage induction motor with class F insulation and IPSS

protection for assured operation in dusty environment

+ Wide operating vltage +/- 10%

+ Motor selected for high ambient of 45°C with power variants 415V/400Vi380V in SO He

+ Motor winding temperature limited to Class 8 temperature rise

+ Optimized ventilation system for cooler operations and reduced nose levels

+ Sold base for reduced vibration levels

+ Regreasable bal bearings

+ Gasket for conduit box

Drive Coupling

+ Ensues efficient poner transmission with uniform load on bearing due to permanent

alignment of atend and motor

+ Easy serviceability and replacement ofthe coupling element without dismanting the

dive system

GG |ohval Series - Highly Reliable —

“\ MAXIMUM Performance

Efficient Air-Oil Separation

OSBIC design

‘The efficient air-ol separation by OSBIC (Oil Separation By Impact and Centifugal action) enables efficient

Separation of air and ol, with minimum pressure drop. The method enables separation of ain three stages,

delivering consistent oi ee air while increasing thelfe of separator element

Stage 1: Impact of air-il miture onthe radial baffle plate reduces kinetic energy

Stage 2: Centrifugal action of ai-ol mixture (spin down action) to shed ofthe ol particles

Stage 3: Air with minor traces of ol will enter the ait-ol separator element placed inside the tank to purity

‘the air (esidual oil cary over level is Ipprn)

+ Smaller oil volume with industry lowest refill requirements

+ ASME design and CEIGB certified

* Minimum pressure drop in tank

* Leak proof flanges with O-rings ensure leak free connections

Integrated Moisture Separator as Standard

* Designed to handle high humid compressed ar outlet from ate-cooler

+ 9996 of bulk water removal by impact and Centrifugal action with minimum pressure drop and_ automatic

discharge of collected water particles by float mechanism

Efficient Air Cooling

+ The compressor is designed to operate in wide temperature range from O'Cto 45°C

with a very low aftercooler approach temperature

* Sucker ype, quiet and high capacity cooling fans reduce the input power while ensuring

efficient cooling airflow

* Unique cooing air path for aftercooler by means of closed air duct which separates

cooling system from rest ofthe unit

+ Easy access to cooler clearing ensures fast maintenance and improves eliaility

Performance Control System

+ An advanced and inteligent gi contral system matches the Global Series compressor needs by

providing precise and complete monitoring and controls

* Intelligent controller enables remote monitoring, synchronizing with Distributed Control System

and SCADA

* The controller enables report generation vz. cumulative report, detailed report forthe previous

15 days and fault report (Previous 99 faults in chronological order with real time stamping and

type of fault)

How loud is too loud?

om AA 105 415 120 [I

OOWHRALD

roms Noma Tee fat Cos Gatun, hdtome Goo

Global Series - High Performance ===

Variable

Frequency Drive

Copaty: 90-160 kW

i Ibu package

sae 98 "OF rabies Firation Range: 1-003 miso sides

Accessories

FEF Reigeration air Dryer Air Receiver Reena

meee Copssy03- 200" i Pattie Fer |

Waking pressure 713 tara IMR Working Pressure {eet

Dimensional Data L(Length) x W(Width) x H(Height) in mm 2830 x 1640 x 2125

Suction Cooling ait outlet cooing aint

iit Pe ttt tt tyiiy

Main motor cooing

| 230

Left Side View Front View Right Side View Rear View Top View

1. Ali ntake Filter

atts Maron 2. Suction Control vale

3. Arend

4. Drive Coupling

5. Hlectic Motar

6. Ai-il Separator Tank

7. Minimum Pressure Valve

8. Cooling Fan

9. After Cooler

10. Moisture Separator COOLED AIR

11, Automatic Drain Hor alk

12, Outlet Valve

13. Oil Cooler oo

14, Air-Ol Separator or on.

15. Oil Filter spin-on} Hor AIR

16. Thermal Valve Unit MIXTURE

= as

78 ouing A

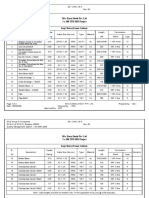

; Pressure Pr Weight

Capacity fo

50H2 kw HP dim | barg psig | barg psig Kg aB(A)

£67555 | 75 | 10 | 167 | 59 | 45 | 65 | 55 | 800 | 2700 5

£G 90-8 90 | 125 166 | 585 7 wo | 8 | 1160 2700 5

699 | 90 | 125 | 152 | 538 | 8 | 116 | 9 | 1305 2700 «| 75

£69011 90 | 125) 133 | 470} 10 | 45 | 11 | 1595 | 2700 5

e955 | 90 | 125 | 199 | 706 | 45) 65 55 | 800 | 3100 | 75

£61108 m0) 150) 198 | 706 | 7 | 102 8 | 1160 3100 5

roti0a | 10 | 150) a4) 6 | 8 | 16 | 9 | 1305 | 310 | 75

Foto1l | 10) 150 164) 580) 10) M5 | 11 | 1595 | 3100 75

611055 | 10 | 150 | 243 | 858 | 45 | 65 | 55 | 800 | 3400 ws

EG 132-8 132) 175) 242 | 855 | 7 | 102 8 | 1160 3400 5

#61329 | 132) 175 | 224 | 791 8 | 6 | 9 | 1305 | 3400 | 75

fo 132-1 | 132] 175 | 201 | 710 | 1 | 145 | 11 | 1595 | 3400 i

613255 | 132| 175 | 291 | 1030| 45) 65 55 | 800 | 3700 5

EG 160-8 160 | 200) 29.1 | 1026) 7 | 102 8 | 116.0 3700 5

G1609 | t60| 200 270) 954| 8 | 116 9 | 1305 3700 | 75

€G 160-11 | 160) 200) 2405) 850] 10 | ws | 11 | 1595 | 3700 5

NOU ee) tse p80 12172008 ene 3

Aa eon coved an ater

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Standard Flushing Procedures PDFDocument6 pagesStandard Flushing Procedures PDFmadan mohan kattaNo ratings yet

- Round 86,66 MMDocument2 pagesRound 86,66 MMmadan mohan kattaNo ratings yet

- ImpDocument2 pagesImpmadan mohan kattaNo ratings yet

- CRR PTDocument6 pagesCRR PTmadan mohan kattaNo ratings yet

- M/s. Basai Steels Pvt. LTD 3 X 100 TPD DRI Project: Bag Filters (Power Cables)Document4 pagesM/s. Basai Steels Pvt. LTD 3 X 100 TPD DRI Project: Bag Filters (Power Cables)madan mohan kattaNo ratings yet

- A0443Document1 pageA0443madan mohan kattaNo ratings yet

- Nozzleless PSFDocument1 pageNozzleless PSFmadan mohan kattaNo ratings yet

- ROSADocument16 pagesROSAmadan mohan kattaNo ratings yet

- Kaman Catalog PDFDocument275 pagesKaman Catalog PDFmadan mohan kattaNo ratings yet

- Kind Atten. Shri Subodh Singh Ji: Bearing Supply-OfferDocument1 pageKind Atten. Shri Subodh Singh Ji: Bearing Supply-Offermadan mohan kattaNo ratings yet

- UNI 7435 DIN 471: Anelli Elastici Di Sicurezza Per AlberiDocument1 pageUNI 7435 DIN 471: Anelli Elastici Di Sicurezza Per Alberimadan mohan kattaNo ratings yet

- Modular Progressive Distributors SMX Stainless Steel AISI 316Document4 pagesModular Progressive Distributors SMX Stainless Steel AISI 316madan mohan kattaNo ratings yet

- Hawe PDFDocument262 pagesHawe PDFmadan mohan katta0% (1)

- Grease Troubleshooting: A Publication of The Lubrication Engineers Technical DepartmentDocument2 pagesGrease Troubleshooting: A Publication of The Lubrication Engineers Technical Departmentmadan mohan kattaNo ratings yet

- DscsDocument6 pagesDscsmadan mohan kattaNo ratings yet

- Oil Air Systems PDFDocument12 pagesOil Air Systems PDFmadan mohan kattaNo ratings yet

- Circulating Lubrication Systems Oil PDFDocument8 pagesCirculating Lubrication Systems Oil PDFmadan mohan kattaNo ratings yet

- Brevini Gear Box PDFDocument261 pagesBrevini Gear Box PDFmadan mohan katta100% (4)