Professional Documents

Culture Documents

Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Education

Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Education

Uploaded by

jayson acunaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Education

Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Education

Uploaded by

jayson acunaCopyright:

Available Formats

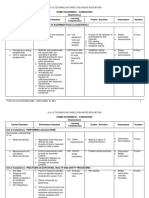

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS - AUTOMOTIVE SERVICING

(Exploratory)

Learning

Content Standard Performance Standard Project / Activities Assessment Duration

Competencies

LESSON 1: USE OF HAND TOOLS

Demonstrate understanding

of/on:

• Planning and 1. Tasks to be undertaken are LO1. Plan and 1. Preparing plan and • Written test 2.5 hours

preparing for task properly identified. prepare for organizing tasks to be • Performance

requirements 2. Appropriate hand tools are tasks to be undertaken in selecting test

identified and selected undertaken tools.

according to task 2. Classifying tools according

requirements. to use.

a. cutting

b. bending/holding

c. driving

d. marking

e. measuring

f. tightening / loosening

• Preparing tools 1. Appropriate hand tools are LO2. Prepare 1. Utilizing appropriate hand • Written test 3.0 hours

• Identifying procedure checked for proper operation hand tools tools • Performance

in operating hand and safety. and check a. Loosening and test

tools 2. All safety procedures in using for proper tightening bolts

• Observing safety tools are discussed and operations /screws and nuts.

requirements/ observed at all times. 2. Inspecting and testing

procedure in using functionality of tools for

hand tools repair and recycling in

• Common faults of preparation for its usability.

hand tools

• Preparing report on 1. Malfunction of hand tools in LO3. Accomplish 1. Conducting an inventory • Written test 2.0 hours

malfunctions of hand unplanned or unusual events report of and preparing report of • Performance

tools in unplanned or are reported. malfunctionin good and damaged tools in test

*TWG on K to 12 Curriculum Guide – version January 31, 2012 1

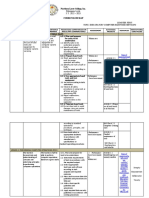

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS - AUTOMOTIVE SERVICING

(Exploratory)

Learning

Content Standard Performance Standard Project / Activities Assessment Duration

Competencies

unusual events g hand tools unplanned or unusual

equipment. events.

• Applying standard 1. Routine maintenance of tools LO4. Maintain 1. Selecting, arranging, and • Written test 2.5 hours

operational are undertaken according to hand tools. maintaining hand tools • Performance test

procedures, principles standard operational 2. Performing operational

and techniques in procedures, principles, and standard procedures,

maintaining hand tools techniques. principles, and techniques

2. Tools are stored safely in in maintaining tools

appropriate locations in

accordance with

manufacturer’s specifications

or standard operating

procedures.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 2

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS - AUTOMOTIVE SERVICING

(Exploratory)

Learning

Content Standard Performance Standard Project / Activities Assessment Duration

Competencies

LESSON 2: PERFORMING MEANSURATION AND CALCULATION

Demonstrate understanding

of/on:

• Types of measuring 1. Objects or components to be LO1. Select 1. Selecting and utilizing • Written and oral 3.0 hours

instruments and measured are identified. measuring measuring tools according test

applications 2. Appropriate measuring tool/ instrument to required tasks • Performance

• Techniques in instrument is selected as per and carry out a. feeler gauge test

measuring and job requirement. measurement b. torque wrench

determining 3. Calculations needed to and c. calipers

tolerance/allowance of complete work/task are calculations. d. industrial

parts/components performed and checked using thermometer.

• Methods of the fundamental operations of 2. Applying specifications to

calculation/conversion mathematics. bolts and nuts.

of units of 3. Converting the following:

measurement Metric system to English

system and vice-versa

- linear measurement

- liquid capacity

- thermal measurement.

• Calibrating, safe 1. Measuring instruments are LO2. Maintain 1. Cleaning and maintaining • Written test 2.5 hours

handling procedures, calibrated, safely handled, measuring measuring tools. • Performance test

and caring of and cleaned before and after instruments. 2. Calibrating and storing

measuring using in accordance with precision instruments in

instruments industry standards. convenient and safe place.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 3

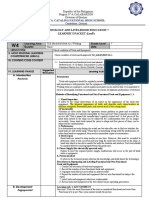

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS - AUTOMOTIVE SERVICING

(Exploratory)

Learning

Content Standard Performance Standard Project / Activities Assessment Duration

Competencies

LESSON 3: INTERPRET PLANS AND DRAWINGS

Demonstrate understanding

of/on:

• Drawing signs, 1. Signs, symbols, and data are LO1. Analyze 1. Constructing traffic signs • Written test 2.5 hours

symbols, and identified according to job signs, and symbols • Performance

abbreviations specifications. symbols 2. Drawing and labeling test

• Identifying symbols 2. Sign, symbols, data, and and data. pictorial drawing of engine

used in plans and abbreviations are determined parts.

drawings according to classification or

• Identifying units of appropriateness in drawings.

measurements

• Basic Technical 1. Necessary tools, materials, LO2. Interpret 1. Drawing and labeling • Written test 2.5 hours

drawing and equipment are identified technical electrical symbols/circuit • Performance

• Technical plans and according to the plan. drawings diagram. test

Schematic Diagram 2. Components, assemblies, or and plans.

objects are recognized.

3. Dimensions and specifications

are identified according to job

requirements.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 4

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS - AUTOMOTIVE SERVICING

(Exploratory)

Learning

Content Standard Performance Standard Project / Activities Assessment Duration

Competencies

LESSON 4: PERFORMING SHOP MAINTENANCE

Demonstrate understanding

of/on:

• Workshop policies and 1. Tools, equipment, and work LO1. Inspect/clean 1. Inspecting and evaluating • Written test 2 .5 hours

service procedures area are inspected and tools and the existing condition of • Performance test

• Standard safe cleaned free from dust, shop tools, equipment, and work

handling of tools, grease, and other substances. equipment. area.

materials, and 2. Cleaning solvent used as per

equipment workshop cleaning

• Types and usage of requirements is observed.

cleaning chemicals 3. Work area is checked and

cleaned.

• Personal safety and 1. Corresponding labels for LO2. Store/ 1. Arranging, labeling and • Written test 3.0 hours

labeling procedures containers and waste arrange tools securing tools and • Performance test

and techniques materials are posted and and shop equipment.

• Principles of total made visible. equipment 2. Performs 5S in workplace.

quality management 2. Tools quality management is

(TQM) and 5S followed.

• Waste management 1. Waste and used materials are LO3. Dispose 1. Surfing internet on • Written test 3.0 hours

o Cleaning disposed in accordance with waste/used Environment Protection • Performance

chemicals / the standard operational lubricants Policies. test

materials procedures and environmental

• Effects of automotive regulations.

wastes on men and 2. Personal safety in disposing

the environment waste and used materials are

observed.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 5

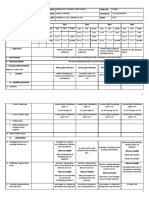

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS - AUTOMOTIVE SERVICING

(Exploratory)

Learning

Content Standard Performance Standard Project / Activities Assessment Duration

Competencies

LESSON 5: PRACTICING OCCUPATIONAL HEALTH AND SAFETY PROCEDURES

Demonstrate understanding

of/on:

• Hazards and risks 1. Workplace hazards and risks LO1. Identify 1. Preparing workplace in • Written test 3.0 hours

identification and are identified and clearly hazards and good and orderly condition • Performance

control explained. risks 2. Making contingency test

• Organizational safety 2. Hazards/risks and their measures in line with

and health protocol corresponding indicators are standard organizational

identified in accordance with procedures

the company procedures.

3. Contingency measures are

recognized and established in

accordance with organizational

procedures.

• Philippine OHS 1. Effects of hazards are LO2. Evaluate 1. Listing down problems and • Written test 2.5 hours

Standards regulations determined. hazards and make necessary solutions

and indicators 2. OHS /ECC issues and risks to hazardous and risky

• Effects of hazards in concerns are identified in workplace condition

the workplace accordance with workplace 2. Reporting the following:

• Ergonomics requirements and legislation. a. common accidents in

3. OHS procedures for controlling the workplace

hazards and risk are strictly b. standard size of tables,

followed. space of work area

4. OHS personal records are filled c. human convenience to

up in accordance with workplace physical

workplace requirements. design of shop

5. Design of facilities/fixtures in facilities/fixture.

human facilities is recognized

*TWG on K to 12 Curriculum Guide – version January 31, 2012 6

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS - AUTOMOTIVE SERVICING

(Exploratory)

Learning

Content Standard Performance Standard Project / Activities Assessment Duration

Competencies

• Clean Air Act 1. Procedures in dealing with LO3. Control 1. Conducting inventory and • Written test 2.5 hours

o Exhaust workplace accidents, fire and hazards and using of: • Performance test

emission emergencies and provision of risks a. PPE • Evaluation report

• Electrical and fire appropriate assistance in the b. fire fighting on DRRP drills

safety code workplace emergencies are equipment

• Disaster preparedness identified and followed in c. emergency/ first aid

and management accordance with the kit/ materials

organization’s OHS policies. d. waste disposal bin.

2. Personal Protective Equipment 2. Video presentation on

(PPE) is correctly used and Disaster Risk Reduction

maintained in accordance with Program.

the organizations OHS 3. Conducting DRRP drills.

procedures and practices.

• Emergency-related 1. Procedures in emergency- LO4. Maintain 1. Conducting OHS • Written test 2.5 hours

drills and training related drills are strictly followed occupational awareness. • Performance test

in line with the established health and 2. Making OHS visual aids.

organization guidelines and safety 3. Simulating OHS practices.

procedures. awareness

2. OHS personal records are filled

up in accordance with

workplace requirements.

3. PPE is maintained in line with

organization guidelines and

procedures.

40 hours

*TWG on K to 12 Curriculum Guide – version January 31, 2012 7

You might also like

- Hazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (DueDocument5 pagesHazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (Duetana83% (6)

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- LESSON PLAN-4 - Use Graduated Measuring DevicesDocument5 pagesLESSON PLAN-4 - Use Graduated Measuring Devicesjaglall chand100% (1)

- Uae Fire Code - Eng - September - 2018Document1 pageUae Fire Code - Eng - September - 2018mhmdjdgmailcomNo ratings yet

- Curriculum Map in Household ServicesDocument6 pagesCurriculum Map in Household ServicesMelcanie91% (11)

- Excavator Leraner Guide PDFDocument32 pagesExcavator Leraner Guide PDFOwen PerrinNo ratings yet

- Samaon SulaimanDocument2 pagesSamaon Sulaimanjayson acunaNo ratings yet

- Course Evaluation FormDocument8 pagesCourse Evaluation Formjayson acuna100% (1)

- CG AutomotiveDocument11 pagesCG AutomotiveJame Paul GalgaoNo ratings yet

- CG Mechanical DraftingDocument6 pagesCG Mechanical DraftingLENIN BRIONESNo ratings yet

- K To 12 CG - Nail Care - v1.0Document5 pagesK To 12 CG - Nail Care - v1.0ROWELYN DIPOSONo ratings yet

- Curguide NailcareDocument5 pagesCurguide NailcareOlive AsuncionNo ratings yet

- DLL EIM11 1stSem1stQuarter Week1Document4 pagesDLL EIM11 1stSem1stQuarter Week1Gelo Dela TorreNo ratings yet

- Curriculum Guide: Exploratory Course On Consumer Electronics ServicingDocument7 pagesCurriculum Guide: Exploratory Course On Consumer Electronics ServicingKim GarzoNo ratings yet

- K To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Document14 pagesK To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Bri CorpuzNo ratings yet

- CG HorticultureDocument7 pagesCG HorticultureEl G. Se ChengNo ratings yet

- K To 12 CG - Agri-Crops - v1.0Document6 pagesK To 12 CG - Agri-Crops - v1.0may tagalogon villacoraNo ratings yet

- Ia - Automotive Servicing CGDocument4 pagesIa - Automotive Servicing CGjayson acunaNo ratings yet

- Home Economics - Dressmaking / Tailoring (Exploratory) : K To 12 Technology and Livelihood EducationDocument5 pagesHome Economics - Dressmaking / Tailoring (Exploratory) : K To 12 Technology and Livelihood Educationjowelyn maderalNo ratings yet

- Curriculum Guide: K To 12 Basic Education CurriculumDocument8 pagesCurriculum Guide: K To 12 Basic Education Curriculumiriel_31No ratings yet

- Ia - Drafting CGDocument4 pagesIa - Drafting CGArlyn AgustinNo ratings yet

- K To 12 CG Animal Production v1.0Document6 pagesK To 12 CG Animal Production v1.0Wildfox DawnNo ratings yet

- Agriculture/Fishery - Horticulture (Exploratory) : K To 12 Technology and Livelihood EducationDocument5 pagesAgriculture/Fishery - Horticulture (Exploratory) : K To 12 Technology and Livelihood EducationRonel Suan100% (1)

- TLE 7-8 ICT - IllustrationDocument8 pagesTLE 7-8 ICT - IllustrationLady Antoniette M. BonggotNo ratings yet

- Grade 7 & 8 Curriculum MapDocument13 pagesGrade 7 & 8 Curriculum MapRussell SanicoNo ratings yet

- Ia - Rac CGDocument3 pagesIa - Rac CGArlyn AgustinNo ratings yet

- Curriculum Map TLE Computer Hardware 7/8Document6 pagesCurriculum Map TLE Computer Hardware 7/8billy jane ramosNo ratings yet

- Syllabus For Drawing 1 (Mechanical Drafting)Document6 pagesSyllabus For Drawing 1 (Mechanical Drafting)Sangguniang Barangay Malinao IlayaNo ratings yet

- Curriculum Guide: Exploratory Course On Commercial CookingDocument5 pagesCurriculum Guide: Exploratory Course On Commercial CookingEl G. Se ChengNo ratings yet

- TLEDocument84 pagesTLEClifford FloresNo ratings yet

- Melcs Tle Grade 7&8Document55 pagesMelcs Tle Grade 7&8JANETH MOJICA100% (2)

- Calibrating Instrumentation and Control DevicesDocument41 pagesCalibrating Instrumentation and Control DevicesmohamedamiiniNo ratings yet

- G7 LEAP - Week 4 SMAWDocument3 pagesG7 LEAP - Week 4 SMAWSHERELYN RODRIGUEZNo ratings yet

- Curriculum Guide: K To 12 Basic Education CurriculumDocument5 pagesCurriculum Guide: K To 12 Basic Education CurriculumBlesel Ashley R. ValerosoNo ratings yet

- Curriculum Map in Grade 7 TleDocument22 pagesCurriculum Map in Grade 7 TleLeo Niño Gonzales Dulce100% (2)

- Q1 CM T.L.E. 7Document4 pagesQ1 CM T.L.E. 7Rue LhynNo ratings yet

- LESSON PLAN-5 - Use Hand ToolsDocument5 pagesLESSON PLAN-5 - Use Hand Toolsjaglall chandNo ratings yet

- Caregiving For Grades 7 To 10Document26 pagesCaregiving For Grades 7 To 10Yeshua YeshaNo ratings yet

- GR 7 Curriculum Map (1st-4th QTR)Document38 pagesGR 7 Curriculum Map (1st-4th QTR)Perla BernardezNo ratings yet

- Curriculum Guide: Exploratory Course On Household ServicesDocument5 pagesCurriculum Guide: Exploratory Course On Household ServicesJovanni Mancao PodadorNo ratings yet

- Grade 7 Curriculum MapDocument3 pagesGrade 7 Curriculum MapRussell SanicoNo ratings yet

- Budget of WorkDocument8 pagesBudget of WorkJocelyn Cortes IntanoNo ratings yet

- TLE MELCs Grade 7 PDFDocument55 pagesTLE MELCs Grade 7 PDFVincent Emmanuel Salibio40% (5)

- Grade 7-12Document84 pagesGrade 7-12Cab VicNo ratings yet

- MELC HE Caregiving G7-8Document2 pagesMELC HE Caregiving G7-8Edilbert Bonifacio GayoNo ratings yet

- Caregiving 7-8 MelcsDocument2 pagesCaregiving 7-8 MelcsEdilbert Bonifacio Gayo0% (1)

- Deped K To 12 Technology and Livelihood Education - Computer Hardware ServicingDocument7 pagesDeped K To 12 Technology and Livelihood Education - Computer Hardware Servicingyachiru121100% (4)

- DLL - Tle Ict Css 10 - q1 - w3Document5 pagesDLL - Tle Ict Css 10 - q1 - w3LORENZO MANALANGNo ratings yet

- Grades 7 and 8 Technology and Livelihood Education TLE Most Essential Learning Competencies MELCsDocument57 pagesGrades 7 and 8 Technology and Livelihood Education TLE Most Essential Learning Competencies MELCsSophy MeganNo ratings yet

- TVE - EP7 - Week 1Document4 pagesTVE - EP7 - Week 1via gepilaNo ratings yet

- CG Aquaculture ExploratoryDocument7 pagesCG Aquaculture Exploratorymarilyn bristolNo ratings yet

- K To 12 CG - Pchs - v1.0Document5 pagesK To 12 CG - Pchs - v1.0Shaira Lhoan C. ReyesNo ratings yet

- TRB 4Document15 pagesTRB 4Cherry Ann SaavedraNo ratings yet

- Job - Sheet-4.2-A, and Process SheetDocument13 pagesJob - Sheet-4.2-A, and Process SheetDenmar PingolNo ratings yet

- GINA3Document2 pagesGINA3Norman T. RegalNo ratings yet

- Mem11011b R1Document8 pagesMem11011b R1Baladev SuraganiNo ratings yet

- CG - Electrical Installation and MaintenanceDocument10 pagesCG - Electrical Installation and MaintenanceEl G. Se ChengNo ratings yet

- Dll-September-27-30, 2022Document6 pagesDll-September-27-30, 2022Daniel BognotNo ratings yet

- CLM Common 5 As of 020708am Use Hand ToolsDocument1 pageCLM Common 5 As of 020708am Use Hand ToolsWilma Arenas MontesNo ratings yet

- Curriculum Map: Demonstrate Understanding Of/onDocument2 pagesCurriculum Map: Demonstrate Understanding Of/onKIMBERLY AGUSTINNo ratings yet

- Etn1023 - Instrument and Test Equipment Set Up & HandlingDocument14 pagesEtn1023 - Instrument and Test Equipment Set Up & Handlingnoor atikah allias50% (2)

- Practical Project Management: Learning to Manage the Professional, Second EditionFrom EverandPractical Project Management: Learning to Manage the Professional, Second EditionRating: 2.5 out of 5 stars2.5/5 (2)

- Re Deployment of Cats For Smaw NC Smaw NC IIDocument1 pageRe Deployment of Cats For Smaw NC Smaw NC IIjayson acunaNo ratings yet

- Career Guidance Portfolio ContentDocument1 pageCareer Guidance Portfolio Contentjayson acunaNo ratings yet

- Contemporary Art Techniques and Perfomace PracticesDocument4 pagesContemporary Art Techniques and Perfomace Practicesjayson acunaNo ratings yet

- How To UnhideDocument1 pageHow To Unhidejayson acunaNo ratings yet

- Weight Lifting Gets You Out of Breath in A Few MinutesDocument2 pagesWeight Lifting Gets You Out of Breath in A Few Minutesjayson acunaNo ratings yet

- How Do I Measure Resting Heart RateDocument4 pagesHow Do I Measure Resting Heart Ratejayson acunaNo ratings yet

- Ia - Automotive Servicing CGDocument4 pagesIa - Automotive Servicing CGjayson acunaNo ratings yet

- Complete Curriculum - K-12 - Physical Education Curriculum Guide73139Document72 pagesComplete Curriculum - K-12 - Physical Education Curriculum Guide73139jayson acunaNo ratings yet

- Apprenticeship and Industry Training: Welder Apprenticeship Course OutlineDocument32 pagesApprenticeship and Industry Training: Welder Apprenticeship Course Outlinejayson acunaNo ratings yet

- Sept09 CH 5Document57 pagesSept09 CH 5jayson acunaNo ratings yet

- Chapter 8 - Landslides Practice Exam and Study GuideDocument11 pagesChapter 8 - Landslides Practice Exam and Study Guidejayson acunaNo ratings yet

- Questions: Volcanoes - True or False?Document3 pagesQuestions: Volcanoes - True or False?jayson acuna100% (1)

- Department of Education Legazpi City Division Orosite High School Legazpi CityDocument3 pagesDepartment of Education Legazpi City Division Orosite High School Legazpi Cityjayson acunaNo ratings yet

- Construction Risk Assessment Plus PresentationDocument20 pagesConstruction Risk Assessment Plus PresentationAmitChakraborty100% (1)

- Case Study 2 - ADocument7 pagesCase Study 2 - AIdaSafina AzizNo ratings yet

- Electrical Safety Construction Site: Allan Soldevilla Biton, ReeDocument28 pagesElectrical Safety Construction Site: Allan Soldevilla Biton, ReeAllan Soldevilla BitonNo ratings yet

- Fire Alarm System Loops I To 4Document4 pagesFire Alarm System Loops I To 4shahbazalam4a5No ratings yet

- Gate Pass Gate Pass: For Any Untoward Incident. For Any Untoward IncidentDocument2 pagesGate Pass Gate Pass: For Any Untoward Incident. For Any Untoward IncidentKatkat AmbosNo ratings yet

- DFMEADocument2 pagesDFMEAPiousPatialaNo ratings yet

- 025.ahda Ziyad Al WafiDocument2 pages025.ahda Ziyad Al WafiAhda Ziyad Al WafiNo ratings yet

- S-PCM Minutes of Meeting: DCBM Sitemgr Eng Mohammad DCBM Hsemgr DCBMDocument3 pagesS-PCM Minutes of Meeting: DCBM Sitemgr Eng Mohammad DCBM Hsemgr DCBMsudeesh kumarNo ratings yet

- Mamlad High School: Third Quarter ExaminationDocument1 pageMamlad High School: Third Quarter ExaminationDenMark Tuazon-RañolaNo ratings yet

- Job Description - Safety Supervisor - RevaDocument8 pagesJob Description - Safety Supervisor - RevacaturzzzzzNo ratings yet

- ICAO SMS M 05 - Risks (R013) 09 (E)Document62 pagesICAO SMS M 05 - Risks (R013) 09 (E)barreto104No ratings yet

- Pile Test (Maintained Load Test - MLT)Document4 pagesPile Test (Maintained Load Test - MLT)Shures Kumar SubramaniyamNo ratings yet

- Risk AssessmentDocument6 pagesRisk Assessmentapi-315532661No ratings yet

- 28 - Confined Space AuditDocument3 pages28 - Confined Space Auditangel_machacaNo ratings yet

- Job Safety Analysis (Jsa)Document9 pagesJob Safety Analysis (Jsa)MohdHuzairiRusliNo ratings yet

- 2 - Food Safety & Sanitation ManagementDocument20 pages2 - Food Safety & Sanitation ManagementMonNo ratings yet

- Mg4012 Naf c00486 Civ Mts 0002 - 02 - Method Statement For Anti Termite WorksDocument13 pagesMg4012 Naf c00486 Civ Mts 0002 - 02 - Method Statement For Anti Termite WorksSagar AliasjackeyNo ratings yet

- CSB - 7 Key Lessons To Prevent Worker Deaths During Hot Work in & Around TanksDocument13 pagesCSB - 7 Key Lessons To Prevent Worker Deaths During Hot Work in & Around TanksZethJeddNo ratings yet

- Occupational Health and SafetyDocument40 pagesOccupational Health and SafetyMark B. BarrogaNo ratings yet

- Reflection On DisasterDocument1 pageReflection On DisasterRaquel Bona Viñas50% (10)

- Organization ChartDocument1 pageOrganization Chartpankajbhatt376No ratings yet

- Fire Risk Assessment ReportDocument19 pagesFire Risk Assessment ReportAnonymous qPiTKbU100% (1)

- CMIT-000-FCD-00 08-000002-0 Project Contractor HSSE Management Procedure...Document65 pagesCMIT-000-FCD-00 08-000002-0 Project Contractor HSSE Management Procedure...nadaNo ratings yet

- SFTY100Document2 pagesSFTY100Kristianne Mae EchavezNo ratings yet

- Risk ReportingDocument3 pagesRisk ReportingMiguel TagustosNo ratings yet

- Disaster Readiness and Risk Reduction (DRRR) : Basic Definitions & TermsDocument10 pagesDisaster Readiness and Risk Reduction (DRRR) : Basic Definitions & TermsJoel BrionesNo ratings yet

- Proja HseDocument11 pagesProja HseAchmad FiqriNo ratings yet

- Egress Fire LPDocument4 pagesEgress Fire LPRobert Paredes DimapilisNo ratings yet