Professional Documents

Culture Documents

03 - Q00564 Rev 4 - ITR - Erection & Aligment Pressure Vessel (QFP 100L)

03 - Q00564 Rev 4 - ITR - Erection & Aligment Pressure Vessel (QFP 100L)

Uploaded by

Torres IvanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 - Q00564 Rev 4 - ITR - Erection & Aligment Pressure Vessel (QFP 100L)

03 - Q00564 Rev 4 - ITR - Erection & Aligment Pressure Vessel (QFP 100L)

Uploaded by

Torres IvanCopyright:

Available Formats

Document No Revision

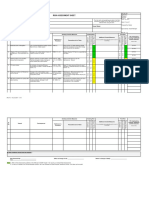

INSPECTION & TEST RECORD Q00564 4

Erection and alignment of pressure vessel Page

1(4)

QFP 100L

Measurement performed Press type: QFP 100L-600 SEND AVURE TECHNOLOGIES A COPY OF THIS

DOCUMENT AFTER EACH ALIGNMENT

At: □ Avure workshop □ Customers site Order no / Serial no:

E-mail: qc.mid@avure.com

By (name):

This document shall be used for alignment of pressure vessels. Alignment requires measurements and adjustments at several levels and locations in order to secure

that the pressure vessel and frame are aligned to each other.

When the alignment has been performed the record shall be collected in the appropriate quality binder and long term stored electronically in the appropriate QA folder.

The alignment record shall be given a unique document name with the following syntax:

Document No - Revision - Project No – Alignment for example Q00564-4-100203-Alignment.

Component / Inspection Acceptance tolerance At alignment of pressure vessel Remark Date/Signature

imparted to a third party nor be used for any unauthorized

This document must not be copied without our written

1. Cylinder and frame support

permission, and the contents thereof must not be

1.1. Rail, Horizontal level (each rail)

purpose. Contravention will be prosecuted.

1.1.1. Rear 0.5/1000 mm

1.1.2. Left front 0.5/1000 mm

Avure Technologies AB

1.1.3. Right front 0.5/1000 mm

1.2. Rail, Level (Parallelism between front to rear rail)

Q00564/004 Released for Production 2014-06-12

1.2.1. Left side ± 1 mm

1.2.2. Right side ± 1 mm

Q00564/004 Released 2014-06-05

2. Wheel carriage

2.1. Hydraulic cylinders makes full stroke in/out -

Printed: June 3, 2014, 11:19 Template Q00520 Rev 2

Document No Revision

INSPECTION & TEST RECORD Q00564 4

Erection and alignment of pressure vessel Page

2(4)

QFP 100L

Component / Inspection Acceptance tolerance At alignment of pressure vessel Remark Date/Signature

3. Closure manipulator, left/right

3.1. Movement over full stroke, parallel movement of front and rear side

3.1.1. Left side ± 0.2 mm

3.1.2. Right side ± 0.2 mm

3.2. Hydraulic cylinder makes full stroke in against the winded cylinder. Gap between winded cylinder and closure. (The closure stops against the yoke before outer position of the

cylinder)

3.2.1. Left side ± 0.2 mm

imparted to a third party nor be used for any unauthorized

3.2.2. Right side ± 0.2 mm

This document must not be copied without our written

permission, and the contents thereof must not be

3.3. Press plate manipulator, centric in frame in closed position

purpose. Contravention will be prosecuted.

3.3.1. Left side ± 1 mm

3.3.2. Right side ± 1 mm

Avure Technologies AB

Q00564/004 Released for Production 2014-06-12

Q00564/004 Released 2014-06-05

Printed: June 3, 2014, 11:19 Template Q00520 Rev 2

Document No Revision

INSPECTION & TEST RECORD Q00564 4

Erection and alignment of pressure vessel Page

3(4)

QFP 100L

Component / Inspection Acceptance tolerance At alignment of pressure vessel Remark Date/Signature

4. Pressure vessel

4.1. Cylinder centric with frame (Check dimension between upper column and end wall and compare with dimensions punched in the end wall). Note original values in brackets XX

and new values YY.

4.1.1. Height direction; front side of column, left side TLA (XX) YY

± 0.2 mm (at install)

± 2 mm (at maintenance)

4.1.2. Height direction; back side of column, left side TLB (XX) YY

± 0.2 mm (at install)

± 2 mm (at maintenance)

4.1.3. Length direction, left side TLV (XX) YY

imparted to a third party nor be used for any unauthorized

This document must not be copied without our written

± 0.2 mm (at install)

± 2 mm (at maintenance)

permission, and the contents thereof must not be

4.1.4. Height direction; front side of column, right side TRA (XX) YY

purpose. Contravention will be prosecuted.

± 0.2 mm (at install)

± 2 mm (at maintenance)

4.1.5. Height direction; back side of column, right side TRB (XX) YY

Avure Technologies AB

± 0.2 mm (at install)

± 2 mm (at maintenance)

4.1.6. Length direction, right side TRV (XX) YY

Q00564/004 Released for Production 2014-06-12

± 0.2 mm (at install)

± 2 mm (at maintenance)

4.1.7. Clearance between front beam cylinder stopper/frame. 1 ± 0.5 mm

Mean value of left and right side

Q00564/004 Released 2014-06-05

Printed: June 3, 2014, 11:19 Template Q00520 Rev 2

Document No Revision

INSPECTION & TEST RECORD Q00564 4

Erection and alignment of pressure vessel Page

4(4)

QFP 100L

Component / Inspection Acceptance tolerance At alignment of pressure vessel Remark Date/Signature

4.2. Clearance closure/press plate, closed position

4.2.1. Left side 1 ± 0.5 mm

4.2.2. Right side 1 ± 0.5 mm

4.3. Clearance press plates/yoke

4.3.1. Left side 1 ± 0.5 mm

4.3.2. Right side 1 ± 0.5 mm

4.4. Centricity, closure with cylinder (Move the closure in and out of the cylinder, measure sideways movement)

imparted to a third party nor be used for any unauthorized

This document must not be copied without our written

4.4.1. Left side ± 0.5 mm

permission, and the contents thereof must not be

purpose. Contravention will be prosecuted.

4.4.2. Right side ± 0.5 mm

4.5. Verification of spot system. (See maintenance manual) -

4.6. Centricity, cylinder with frame opening, left to right. With ± 1 mm

Avure Technologies AB

cylinder centred, adjust guide wheels on front frame.

4.7. Summary of clearance between guide wheel/rail on each 1 ± 0.5 mm

rail

Q00564/004 Released for Production 2014-06-12

Q00564/004 Released 2014-06-05

Figure 1. X can be substituted with either L for left and R for right in TXA, TXB and TXV

Printed: June 3, 2014, 11:19 Template Q00520 Rev 2

You might also like

- ITP Format - Excel GEP 1120Document22 pagesITP Format - Excel GEP 1120raghuvarma100% (1)

- Manual Mantenimiento PA 38 PDFDocument7 pagesManual Mantenimiento PA 38 PDFtincho FeldmanNo ratings yet

- 2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFDocument17 pages2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFdang2172014100% (1)

- Process Flow Diagram (PFD)Document1 pageProcess Flow Diagram (PFD)Arun Pratap Singh ChauhanNo ratings yet

- QCFCDocument4 pagesQCFCAstronNo ratings yet

- Plumbing, SanitaryDocument2 pagesPlumbing, Sanitarykumarakash122392No ratings yet

- CPC Ncwi L e 0010 Ncwi Iws DatasheetDocument53 pagesCPC Ncwi L e 0010 Ncwi Iws DatasheetNguyen Ninh BinhNo ratings yet

- Small Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlocksDocument4 pagesSmall Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlockseleanorNo ratings yet

- Codo 90 6 SCH STD Astm A234 348205Document1 pageCodo 90 6 SCH STD Astm A234 348205antoniosofwareNo ratings yet

- Uncontrolled If Printed: SCALE: 1:10 SCALE: 1:10Document1 pageUncontrolled If Printed: SCALE: 1:10 SCALE: 1:10AneesNo ratings yet

- Inverter Catalog - MUST 2020 NEWDocument26 pagesInverter Catalog - MUST 2020 NEWsteven6diaz-2No ratings yet

- Portfolio Blank FormDocument2 pagesPortfolio Blank FormMohanie DatualiNo ratings yet

- AK 98 V3 Replacement Matrix-AK98DCC-408722Document10 pagesAK 98 V3 Replacement Matrix-AK98DCC-408722JESSICA ALBARRAN DOMINGUEZNo ratings yet

- ALL WPS Rampco EthanDocument38 pagesALL WPS Rampco EthanAli TavakoliNo ratings yet

- Pressure Test Package: Project Contractor Sub-ContractorDocument53 pagesPressure Test Package: Project Contractor Sub-ContractorABAID ULLAHNo ratings yet

- Lifting - Equipment - Matrix1 (Under Constrution)Document1 pageLifting - Equipment - Matrix1 (Under Constrution)PradeepNo ratings yet

- MPI CertifiactesDocument1 pageMPI CertifiactesAdvanced Quality Centre AQCNo ratings yet

- Yhto Oq 5990 Lmu3 2500 MC QC Itp 001 Itp Fabrication r01 (1) r2Document12 pagesYhto Oq 5990 Lmu3 2500 MC QC Itp 001 Itp Fabrication r01 (1) r2SURAJ PRSADNo ratings yet

- QA MATRIX SHEET - RadiatorDocument4 pagesQA MATRIX SHEET - RadiatorBaljeet SinghNo ratings yet

- MEO 001 TC Turbine Water WashingDocument3 pagesMEO 001 TC Turbine Water WashingaskmonuNo ratings yet

- Risk Assessment For Drainage uPVC PipesDocument1 pageRisk Assessment For Drainage uPVC PipesZameer Basha Navzath AliNo ratings yet

- 000 J PQP 50001 001 R0aDocument11 pages000 J PQP 50001 001 R0aHerwin MaghinayNo ratings yet

- Process Flow Diagram FORDocument17 pagesProcess Flow Diagram FORMartin AdasmeNo ratings yet

- Quality Contol Plan Piping Erection (Above & Underground) 2542-000-QCP-1320-001 - 0 PDFDocument33 pagesQuality Contol Plan Piping Erection (Above & Underground) 2542-000-QCP-1320-001 - 0 PDFZohrab Dadashov100% (1)

- Agarwal & Gardner - 4Document14 pagesAgarwal & Gardner - 4hijoetigreNo ratings yet

- RLS Spect-Ct 2 0Document2 pagesRLS Spect-Ct 2 0Gust YouNo ratings yet

- Tle-01 Dossier.Document39 pagesTle-01 Dossier.suria qaqcNo ratings yet

- Sensors 2 1 PDFDocument126 pagesSensors 2 1 PDFhosseinNo ratings yet

- SI Auto Transm BPT 06 18 Rev2Document1 pageSI Auto Transm BPT 06 18 Rev2deepak.sNo ratings yet

- Asme Sec Ix 2019 381Document1 pageAsme Sec Ix 2019 381Balkishan DyavanapellyNo ratings yet

- 2216 pdf7 PDFDocument6 pages2216 pdf7 PDFRobert Blake DesignsNo ratings yet

- Centre of PressureDocument8 pagesCentre of PressuretarumNo ratings yet

- 2107 351 Va 8900 00002 - 002Document1 page2107 351 Va 8900 00002 - 002Engr.Muhammad DanishNo ratings yet

- 2107 351 Va 8900 00003 - 002Document1 page2107 351 Va 8900 00003 - 002Engr.Muhammad DanishNo ratings yet

- Intergraged Management System: Without Controls With ControlsDocument5 pagesIntergraged Management System: Without Controls With ControlsMohammed JavidNo ratings yet

- QCPC - Wide Roller 35,5Document1 pageQCPC - Wide Roller 35,5rianNo ratings yet

- Ullweii Deliverability L'vlonitoring: A Case HistoryDocument8 pagesUllweii Deliverability L'vlonitoring: A Case HistoryvastaguenNo ratings yet

- Alco Valves RTG Brochure 01-07-2017 PDFDocument56 pagesAlco Valves RTG Brochure 01-07-2017 PDFGuillermo de la Fuente SantiagoNo ratings yet

- Alco ValvesDocument56 pagesAlco ValvesGuillermo de la Fuente SantiagoNo ratings yet

- 141 CC 403 02008 - Q - CommentDocument25 pages141 CC 403 02008 - Q - CommentChandra KanthNo ratings yet

- GDU System Architecture P79 04-03-23 FINALDocument4 pagesGDU System Architecture P79 04-03-23 FINALbennsavyaalrawafNo ratings yet

- Quality Assurance Plan: Raw Material ProcurmentDocument2 pagesQuality Assurance Plan: Raw Material ProcurmentHuỳnh Ngọc HiệpNo ratings yet

- FAA 2018 0589 0005 - Attachment - 2Document10 pagesFAA 2018 0589 0005 - Attachment - 2hossein kavehNo ratings yet

- AVK Check-Valves BrochureDocument32 pagesAVK Check-Valves BrochureHadi SofyanNo ratings yet

- Pressure Relief Valves: Item Number Service SheetDocument14 pagesPressure Relief Valves: Item Number Service SheetMaura ApostolacheNo ratings yet

- All Wps Rampco AsuDocument33 pagesAll Wps Rampco AsuAli TavakoliNo ratings yet

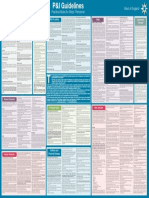

- P&I Guidelines: West of England Practical Notes For Ships' PersonnelDocument1 pageP&I Guidelines: West of England Practical Notes For Ships' PersonnelnostremarumNo ratings yet

- Typical - Package ITPDocument23 pagesTypical - Package ITPrandyNo ratings yet

- GDU1 - System Architecture REV B - V1Document5 pagesGDU1 - System Architecture REV B - V1bennsavyaalrawafNo ratings yet

- 1995-Reducing The Risk of Stuck Pipe in The NetherlandsDocument9 pages1995-Reducing The Risk of Stuck Pipe in The Netherlandssobhan mohammadiNo ratings yet

- Chien1995 PDFDocument6 pagesChien1995 PDFFelipeMorenoNo ratings yet

- ALL WPS Rampco MethanolDocument73 pagesALL WPS Rampco MethanolAli TavakoliNo ratings yet

- SF-32 WTP D.S. 2,660 L/S EF-22 D.S. 2,660 L/S: NotesDocument1 pageSF-32 WTP D.S. 2,660 L/S EF-22 D.S. 2,660 L/S: NotesJC DC AcostaNo ratings yet

- Inspection Test Plan For Erection of Tower CraneDocument5 pagesInspection Test Plan For Erection of Tower CraneMarco AragonesNo ratings yet

- 5.9.1 System Safety Assessment: (Project Name) For M-NAVDocument9 pages5.9.1 System Safety Assessment: (Project Name) For M-NAVDimeski KoceNo ratings yet

- PASS - Equip - Product DescriptionDocument3 pagesPASS - Equip - Product DescriptionsrashmiiiscNo ratings yet

- Investigation On A Blockerless Cascade Thrust Reverser System Based On Response Surface MethodDocument13 pagesInvestigation On A Blockerless Cascade Thrust Reverser System Based On Response Surface MethodNguyễn Đức HuyNo ratings yet

- 100 VT 001 Visual Examination in Accordance With The ASME Boiler and Pressure Vessel CodeDocument5 pages100 VT 001 Visual Examination in Accordance With The ASME Boiler and Pressure Vessel CodejmiguelroNo ratings yet

- AS4662CDocument3 pagesAS4662Can NanNo ratings yet

- FIBA Basketball World Cup 2023 TimelineDocument1 pageFIBA Basketball World Cup 2023 TimelineTorres IvanNo ratings yet

- Plan For Site Acceptance Test: Project No. 101000. Q00567-2-ITR-101000Document1 pagePlan For Site Acceptance Test: Project No. 101000. Q00567-2-ITR-101000Torres IvanNo ratings yet

- 01 AT01093-001 Certificate of AcceptanceDocument1 page01 AT01093-001 Certificate of AcceptanceTorres IvanNo ratings yet

- Documentation Cover LetterDocument1 pageDocumentation Cover LetterTorres IvanNo ratings yet

- Danfoss SFVLDocument8 pagesDanfoss SFVLTorres Ivan100% (1)

- HeraDocument1 pageHeraTorres IvanNo ratings yet

- Machine Design Handbook For EngineeriesDocument82 pagesMachine Design Handbook For EngineeriesTorres IvanNo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020SabariPandiyanNo ratings yet

- Production ManagementDocument26 pagesProduction Managementkevin punzalan100% (5)

- Power EPC ConsultantsDocument189 pagesPower EPC Consultantsanooppellissery20097159100% (1)

- Digital Control Systems (Elective) : Suggested ReadingDocument1 pageDigital Control Systems (Elective) : Suggested ReadingBebo DiaNo ratings yet

- W2AEW Videos (Apr 29, 2017) : Topics Listed NumericallyDocument12 pagesW2AEW Videos (Apr 29, 2017) : Topics Listed Numericallyamol1agarwalNo ratings yet

- Marketing Management Project: Submitted byDocument41 pagesMarketing Management Project: Submitted byrpotnisNo ratings yet

- اسئلة بروتوكولات الفصل الاولDocument21 pagesاسئلة بروتوكولات الفصل الاولرسول ابراهيم عبد علي رويعيNo ratings yet

- Scribd ResumeDocument2 pagesScribd ResumeaaronschrankNo ratings yet

- Pink Floyd - LyricsDocument97 pagesPink Floyd - LyricsИван ВащенкоNo ratings yet

- Unit 1 HWDocument4 pagesUnit 1 HWvanhaNo ratings yet

- T5 B68 Craig Unger FDR - 5-21-04 Stull Email - Unger Saudi Flight Docs 616Document6 pagesT5 B68 Craig Unger FDR - 5-21-04 Stull Email - Unger Saudi Flight Docs 6169/11 Document ArchiveNo ratings yet

- Reverse CalculationDocument7 pagesReverse CalculationKanishka Thomas Kain100% (1)

- School - Guest Faculty Management SystemDocument1 pageSchool - Guest Faculty Management SystemSuraj BadholiyaNo ratings yet

- HCIA-Transmission V2.0 Exam OutlineDocument3 pagesHCIA-Transmission V2.0 Exam Outlinemohammd khairyNo ratings yet

- Final Sample Report of Maruti Car CompanyDocument69 pagesFinal Sample Report of Maruti Car Companyofficial vrNo ratings yet

- Talent AcquisitionDocument2 pagesTalent AcquisitionkiranNo ratings yet

- Filtrec F040 SeriesDocument8 pagesFiltrec F040 Serieshkhan10No ratings yet

- Expedition DiaryDocument23 pagesExpedition DiaryAnkur JhunjhunwalaNo ratings yet

- CCE Quiz Batasan Set - SolutionDocument4 pagesCCE Quiz Batasan Set - SolutionJoovs JoovhoNo ratings yet

- 6 TransmissionDocument81 pages6 Transmissionalexis aguirre espejoNo ratings yet

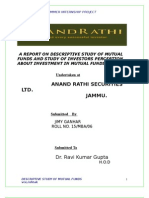

- Anand RathiDocument95 pagesAnand Rathivikramgupta195096% (25)

- Data SheetDocument48 pagesData SheetLost HumeraNo ratings yet

- A Study On Operational Audit of Hospital - Kaushalya HospitalDocument105 pagesA Study On Operational Audit of Hospital - Kaushalya Hospitalashish patelNo ratings yet

- DumbDocument10 pagesDumbJura LauraNo ratings yet

- Depth of FocusDocument7 pagesDepth of FocusDr-Riya MondalNo ratings yet

- Energy and Energy Transformations: Energy Makes Things HappenDocument8 pagesEnergy and Energy Transformations: Energy Makes Things HappenLabeenaNo ratings yet

- A Question of Energy Chris ThomasDocument12 pagesA Question of Energy Chris ThomasStephanie White Tulip PopescuNo ratings yet

- Brochure Fisher Fieldvue Dvc2000 Digital Valve Controllers en 124728Document4 pagesBrochure Fisher Fieldvue Dvc2000 Digital Valve Controllers en 124728Kaushal ParmarNo ratings yet

- The 2021 EY Scholarship: The Bahamas, Bermuda, British Virgin Islands and The Cayman IslandsDocument3 pagesThe 2021 EY Scholarship: The Bahamas, Bermuda, British Virgin Islands and The Cayman IslandsKingshuk MukherjeeNo ratings yet

- Drivewindow BasicsDocument34 pagesDrivewindow BasicsYaa ShinNo ratings yet