Professional Documents

Culture Documents

The World's Highest-Climbing Construction Hoist Is Used To Build The World's Tallest Structure

The World's Highest-Climbing Construction Hoist Is Used To Build The World's Tallest Structure

Uploaded by

Boruida MachineryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The World's Highest-Climbing Construction Hoist Is Used To Build The World's Tallest Structure

The World's Highest-Climbing Construction Hoist Is Used To Build The World's Tallest Structure

Uploaded by

Boruida MachineryCopyright:

Available Formats

Case study:

The world’s highest-climbing construction hoist

is used to build the world’s tallest structure

CN Tower, Toronto, Canada, 553 m

Case study:

Two Alimak Super Scando construction hoists were used during the slipform construction of

the world’s tallest free-standing structure: Toronto’s CN Tower. With lifting heights of 450m,

the two Alimak hoists remained on site for 28 months, until the tower’s completion in 1976.

The world’s tallest free-standing structure

In 1973, work began clearing the site for what was to

become the world’s tallest free-standing structure: the

553m CN Tower. Completed in 1976, the CN Tower held

the record for world’s highest tower for 34 years, until the

completion of the Burj Khalifa in 2010. As a symbol of

Canada and a favorite landmark of the Toronto city sky-

line, the CN tower is listed as one of the modern Seven

Wonders of the World.

The world’s highest-climbing construction hoist

As slipform casting began on the tower, Alimak (then

Linden-Alimak) delivered two Alimak Super Scando hoists

to site, transported between 13 freight cars. With a lifting

height of 450m, the Super Scando was the world’s highest-

climbing construction hoist at the time. Pin-driven hoist

cages powered by electro-hydraulic units allowed the

hoists to be steplessly controlled from 0 to 1.6 m/sec, while

the specially-constructed hoist cages permitted a loading

capacity of 2 tonnes per hoist.

While originally specified for 450m lifting heights,

one hoist was reduced to a lifting height of 380m once

construction commenced. Used during slipform construc-

tion of the concrete tower, the Super Scandos transported

The CN Tower was completed in 1976, at which point it

materials, equipment and the 100-strong workforce on

claimed the title of the tallest self-supporting structure in

site daily. Both units were employed 24 hours a day, 7 days

the world. The tower cost approximately CDN $63 million,

a week, remaining on site for a total of 28 months.

the rough equivalent of $249 million in today’s dollars. It

Reducing downtime

currently houses the antennas for five TV and five radio

stations, three observation decks and a rotating restaurant

Hoist downtime during construction was extremely low,

at 335m. Today, the tower remains the tallest free-stand-

with a combined total of 25 hours for the two hoists over

ing structure in the Western Hemisphere and attracts

the duration of the project. Minimal downtime was

more than two million international visitors each year.

achieved by:

• Ensuring Alimak’s representative at the time, Heede

DETAILS

International, stocked a ready supply of additional

Location: CN Tower, Toronto, Canada

parts, thereby eliminating repair delays

Product model: 2 x ALIMAK SUPER SCANDO

• Carrying out regular service and maintenance on the

Application: Tower construction, men and materials hoists

hoists as part of a proactive maintenance approach

Capacity: 2,000 kg

• Cooperation between the CN Tower construction team,

Speed: 1.6 m/s

Heede International and Alimak to identify and elimi-

Lifting height: 450 m

516 EN/Aug 1976. Reprinted Aug. 2019

nate potential problems.

www.alimak.com

Pictures are illustrative only and do not necessarily show the configuration of products on the market at a given point in time. Products must be used in conformity with safe practice and applicable

statutes, regulations, codes and ordinances. Specifications of products and equipment shown herein are subject to change without notice. Copyright © 1976-2019 Alimak Group. All rights reserved.

Alimak and Scando are registered trademarks of Alimak Group.

You might also like

- Whiting Crane Handbook - Third EditionDocument205 pagesWhiting Crane Handbook - Third EditionJuan RubioNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Caterpillar Mining Truck Brochure PDFDocument28 pagesCaterpillar Mining Truck Brochure PDFmark tower100% (1)

- PRoj MangementDocument31 pagesPRoj MangementNeeraj S100% (1)

- Offshore and Harbour Cranes PDFDocument20 pagesOffshore and Harbour Cranes PDFHemanth Kumar Sarosh KiranNo ratings yet

- Checklist - Using A Mobile HoistDocument2 pagesChecklist - Using A Mobile HoistMorganNo ratings yet

- ALIMAK Scando 650 InstallDocument66 pagesALIMAK Scando 650 InstallAya JiboNo ratings yet

- Hoist by TechnologyDocument6 pagesHoist by TechnologyAnonymous ntE0hG2TPNo ratings yet

- Cranes With Brains: Euromax - The Modern Automatic Container TerminalDocument4 pagesCranes With Brains: Euromax - The Modern Automatic Container TerminalElafanNo ratings yet

- Succ Story Shipbuilding2014Document11 pagesSucc Story Shipbuilding2014lyesNo ratings yet

- 1.construction Management FrameworkDocument93 pages1.construction Management FrameworkRajiv DandekhyaNo ratings yet

- Aexq1170 01Document34 pagesAexq1170 01Jose FerreiraNo ratings yet

- TUKAN EnglDocument6 pagesTUKAN EnglAndi Fatimah Azzahra Azwar0% (1)

- Cranes Today AprDocument84 pagesCranes Today Aprdinamo12345No ratings yet

- Ulmaconstruction High Rise Building Construction CatalogueDocument38 pagesUlmaconstruction High Rise Building Construction Cataloguemodestus nalleNo ratings yet

- Dynamic ArchitectureDocument32 pagesDynamic ArchitectureAmeena AmeerNo ratings yet

- Unibridge Military Applications BrochureDocument8 pagesUnibridge Military Applications Brochuredjb300No ratings yet

- Iwaki Case Study 13082012Document4 pagesIwaki Case Study 13082012Thiban KumarNo ratings yet

- Cathryn Hooper - Floating Offshore Wind PDFDocument11 pagesCathryn Hooper - Floating Offshore Wind PDFStedroy Roache100% (1)

- OTC19073 Float-Overs Offshore West AfricaDocument10 pagesOTC19073 Float-Overs Offshore West AfricaCees van ZandvlietNo ratings yet

- Mastclimber Brochure - London - 2014Document28 pagesMastclimber Brochure - London - 2014Abdelrahman ElkhollyNo ratings yet

- NFT-ATC Cranes Who We Are2022Document27 pagesNFT-ATC Cranes Who We Are2022Sherif ZahranNo ratings yet

- Prefabricated Pre-Finished Volumetric Construction (PPVC) PPVC Lifting Best PracticesDocument31 pagesPrefabricated Pre-Finished Volumetric Construction (PPVC) PPVC Lifting Best PracticesPyae PhyoNo ratings yet

- Construction and WeightDocument79 pagesConstruction and Weightusman nawazNo ratings yet

- Construction of A Culverts DesignDocument19 pagesConstruction of A Culverts DesignNani CherryNo ratings yet

- MFM Darling Harbour Live FA RGBDocument3 pagesMFM Darling Harbour Live FA RGBEmilio JuárezNo ratings yet

- Alufer - CorporatePresentation Q2 2021 1Document12 pagesAlufer - CorporatePresentation Q2 2021 1enjaegerNo ratings yet

- AMC FacilitiespdfDocument12 pagesAMC FacilitiespdfgodfreyreggioNo ratings yet

- OTD Product Services Presentation (2017) PDFDocument30 pagesOTD Product Services Presentation (2017) PDFPrashant KrishnanNo ratings yet

- Verma 2022 IOP Conf. Ser. Mater. Sci. Eng. 1258 012019Document8 pagesVerma 2022 IOP Conf. Ser. Mater. Sci. Eng. 1258 012019Rohan DeswalNo ratings yet

- The Operation Of: Dry Docking ShipsDocument205 pagesThe Operation Of: Dry Docking ShipskfslmsbaseNo ratings yet

- LDD Gwynt y Môr OWFDocument2 pagesLDD Gwynt y Môr OWFmasih.jr.1401No ratings yet

- Nepean Conveyors Projects CapabilityDocument13 pagesNepean Conveyors Projects CapabilityFelipe RibeiroNo ratings yet

- Guide To Choose An Overhead CraneDocument4 pagesGuide To Choose An Overhead CraneyufeigroupNo ratings yet

- Self Elevating Jackups - Zakher MarineDocument34 pagesSelf Elevating Jackups - Zakher MarineOffshore JackupNo ratings yet

- Otc 18587 MS PDocument15 pagesOtc 18587 MS PSiul Otrebla AtelavazNo ratings yet

- Container Crane Recycling: Upgrade and RelocationDocument2 pagesContainer Crane Recycling: Upgrade and RelocationAmable FuentesNo ratings yet

- Port Handling 8x11 SecDocument4 pagesPort Handling 8x11 Secdedi yusufNo ratings yet

- Titanic-The 'Unsinkable Ship'Document17 pagesTitanic-The 'Unsinkable Ship'Arnab SenNo ratings yet

- DEME Offshore Brochure - 2022Document16 pagesDEME Offshore Brochure - 2022amin32No ratings yet

- BK-Presentation (Assignment 01)Document31 pagesBK-Presentation (Assignment 01)a klNo ratings yet

- VSL - Puente Unidad MexicoDocument2 pagesVSL - Puente Unidad MexicohedyNo ratings yet

- Dofasco RCM Case StudyDocument3 pagesDofasco RCM Case StudyJustin ChanNo ratings yet

- D391000177-MKT-001 Rev 06 WISE Catalog PDFDocument28 pagesD391000177-MKT-001 Rev 06 WISE Catalog PDFpendexxNo ratings yet

- Archicture Design For Green HomesDocument4 pagesArchicture Design For Green HomessokarankumarNo ratings yet

- An Implementation of Risk-Based Inspection For Elevator MaintenanceDocument10 pagesAn Implementation of Risk-Based Inspection For Elevator MaintenanceMauricio GalvisNo ratings yet

- IADC Vol-1 01 Type of Drilling RigsDocument19 pagesIADC Vol-1 01 Type of Drilling RigsJ Alberto Grandez M100% (2)

- Устройство для пересадки персоналаDocument28 pagesУстройство для пересадки персоналаRustem IakhinNo ratings yet

- Coll. - Types of Drilling Rigs (RT) - Stand-Alone Chapter of The IADC Drilling Manual. 1 (2015)Document531 pagesColl. - Types of Drilling Rigs (RT) - Stand-Alone Chapter of The IADC Drilling Manual. 1 (2015)ritesh rahangdaleNo ratings yet

- Design and Construction of Marine Shiplift Facility-L&TDocument4 pagesDesign and Construction of Marine Shiplift Facility-L&TSankar CdmNo ratings yet

- An Implementation of Risk-Based Inspection For Elevator MaintenanceDocument10 pagesAn Implementation of Risk-Based Inspection For Elevator MaintenancePrasad PNo ratings yet

- TU 515R Technical SpecificationDocument24 pagesTU 515R Technical Specificationgeorge_zouridisNo ratings yet

- Brochure Flexi France - ENGDocument8 pagesBrochure Flexi France - ENGJhon HernandezNo ratings yet

- Heavy Duty 2015 enDocument20 pagesHeavy Duty 2015 ensergio anguera cabezueloNo ratings yet

- L1 - 2 - Shipyard Productivity PDFDocument33 pagesL1 - 2 - Shipyard Productivity PDFattiori fabriceNo ratings yet

- Lifting and Handling Product Portfolio PDFDocument33 pagesLifting and Handling Product Portfolio PDFArzuQafarovNo ratings yet

- Trident CraneDocument2 pagesTrident CranePavan RayNo ratings yet

- TZ CompanyDocument18 pagesTZ Companyamir esmaeilzareNo ratings yet

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- From T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedFrom EverandFrom T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedNo ratings yet

- HSMARINE Products at Atb AtcDocument7 pagesHSMARINE Products at Atb AtcBoruida MachineryNo ratings yet

- T LiftDocument4 pagesT LiftBoruida MachineryNo ratings yet

- SA Raxtar TheBeastDocument4 pagesSA Raxtar TheBeastBoruida MachineryNo ratings yet

- HSMARINE Products AkcDocument5 pagesHSMARINE Products AkcBoruida MachineryNo ratings yet

- Alimak Industrial Warehouse Lifts: Vertical Access Solutions For Warehousing FacilitiesDocument4 pagesAlimak Industrial Warehouse Lifts: Vertical Access Solutions For Warehousing FacilitiesBoruida MachineryNo ratings yet

- Hsmarine OffshoreDocument7 pagesHsmarine OffshoreBoruida MachineryNo ratings yet

- ALIMAK SCANDO 450 DOL 32ext. 50Hz 1278 EN Oct 2020Document1 pageALIMAK SCANDO 450 DOL 32ext. 50Hz 1278 EN Oct 2020Boruida MachineryNo ratings yet

- HSMARINE Products AkDocument5 pagesHSMARINE Products AkBoruida MachineryNo ratings yet

- Alimak Install Industrial Elevator Within An Existing Shaft at QNI's Palmer Nickel and Cobalt RefineryDocument4 pagesAlimak Install Industrial Elevator Within An Existing Shaft at QNI's Palmer Nickel and Cobalt RefineryBoruida MachineryNo ratings yet

- Hsmarine Tugs and WorkboatsDocument3 pagesHsmarine Tugs and WorkboatsBoruida MachineryNo ratings yet

- Doka Accessory Box: Art. N° 583010000Document9 pagesDoka Accessory Box: Art. N° 583010000Boruida MachineryNo ratings yet

- Alimak Super Scando FC Manual Elevator Cable PDFDocument71 pagesAlimak Super Scando FC Manual Elevator Cable PDFBoruida MachineryNo ratings yet

- ANKA Industrial ElevatorsDocument1 pageANKA Industrial ElevatorsBoruida MachineryNo ratings yet

- Frami Pallet 1.20m and 1.50m: 1997 Models OnwardDocument5 pagesFrami Pallet 1.20m and 1.50m: 1997 Models OnwardBoruida MachineryNo ratings yet

- Shaft Platform: The Cost-Saving System For Forming Inside-ShaftsDocument2 pagesShaft Platform: The Cost-Saving System For Forming Inside-ShaftsBoruida MachineryNo ratings yet

- 261 Many Tower Cranes, Self Erecting Cranes and Accessories CatalogueDocument20 pages261 Many Tower Cranes, Self Erecting Cranes and Accessories CatalogueBoruida MachineryNo ratings yet

- Doka Pallet For Staxo/Aluxo: 1998 Models Onward 2007 Models Onward 2009 Models OnwardDocument5 pagesDoka Pallet For Staxo/Aluxo: 1998 Models Onward 2007 Models Onward 2009 Models OnwardBoruida MachineryNo ratings yet

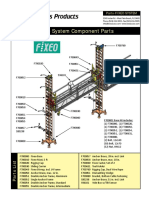

- Parts-Fixeo System ComponentsDocument1 pageParts-Fixeo System ComponentsBoruida MachineryNo ratings yet

- FEM 1.001-1 Object and ScopeDocument26 pagesFEM 1.001-1 Object and ScopeBoruida MachineryNo ratings yet

- FX Cable Suspended Platform LR FADocument6 pagesFX Cable Suspended Platform LR FABoruida MachineryNo ratings yet

- Single Man Cradle - Technical DataDocument5 pagesSingle Man Cradle - Technical DataFrancis BautistaNo ratings yet

- The AS 7 Wire Rope HoistDocument24 pagesThe AS 7 Wire Rope Hoistben_aizziNo ratings yet

- Manual Lever and Hoist BlockDocument11 pagesManual Lever and Hoist BlockLuffy11No ratings yet

- Polipastos CM Valuestar ManualDocument29 pagesPolipastos CM Valuestar ManualJoako TorresNo ratings yet

- 079 - 125 Ton Monorail Air Hoist User ManualDocument46 pages079 - 125 Ton Monorail Air Hoist User ManualIgab Punia AtmajaNo ratings yet

- Brugg RopeLife ENDocument16 pagesBrugg RopeLife ENBehzad PourazadNo ratings yet

- BA LIFTKET 2011 04a EnglischDocument36 pagesBA LIFTKET 2011 04a EnglischReymart ManablugNo ratings yet

- 130718Document176 pages130718Th NattapongNo ratings yet

- Tender Document For CraneDocument10 pagesTender Document For Craneamechmar5935No ratings yet

- WirelessEstimatorJHA YESElevatedDocument5 pagesWirelessEstimatorJHA YESElevatedmohammed tofiqNo ratings yet

- Rigger - S HandbookDocument156 pagesRigger - S HandbookGlemarck NaboaNo ratings yet

- Cranes and Lifting Equipment: Standard Operating ProceduresDocument10 pagesCranes and Lifting Equipment: Standard Operating ProceduresKryptonNo ratings yet

- American Crane PDFDocument12 pagesAmerican Crane PDFJuan Carlos RuizNo ratings yet

- Fully Hydraulic Crawler Crane: Lifting Capacity 250 Metric TonsDocument12 pagesFully Hydraulic Crawler Crane: Lifting Capacity 250 Metric Tons이현기No ratings yet

- Design Report - Gantry Crane 20ton8.53mspanDocument34 pagesDesign Report - Gantry Crane 20ton8.53mspanAdeeb Shahzada100% (1)

- SHE Spec - Lifting Equipment - Kusile Power StationDocument51 pagesSHE Spec - Lifting Equipment - Kusile Power StationMatthew LeeNo ratings yet

- Factories ActDocument120 pagesFactories ActCefi JohnNo ratings yet

- Guidelines On Safety of Tower Cranes (Version 2) July 2010 - eDocument78 pagesGuidelines On Safety of Tower Cranes (Version 2) July 2010 - eIlanildo DiasNo ratings yet

- Ops 0055 July 12016Document164 pagesOps 0055 July 12016Aizat NajibNo ratings yet

- LCMBrochureFinal PDFDocument20 pagesLCMBrochureFinal PDFPrime Energy Warehouse-YemenNo ratings yet

- International: Dry CargoDocument8 pagesInternational: Dry CargoGustavo PalaciosNo ratings yet

- Rope Drum Hoist For Overshot Gate PDFDocument12 pagesRope Drum Hoist For Overshot Gate PDFariza15100% (1)

- Manual General (ElevaciónArrastre) Paccar PDFDocument86 pagesManual General (ElevaciónArrastre) Paccar PDFNelly Beltrán CuellarNo ratings yet

- P.DC Pro 1-20, DCM1-5Document68 pagesP.DC Pro 1-20, DCM1-5Andi KastrawanNo ratings yet

- Rhino CranesDocument21 pagesRhino CranesecocadecNo ratings yet

- Ind Mwide 002 69 Report TC 57Document6 pagesInd Mwide 002 69 Report TC 57Daryl HernandezNo ratings yet

- Hoists Spare PartsDocument46 pagesHoists Spare PartsWiesław WarnelNo ratings yet

- Lateral Stiffness and Deflection Characteristics of Guide Cable With Multi-Boundary ConstraintsDocument13 pagesLateral Stiffness and Deflection Characteristics of Guide Cable With Multi-Boundary Constraintssoheil norooziNo ratings yet