Professional Documents

Culture Documents

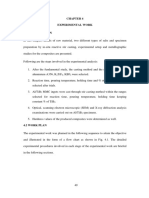

List of Figures: Fig No Topics Page No

List of Figures: Fig No Topics Page No

Uploaded by

Mohammed Hussain0 ratings0% found this document useful (0 votes)

19 views2 pagesThis document contains a list of figures and their corresponding topics and page numbers. It includes 28 figures that show various topics related to reinforcement shapes, fatigue crack growth, S-N curves, casting and machining processes, stir casting equipment, fatigue specimens and testing, heat treatment processes, and microstructure images of aluminum 6061 with varying amounts of reinforcement. The figures are presented in numerical order and provide visual representations to accompany topics in the document.

Original Description:

Figures

Original Title

LIST OF FIGURES

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains a list of figures and their corresponding topics and page numbers. It includes 28 figures that show various topics related to reinforcement shapes, fatigue crack growth, S-N curves, casting and machining processes, stir casting equipment, fatigue specimens and testing, heat treatment processes, and microstructure images of aluminum 6061 with varying amounts of reinforcement. The figures are presented in numerical order and provide visual representations to accompany topics in the document.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

19 views2 pagesList of Figures: Fig No Topics Page No

List of Figures: Fig No Topics Page No

Uploaded by

Mohammed HussainThis document contains a list of figures and their corresponding topics and page numbers. It includes 28 figures that show various topics related to reinforcement shapes, fatigue crack growth, S-N curves, casting and machining processes, stir casting equipment, fatigue specimens and testing, heat treatment processes, and microstructure images of aluminum 6061 with varying amounts of reinforcement. The figures are presented in numerical order and provide visual representations to accompany topics in the document.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

LIST OF FIGURES

FIG NO TOPICS PAGE NO

Fig 1.1 Shows that Different shapes of reinforcement. 05

Fig.3.1 Shows that Micrographs showing how surface fatigue 18

cracks grow as material is further cycled

Fig 3.2 Shows that S-N curve for a brittle aluminium with an 20

ultimate tensile strength of 320 MPa

Fig 5.1 Shows that Crucible 27

Fig 5.2 Shows that Mixing of Powders 27

Fig 5.3 Shows that Removing of material from Die 27

Fig 5.4 Shows that Allowing for solidification 27

Fig 5.5 Shows that Casting Specimens 28

Fig 5.6 Shows that Machining of Specimens 28

Fig 5.7 Shows that Machined Specimens 28

Fig 6.1 Shows that Aluminium 6061 30

Fig 6.2 Shows that KBF4 Power 30

Fig 6.3 Shows that Cryolite powder 31

Fig 6.4 Shows that Stir casting equipment 35

Fig 6.5 Shows that Crucible 35

Fig 6.6 Shows that Die preparation 35

Fig 6.7 Shows that Pouring of molten metal 35

Fig 7.1 Shows that Fatigue specimen 37

Fig 7.2 Shows that Fatigue Test Equipment 38

Fig 7.3 Shows that Fatigue Test Equipment 39

Fig 7.4 Shows that Fatigue specimens 41

Fig 7.5 Shows that Fatigue stress cycle 42

Fig 8.1 Shows that T6 heat treatment process 46

Fig 8.2 Shows that Muffle Furnace 47

Fig 8.3 Shows that Specimens placed inside the muffle furnace 47

Fig 8.4 Shows that Heat treated specimens 47

Fig 9.1 Shows that The Prepared Specimen for Microstructure 48

(with Heat Treatment)

Fig 9.2 Shows that The Prepared Specimen for Microstructure 48

(Without Heat Treatment)

Fig 9.3 Shows that Al 6061 SEM 49

Fig 9.4 Shows that Al 6061 + 1% reinforcement 49

Fig 9.5 Shows that Al 6061 + 2% reinforcement 49

Fig 9.6 Shows that Al 6061 + 3% reinforcement 49

Fig 9.7 Shows that Al 6061 + 4% reinforcement 49

Fig 9.8 Shows that Al 6061 + 5% reinforcement 49

You might also like

- Heat Treatment by T V Rajan PDFDocument399 pagesHeat Treatment by T V Rajan PDFManikandan69% (13)

- Exercise Problems (CH 7,8,9,10)Document22 pagesExercise Problems (CH 7,8,9,10)srinis4777-1No ratings yet

- Fabrication of Alumina Crucible: Rini Binti RuslamDocument24 pagesFabrication of Alumina Crucible: Rini Binti RuslamkartikkeyyanNo ratings yet

- Chapter 1 IntroductionDocument4 pagesChapter 1 Introductionmeetshah92No ratings yet

- Chapters Page No. 1 2. Literature Survey 5Document4 pagesChapters Page No. 1 2. Literature Survey 5SATHISH RCNo ratings yet

- Heat 2Document1 pageHeat 2yingwuenchanNo ratings yet

- 07 JPNT Kim f4 Modul5Document9 pages07 JPNT Kim f4 Modul5Abdul ManafNo ratings yet

- MY BATCH PDF PraneethhhhDocument8 pagesMY BATCH PDF PraneethhhhMythry CybercafeNo ratings yet

- 4Document7 pages4Dinesh RawatNo ratings yet

- TrialDocument6 pagesTrialBenjamin TeeNo ratings yet

- 0625 TQ P3 Thermal v2Document6 pages0625 TQ P3 Thermal v2ammara shafiqueNo ratings yet

- Extra Sheet 2 (Sent Online)Document13 pagesExtra Sheet 2 (Sent Online)Mona Abd-ElazizNo ratings yet

- July 2004Document6 pagesJuly 2004ffgfgfgffgNo ratings yet

- Experimental WorkDocument12 pagesExperimental Workmohd nadeemNo ratings yet

- Powder Lab Repo 1 v2Document7 pagesPowder Lab Repo 1 v2azhar alakNo ratings yet

- Nickel Iron BatteryDocument229 pagesNickel Iron Batterygunawansigi36No ratings yet

- Castingch 05Document50 pagesCastingch 05hoang datNo ratings yet

- ACEFigure No PDFDocument1 pageACEFigure No PDFHatim ValiNo ratings yet

- ON2015Document18 pagesON201524.linhthuy.pham.stNo ratings yet

- Chemistry Perfect Score Module Form 4 Set 1Document27 pagesChemistry Perfect Score Module Form 4 Set 1ZekZanaNo ratings yet

- Modern Blast Furnace IronmakingDocument10 pagesModern Blast Furnace IronmakingNancy Carolina Prieto Martinez100% (2)

- List of Figures Final 1Document1 pageList of Figures Final 1syednomanmohiuddin412No ratings yet

- AcknowledgementDocument6 pagesAcknowledgementMathew P RejiNo ratings yet

- Exercise Chapter Land and Its ResourcesDocument6 pagesExercise Chapter Land and Its ResourcesWan ShuhaimiNo ratings yet

- I. Direct Cost 1.0 General Requirements 2.0 EarthworksDocument4 pagesI. Direct Cost 1.0 General Requirements 2.0 EarthworksIrene B. QuiñonesNo ratings yet

- Modul Electricity 2019Document24 pagesModul Electricity 2019Cart Kartika100% (7)

- Electricity QuestionsDocument24 pagesElectricity QuestionsNorKamilahMakhtarNo ratings yet

- Spilt Tensile Strength Test 29 3.6.3 Flexural Strength Test 29Document4 pagesSpilt Tensile Strength Test 29 3.6.3 Flexural Strength Test 29Mallesh ArjaNo ratings yet

- Electrochemistry and Oxidation and ReductionDocument32 pagesElectrochemistry and Oxidation and ReductionHajar Norasyikin Abu BakarNo ratings yet

- DMX5204 Final 2021Document6 pagesDMX5204 Final 2021Sanjeewa PrabathNo ratings yet

- Effect of Stress Relief Annealing and Homogenizing Annealing On The Microstructure and Mechanical Properties of Cast BrassDocument5 pagesEffect of Stress Relief Annealing and Homogenizing Annealing On The Microstructure and Mechanical Properties of Cast BrassJigar M. UpadhyayNo ratings yet

- Combustion Efficiency TablesDocument204 pagesCombustion Efficiency TablesRodolfo FernandezNo ratings yet

- Paper 3 Chemistry EditedDocument7 pagesPaper 3 Chemistry EditedBaskaran Manogaran0% (1)

- Cold Heading For FastnersDocument93 pagesCold Heading For Fastnersamh.fpdNo ratings yet

- List of FiguresDocument1 pageList of FiguresThiru JaganNo ratings yet

- List of Figures: Figure No. Title Page NoDocument1 pageList of Figures: Figure No. Title Page NoThiru JaganNo ratings yet

- List of Table: Table No Topics Page NoDocument2 pagesList of Table: Table No Topics Page NoMohammed HussainNo ratings yet

- Theory Chp 7 PressureDocument8 pagesTheory Chp 7 PressureAdmin Hijau EducareNo ratings yet

- Igcse P3 N15Document20 pagesIgcse P3 N15ruppertoopersdorffNo ratings yet

- CI 9 Co Science Paper 4 Paper 6Document21 pagesCI 9 Co Science Paper 4 Paper 6Jyoti SinghNo ratings yet

- DP Table of ContentsDocument5 pagesDP Table of ContentsPurna Suresh PedamalluNo ratings yet

- MT1Document1 pageMT1Afthal AhmedNo ratings yet

- Chemistry Perfect Score Module Form 4 2011 No LogoDocument96 pagesChemistry Perfect Score Module Form 4 2011 No Logohome8008100% (2)

- Mix Typ e Wa Ter Rati o W/B T o Bin Der Crush Ing (Tons) Loa Ds Stren GTH (Psi)Document9 pagesMix Typ e Wa Ter Rati o W/B T o Bin Der Crush Ing (Tons) Loa Ds Stren GTH (Psi)Asghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)No ratings yet

- Paper 3 SPM 2011 Mastery PracticesDocument30 pagesPaper 3 SPM 2011 Mastery PracticesaganbasmNo ratings yet

- Bitumen Softening Test PDFDocument6 pagesBitumen Softening Test PDFanbertjonathanNo ratings yet

- 5.2 Principles of Chemical Vapor DepositionDocument9 pages5.2 Principles of Chemical Vapor DepositionAtul NainawatNo ratings yet

- k2 f4 A KIMIADocument27 pagesk2 f4 A KIMIAAzalida Md YusofNo ratings yet

- Sbea1913 Construction Practice Project 2: Construction Site Developer: Bandar Nusajaya Development SDN BHDDocument96 pagesSbea1913 Construction Practice Project 2: Construction Site Developer: Bandar Nusajaya Development SDN BHDTenghong LimNo ratings yet

- Assessment of Corrosion Rate of DissimilDocument72 pagesAssessment of Corrosion Rate of Dissimillorenaov177No ratings yet

- Lid /penutup Crucible Magnesium RibbonDocument6 pagesLid /penutup Crucible Magnesium RibbonEIJA_HAFIZA867602No ratings yet

- Paper 3 SPM 2011 Mastery PracticesDocument30 pagesPaper 3 SPM 2011 Mastery Practicesaganbasm100% (1)

- Worksheet 07052020Document2 pagesWorksheet 07052020shirlynNo ratings yet

- COSTESTDocument3 pagesCOSTESTcuteboy842No ratings yet

- PCB ContentDocument3 pagesPCB ContentPreet ChahalNo ratings yet

- Fulltext01Document118 pagesFulltext01ANDRE LUIS BRITO BAPTISTANo ratings yet

- Modular Forms and Special Cycles on Shimura Curves. (AM-161)From EverandModular Forms and Special Cycles on Shimura Curves. (AM-161)No ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- E-Receipt For State Bank Collect Payment: Government Engineering College, Raichur DateDocument1 pageE-Receipt For State Bank Collect Payment: Government Engineering College, Raichur DateMohammed HussainNo ratings yet

- Mohammed Hussain Pasha: Mechanical EngineerDocument2 pagesMohammed Hussain Pasha: Mechanical EngineerMohammed HussainNo ratings yet

- List of Table: Table No Topics Page NoDocument2 pagesList of Table: Table No Topics Page NoMohammed HussainNo ratings yet

- Akheel ResumeDocument1 pageAkheel ResumeMohammed HussainNo ratings yet

- Raft Modeling in Etabs - Foundation Design - Structural Engineering Forum of Pakistan PDFDocument1 pageRaft Modeling in Etabs - Foundation Design - Structural Engineering Forum of Pakistan PDFKenny Manuel Vettoor100% (1)

- History of Chemistry: Name: Vine D. OrtegaDocument8 pagesHistory of Chemistry: Name: Vine D. OrtegaVine OrtegaNo ratings yet

- AB Process Engineering SyllabusDocument2 pagesAB Process Engineering SyllabusryeueNo ratings yet

- 802111LBDocument18 pages802111LBAbirami MuruganNo ratings yet

- Additional Mousetrap Investigation NotesDocument69 pagesAdditional Mousetrap Investigation NotesPradeep WalaweNo ratings yet

- GB Rca Car 2023 001Document2 pagesGB Rca Car 2023 001cameron toolseeNo ratings yet

- Sheet Pile Design SampleDocument4 pagesSheet Pile Design SampleMarvin SabadoNo ratings yet

- Analisis Kandungan Air, Abu, Dan Logam Berat Pada Kopi Bubuk Asal GayoDocument8 pagesAnalisis Kandungan Air, Abu, Dan Logam Berat Pada Kopi Bubuk Asal GayoKevin LaksmonoNo ratings yet

- Thermo Scientific FHZ 691-10: Wide-Range Dose Rate ProbeDocument2 pagesThermo Scientific FHZ 691-10: Wide-Range Dose Rate ProbeSkjhkjhkjhNo ratings yet

- MCE 302 MEx Questions (May 02, 2023) Q 2Document2 pagesMCE 302 MEx Questions (May 02, 2023) Q 2Sergen YalçınNo ratings yet

- Physics Practical HandbookDocument20 pagesPhysics Practical HandbookMOHAMED SHAMIR BIN TAJUDEENNo ratings yet

- Physics HL - WORKED SOLUTIONS by Chris HamperDocument111 pagesPhysics HL - WORKED SOLUTIONS by Chris HamperAdya BhardwajNo ratings yet

- PTSP Subjective QuestionsDocument5 pagesPTSP Subjective QuestionsmanikrishnaswamyNo ratings yet

- API 510. Daily Exam-3 (Closed Book)Document5 pagesAPI 510. Daily Exam-3 (Closed Book)Maher ShehabNo ratings yet

- DL 0 DegreeDocument2,120 pagesDL 0 DegreePraveen CyssanNo ratings yet

- Week 7Document11 pagesWeek 7Bl ParadiseNo ratings yet

- 0077 PDF C01Document7 pages0077 PDF C01Rıfat BingülNo ratings yet

- Thermoelectric PropertiesDocument4 pagesThermoelectric PropertiesM ZarakNo ratings yet

- Jee-Advanced-Current Electricity Question BankDocument166 pagesJee-Advanced-Current Electricity Question BankYashNo ratings yet

- Literature ReviewDocument9 pagesLiterature ReviewVinod kumarNo ratings yet

- Unesco - Eolss Sample Chapters: Earthquake Ground MotionDocument9 pagesUnesco - Eolss Sample Chapters: Earthquake Ground MotionEba GetachewNo ratings yet

- September 2018 PDFDocument92 pagesSeptember 2018 PDFsambhavjoshi100% (1)

- Structural Control of Ore DepositsDocument22 pagesStructural Control of Ore DepositsajreateguicNo ratings yet

- LectureDocument128 pagesLectureDiego FernandezNo ratings yet

- Alagappa Chettiar Government College of Engineering and Technology Karaikudi - 630 003Document2 pagesAlagappa Chettiar Government College of Engineering and Technology Karaikudi - 630 003Rohan ARKNo ratings yet

- Flow Zone Indicator Guided Workflows For PetrelDocument11 pagesFlow Zone Indicator Guided Workflows For PetrelAiwarikiaar100% (1)

- Bai Giang CT361Document111 pagesBai Giang CT361Joe PhạmNo ratings yet

- Steel Cord Conveyor Belts: Guide Values For The Mass and ThicknessDocument3 pagesSteel Cord Conveyor Belts: Guide Values For The Mass and ThicknessRaja NarenderNo ratings yet

- RM NotesDocument102 pagesRM NotesLeo BoyNo ratings yet

- Numerical Study of SNCR Application To A Full-Scale Stoker Incinerator at Daejon 4th Industrial ComplexDocument13 pagesNumerical Study of SNCR Application To A Full-Scale Stoker Incinerator at Daejon 4th Industrial ComplexAsmita AtreNo ratings yet