Professional Documents

Culture Documents

Clutch Packs Install PDF

Clutch Packs Install PDF

Uploaded by

pedro sanchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clutch Packs Install PDF

Clutch Packs Install PDF

Uploaded by

pedro sanchezCopyright:

Available Formats

Página 1 de 4

TM10147 - 410J Backhoe Loader (S.N. —161616)

Clutch Packs Install

Clutch Packs Install

1.

TX1020118-UN: Torque Converter Side Bearing Outer Rings and Suction Tube Installation

LEGEND:

20 - Bearing Cup (7 used)

21 - Cap Screw (2 used)

22 - Oil Suction Tube

Apply petroleum jelly to bearing cups (20).

2. Install bearing cups (20).

3. Install oil suction tube (22).

4.

TX1023851-UN: O-ring and Bearing Outer Races

LEGEND:

19 - Bearing Cup (5 used)

23 - O-rings (2 used)

Apply petroleum jelly to bearing cups (19).

5. Install bearing cups (19)

6. NOTE:

Use petroleum jelly to hold O-rings in place during assembly.

Install O-rings (23).

7.

TX1021630-UN: 2nd, 3rd, and MFWD Installation

LEGEND:

9 - Second Speed Clutch Pack

10 - Mechanical Front Wheel Drive (MFWD) Clutch Pack

11 - Third Speed Clutch Pack

file://C:\ProgramData\Service ADVISOR\Temp\TM10147_09001faa805b8442.html 04/12/2017

Página 2 de 4

12 - Eyebolt (2 used)

13 - Screen Sheet

24 - Snap Ring (2 used)

25 - Snap Ring

26 - Pilot Hole (2 used)

27 - Bolts (2 used)

Apply petroleum jelly to snap O-rings (24 and 25).

8. Install bolts (27) through screen sheet (13).

9.

CAUTION:

Prevent possible crushing injury from heavy component. Use appropriate lifting device.

Align bolts (27) with pilot holes (26) to install clutch packs (9—11) together with screen sheet (13).

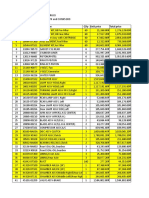

Item Measurement Specification

Second, Third, and MFWD Clutch Weight (approximate) 27 kg

Pack 60 lb

10.

TX1021690-UN: First Speed Clutch Install

LEGEND:

8 - First Speed Clutch

28 - Snap Ring (2 used)

Apply petroleum jelly to snap rings (28) and install clutch (8).

11.

TX1021688-UN: Reverse and Low Range Clutch Install

LEGEND:

5 - Low Range Clutch

7 - Reverse Clutch

29 - Snap Ring (2 used)

30 - Snap Ring (3 used)

Apply petroleum jelly to snap rings (29 and 30) and install clutches (5 and 7) together.

12.

TX1021693-UN: High Range Forward Clutch Install

file://C:\ProgramData\Service ADVISOR\Temp\TM10147_09001faa805b8442.html 04/12/2017

Página 3 de 4

LEGEND:

6 - High Range Forward Clutch

31 - Snap Ring

Apply petroleum jelly to snap rings (31) and install clutch (6).

13. NOTE:

Bolts (27) must be installed properly before the transmission halves are installed.

TX1021714-UN: Transmission Case Installation

LEGEND:

3 - Eyebolts

27 - Bolts

Install lifting eyebolts (3) and attach hoist.

14. Clean mating surfaces of transmission case halves with PM37509 Cure Primer.

15. Apply PM38657 High Flex Form-In-Gasket to mating surfaces of transmission halves.

16.

CAUTION:

Prevent possible crushing injury from heavy component. Use appropriate lifting device.

NOTE:

Bolts (27) must be installed properly before the transmission halves are installed.

TX1021714-UN: Transmission Case Installation

LEGEND:

3 - Eyebolts

27 - Bolts

Install lifting eyebolts (3) and attach hoist.

Item Measurement Specification

Transmission Case Half Weight (approximate) 42 kg

93 lb

file://C:\ProgramData\Service ADVISOR\Temp\TM10147_09001faa805b8442.html 04/12/2017

Página 4 de 4

17.

TX1021717-UN: Transmission Case Cap Screws and Pins

LEGEND:

1 - Dowel Pins (2 used)

2 - Cap Screw (24 used)

32 - Bracket

Install bracket (32).

18. Align the dowel holes.

19. Install dowel pin (1) until flush.

20. Tighten cap screws (2) with a run up torque of 20 N·m (177 lb-in) at a 45° rotation.

Item Measurement Specification

Transmission Case Mounting Cap Run Up Torque 20 N·m

Screws 177 lb-in

21. Tighten cap screws (2).

Item Measurement Specification

Transmission Case Mounting Cap Torque 65 N·m

Screws 48 lb-ft

LOCTITE is a trademark of Henkel Corporation KK70125,0000762-19-20080213

file://C:\ProgramData\Service ADVISOR\Temp\TM10147_09001faa805b8442.html 04/12/2017

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 100-4102 Valve Gp-Control - SwingDocument3 pages100-4102 Valve Gp-Control - Swingpedro sanchezNo ratings yet

- Clutch Packs RemoveDocument4 pagesClutch Packs Removepedro sanchezNo ratings yet

- Convenciones Códigos Sistema Obd Ii: Service Department - CET GM ColmotoresDocument16 pagesConvenciones Códigos Sistema Obd Ii: Service Department - CET GM Colmotorespedro sanchezNo ratings yet

- Sicurezza AT000108 - E - Rev0Document36 pagesSicurezza AT000108 - E - Rev0pedro sanchezNo ratings yet

- D6TMaintenance Interval ScheduleDocument12 pagesD6TMaintenance Interval Schedulepedro sanchezNo ratings yet

- 320D FAL Solenoid Valve (Proportional Reducing) - Calibrate PDFDocument25 pages320D FAL Solenoid Valve (Proportional Reducing) - Calibrate PDFpedro sanchez100% (2)

- D6R Maintenance Interval ScheduleDocument12 pagesD6R Maintenance Interval Schedulepedro sanchezNo ratings yet

- 320D FAL Especificaciones Hidraulicas PDFDocument6 pages320D FAL Especificaciones Hidraulicas PDFpedro sanchez100% (1)

- Man DG ActuaterDocument4 pagesMan DG ActuaterAdeelNo ratings yet

- Bearing N PDFDocument160 pagesBearing N PDFAnonymous hxQ7PNOQNo ratings yet

- Valvulas BarksdaleDocument4 pagesValvulas Barksdalends2006sNo ratings yet

- Overhead and Underground Distribution Lines: April Rose D. Herrera EE-5ADocument40 pagesOverhead and Underground Distribution Lines: April Rose D. Herrera EE-5AisraeljumboNo ratings yet

- Cleaning Small-Galvo MirrorsDocument9 pagesCleaning Small-Galvo MirrorsGiulia LazzariNo ratings yet

- Cable SizingDocument10 pagesCable SizingAhmed MagdyNo ratings yet

- Indoor Lighting - 380 KV GIS Building - Ground FloorDocument3 pagesIndoor Lighting - 380 KV GIS Building - Ground FloorSomnath DasNo ratings yet

- Control of Synchronous MotorDocument12 pagesControl of Synchronous MotorSaravanan T YNo ratings yet

- Brochure Shellplant LowResDocument126 pagesBrochure Shellplant LowResLina GuerreroNo ratings yet

- Medium Voltage Terminations: Catalogue 2017Document32 pagesMedium Voltage Terminations: Catalogue 2017zaheerNo ratings yet

- Daily Activity Accomplishments and Materials Monitoring Sheet For Fire FightingDocument4 pagesDaily Activity Accomplishments and Materials Monitoring Sheet For Fire Fightingzineddine sofieneNo ratings yet

- MWA300/330A: 3-Phase Ratio and Winding Resistance AnalyzerDocument6 pagesMWA300/330A: 3-Phase Ratio and Winding Resistance AnalyzerJavier CuzcoNo ratings yet

- Exp. 5 - Continuity Test For A Given Electrical Circuit Need For Continuity TestingDocument12 pagesExp. 5 - Continuity Test For A Given Electrical Circuit Need For Continuity Testingrishika chhibberNo ratings yet

- Cold Milling Machine W 1900: Efficient Milling in The 2-m ClassDocument16 pagesCold Milling Machine W 1900: Efficient Milling in The 2-m ClassAly Abdelhamed100% (2)

- 104 en - Multifunction Power Supply, Large - PRA-MPS3Document23 pages104 en - Multifunction Power Supply, Large - PRA-MPS3Wilmer MojicaNo ratings yet

- FIFE Symat 70G PDFDocument25 pagesFIFE Symat 70G PDFmartian18298706100% (1)

- Bizhub 501/421/361: Troubleshooting of C-2403: - ContentsDocument6 pagesBizhub 501/421/361: Troubleshooting of C-2403: - ContentsGabiNo ratings yet

- GT250 Parts CatalogueDocument116 pagesGT250 Parts CatalogueMateu mulet reyesNo ratings yet

- Protection Relay: JD-5 Integrated Protector MotorDocument3 pagesProtection Relay: JD-5 Integrated Protector Motorzaki amNo ratings yet

- CB SF1&SFset PDFDocument52 pagesCB SF1&SFset PDFYudhika CibroNo ratings yet

- SON RM IP10 - UserguideDocument84 pagesSON RM IP10 - UserguideYacoub DOMANo ratings yet

- Sharp Ar-162-163-201-206-207Document71 pagesSharp Ar-162-163-201-206-207rostelsNo ratings yet

- DC DC Converters Output NoiseDocument10 pagesDC DC Converters Output NoiseMallickarjuna AsNo ratings yet

- Type MRTP Supervision For AC Pilot CircuitsDocument8 pagesType MRTP Supervision For AC Pilot CircuitsNguyễn Huy HoàngNo ratings yet

- 701P46713 7142 Service Manual PDFDocument343 pages701P46713 7142 Service Manual PDFCristian BobaruNo ratings yet

- Dk51280-1103a-33t (DP60P5S)Document221 pagesDk51280-1103a-33t (DP60P5S)agus marsito83% (6)

- Cover Interposer Tray CI5010 (B835-57/66)Document37 pagesCover Interposer Tray CI5010 (B835-57/66)Jesus Mack GonzalezNo ratings yet

- Pioneer Cd-Ib100ii Ipod-Adapter SMDocument28 pagesPioneer Cd-Ib100ii Ipod-Adapter SMGiovanniNo ratings yet

- Manual Stiga VILLA 92 MDocument6 pagesManual Stiga VILLA 92 MCzesław WierzchowskiNo ratings yet

- Reccomended Parts List of UD TruckDocument2 pagesReccomended Parts List of UD TruckJamyansuren TseveendorjNo ratings yet