Professional Documents

Culture Documents

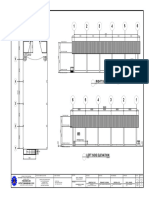

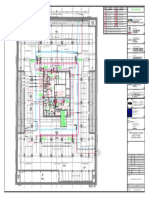

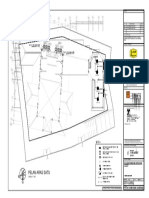

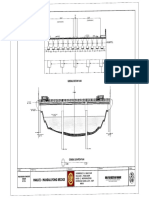

Section 1-1 Section 2-2 Section 3-3: Good For Construction

Section 1-1 Section 2-2 Section 3-3: Good For Construction

Uploaded by

ZaidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 1-1 Section 2-2 Section 3-3: Good For Construction

Section 1-1 Section 2-2 Section 3-3: Good For Construction

Uploaded by

ZaidCopyright:

Available Formats

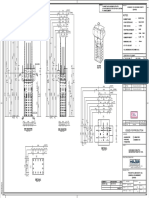

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

CL OF PILE CL OF PILE

EXISTING LEVEL EXISTING LEVEL

(MIN.)

(MIN.)

A PILE CAP PILE CAP A

500

500

PILE CAP REINF. PILE CAP REINF.

TOP OF PILE CAP TOP OF PILE CAP

300

300

(TYP)

(TYP)

16 Ø 1500 c/c 16 Ø 1500 c/c 16 Ø 1500 c/c

B B

2200

2200

PIPE FOR CROSS PIPE FOR CROSS PIPE FOR CROSS

HOLE SONIC HOLE SONIC HOLE SONIC

TEST(AS PER TEST(AS PER TEST(AS PER

TECHNICAL TECHNICAL TECHNICAL

SPECIFICATION) SPECIFICATION) SPECIFICATION)

SECTION 1-1 SECTION 2-2 SECTION 3-3

300

300

75

75

CUT OFF LEVEL OF PILE CUT OFF LEVEL OF PILE

C (FOR PG6) (FOR PG6) (FOR PG6) C

SCALE 1:15 SCALE 1:15 SCALE 1:15

75 75

75 THK. 75 THK.

LEVELLING LEVELLING

COURSE COURSE BOTTOM OF PILE CAP '1'

NO LAPPING ZONE

1 1 1 1

8000

4000

4000

D D

LENGTH

LAP

(LAPPING ZONE)

+ + + + 16 Ø 1500 c/c 16 Ø 1500 c/c 16 Ø 1500 c/c

1.3 X LAP

E E

L1

L1

LENGTH

LAP

PIPE FOR CROSS PIPE FOR CROSS PIPE FOR CROSS

9650

9650

HOLE SONIC HOLE SONIC HOLE SONIC

TEST(AS PER TEST(AS PER TEST(AS PER

TECHNICAL TECHNICAL TECHNICAL

DETAIL OF SHOWING SECTION 1-1 SPECIFICATION)

SECTION 2-2 SPECIFICATION)

SECTION 3-3 SPECIFICATION)

(FOR PG7) (FOR PG7) (FOR PG7)

LAPPING ZONE

4000

4000

SCALE 1:15 SCALE 1:15 SCALE 1:15

SCALE 1:10

F F

LENGTH OF PILE = L

LENGTH OF PILE = L

2 2 2 2

REINFORCEMENT & LENGTH OF PILE NOTES:

SPACER BAR (TYP.) SPACER BAR (TYP.)

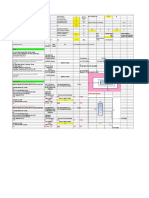

WORKING LOAD 1. ALL DIMENSIONS ARE IN MM.

CURTAILMENT

(NORMAL CONDITION) 2. DO NOT SCALE THE DIMENSIONS. ONLY WRITTEN DIMENSIONS SHALL BE

PILE PIER LENGTH

BAR - 01 BAR - 1a BAR - 02 BAR - 2a BAR - 03 BAR - 04 BAR - 05 FOLLOWED.

GROUP MARKED (L1) VERTICAL HORIZONTAL 3. ANY DISCREPANCIES MUST BE BROUGHT TO THE NOTICE OF THE

IN MM

G (T) (T) CONSULTANT BEFORE EXECUTION OF WORK AT SITE. G

4. GRADE OF CONCRETE

LAP

FOR PILE : M-40

SHAPE OF - - - - FOR LEVELLING COURSE : M-15

BAR

5. MINIMUM CLEAR COVER SHALL BE 75 mm.

6. ROUTINE PILE LOAD TEST WILL BE CARRIED OUT IN ACCORDANCE TO

PG6 C15 & C46 20 Q 20 NOS. - 25 Q 20 NOS. - 8 Q 150 c/c 12 Q 150 c/c 16 Q 150 c/c 8600 627.3 7 PROVISIONS OF IS:2911 (PART-4)-2010 AND CONTRACT AGREEMENT.

7. ALL T.M.T. REINFORCEMENT BARS SHALL CONFORM TO

PG6 C30 & C47 20 Q 20 NOS. 16 Q 20 NOS. 25 Q 20 NOS. 16 Q 20 NOS. 8 Q 150 c/c 12 Q 150 c/c 16 Q 150 c/c 8600 637.9 7.2 IS:1786 GRADE Fe-500D.

8. STIFFENER RINGS AS PER CODAL REQUIREMENT. SHALL BE PROVIDED.

PG7 C45 & C48 25 Q 22 NOS. - 20 Q 22 NOS. - 8 Q 150 c/c 12 Q 150 c/c 16 Q 150 c/c 8600 421.7 5.3 9. CONCRETE IN THE PILE SHALL BE CAST TO FULL DEPTH IN SINGLE POUR.

10. FOR LOCATION OF PILE GROUP REFER DWG NO.

H +

+ DM09-AYE-ST-DDT-GHA-STN-SBX-00101 & 00111. H

11. NOT MORE THAN 50% OF BARS SHALL BE LAPPED AT ANY SECTION. LAP

LENGTH SHALL BE INCREASED BY 25% IF 100% BARS ARE PROPOSED TO BE

LAPPED IN A VERTICAL PILE REINFORCEMENT.

12. ANCHORAGE OF SPIRAL REINFORCEMENT SHALL BE PROVIDED BY 1.5 EXTRA

SCHEDULE OF FOUNDATION TURNS OF THE SPIRAL BAR AT EACH END OF SPIRAL UNITS.

13. TWO BUNDLE BARS SHALL BE TIED TOGETHER TO ENSURE THE BARS

Pile Length (L) REMAINING TOGETHER.

3 3 3 3 Pile Group No

Rail Top Level - Existing Ground Pile Cap Top Level Pile Cap Bottom Pile Cut off Level Pile Termination

Below Cut-off 14. BARS IN BUNDLE SHALL TERMINATE AT DIFFERENT POINTS SPACED APART

Pier No.

RTL (m) Level (m) (m) Level (m) (m) Level (m) BY NOT LESS THAN 40 TIMES THE BARS DIAMETER EXCEPT FOR BUNDLE BAR

Level (m)

STOPPING AT A SUPPORT.

I 15. MINIMUM LAP LENGTH SHALL BE 64Xd WHERE "d" IS THE DIAMETER OF I

PG6 C15 & C46 230.600 205.800 205.300 203.100 203.175 173.675 29.5m SMALLER BAR. THE SPACING OF TRANSVERSE REINFORCEMENT SHALL NOT

BE MORE THAN 150mm AT THE LOCATIONS WHERE BARS ARE LAPPED. LAP

LENGTH SHALL BE INCREASED BY 25% FOR BUNDLE BAR.

1.5 TURN AT THE 1.5 TURN AT THE PG6 C30 & C47 230.600 203.670 203.170 200.970 201.045 171.545 29.5m

16. LAPS SHALL BE SUITABLY STAGGERED AND MINIMUM C/C DISTANCE

END OF SPIRAL END OF SPIRAL

BETWEEN ADJACENT LAPS SHALL BE 1.3 TIME LAP LENGTH.

PG7 C45 & C48 230.600 203.670 203.170 200.970 201.045 171.545 29.5m 17. THE 'L' BENDS IN THE REINFORCEMENTS AT THE BOTTOM OF THE PILES

75

75

SHOULD NOT BE PROVIDED TO AVOID THE FORMATION OF SOFT TOE AS PER

CLAUSE 709.6.2.3 OF IRC 78.

1200 1200

18. LAPPING PORTION OF HOOPS SHALL BE STAGGERED ALONG LENGTH OF

64xd PILE.

(Min)

J PILE REINFORCEMENT PILE REINFORCEMENT 19. EARTHING DETAILS SHALL BE PROVIDED IN PILE AS PER RELEVANT

DRAWINGS.

J

(FOR PILE GROUP PG6) (FOR PILE GROUP PG7)

SCALE 1:25 SCALE 1:25

PILE CO-ORDINATES SHALL BE VERIFIED AT SITE BEFORE EXECUTION

DETAIL - 1

('d' IS THE DIAMETER OF STIRRUPS) GOOD FOR CONSTRUCTION

(SCALE 1:10)

THIS GFC HAS BEEN PREPARED BASED ON REV-D0

K K

CLIENT DETAIL DESIGN CONSULTANT DDC INTER-DISCIPLINE PROOF CONSULTANT GENERAL CONSULTANT : NO OBJECTION BY NCRTC NOTES: SCALE

COORDINATION LKT Engineering Consultants Ltd

1. ALL DIMENSIONS ARE IN MILLIMETERS UNLESS MENTIONED.

2. ALL DIMENSIONS ARE TO BE READ AND NOT MEASURED.

DELHI-MEERUT RRTS AS SHOWN

63/12A, IInd floor, Main Rama 3. ANY DISCREPANCY MUST BE BROUGHT TO THE NOTICE OF THE NCRTC BEFORE

road Industrial area

SIGNATURE EXECUTION OF WORK AT SITE.

LOCATION: GHAZIABAD STATION DATE

D-99, 4th Floor ,Sector 2, Noida - 201301 (U.P) (Opp. Kirti Nagar Metro Station) 4. THIS DRAWING MUST BE READ IN CONJUNCTION WITH ALL RELEVANT

NATIONAL CAPITAL REGION TRANSPORT CORPORATION Najafgargh road,New ARCHITECTURAL, STRUCTURAL, PLUMBING & FIRE FIGHTING, ELECTRICAL AND 25/03/2020

Delhi-110015 AM/DESIGN TRAFFIC MANAGEMENT DRAWINGS.

TITLE: REINFORCEMENT DETAIL OF PILE FOR

(A JV OF GOVERNMENT OF INDIA AND PARTICIPATING STATE GOVERNMENTS) NAME SIGNATURE NAME SIGNATURE REV.

7/6, AMDA BUILDING, SIRI FORT INSTITUTIONAL AREA, AUGUST KRANTI MARG , NEW

CHIEF STRUCTURE

PILE GROUP PG6 AT C15, C30, C46 &

DELHI - 110049 DRAWN A.Kumar NAME SIGNATURE

DESIGN EXPERT DGM/DESIGN C47 AND PG7 AT C45 & C48 G1

L PROJECT DESIGNED M.Zaid CHECKED

SENIOR STRUCTURE

NCRTC DRG NO: STATUS L

CONTRACT DM-09-DDC: ENGAGEMENT OF DETAIL DESIGN CONSULTANT (DDC) FOR DESIGN EXPERT ELEVATED

DETAIL DESIGN AND DRAWINGS OF FOUR NUMBERS OF ELEVATED RRTS STATIONS STRUCTURE DESIGN

ED/DESIGN GFC

(SAHIBABAD, GHAZIABAD, GULDHAR AND DUHAI) IN THE SECTION FROM SAHIBABAD CHECKED R.Sachdeva REVIEWED

ENGINEER G1 ISSUED AS GOOD FOR CONSTRUCTION 25/03/2020 DRG NO: SHEET

RAMP TO EPE CROSSING AND MAINTENANCE DEPOTS AT DUHAI AND MODIPURAM, ASSISTANT STRUCTURE CPM

FOR DELHI-MEERUT REGIONAL RAPID TRANSIT SYSTEM (RRTS) CORRIDOR. APPROVED P. Banerjee APPROVED

DESIGN ENGINEER REV NO DESCRIPTION DATE SIGN DM09-AYE-ST-DDT-GHA-STN-SBX-00106 SH 1 OF 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

You might also like

- Worked Examples For Steel Design To Eurocode 3Document167 pagesWorked Examples For Steel Design To Eurocode 3jim_structural67% (6)

- DWall, Capping Beam and Skin Wall Details-Ss PDFDocument1 pageDWall, Capping Beam and Skin Wall Details-Ss PDFSanjay Boss100% (1)

- Tiny Tweaks James WedmoreDocument31 pagesTiny Tweaks James WedmoreErise Global100% (1)

- Section A-A: Key PlanDocument2 pagesSection A-A: Key PlanGajendra BishtNo ratings yet

- PILE PILE CAP & PIER - 25.10.2023-Comments-28-10-23Document5 pagesPILE PILE CAP & PIER - 25.10.2023-Comments-28-10-23Tanveer IqbalNo ratings yet

- ROAD OVER BRIDGE DWG-Layout1Document1 pageROAD OVER BRIDGE DWG-Layout1Anjali M SNo ratings yet

- Pier RevisedDocument4 pagesPier RevisedMrinal KayalNo ratings yet

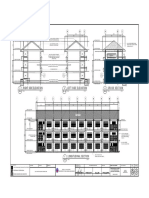

- G+3 StructureDocument1 pageG+3 StructureMANNANo ratings yet

- Gad 2911202301Document1 pageGad 2911202301ecore1990No ratings yet

- Box Drawing (2X6.5X6.5)Document1 pageBox Drawing (2X6.5X6.5)Avinash ManglamNo ratings yet

- 1101 MNB CH 32+340 R2 UpdatedDocument1 page1101 MNB CH 32+340 R2 UpdatedSatyavijet ChilakapatiNo ratings yet

- Detail of C1F1: Foundation PlanDocument1 pageDetail of C1F1: Foundation PlanEury AlzagaNo ratings yet

- Sda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Document1 pageSda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Himani PatelNo ratings yet

- CombinepdfDocument3 pagesCombinepdfNitinNo ratings yet

- Barretto A2Document1 pageBarretto A2adylmaesNo ratings yet

- Sectional Elevation B-B: NOTES (24+000)Document1 pageSectional Elevation B-B: NOTES (24+000)Abhijeet SahuNo ratings yet

- 18.details of MPSDocument1 page18.details of MPSSachin GiriNo ratings yet

- 06 DRG 15 R0Document1 page06 DRG 15 R0Anirudh SabooNo ratings yet

- Sicad - 2007-Septic TankDocument1 pageSicad - 2007-Septic TankLimar SetstraNo ratings yet

- Section Thru A Catwalk Layout: Scale 1:50 - Scale 1:50Document1 pageSection Thru A Catwalk Layout: Scale 1:50 - Scale 1:50Peter John RoblesNo ratings yet

- s2Document3 pagess2Alaa MansourNo ratings yet

- Ground Floor Plan: Schedule of Floor FinishesDocument1 pageGround Floor Plan: Schedule of Floor FinishesMJian VergaraNo ratings yet

- Details of Shallow FoundationDocument1 pageDetails of Shallow FoundationRishikesh AnandNo ratings yet

- To Mudkhed To Bellur: GL.363.749 GL.363.253Document1 pageTo Mudkhed To Bellur: GL.363.749 GL.363.253yedidiNo ratings yet

- Get An: ArchitectDocument1 pageGet An: Architectflor johnNo ratings yet

- Front Elevation Rear Side Elevation: "Proposed Two (2) Storey Extension"Document1 pageFront Elevation Rear Side Elevation: "Proposed Two (2) Storey Extension"Kali BearNo ratings yet

- Right Side Elevation: Proposed StageDocument1 pageRight Side Elevation: Proposed StageMarc Dared CagaoanNo ratings yet

- 3 MLD PTU PUNJAB-ModelDocument1 page3 MLD PTU PUNJAB-ModelMohit ChauhanNo ratings yet

- PL San Isidro IlayaDocument5 pagesPL San Isidro IlayaLorenz Carlo Robedillo GonzalesNo ratings yet

- TOP View: Hadoron Studio INC As Built PlanDocument1 pageTOP View: Hadoron Studio INC As Built PlankitnaNo ratings yet

- Tablero General TG 208V/120V - 3f - 60 Hz. (3F+N+ T) : 1000mm 1000mmDocument1 pageTablero General TG 208V/120V - 3f - 60 Hz. (3F+N+ T) : 1000mm 1000mmDennis FalNo ratings yet

- Ahpl PG LK2 Img 100 PDFDocument1 pageAhpl PG LK2 Img 100 PDFKish Shan S SubediNo ratings yet

- Screenshot 2024-03-14 at 5.40.12 PMDocument1 pageScreenshot 2024-03-14 at 5.40.12 PMalesia.achieveNo ratings yet

- CICPL-D1041-ST-LVUP-GAD-0+590-001Document4 pagesCICPL-D1041-ST-LVUP-GAD-0+590-001CivilBaba D1022No ratings yet

- CCMC BV FTB SHD Mep FP 302a R.00Document1 pageCCMC BV FTB SHD Mep FP 302a R.00Thai ChheanghourtNo ratings yet

- Electrical Layout - L1Document1 pageElectrical Layout - L1sushant moreyNo ratings yet

- Front - & Internal View Panel PLCDocument1 pageFront - & Internal View Panel PLCcharlie charlieNo ratings yet

- Final Sheet-Model - PDF 1Document1 pageFinal Sheet-Model - PDF 1Prateek SharmaNo ratings yet

- Revised Plan-09012023Document1 pageRevised Plan-09012023s1s4nplayNo ratings yet

- Ms Leonidas S1Document1 pageMs Leonidas S1Sancho AcbangNo ratings yet

- South Kuwait: Koc Approvals Contractor RevisionDocument4 pagesSouth Kuwait: Koc Approvals Contractor RevisionEr Md AamirNo ratings yet

- Ac 02 PDFDocument1 pageAc 02 PDFmohd shafis abdul hameedNo ratings yet

- Technical Specification - Mangalore Station PipingDocument21 pagesTechnical Specification - Mangalore Station PipingbecpavanNo ratings yet

- NCRTC DM086 STC LS02 CCT M2 DR 10350 - DDocument1 pageNCRTC DM086 STC LS02 CCT M2 DR 10350 - Dsandesh negiNo ratings yet

- 05.RR Moh Nam Rein Km.2+279 04commentsDocument1 page05.RR Moh Nam Rein Km.2+279 04commentsPraveen CyssanNo ratings yet

- Ramp Plan: Ramp Up Ramp Up Ramp UpDocument1 pageRamp Plan: Ramp Up Ramp Up Ramp Upestabaya12No ratings yet

- RDDocument1 pageRDirenedcomandanteNo ratings yet

- 150KL-12M Nandauri Gaindas Gad2Document1 page150KL-12M Nandauri Gaindas Gad2shailenderNo ratings yet

- Third Floor BlankDocument1 pageThird Floor BlankClyde Jervin MatulacNo ratings yet

- Footing ScheduleDocument1 pageFooting ScheduleChristian Kyle BeltranNo ratings yet

- Building Materials $ Construction Techniques Stuti Sharma B.Arch 3Rd YearDocument1 pageBuilding Materials $ Construction Techniques Stuti Sharma B.Arch 3Rd YearstutiNo ratings yet

- 6Document1 page6shashi rajhansNo ratings yet

- 2Document1 page2shashi rajhansNo ratings yet

- Floorplan WarehouseDocument1 pageFloorplan Warehousekent diamanteNo ratings yet

- Makati - Mandaluyong Bridge: General Section PlanDocument1 pageMakati - Mandaluyong Bridge: General Section PlangregNo ratings yet

- 德福豚丼去水圖Document1 page德福豚丼去水圖Wong Ting FungNo ratings yet

- NBS125 1Document1 pageNBS125 1April DariaNo ratings yet

- Right Side Elevation Left Side Elevation Cross Section: C B A C B A C B ADocument1 pageRight Side Elevation Left Side Elevation Cross Section: C B A C B A C B AMalson GutierrezNo ratings yet

- Front Elevation Right Side Elevation: E F D C B A 8 7 6 5 4 3 2 1Document1 pageFront Elevation Right Side Elevation: E F D C B A 8 7 6 5 4 3 2 1kuya prexNo ratings yet

- RC Link Slab at Piers For PSC Plank DecksDocument1 pageRC Link Slab at Piers For PSC Plank DecksJirachai LaohaNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- NCRTC DM009 AYE GHAZ STN M3 CV 00031 - RpandeyDocument1 pageNCRTC DM009 AYE GHAZ STN M3 CV 00031 - RpandeyZaidNo ratings yet

- Isolated Footing With Actual SurchargeDocument1 pageIsolated Footing With Actual SurchargeZaidNo ratings yet

- DM09 Aye ST DMM Sah STN SBX 10121 - D2 PDFDocument172 pagesDM09 Aye ST DMM Sah STN SBX 10121 - D2 PDFZaidNo ratings yet

- Uprabhat AS Profile Summary: ORE Ompetencies and ChievementsDocument2 pagesUprabhat AS Profile Summary: ORE Ompetencies and ChievementsZaidNo ratings yet

- "Rail and Metro: Perspectives and Challenges": S&S Invites You ToDocument2 pages"Rail and Metro: Perspectives and Challenges": S&S Invites You ToZaidNo ratings yet

- Pot & Pot Cum Ptfe Bearing To Irc: 83 - 2002 (Part - Iii) : A Product From Kantaflex (India) PVT LimitedDocument2 pagesPot & Pot Cum Ptfe Bearing To Irc: 83 - 2002 (Part - Iii) : A Product From Kantaflex (India) PVT LimitedZaidNo ratings yet

- Position Details: Areas of Accountabilities (List Up To 10 Prime Activities) % of Time SpentDocument3 pagesPosition Details: Areas of Accountabilities (List Up To 10 Prime Activities) % of Time SpentZaidNo ratings yet

- Laurel Doll Amigurumi Free PatternDocument21 pagesLaurel Doll Amigurumi Free PatternHuyền TrangNo ratings yet

- (Shuangzhu Jia Et Al 2020) Study On The Preparing and Mechanism of Chitosan-Based Nanomesoporous Carbons by Hydrothermal MethodDocument21 pages(Shuangzhu Jia Et Al 2020) Study On The Preparing and Mechanism of Chitosan-Based Nanomesoporous Carbons by Hydrothermal MethodSilvia Devi Eka PutriNo ratings yet

- Alcantara - Module 10 - 2ged SS-03Document2 pagesAlcantara - Module 10 - 2ged SS-03Janine AlcantaraNo ratings yet

- YCT Heat Transfer NEET JEE Questions PracticeDocument81 pagesYCT Heat Transfer NEET JEE Questions Practicedrsantanuchakraborty91No ratings yet

- Ericka Joyce O. Reynera: PERSONAL - INFORMATIONDocument2 pagesEricka Joyce O. Reynera: PERSONAL - INFORMATIONdead insideNo ratings yet

- Agile TestingDocument5 pagesAgile TestingAman YadavNo ratings yet

- UpsDocument31 pagesUpsThuyaNo ratings yet

- World's No.1 LCD/LED Solution Designer World's Leading Interactive & Collaboration Solution BrandDocument3 pagesWorld's No.1 LCD/LED Solution Designer World's Leading Interactive & Collaboration Solution BrandINTELL WAVESNo ratings yet

- Sample QuestionDocument2 pagesSample QuestionSiddartha CHNo ratings yet

- 2018 Weekly CalendarDocument3 pages2018 Weekly CalendarFabian FebianoNo ratings yet

- Ai PresentationDocument13 pagesAi Presentationapi-534191655No ratings yet

- Georgina Smith - Resume 1Document3 pagesGeorgina Smith - Resume 1api-559062488No ratings yet

- Bullz Audio Catalog 2013Document20 pagesBullz Audio Catalog 2013Jhonne TJ (TJ)No ratings yet

- Whittaker Dynamics 17Document442 pagesWhittaker Dynamics 17Mahmoud Ahmed 202201238No ratings yet

- 4final Examination Prof Ed 10Document7 pages4final Examination Prof Ed 10Danelle EsparteroNo ratings yet

- Electrical Circuit Lab ManualDocument38 pagesElectrical Circuit Lab Manualecessec67% (3)

- Statement of PurposeDocument3 pagesStatement of PurposeehsanNo ratings yet

- Mapeh GR9 First Quarter ReviewerDocument8 pagesMapeh GR9 First Quarter ReviewerRalph Emerson SantillanNo ratings yet

- VIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFDocument83 pagesVIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFOsamaAliMoussaNo ratings yet

- Alere G1 Glucose Meter ManualDocument55 pagesAlere G1 Glucose Meter ManualSundar Rajan33% (6)

- Springer Nature Latex TemplateDocument13 pagesSpringer Nature Latex TemplateAndres FloresNo ratings yet

- EDU CAT EN DF1 FI V5R19 Toprint PDFDocument14 pagesEDU CAT EN DF1 FI V5R19 Toprint PDF3pherNo ratings yet

- SkillsDocument7 pagesSkillsRufus RajNo ratings yet

- Organic Halides Introduction Class-1 NotesDocument15 pagesOrganic Halides Introduction Class-1 Notessiddhartha singhNo ratings yet

- Microsoft Project TOCDocument5 pagesMicrosoft Project TOCali_zulfikarNo ratings yet

- Arthur Wolk v. Olson, 10-3352, Opposition To Motion To CertifyDocument56 pagesArthur Wolk v. Olson, 10-3352, Opposition To Motion To CertifyTed FrankNo ratings yet

- Policy Copy 3005 314095178 00 000Document3 pagesPolicy Copy 3005 314095178 00 000alagardharshan2No ratings yet

- Safety Manual (B-80687EN 10)Document35 pagesSafety Manual (B-80687EN 10)Jander Luiz TomaziNo ratings yet

- Comparative Investment ReportDocument8 pagesComparative Investment ReportNelby Actub MacalaguingNo ratings yet