Professional Documents

Culture Documents

Sysmex CA-1500 PDF

Sysmex CA-1500 PDF

Uploaded by

Nasr Eldin AlyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sysmex CA-1500 PDF

Sysmex CA-1500 PDF

Uploaded by

Nasr Eldin AlyCopyright:

Available Formats

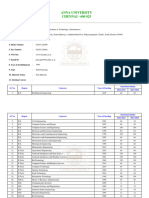

Sysmex® CA-1500 System

Instrument Specifications

Effective: November 2001

Instrument Weight and Dimensions

Weight

780 mm (31 in.)

84.5 kg (186 lb) without cap piercer

1000 mm (40 in.) 87.5 kg (193 lb) with cap piercer

with lid open

500 mm (20 in.) Dimensions

780 mm wide x 500 mm high x

780 mm deep

500 mm (20 in.) (31 in. w x 20 in. h x 31 in. d)

Additional Instrument

Clearances (Minimum)

• 360° access is needed for service.

Provide at least 500 mm (20 in.) access

280 mm (11 in.) to side, rear and top panels.

• Analyzer and sampler unit must be

supported by a continuous solid

surface.

• The receptacle must be accessible to

the 1.8 m (6 ft.) power cord furnished

with the instrument.

Room Environment

Operating Temperature

Room temperature must be 15°C–30°C

(59°F–86°F). Optimum temperature is

23°C (73°F).

Relative Humidity

Between 30% and 85%

Average Thermal Output

2457 BTU/hr (720 W)

Water Requirements Electrical Installation Requirements Host Interfacing

Options Available Power Requirements Connection

• 20 L Cubitainer of reagent grade water Line Voltage A 9-pin D-SUB female connector is

without preservatives using float required for hookup to the male

switch #14. These voltages may be used: connector used for host communications

117 V ac ± 10% port.

• 20 L refillable container of deionized

220 V ac ± 10%

or distilled water using float switch

240 V ac ± 10%

#17 Signal Level

Frequency Conforms to JIS C6361.

Data Control

Waste Requirements 50 or 60 Hz. Level Signal Signal

+3V or higher Logic 0, ON

Options Available Start Bit

Power Consumption

• 20 L container with Float SW #19 -3V or lower Logic 1, OFF

The system uses 720 VA or less, including

• Floor drain using Wiring Cord #2188 to Stop Bit

main unit, sampler, optional ID barcode

bypass the float switch monitoring reader, and excluding optional printers.

circuit

Installation

• Cubitainer for boxed waste using float Classification

switch #20 The Sysmex® CA-1500 system will be

• Type of protection against electrical installed by a qualified Dade Behring Inc.

Liquid Waste Output shock: Class I Equipment representative. The installation will

Tubing is supplied for external waste • Degree of protection against electrical include checkout of all aspects necessary

disposal. Maintenance of the waste shock: Type B Equipment to ensure the equipment is fully

tubing from the instrument to the operational.

disposal point is the responsibility of the WARNING: Be sure to ground the system.

user. The disposal point should be Inadequate grounding could cause electrical

selected in accordance with local shocks.

hazardous waste guidelines.

Receptacle

Customer must provide an appropriate

receptacle, installed by a qualified

electrician before arrival of the

instrument.

Complies with the requirements of

ETL UL STD 3101-1 and CSA C22.2

No. 1010.1-92 safety standards for

nonpatient-vicinity laboratory

equipment.

For additional information or to reach a Dade Behring

representative, please call 1-800-242-3233 DADE BEHRING INC.

Hemostasis Group

© Dade Behring Inc.

1717 Deerfield Rd.

TB 01-004 11/01 Deerfield, IL 60015-0778

You might also like

- Electronics For Electricians 7th Edition Herman Solutions ManualDocument13 pagesElectronics For Electricians 7th Edition Herman Solutions Manuallaurenstarkntmkfdjrqz100% (13)

- Service Manual BB15 PDFDocument117 pagesService Manual BB15 PDFNasr Eldin Aly100% (1)

- Manual de Instalacion Osko XR5 - Rayos X Convencional Analogico Data SheetDocument6 pagesManual de Instalacion Osko XR5 - Rayos X Convencional Analogico Data SheetLeandro Pabon Villarreal100% (1)

- CO2 Tester PDFDocument20 pagesCO2 Tester PDFNasr Eldin AlyNo ratings yet

- CO2 Tester PDFDocument20 pagesCO2 Tester PDFNasr Eldin AlyNo ratings yet

- Service Manual BB & BBK 6000 Serie PDFDocument240 pagesService Manual BB & BBK 6000 Serie PDFNasr Eldin AlyNo ratings yet

- Service Manual BB & BBK 6000 Serie PDFDocument240 pagesService Manual BB & BBK 6000 Serie PDFNasr Eldin AlyNo ratings yet

- Acorn TD82 UsermanualDocument32 pagesAcorn TD82 UsermanualJesusvs5850% (2)

- Msa Breathing Apparatus ManualDocument60 pagesMsa Breathing Apparatus ManualerssNo ratings yet

- Quick Reference: Turn OrderDocument5 pagesQuick Reference: Turn OrderDani Havn100% (1)

- The Art of Immersion PDFDocument199 pagesThe Art of Immersion PDFHayri Yildirim100% (4)

- CSEC Information Technology Syllabus With Specimen Papers 2020 PDFDocument126 pagesCSEC Information Technology Syllabus With Specimen Papers 2020 PDFyson lagrimasNo ratings yet

- Autolube System (HYD) OverviewDocument21 pagesAutolube System (HYD) OverviewDaniel Alfonso Diaz FloresNo ratings yet

- Service Manual: Torinitron Color Graphic DisplayDocument87 pagesService Manual: Torinitron Color Graphic DisplayHristo IvanovNo ratings yet

- Abb Kent Taylor 504-505-506 TDocument6 pagesAbb Kent Taylor 504-505-506 TJulio RodriguezNo ratings yet

- Netsure 2100 SeriesDocument2 pagesNetsure 2100 SeriesTalha NasrNo ratings yet

- SEN-DS-02246-En - Impeller Series 220BR Insertion Style Flow Sensor Product Data Sheet-1Document2 pagesSEN-DS-02246-En - Impeller Series 220BR Insertion Style Flow Sensor Product Data Sheet-1Ricardo CampbellNo ratings yet

- ChlorideEDP90 Data Sheet IGBTDocument2 pagesChlorideEDP90 Data Sheet IGBTDeiaa sowwanNo ratings yet

- Soliswitch FTE30: Technical InformationDocument8 pagesSoliswitch FTE30: Technical InformationStanley PolancoNo ratings yet

- Huawei BPM36K1 Modulo BaipassDocument6 pagesHuawei BPM36K1 Modulo Baipassrodrigo viverosNo ratings yet

- Ultron NT 20 To 4000kVA - DatasheetDocument2 pagesUltron NT 20 To 4000kVA - DatasheetAnil RajputNo ratings yet

- Straight Gate DatasheetDocument2 pagesStraight Gate DatasheetDavid BaylissNo ratings yet

- Signet 2551 Magmeter Flow Sensor: FeaturesDocument6 pagesSignet 2551 Magmeter Flow Sensor: FeaturesLuis Breña DiazNo ratings yet

- 7500cs 7500cx ICPMS Site Preparation ChecklistDocument6 pages7500cs 7500cx ICPMS Site Preparation ChecklistdriveNo ratings yet

- KM 23 Revise1Document4 pagesKM 23 Revise1umar muttaqinNo ratings yet

- Schneider Electric Xantrex Grid Tie Solar Inverter SeriesDocument2 pagesSchneider Electric Xantrex Grid Tie Solar Inverter SeriesPavel LaurinecNo ratings yet

- GF Signet Mag Flow Meter Insertion TypeDocument6 pagesGF Signet Mag Flow Meter Insertion TypeImran Ahmed KhanNo ratings yet

- 48-135.10 Digital E3 Modulevel Liquid Level Displacer TransmitterDocument12 pages48-135.10 Digital E3 Modulevel Liquid Level Displacer TransmitterArif DarmawanNo ratings yet

- Ec Rtu L: Controlsô L M v3.3 Certified Roof Top Unit ControllerDocument4 pagesEc Rtu L: Controlsô L M v3.3 Certified Roof Top Unit ControllerErdinc KlimaNo ratings yet

- RTS DC Servo DriveDocument4 pagesRTS DC Servo DriveJunaid YNo ratings yet

- LEA ProtectPlus S300 ENDocument2 pagesLEA ProtectPlus S300 ENRichard RoperNo ratings yet

- Intelidrive Lite DatasheetDocument4 pagesIntelidrive Lite DatasheetArnoud NegraoNo ratings yet

- Bitronics Distribution Grid Monitor Datasheet 061223 1686593474Document2 pagesBitronics Distribution Grid Monitor Datasheet 061223 1686593474Franco FelipeNo ratings yet

- 118 ITM Product Brochure (2010)Document4 pages118 ITM Product Brochure (2010)denny yusufNo ratings yet

- Ge Critical Power Ep Ups DatasheetDocument2 pagesGe Critical Power Ep Ups DatasheetLong LeoNo ratings yet

- 3VA11163ED320AA0 Datasheet enDocument7 pages3VA11163ED320AA0 Datasheet enSreegith ChelattNo ratings yet

- Digital Multimeters: High Performance 5 1/2 To 3 1/2 Digit Bench DMMDocument2 pagesDigital Multimeters: High Performance 5 1/2 To 3 1/2 Digit Bench DMMhaha2012No ratings yet

- Liebert-Gxt-Mt+ Datasheet-1kva-To-3kvaDocument2 pagesLiebert-Gxt-Mt+ Datasheet-1kva-To-3kvaJl EscalanteNo ratings yet

- P - DS - nrg600BT10 & nrg600BT20S - 052118 - v5Document4 pagesP - DS - nrg600BT10 & nrg600BT20S - 052118 - v5m3y54mNo ratings yet

- 1762sc IF8u DatasheetDocument2 pages1762sc IF8u Datasheetambresh.09No ratings yet

- 970-0059-01-01 Rev A - DR Series 50 HZ Data SheetDocument2 pages970-0059-01-01 Rev A - DR Series 50 HZ Data Sheetourbina_eigNo ratings yet

- Sonda - TCP0030A Marca - TektronixDocument4 pagesSonda - TCP0030A Marca - Tektronixpalaciosfulgencio3No ratings yet

- Conext Core XC-NA Spec SheetDocument2 pagesConext Core XC-NA Spec Sheetbianca7sallesNo ratings yet

- InteliLite AMF25 1 2 1 DatasheetDocument4 pagesInteliLite AMF25 1 2 1 DatasheetStanley Florencio100% (1)

- 3VA11806EF320AA0 Datasheet enDocument8 pages3VA11806EF320AA0 Datasheet enbethonetNo ratings yet

- Power Controllers E-SAFEDocument2 pagesPower Controllers E-SAFEEliasNo ratings yet

- K8ab-Ph Ca csm1996 PDFDocument8 pagesK8ab-Ph Ca csm1996 PDFnl vinay kumarNo ratings yet

- InteliGen GSC C Datasheet v3Document4 pagesInteliGen GSC C Datasheet v3CalebNo ratings yet

- 5A IntegratorDocument5 pages5A IntegratorWilsonNo ratings yet

- InteliLite - MRS16 1 2 1 DatasheetDocument4 pagesInteliLite - MRS16 1 2 1 DatasheetJuuOchanteNo ratings yet

- InteliLite AMF25 1.1 DatasheetDocument4 pagesInteliLite AMF25 1.1 DatasheetMohamed ElgounaNo ratings yet

- Bobina RogowskiDocument3 pagesBobina RogowskiEmerson Müller Juarez AvilaNo ratings yet

- Anatel 600Document2 pagesAnatel 600Kamal ChokshiNo ratings yet

- RECT, Modul SM2000,48V/40A, AEGDocument7 pagesRECT, Modul SM2000,48V/40A, AEGjksiswanto100% (2)

- SYN 50-XH-1 Datasheet EN 202305Document2 pagesSYN 50-XH-1 Datasheet EN 202305Radu TeodorescuNo ratings yet

- Stand Alone Merging Unit (SAMU) : General Features InterfacesDocument2 pagesStand Alone Merging Unit (SAMU) : General Features InterfacesRafael GuzmanNo ratings yet

- 3RT50451AP00 Datasheet enDocument4 pages3RT50451AP00 Datasheet enAtiqah Putri SariNo ratings yet

- Option "AVS" - Automatic IRROMETER: Automation and Output OptionsDocument2 pagesOption "AVS" - Automatic IRROMETER: Automation and Output OptionsYooSeop JangNo ratings yet

- Pvi 23Tl & Pvi 28Tl: 3-Ph Transformerless Commercial String InvertersDocument2 pagesPvi 23Tl & Pvi 28Tl: 3-Ph Transformerless Commercial String InvertersBaggi NNo ratings yet

- 3VA10962ED320AA0 Datasheet enDocument8 pages3VA10962ED320AA0 Datasheet enSher Bahadur VermaNo ratings yet

- I4eti UPSDocument4 pagesI4eti UPSRavi prasad GurugubelliNo ratings yet

- 3VA21105MN360AA0 Datasheet enDocument6 pages3VA21105MN360AA0 Datasheet enAlif MustaqimNo ratings yet

- Champ T400: The World Class Inverter Based DC WelderDocument2 pagesChamp T400: The World Class Inverter Based DC WelderNaresh ANo ratings yet

- ALtivar BroshureDocument7 pagesALtivar BroshureMiguell UgNo ratings yet

- 3KC84480FA220GA3 Datasheet enDocument6 pages3KC84480FA220GA3 Datasheet enRama CFHNo ratings yet

- 3.sensor de CaudalDocument4 pages3.sensor de CaudalGONZALO ROJASNo ratings yet

- Phase-Sequence Phase-Loss Relay: K8AB-PH1-LDocument8 pagesPhase-Sequence Phase-Loss Relay: K8AB-PH1-LLượng TrầnNo ratings yet

- Twido TWDLCAE40DRFDocument11 pagesTwido TWDLCAE40DRFErika BecerraNo ratings yet

- 3VA11166EF320AA0 Datasheet enDocument6 pages3VA11166EF320AA0 Datasheet enDiego Maza VargasNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Cal LCDocument1 pageCal LCNasr Eldin AlyNo ratings yet

- Precision: We Can You CanDocument16 pagesPrecision: We Can You CanNasr Eldin AlyNo ratings yet

- Datasheet, D4E225BC0102Document11 pagesDatasheet, D4E225BC0102Nasr Eldin AlyNo ratings yet

- Konica - Bizhub C266Document110 pagesKonica - Bizhub C266Nasr Eldin AlyNo ratings yet

- O-Light CuringDocument16 pagesO-Light CuringNasr Eldin AlyNo ratings yet

- Axelmed Presents Paradigma: Product HighlightsDocument2 pagesAxelmed Presents Paradigma: Product HighlightsNasr Eldin AlyNo ratings yet

- Ice Cold and Efficient: A New Generation of Surgical LightsDocument12 pagesIce Cold and Efficient: A New Generation of Surgical LightsNasr Eldin AlyNo ratings yet

- High Performance Mobile Surgical C-Arm: H.F. Generator & Rotating Anode Tube With Digital WorkstationDocument5 pagesHigh Performance Mobile Surgical C-Arm: H.F. Generator & Rotating Anode Tube With Digital WorkstationNasr Eldin Aly100% (1)

- Rohs Integration Report: East Notice CertificationDocument8 pagesRohs Integration Report: East Notice CertificationNasr Eldin AlyNo ratings yet

- Item Description Type No. OP-Chair, Balance Plus W/ Brake: Terms & ConditionsDocument1 pageItem Description Type No. OP-Chair, Balance Plus W/ Brake: Terms & ConditionsNasr Eldin AlyNo ratings yet

- Infant Warmers - Dec.2017Document2 pagesInfant Warmers - Dec.2017Nasr Eldin AlyNo ratings yet

- Item P/N Ref - Image Unit Price ($) Moq Description: Shenzhen Medke Technology Co., LTDDocument3 pagesItem P/N Ref - Image Unit Price ($) Moq Description: Shenzhen Medke Technology Co., LTDNasr Eldin AlyNo ratings yet

- Asus 1201N Free Laptop SchematicDocument54 pagesAsus 1201N Free Laptop SchematicNasr Eldin Aly100% (1)

- Sechrist: Technical Bulletin Safety DeviceDocument2 pagesSechrist: Technical Bulletin Safety DeviceNasr Eldin AlyNo ratings yet

- Cytoperm & BBD 6220 PDFDocument285 pagesCytoperm & BBD 6220 PDFNasr Eldin AlyNo ratings yet

- Cytoperm & BBD 6220 PDFDocument285 pagesCytoperm & BBD 6220 PDFNasr Eldin AlyNo ratings yet

- Walkaway Plus System Technical Specifications and RequirementsDocument2 pagesWalkaway Plus System Technical Specifications and RequirementsNasr Eldin AlyNo ratings yet

- AMSCO® LD202 In-Ceiling Lighting SystemDocument3 pagesAMSCO® LD202 In-Ceiling Lighting SystemNasr Eldin AlyNo ratings yet

- Matrx Fraser mdm65917Document2 pagesMatrx Fraser mdm65917Nasr Eldin AlyNo ratings yet

- MedGyn ColposcopeDocument70 pagesMedGyn ColposcopeNasr Eldin AlyNo ratings yet

- VersaCare SiderailPcb PDFDocument2 pagesVersaCare SiderailPcb PDFNasr Eldin AlyNo ratings yet

- MedGyn ProductsDocument60 pagesMedGyn ProductsNasr Eldin AlyNo ratings yet

- Porter and Matrx 2013 Catalog PDFDocument48 pagesPorter and Matrx 2013 Catalog PDFNasr Eldin AlyNo ratings yet

- ONEGY CatalogDocument22 pagesONEGY CatalogIsmail BartonNo ratings yet

- 1-Multi Criteria Supplier Selection PDFDocument13 pages1-Multi Criteria Supplier Selection PDFKavitha Reddy GurrralaNo ratings yet

- Information Analyzer Data Quality Rules Implementations Standard Practices - 01052012Document94 pagesInformation Analyzer Data Quality Rules Implementations Standard Practices - 01052012abreddy2003No ratings yet

- Cooling and Dehumidification - High Latent Load ApplicationDocument4 pagesCooling and Dehumidification - High Latent Load ApplicationNidas SameeraNo ratings yet

- BEMEM103Document4 pagesBEMEM103Keerti HulakantanavarNo ratings yet

- Cae Sample Test 4 KeyDocument1 pageCae Sample Test 4 KeyAnaNo ratings yet

- Aero FlexDocument32 pagesAero Flexdharamvirpmp100% (1)

- HT2524 Satellite Router: Technical SpecificationsDocument1 pageHT2524 Satellite Router: Technical SpecificationsAFF NO LIMITNo ratings yet

- Strongly Typed Views in ASPDocument4 pagesStrongly Typed Views in ASPsaipkNo ratings yet

- Week #6: Laplace Transforms - IntroductionDocument31 pagesWeek #6: Laplace Transforms - IntroductionAbasi IbrahimNo ratings yet

- Cerrtificacion Ul Mech - Codos y OtrosDocument4 pagesCerrtificacion Ul Mech - Codos y OtrosJavier BautistaNo ratings yet

- 20.10.20 Line CodingDocument27 pages20.10.20 Line CodingDivyanshi SharmaNo ratings yet

- WEEK 007 008 MODULE Selecting and Cutting Out Part of An ImageDocument3 pagesWEEK 007 008 MODULE Selecting and Cutting Out Part of An ImagedsdsdNo ratings yet

- Virtualisation in Cloud ComputingDocument21 pagesVirtualisation in Cloud ComputingMegha Mishra100% (2)

- Bannari Amman Institute of TechnologyDocument146 pagesBannari Amman Institute of Technologydurai kathirNo ratings yet

- B 9781509963379Document379 pagesB 9781509963379enazifiNo ratings yet

- Chapter 3 Exercises - ABC SystemDocument2 pagesChapter 3 Exercises - ABC SystemMandy KhouryNo ratings yet

- Modicon Momentum - 172JNN21032Document2 pagesModicon Momentum - 172JNN21032Larry PLCHNo ratings yet

- Noxon ClipsDocument12 pagesNoxon ClipsZoran DanilovNo ratings yet

- DayZ Server Starting KitDocument6 pagesDayZ Server Starting KitWachirarat Ton ChomchomeNo ratings yet

- XT1710-Moto Z2 Play AMPs - Repair Center Troubleshooting GuideDocument48 pagesXT1710-Moto Z2 Play AMPs - Repair Center Troubleshooting Guidekarenchristinasantos87No ratings yet

- Contoh Soal Perpindahan Panas TransienDocument3 pagesContoh Soal Perpindahan Panas TransienprosedurNo ratings yet

- Buildings 12 00838 v2Document21 pagesBuildings 12 00838 v2Mia S. RetomeNo ratings yet