Professional Documents

Culture Documents

Membrane Performance Factors: Temperature Correction

Membrane Performance Factors: Temperature Correction

Uploaded by

Waqas ButtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Membrane Performance Factors: Temperature Correction

Membrane Performance Factors: Temperature Correction

Uploaded by

Waqas ButtCopyright:

Available Formats

Membrane Performance Factors

Temperature Correction

Temperature of the feed water and the net driving pressure across the element must be taken into account

before comparing or evaluating the performance of a membrane element or a reverse osmosis system.

Temperature Correction Factor

The water temperature is one of the key factors in the performance of the reverse osmosis membrane element.

The higher the temperature, the more the product flow, and vice versa.

All reverse osmosis membrane elements and systems are rated at 77º Fahrenheit (25º Celsius).

To find the membrane permeate rate at a different temperature, follow these steps:

Find the temperature correction factor (TCF) from the below table. Divide the rated permeate flow at 77º

Fahrenheit by the temperature correction factor. The result is the permeate flow at the desired temperature.

Rated Permeate Flow ÷ TCF = Temperature Correct Flow

Example

QUESTION: For a thin-film membrane permeate rated at 1800 gallons per day at 77º Fahrenheit, what is the

actual permeate rate at 59º Fahrenheit?

ANSWER: Temperature correction factor (from below table) for 59ºF = 1.422

Permeate flow at 59 degrees Fahrenheit = 1800 ÷ 1.422 = 1266 gallons/day

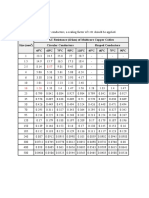

Feed Water Temperature TCF for Feed Water Temperature TCF for

ºC ºF Thin Film ºC ºF Thin Film

10.0 50 1.711 20 68 1.189

10.5 50.9 1.679 20.5 68.9 1.168

11.0 51.8 1.648 21.0 69.8 1.148

11.5 52.7 1.618 21.5 70.7 1.128

12.0 53.6 1.588 22.0 71.6 1.109

12.5 54.5 1.558 22.5 72.5 1.090

13.0 55.4 1.530 23.0 73.4 1.071

13.5 56.3 1.502 23.5 74.3 1.053

14.0 57.2 1.475 24.0 75.2 1.035

14.5 58.1 1.448 24.5 76.1 1.017

15.0 59 1.422 25.0 77 1.000

15.5 59.9 1.396 25.5 77.9 0.985

16.0 60.8 1.371 26.0 78.8 0.971

16.5 61.7 1.347 26.5 79.7 0.957

17.0 62.6 1.323 27.0 80.6 0.943

17.5 63.5 1.299 27.5 81.5 0.929

18.0 64.4 1.276 28.0 82.4 0.915

18.5 65.3 1.254 28.5 83.3 0.902

19.0 66.2 1.232 29.0 84.2 0.889

19.5 67.1 1.210 29.5 85.1 0.877

Visit us on the web for our complete product line and in-depth technical information. www.appliedmembranes.com

(760) 727-3711• FX: (760) 727-4427

sales@appliedmembranes.com

ARE TRADEMARKS OF APPLIED MEMBRANES, INC. © 2012

Membrane Performance Factors

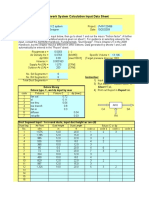

Net Pressure Correction

Net Pressure Correction

The higher the net pressure on a membrane element, the higher the permeate rate. A rough value of osmotic

pressure of water can be calculated roughly by the following rule:

Osmotic pressure (PSI) = Total Dissolved Solids ÷ 100

To estimate the effect of net pressure, follow these steps:

1. Calculate the net pressure under operating conditions (Pop)

Pop = Average applied pressure - Average osmotic pressure of the feed water

2. Calculate the net pressure at which the membrane element is rated (Pr)

Pr = Rated pressure - Osmotic pressure of test solution

3. Expected permeate flow at operating conditions = Rated permeate flow × Pop / (Pr)

Example

QUESTION:

For a thin-film 4 × 40” membrane element, using a 2000 ppm, sodium chloride solution at 225 psi and 77 degrees

Fahrenheit, the permeate rate is 1800 gallons/day. What is the permeate rate at 150 psi, feed water with 1000

TDS and temperature of 59 degrees Fahrenheit?

ANSWER:

Follow the below steps to come to your answer:

1. Temperature correction: Using the Temperature correction factor for 59°F (1.422) from the table:

1800 gpd Rated Flow ÷ 1.422 = 1266 gpd

2. Osmotic Pressure: TDS of 1,000 ÷ 100 = 10 psi

3. Applied Net Pressure: 150 psi feed pressure – 10 psi osmotic pressure = 140 net pressure (Pop)

4. Rated net Pressure:

a. Osmotic pressure of the membrane pressure is 2000 ÷ 100 = 20

b. 225 psi feed pressure – 20 psi osmotic pressure = 205 psi rated net pressure (Pr)

Using the numbers found in the 4 steps above, our calculation [Rated permeate flow × Pop / (Pr)] will be:

1266 × 140 ÷ 205 = 865 gpd

Note:

When designing a system additional detailed calculations are necessary to take into account the effect of pressure drop

and variation in total dissolved solids (TDS) throughout the system. Please contact us if you require further information.

Visit us on the web for our complete product line and in-depth technical information. www.appliedmembranes.com

(760) 727-3711• FX: (760) 727-4427

sales@appliedmembranes.com

ARE TRADEMARKS OF APPLIED MEMBRANES, INC. © 2012

You might also like

- Learner Guide: Cambridge O Level Biology 5090Document45 pagesLearner Guide: Cambridge O Level Biology 5090Dawood100% (1)

- Activity 1 - Biochemical ProcessesDocument4 pagesActivity 1 - Biochemical ProcessesMy Roses Are RosèNo ratings yet

- Jubail HDPE Pipes CatalogueDocument4 pagesJubail HDPE Pipes Catalogueمحمود أبو الحسن67% (3)

- Cyanide Remediation: Current and Past TechnologiesDocument26 pagesCyanide Remediation: Current and Past TechnologiesCoraKiriNo ratings yet

- Elga Centra - R60-R120Document16 pagesElga Centra - R60-R120farouk beNo ratings yet

- Grade 8 Science: Manitoba Education and Training 2000Document50 pagesGrade 8 Science: Manitoba Education and Training 2000Henry LanguisanNo ratings yet

- Joan Fong Et Al. (2013) LSS Practical Book - B - Teacher EditionDocument118 pagesJoan Fong Et Al. (2013) LSS Practical Book - B - Teacher EditionJoe75% (4)

- Ac Resistance and Reactance 50 HZDocument6 pagesAc Resistance and Reactance 50 HZJoseph B Delos ReyesNo ratings yet

- Shear Box Test ReportDocument6 pagesShear Box Test Reportnishan_ravin50% (2)

- Data Sheet: Equipment Wire Equipment Wire Equipment Wire Equipment WireDocument3 pagesData Sheet: Equipment Wire Equipment Wire Equipment Wire Equipment Wireamro emadNo ratings yet

- Ac Resistances: Table 3.26 Multi Conductor Cables - AC Resistances (M /M)Document1 pageAc Resistances: Table 3.26 Multi Conductor Cables - AC Resistances (M /M)subramanyaNo ratings yet

- 2021 Dwyer Catalog - Rev.8 PDFDocument500 pages2021 Dwyer Catalog - Rev.8 PDF12345laurNo ratings yet

- Miracle Uninyvin CablesDocument4 pagesMiracle Uninyvin CablesDharmesh ChanawalaNo ratings yet

- Viscosity-Tables Substances WaterDocument3 pagesViscosity-Tables Substances WaterHarshal JadhavNo ratings yet

- Uninyvin: Certified CompanyDocument4 pagesUninyvin: Certified CompanyDEEPAKNo ratings yet

- DCP WIDENING - CobaDocument456 pagesDCP WIDENING - CobaArtoNo ratings yet

- KEI Productcatalogue - RemovePdfPagesDocument7 pagesKEI Productcatalogue - RemovePdfPagesammu pallaviNo ratings yet

- Dow 01601396545Document1 pageDow 01601396545jose luisNo ratings yet

- Ceramic Capacitor 3 - Digit CodesDocument1 pageCeramic Capacitor 3 - Digit CodesChris HussNo ratings yet

- Capacitor Codes TechStudyCellDocument1 pageCapacitor Codes TechStudyCellMuleNo ratings yet

- Fea AssignmentDocument6 pagesFea AssignmentRoshane Nanayakkara0% (1)

- Heat Coil CalculationDocument2 pagesHeat Coil CalculationZhao XuanNo ratings yet

- Tensile Test On Cast IronDocument15 pagesTensile Test On Cast IronElmer Ibanez JrNo ratings yet

- Cuantias de AceroDocument3 pagesCuantias de AceroJulio Jose Lacayo CascoNo ratings yet

- SL-T - Sanarya DashtiDocument16 pagesSL-T - Sanarya DashtiPRATEEK SHARMANo ratings yet

- ForecastingDocument12 pagesForecastingMohoua SRNo ratings yet

- Katalog MKM N2xy 1 CDocument1 pageKatalog MKM N2xy 1 CAhmad ZulkarnaenNo ratings yet

- UPM PHY3401 Mini Project Assignment Info and QuestionsDocument9 pagesUPM PHY3401 Mini Project Assignment Info and QuestionsMohd Amiruddin Abd RahmanNo ratings yet

- Centricast CL 1520 Data SheetDocument6 pagesCentricast CL 1520 Data SheetOlmer Romero MendezNo ratings yet

- Certificado BombasDocument3 pagesCertificado BombasRoger Quevedo MachucaNo ratings yet

- DFD LP Technical Information 1614Document4 pagesDFD LP Technical Information 1614FareethAbdullahNo ratings yet

- CHEE3741 2016 Assignments PDFDocument16 pagesCHEE3741 2016 Assignments PDFJoshua MitchellNo ratings yet

- Compaction Test: Bandar Udara Bintan ResortDocument9 pagesCompaction Test: Bandar Udara Bintan ResortRizky Rahmandhito0% (1)

- Reservoir TempDocument30 pagesReservoir TempKhaled AdelNo ratings yet

- Sakshi C February 13 PDFDocument12 pagesSakshi C February 13 PDFSakshi JainNo ratings yet

- PCT-original PCT MergedDocument11 pagesPCT-original PCT MergedBryan GiranoNo ratings yet

- Metering Pumps: Models A and BDocument5 pagesMetering Pumps: Models A and Bbmanojkumar16No ratings yet

- Genetron407C PressureTempChart TechToolDocument2 pagesGenetron407C PressureTempChart TechToolagus sutiawanNo ratings yet

- SL-T - Laila AlsayeghDocument8 pagesSL-T - Laila AlsayeghPRATEEK SHARMANo ratings yet

- CSB GP12170Document1 pageCSB GP12170Alfin RiyadiNo ratings yet

- AERO3000 Equation ListDocument19 pagesAERO3000 Equation ListlalalallkjdlfjlkNo ratings yet

- V: 3.3 - 200 Volts P: 1.5 Watts: Silicon Zener DiodesDocument4 pagesV: 3.3 - 200 Volts P: 1.5 Watts: Silicon Zener DiodesFazar AhmadNo ratings yet

- Dow 01603169736Document1 pageDow 01603169736jose luisNo ratings yet

- AC and DC Voltage Drop Calculator With Formulas and ExamplesDocument13 pagesAC and DC Voltage Drop Calculator With Formulas and ExamplesNANDHAKUMAR ANo ratings yet

- Simulation of Vapour Compression CycleDocument31 pagesSimulation of Vapour Compression CycleAlessandro LamaNo ratings yet

- Table D - Oil Producton (MBD)Document16 pagesTable D - Oil Producton (MBD)ika satuNo ratings yet

- Datasheet Ac 500 2Document11 pagesDatasheet Ac 500 2Yay B. GicoNo ratings yet

- C E B P: Apacity Valuation of Ored ILEDocument3 pagesC E B P: Apacity Valuation of Ored ILEChowdhury PriodeepNo ratings yet

- Tài Methyl-Acetate-Plant-DesignDocument18 pagesTài Methyl-Acetate-Plant-DesignLe Anh QuânNo ratings yet

- Current Carrying Capacity CABLES - BVDocument3 pagesCurrent Carrying Capacity CABLES - BVStefanita100% (1)

- Therminol 55Document5 pagesTherminol 55Dinesh KumarNo ratings yet

- Centricast CL 2030 Data SheetDocument6 pagesCentricast CL 2030 Data SheetOlmer Romero MendezNo ratings yet

- Dow 01604300469Document1 pageDow 01604300469Boris BirinNo ratings yet

- FT Vidrio Plomado MEDX-GAMMADocument2 pagesFT Vidrio Plomado MEDX-GAMMACarlos Manuel Alban RuizNo ratings yet

- Lab 2Document18 pagesLab 2Dodiya NikunjNo ratings yet

- Bateria GP1272F2 12-7ahDocument1 pageBateria GP1272F2 12-7ahVentas Prime TelecomNo ratings yet

- Multicore Cables: Copper ConductorsDocument3 pagesMulticore Cables: Copper ConductorsDodik RahmadNo ratings yet

- GP Series: Valve Regulated Lead Acid BatteryDocument1 pageGP Series: Valve Regulated Lead Acid BatteryadelgcNo ratings yet

- GP Series: Valve Regulated Lead Acid BatteryDocument1 pageGP Series: Valve Regulated Lead Acid BatteryBrayanNo ratings yet

- En Ag2100marinesmoothDocument2 pagesEn Ag2100marinesmootheloy marroquinNo ratings yet

- Photron High Speed CameraDocument2 pagesPhotron High Speed Cameramaryam ebrahimiNo ratings yet

- Ductwork System Calculation Input Data Sheet: Fixture Library Fixture Type, C, and DP Input by UserDocument8 pagesDuctwork System Calculation Input Data Sheet: Fixture Library Fixture Type, C, and DP Input by Usersunii19847908No ratings yet

- CSB GP12400Document1 pageCSB GP12400Alfin RiyadiNo ratings yet

- Emerson Flow Meter Technical Size - TatweerDocument1 pageEmerson Flow Meter Technical Size - TatweerZidan ZeusNo ratings yet

- No. Peak Intensity Corr. Intensity Base (H) Base (L) Area Corr. AreaDocument2 pagesNo. Peak Intensity Corr. Intensity Base (H) Base (L) Area Corr. AreaZakenia Khairunnisa FalahNo ratings yet

- 15 Water Treatment Training Reverse OsmosisDocument50 pages15 Water Treatment Training Reverse OsmosisWaqas ButtNo ratings yet

- Total Dissolved Solids Vs Total Dissolved Salts ("TDS") : Methods Used For TDS AreDocument2 pagesTotal Dissolved Solids Vs Total Dissolved Salts ("TDS") : Methods Used For TDS AreWaqas ButtNo ratings yet

- Technotes: Basics of Ro TroubleshootingDocument4 pagesTechnotes: Basics of Ro TroubleshootingWaqas ButtNo ratings yet

- Is Perfection, Because A Higher Standard Is Yet UnknownDocument12 pagesIs Perfection, Because A Higher Standard Is Yet UnknownWaqas ButtNo ratings yet

- Chemical Enginnering November 2015Document80 pagesChemical Enginnering November 2015Gaston ChauNo ratings yet

- Biology Class 9 Revised Syllabus Break Up 2020-21-23Document7 pagesBiology Class 9 Revised Syllabus Break Up 2020-21-23MohammadNo ratings yet

- Chapter 7 SolutionDocument26 pagesChapter 7 SolutionNguyễn HùngNo ratings yet

- Filmtec™ Membranes Flow Factor For Ro System DesignDocument3 pagesFilmtec™ Membranes Flow Factor For Ro System DesignJuan MendozaNo ratings yet

- 1.4 Membrane Transport (53 Marks) : MarkschemeDocument20 pages1.4 Membrane Transport (53 Marks) : Markschemelayal hashem0% (2)

- Chapter 2 Solutions OtturDocument34 pagesChapter 2 Solutions Ottursukaina fatimaNo ratings yet

- Osmosis Experiment BiologyDocument4 pagesOsmosis Experiment BiologyEdgar UbaldeNo ratings yet

- Water For Injection Prepared by Reverse OsmosisDocument2 pagesWater For Injection Prepared by Reverse OsmosisReza-ul JalilNo ratings yet

- 1 Gcse Aqa BiologyDocument43 pages1 Gcse Aqa Biologycharlotteamy10No ratings yet

- Xii Chemistry Patna RegionDocument235 pagesXii Chemistry Patna RegionPrashant Jain100% (1)

- (2013) A Novel Hybrid Process of Reverse Electrodialysis and Reverse Osmosis For Low Energy Seawater Desalination and Brine ManagementDocument11 pages(2013) A Novel Hybrid Process of Reverse Electrodialysis and Reverse Osmosis For Low Energy Seawater Desalination and Brine ManagementgiacalaNo ratings yet

- Internship Report 2018Document29 pagesInternship Report 2018Nabeel AkbarNo ratings yet

- Chemlab Report2Document15 pagesChemlab Report2Czarriel F. Flores100% (1)

- Solution Notes PPT 3Document48 pagesSolution Notes PPT 3PRAGYAN 10ANo ratings yet

- Class 9 PWDocument16 pagesClass 9 PW2982No ratings yet

- Osmotic Dehydration QuizDocument7 pagesOsmotic Dehydration QuizTamizh TamizhNo ratings yet

- Lab Procedure For Osmosis AdvancedDocument4 pagesLab Procedure For Osmosis Advancedapi-264668182No ratings yet

- CBSE Class-12 Chemistry Quick Revision Notes Chapter-02: SolutionsDocument5 pagesCBSE Class-12 Chemistry Quick Revision Notes Chapter-02: SolutionsHarshit SonkariaNo ratings yet

- IGCSE Biology NotesDocument15 pagesIGCSE Biology NotesCrystal Wong100% (14)

- HtwoO and BufferDocument7 pagesHtwoO and BufferManila MedNo ratings yet

- Preparation and Characterization of Low-Cost Ceramic Microfiltration Membranes For The Removal of Chromate From Aqueous SolutionsDocument15 pagesPreparation and Characterization of Low-Cost Ceramic Microfiltration Membranes For The Removal of Chromate From Aqueous SolutionsrishiNo ratings yet

- IMPLANTSDocument11 pagesIMPLANTSRavi ParasharNo ratings yet

- 4.1 Introduction Absorption by RootsDocument5 pages4.1 Introduction Absorption by Rootsankurbiology67% (3)