Professional Documents

Culture Documents

IRCD

IRCD

Uploaded by

Bui Khoi Nguyen0 ratings0% found this document useful (0 votes)

178 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

178 views8 pagesIRCD

IRCD

Uploaded by

Bui Khoi NguyenCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

SS ee a ee

hacmsalecitiid . " nenenids

Haskel Range of

Injection Rate Control Devices

Haskel Intemational, Ine. has nearly

60 years of hydraulic and pneumatic

engineering experience in the design

and manufacture of one of the widest

ranges of airdriven liquid. pumps,

chemical injection pumps, gas boesters,

s and

‘smarket

air pressure amplifie

ble in tod

Located in Burbank, California, USA

with a further manufacturing plant in

Sunde:

ind, UK., the company has

lly placed offices and

dedicated distributors throughout

Europe, Asia, Pacific Rim and the

Americas,

In 1997, Haskel Intern

acquired Palpro Ltd. located in the

United Kingdom. ‘The Palpro IRCD

Unjection Rate Control Device) is a

al, Tne:

unique and revolutionary system for

point injection of chemicals

into oil and gas production systems.

A continuous investment in the most

modern machinery and technological

advances ensures Haskel remains

among the leaders in the field of

chemical injection,

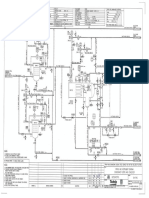

througheut the system, provided that

the flow control valve (variable

orifice) does not alter. ‘This ensures

that fluid through the IRCD. will

only change if the flow control valve

is adjusted.

High Pressure

Supply in

‘The Haskel IRCD is a unique and revolutionary system for the

multipoint injection of chemicals into Oil and Gas production

systems. The IRCD can be supplied as individual units or in a

panel configuration which can be installed adjacent to the

point of injection,

Additionally, they require only one high pressure feed line

from either an air or electric-driven chemical injection pump,

ho matter bow many injection points the system may contain,

Capable of handling flow rates as low as 20 mi/hr. and up to

5,000 L/hr, with injection pressures up to 15,000 psi, the

IRCD has no moving parts, requires no electric power and is

silent during operation.

Dperation

How the IRCD Operates

Features and Benefits:

Accurate

* Flow rates as low as

20 mi/hr.

+ Flow rates as high as

5,000 L/hr.

# Pressure ratings up to

15,000 psi

No Moving Parts

‘+ Requires one high pressure

line reducing the number of

pumps required, regardless of

number of injection points

‘+ Reduces maintenance cost

‘« Reduces the problem of leaks

Built to Your Specifications

© Supplied individually or in

panel configurations

For more detailed information, refer

to the “Benefits of the IRCD Over

Conventional Chemical Metering

System”.

Compare the Two Systems

‘The Hastel injgetion rate control device system

provides many advantages over conventional

‘Pump systems as these photographs illustrate

When a comparison is

systems, the num

offered by the Haskel IRCD system is cleurly

Benefits of the IRCD

Over Conventional Chemical

Metering Systems

Smaiter space Requirements

‘The Haskel system saves considerable space over

ventional systems

requiring separate metering pumps for each injection point

Less Weight

In many cases, up 10 120 Ib per injection point can be saved by

removing the metering pumps, pipework, motors and skid steelwork.

Lower Installation Cost

(On-site installation costs are substantially reduced as the IRCD system

roquites only one high pressure line from the feed pump to the area of

injection point(s). Compared w multi-point meter

pump

{installations requiring multiple runs of high pressure tubing to the point

of injection(s), significant savings of time and expense can be realized

with the elimination of leaks.

Easier to Add Units to Existing system

The IRCD system cen be expanded easily by adding further units or

tecing into the ring nan,

Less Pumps Used

Reduction in the number of pumps utilized allows substantial savings in

capital, maintenance, spare paris and weight.

No Moving Parts

No glands snd a redvetion in tubing runs

equates 10 fewer leakage probl

associated safety problems and loss of

‘expensive chemical

Less Maintenance

‘The IRCD with no moving parts requires

considerably less maintenance and allows

for quick and easy removal

Control atthe Point of Injection

Contiol of the injection rate is achieved

by fitting the IRCD directly at the

injection point. Injection is not affected

iespective of the length of the injection

line.

Local or Remote

Actual Flow Indication

Units can be ited with either an

electronic flowmeter with +0.2% accuracy

(standart) ora built-in VA meter

Smooth Flow at the Injection

Point Improves Performance

Met

pu

Haskel IRCD system avoids this problem

ing_can become inaccurate when

ping into long discharge lines. The

{due to the smooth flow and the ability to

control the flow rate

poi

nat the injection

Not Susceptible to

Temperature Extremes

Suitable forall environmenss,

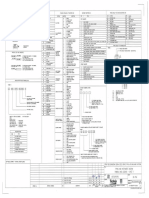

Designing Your IRCD System

ne of the advamages of the Haskel For example

TICS Whe patton Sn eof i

positive displacement pumps needed etc Ce er

pump per chemical is required, ‘The 1 3t0 10 L/h. 400 psig

Sizing of this pamp is very important. 2 110 7 Ltr. 800 psig

When considering the use ofthe Haskel 3 to 11 Law. 2,000 psig

IRCD, the following parameters should 4 Wasik 000 pale

be defined: Futures 7 t0.20 Liar. 200 psig

1. The maximum total volume of fluid Foruee Tw 15Lie. 200 psig

1 be injected, taking into consideration

paste aso Total Maximum Fiow 63.5 L/h. at 3,000 psig

; _ : Using the parameters listed, the selected pump must be espable of

MSsasglGy ad Becta 65.5 x 120% = 78 Uhr. ai 3,400 psig

consideration future expansion

2. The single highest pressure thats 10

Once these questions have been The preferred method of controling ring main pressure is by

answered, the selected pump should using a buck pressure control valve that provides a constant bleed

have an outpat capacity of 120% of the of exaess fluid back to the sapply tank. This valve ean be spring

maximum system demand. ‘The output or gas fond. Gs loaded valves are preferred as they provide

pressure should be 400 psi higher thin etter accuracy and control of the ring main pressure. See

the single highest point known ot diagram (neat page) fora typical installation,

expected,

Typical Questions and Answers:

Will low be affected if I chu

prossures change?

No. All of the IRCD's operate indepentently of other nts In the system, They are designed to

Inject at a set rate irrespective of system pressure fluctuations

1 Flow rate, isolate the IRCD, or if the ring main orin

What type of pump should 1 use?

Any positive displacement pump such as Haskel's chemical injection pump series will be suitable.

What flow tundown can I expect with my IRCD?

Ifyou are using a coriolis meter to calibrate your IRCD, then you will achieve a numdown of up

10 10010 J. When using a VA meter, you canexpect a turndown of up to 20 101

Low Flow System Specifications

MODELING NUMBER SGOT HIGH PRESSURE UNIT

Elastomer Pert Pera

Medium Low Flow System Specifications

Menten) Ory oe ae

‘Max. Operating Pressure 10.00 psig/ 60 bar 5.000 pig /1.038 bur

Flow Range Sqph/200 p60 000 ph | 53 gt /200 jp 530 gh 2,000 It

St Stns Stet Duplex States Stst

Siaetoiye Perfor Perf

igh Flow System Specifications

eu eam Cater a a

Consider the benefits of owning an IRCD.

* With subsidiaries and distributors around the world your IRCD

can be serviced by Haskel trained technicians wherever the

installation.

* Awide range of flows

* Over 15 years experience of solving customers liquid flow

distribution problems.

All of this backed by a world class international company.

For more information contact your nearest office of find us at www.Haskel.com

Haskel Enorgy Syateme Lid. Hache! HochdnuckSystome GmbH Haskol Espafa SRL.

Noth Hyton Ba astas Wesel Passo Ubarburu Bt Eat 5+ Ya Planta

‘Suedetiand SRS 2JD + Englend, UK Frit Habor Strasse + Germany Locales 1¥2 «Pol. 27 Martutene

“To d-191-540-1212+ Fax 44-191-549-0911 Tel 49:281-98.48-00 «Fax: 49.28196-48-(20 205 Astigarraga Gipuzkoa + Spain

ww Haskel de Tol: 34-943-47 45-66 «Fax 34 943-45-1-86

Haske! (Asia) Pte. Lid. wna Haskel-es.com

23 Tagore Lane #0307 Haskel-General Pneumatic

Tagore 23 Warehouse Complex 4rue du haute de fa Cuppe Haskel Energy Systems Limited

Singapore 78760 F-59650 Vilonewve D'Ascy, France Unit 14 Aways Industrial Estate

Tel 65.6485-7559 + Fax 65-6455-2681 Tol: $8-220-04-86-00 Pitmedden Road, Dyce

vw Haskal.com.sg Fax: 33-320-33:31-95 Aerdeen, AB21 ODT Scand

Tel: 49-1226-7717e4 Fax 46-1224-720682

Haske! Australasia Pe, Lia. Fastel Benelux BV.

P.O, Box 257 Cobatsaai 28 askel tallana S.A.L.

Salabury, 0144107 ~Austata 2718 AN Zoetemeer -Netheands Via Carabeli, 28

Tol 617-927918-Fax 617-2077 6129 Te31-79.961-04-72-Fax:3170-160.050 21041 Albzzato (VA) aly

war HaskaLcom au To-29-291-087505 - Fax: 90:291.087507

ean Hash it

Haskel International, Inc.

100 East Graham Place

Burbank, CA 91602, USA

‘Telephone: (818) 843-4000

Fax (818) 556-2549 or (818) 841-4291

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Nam (PVN) Cac Thong Bao, Huong Dan Cua Benh Vien THDNG Nhit - Boy TeDocument7 pagesNam (PVN) Cac Thong Bao, Huong Dan Cua Benh Vien THDNG Nhit - Boy TeBui Khoi NguyenNo ratings yet

- DN Process Plan WKG - BKNDocument13 pagesDN Process Plan WKG - BKNBui Khoi NguyenNo ratings yet

- 1014-BKTNG-PR-PID-2020 - Rev 0 - Piping and Instrument Diagram Produced Water Treatment Package PDFDocument1 page1014-BKTNG-PR-PID-2020 - Rev 0 - Piping and Instrument Diagram Produced Water Treatment Package PDFBui Khoi NguyenNo ratings yet

- 1014-BKTNG-PR-PID-2018 - Rev 1 - Piping and Instrument Diagram Condensate Filters and CoalescersDocument1 page1014-BKTNG-PR-PID-2018 - Rev 1 - Piping and Instrument Diagram Condensate Filters and CoalescersBui Khoi NguyenNo ratings yet

- 1014-BKTNG-PR-PID-2001 - Rev 1 - Piping and Instrument Diagram Wellheads and Flowlines PDFDocument1 page1014-BKTNG-PR-PID-2001 - Rev 1 - Piping and Instrument Diagram Wellheads and Flowlines PDFBui Khoi Nguyen100% (1)

- 1014-BKTNG-PR-PID-0001 - Rev 0 - Piping and Instrument Diagram Symbols and Legends - Sheet 1Document1 page1014-BKTNG-PR-PID-0001 - Rev 0 - Piping and Instrument Diagram Symbols and Legends - Sheet 1Bui Khoi NguyenNo ratings yet

- 1014-BKTNG-PR-PID-0008 - Rev 0 - Piping and Instrument Diagram Symbols and Legends - Sheet 8 PDFDocument1 page1014-BKTNG-PR-PID-0008 - Rev 0 - Piping and Instrument Diagram Symbols and Legends - Sheet 8 PDFBui Khoi NguyenNo ratings yet

- 135355-01-REP-06-012 - Update 19.5Document28 pages135355-01-REP-06-012 - Update 19.5Bui Khoi NguyenNo ratings yet

- PSV Sizing Psv-414 UpdateDocument7 pagesPSV Sizing Psv-414 UpdateBui Khoi NguyenNo ratings yet

- PSV Sizing Psv-402 Update PsetDocument7 pagesPSV Sizing Psv-402 Update PsetBui Khoi NguyenNo ratings yet