Professional Documents

Culture Documents

Section 2: Normal Procedures

Section 2: Normal Procedures

Uploaded by

haileOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 2: Normal Procedures

Section 2: Normal Procedures

Uploaded by

haileCopyright:

Available Formats

TC APPROVED BHT-505-FM-1

Section 2

NORMAL PROCEDURES

2

TABLE OF CONTENTS

Paragraph Page

Subject Number Number

Introduction ............................................................................................ 2-1 ........... 2-3

Cold weather operations ................................................................... 2-1-A ....... 2-3

Flight planning ....................................................................................... 2-2 ........... 2-4

Preflight check ....................................................................................... 2-3 ........... 2-4

Before exterior check ........................................................................ 2-3-A ....... 2-4

Exterior check .................................................................................... 2-3-B ....... 2-4

Fuselage — Cabin Right Side ....................................................... 2-3-B-1 .... 2-4

Fuselage — Center Right Side...................................................... 2-3-B-2 .... 2-5

Cabin Roof ...................................................................................... 2-3-B-3 .... 2-5

Fuselage — Aft right side.............................................................. 2-3-B-4 .... 2-6

Fuselage — Full aft ........................................................................ 2-3-B-5 .... 2-6

Fuselage – Aft left side .................................................................. 2-3-B-6 .... 2-6

Fuselage — Cabin left side ........................................................... 2-3-B-7 .... 2-6

Fuselage — Front........................................................................... 2-3-B-8 .... 2-7

Interior check ......................................................................................... 2-4 ........... 2-7

Prestart check .................................................................................... 2-4-A ....... 2-8

Engine start ............................................................................................ 2-5 ........... 2-9

Dry motoring run................................................................................ 2-5-A ....... 2-9

Systems Check ...................................................................................... 2-6 ........... 2-10

Preliminary hydraulic system check................................................ 2-6-A ....... 2-10

Flame out protection system (FOPS) test ....................................... 2-6-B ....... 2-10

Engine run-up..................................................................................... 2-6-C ....... 2-10

Hydraulic system check .................................................................... 2-6-D ....... 2-10

Auxiliary control unit (ACU) test ...................................................... 2-6-E ....... 2-11

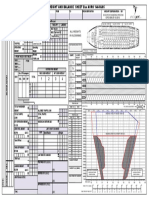

Power assurance check (PAC) ......................................................... 2-6-F........ 2-11

Before takeoff......................................................................................... 2-7 ........... 2-11

Takeoff .................................................................................................... 2-8 ........... 2-11

In-flight Operations................................................................................ 2-9 ........... 2-12

In-flight - Transfer of control from Pilot A to

Pilot B (Dual controls installed)........................................................ 2-9-A ....... 2-12

Descent and Landing............................................................................. 2-10 ......... 2-12

Engine shutdown ................................................................................... 2-11 ......... 2-12

Postflight check ..................................................................................... 2-12 ......... 2-13

Export Classification C, ECCN EAR99 30 OCT 2019 Rev. 5 2-1/2-2

TC APPROVED BHT-505-FM-1

Section 2

NORMAL PROCEDURES

2

2-1. INTRODUCTION Battery starts have been demonstrated to

-35°C (-31°F) with standard 17 amp-hour

This section contains instructions and battery.

procedures for operating helicopter from

planning stage, through actual flight When the BATT switch is selected to the ON

conditions, to securing helicopter after position, the battery heater will start warming

landing. up the battery prior to energizing the aircraft's

systems. A delay of up to 12 minutes could be

Normal and standard conditions are assumed observed.

in these procedures. Pertinent data in other

sections is referenced when applicable. Once power is applied to helicopter, it may

take a few minutes for the Multi-Function

Instructions and procedures contained herein Display (MFD) and the Primary Flight Display

are written for purpose of standardization and (PFD) to be readable.

are not applicable to all situations.

To ensure that the battery is providing optimal

Refer to the G1000H Integrated Flight Deck performance, the engine start should be

Pilot's Guide (190-02064-00) and the Cockpit initiated only when the BATTERY COLD

Reference Guide (190-02065-00) for system caution message and BATT HEATER ON

operation. advisory message are extinguished.

The transponder ADS-B Out system has been

shown to meet equipment requirements of 14 During engine start in cold temperatures, high

engine oil pressure is normal. Normal oil

CFR 91.227.

pressure and temperature indications as per

2-1-A. COLD WEATHER OPERATIONS Section 1 (limitations) should be obtained

after approximately 5 minutes at idle.

To preserve electrical power when the battery

has been cold soaked below -5°C (23°F), do

not select BATT ON unless an engine start is

to be performed. Tasks requiring electrical

power should be performed shortly after an

engine shutdown or immediately prior to an

engine start. Starting the engine with a battery

at less than 25.7 volts may result in a hot start.

Export Classification C, ECCN EAR99 30 OCT 2019 Rev. 5 2-3

BHT-505-FM-1 TC APPROVED

2-3-A. BEFORE EXTERIOR CHECK

2-2. FLIGHT PLANNING

1. Flight planning — Completed.

Each flight should be planned adequately to

ensure safe operations and to provide pilot 2. Publications — Checked.

with data to be used during flight.

3. GW and CG — Computed.

Check type of mission to be performed and

destination. 4. Helicopter servicing — Completed.

Determine that helicopter has adequate 2-3-B. EXTERIOR CHECK

performance to complete mission using

appropriate performance charts in Section 4

(performance data). WARNING

Determine that helicopter weight and balance IF HELICOPTER HAS BEEN

will be within limits during entire mission. Use EXPOSED TO SNOW OR ICING

the appropriate weight and balance charts as CONDITIONS, SNOW AND ICE

per Section 5 (weight and balance) and SHALL BE REMOVED FROM ALL

Section 1 (limitations). CRITICAL SURFACES AND ENGINE

INTAKE AREA PRIOR TO FLIGHT.

NOTE

Fuel flow indication is an aid to flight

WARNING

planning only and may not provide

the accuracy level upon which the

pilot can solely base a decision FAILURE TO REMOVE THE ROTOR

associated with maximum in-flight TIE-DOWNS BEFORE ENGINE

range. STARTING MAY RESULT IN SEVERE

DAMAGE AND POSSIBLE INJURY.

2-3. PREFLIGHT CHECK

2-3-B-1. FUSELAGE — CABIN RIGHT SIDE

Pilot is responsible for determining whether

the helicopter is in condition for safe flight. 1. Main rotor blades — Tie–downs

removed, condition.

NOTE 2. Windshield — Condition.

A preflight check is not intended to

3. Pitot tube and right static port —

be a detailed mechanical inspection,

Condition.

but simply a guide to help pilot

check condition of helicopter. It may

4. Mirror (if installed) — Condition and

be as comprehensive as conditions

security.

warrant at discretion of pilot.

5. Cabin door and hinge bolts —

All areas checked shall include a visual check Condition and security.

for evidence of corrosion, particularly when

helicopter is flown near salt water or in areas 6. Windows — Condition and security.

of high industrial emissions.

7. Landing gear — Condition and

ground handling wheel removed.

2-4 6 NOV 2017 Export Classification C, ECCN EAR99

TC APPROVED BHT-505-FM-1

2-3-B-2. FUSELAGE — CENTER RIGHT 15. Hydraulic reservoir filler cap color —

SIDE Noted.

1. Transmission — Check oil level 16. Hydraulic reservoir filler cap —

within OIL LEVEL markings. Closed and secure.

2. Engine inlet — Remove covers, 17. Hydraulic reservoir — Check fluid

condition and security. level.

ENGINE AND TRANSMISSION 18. Hydraulic actuators and lines —

COMPARTMENT: Condition, security, interference,

leakage.

3. Main driveshaft aft flexure —

19. Cabin roof, forward and

Condition.

transmission fairings — Clean and

4. Engine pan — Evidence of oil secured.

leakage.

20. Transmission mounts — Condition

5. Engine mounts — Condition and and security.

security.

21. Transmission area — Cleanliness.

6. Hoses and tubing — Chafing,

2-3-B-3. CABIN ROOF

security, and condition.

7. Engine oil filter pre-blockage 1. Main rotor — Condition and security.

indicator — Retracted.

2. Main rotor blade doublers and skin —

8. Engine fuel filter blockage indicator Condition.

— Retracted.

3. Pitch horn trunnion bearing — Wear

9. Rotor brake (if installed) — and security.

Condition, leak and security.

4. Main rotor mast, static stops —

10. Rotor brake pads (if installed) — Condition and evidence of contact.

Confirm retracted. 5. Main rotor pitch links — Condition

11. Engine cowling — Secured. and security of attachment bolts.

12. Main driveshaft, forward part — 6. Swashplate assembly Condition —

Condition. security of attached controls.

13. Transmission oil filter impending 7. Swashplate boot — Condition.

bypass indicator — Retracted. 8. Control linkages to swashplate —

14. Engine oil reservoir — Check oil Condition, security of attachment

level, filler cap security. bolts.

9. Antenna(s) — Condition.

NOTE

10. Exhaust cover — Removed.

Installation of the black hydraulic

reservoir cap (P/N 53990) permits 11. Exhaust — Condition and security.

engine starts at OAT -40°C (-40°F)

and above.

Export Classification C, ECCN EAR99 30 OCT 2019 Rev. 5 2-5

BHT-505-FM-1 TC APPROVED

2-3-B-4. FUSELAGE — AFT RIGHT SIDE 9. Tail rotor blades — General

condition.

1. Upper aft fairing — Condition and

security. 10. Tail rotor yoke — Condition.

2. External power access door — 2-3-B-6. FUSELAGE – AFT LEFT SIDE

Secured.

1. Tailboom — Condition.

3. Circuit breaker panel — Checked.

2. Horizontal stabilizer — Condition

4. Avionics shelf Condition, — and security.

cleanliness and security.

3. Red position light — Condition.

5. Avionics access door — Secured.

4. Tail rotor driveshaft cover —

6. Lower aft fairing — Secured. Condition and security.

7. Tailboom attachment — Secured. 5. Tailboom attachment — Secured.

8. ELT antenna (if installed) — 6. Upper aft fairing — Condition and

Condition and security. security.

9. RAD ALT antennas (if installed) — 7. Engine fairing — Condition and

Condition and security. security.

10. Tail rotor driveshaft cover — 8. Lower aft fairing — Condition and

Condition and security. security.

11. Tailboom — Condition. 2-3-B-7. FUSELAGE — CABIN LEFT SIDE

12. Horizontal stabilizer — Condition

and security. NOTE

13. Green position light — Condition. If helicopter is not parked on a level

surface, fuel drain system may not

2-3-B-5. FUSELAGE — FULL AFT properly drain contaminants. Refer

to BHT-505-MD-1, section 2 for the

1. Vertical fin — Condition and security

detailed fuel drain procedure.

of attachment.

2. Aft position light — Condition. 1. Fuel drain hand pump — Installed.

3. Anti-collision light and navigation 2. Fuel — Drain as required (13.53 oz

antenna — Condition and security. (400 ml) minimum).

4. Tail damper — Condition and 3. Fuel drain hand pump — Stowed and

security. secured.

5. Tail rotor guard — Condition and 4. Fuel filler cap and fuel filler access

security. door — Condition, closed and

secured.

6. Tail rotor gearbox — Oil level, leaks

and security. 5. Hydraulic oil filter differential

pressure indicator (if installed) —

7. Tail rotor — Tie-down removed, Retracted.

condition and free movement.

6. Forward fairing — Secured.

8. Tail rotor controls — Condition and

security. 7. Side panel — Secured.

2-6 Rev. 6 16 APR 2020 Export Classification C, ECCN EAR99

TC APPROVED BHT-505-FM-1

8. Cabin doors and hinge bolts — NOTE

Condition and security.

Display Units (DU) are not

9. Windows — Condition and security. compatible with use of polarized

10. Landing gear — Condition and sunglasses.

ground handling wheel removed.

1. Cabin interior — Clean and

11. Left static port — Condition. equipment secured.

2-3-B-8. FUSELAGE — FRONT 2. Pedal position — Adjusted and

secured.

1. Exterior surfaces — Condition.

3. Fire extinguisher — Installed and

2. Windshield — Condition and secured.

cleanliness.

4. Cabin loading — Maintain CG within

3. Vent air intake — Free of debris. limits.

4. Snow baffle (if installed) — Condition 5. All seat belts — Secured.

and security.

6. Doors — Secured.

5. Mirror (if installed) — Condition and

security. 7. Flight crew seats — Forward and

locked.

6. Landing lights — Condition.

8. Pilot throttle — IDLE.

7. Antennas (if installed) — Condition

and security. 9. Copilot throttle (if installed) — IDLE.

8. Belly and belly panels — Condition 10. LDG LTS — OFF.

and security.

11. BATT — OFF.

9. Vertical tunnel panel — Condition

12. GEN — OFF.

and security.

13. REVERSIONARY display (REV) —

2-4. INTERIOR CHECK NORM.

14. ANTI COLL LT — OFF.

WARNING

15. POS LT — OFF.

PRIOR TO START, PERFORM AN 16. PITOT heater — OFF.

ASSESSMENT TO ENSURE THAT

FULL YAW PEDAL CONTROL MOTION NOTE

IS AVAILABLE AND THAT THE

ENGINE AND HYD SWITCHES CAN BE PNL LT rheostat shall be set to AUTO

OPERATED WHEN SITTING WITH THE to prevent the PFD and MFD dimming

BACK RESTING AGAINST THE SEAT. during engine starts.

IF REQUIRED, INSTALL CREW SEAT

BACK PAD P/N UAA1505-155-301. 17. PNL LT — AUTO.

THIS BACK PAD IS INTENDED FOR

18. HYD SYS — ON.

F L I G H T C RE W M E M B E R S O NL Y .

TYPICALLY, PILOTS OVER 5 FEET 6 19. ENGINE — OFF.

INCHES (1.68M) WOULD NOT

REQUIRE IT. 20. BLEED AIR and VENT — OFF.

Export Classification C, ECCN EAR99 30 OCT 2019 Rev. 5 2-7

BHT-505-FM-1 TC APPROVED

NOTE 9. FUEL PRESS warning — Illuminated.

The INTERIOR LT should be turned 10. ENG OIL PSI LO warning —

ON and oriented toward the center Illuminated.

console to illuminate the control

11. XMSN OIL PRESS warning —

panel.

Illuminated.

21. INTERIOR LT — As required. 12. GEN caution — Illuminated.

22. Garmin displays — Condition and 13. WOG advisory — Illuminated.

cleanliness.

14. EXT POWER advisory (if connected)

23. Standby instruments — Condition. — Illuminated.

24. Compass and compass card — 15. Weight and balance — Computed.

Condition.

16. AUD TST softkey (ENGINE page/

25. EMERGENCY FUEL SHUTOFF — ON TEST PAGE) — Press to activate.

(full aft), witness wired.

Verify the following tones and

26. Rotor brake handle (if installed) — systems:

UP and latched.

• Master warning (ping repeating 3

2-4-A. PRESTART CHECK times)

1. If night VFR flight is expected — • Low rotor RPM alert (continuous

Standby instrument — ON. warble)

2. BATT — ON. • ENGINE OUT (voice message)

3. Garmin system power up — • ECU FAIL (voice message)

Complete.

• Airspeed above VNE (continuous

4. Engine out audio — Activated. ting).

5. MASTER W/C acknowledgement • 150 feet (voice).

softkey — Push to mute audio.

• Master caution (single ping tone)

NOTE

• Engine fire (voice message)

To prevent illumination of BATTERY

FAIL and BATTERY FAULT cautions, • Impending exceedance (double

do not connect external power ping)

source until the BATT HEATER ON

• RPM remote light illuminates

advisory and the BATTERY COLD

caution are extinguished. • Avionics fans operate

6. External power — Connected (if 17. AUD TST softkey — Press to cancel.

required).

18. CHIP TST softkey — Press once,

7. ECU MAINT advisory — Momentary confirm CHIP TEST OK.

displayed during power up.

19. FIRE TST softkey — Press once,

8. ENGINE OUT warning — Illuminated. confirm FIRE TEST OK.

2-8 Rev. 6 16 APR 2020 Export Classification C, ECCN EAR99

TC APPROVED BHT-505-FM-1

20. Flight controls — Check full travel, 7. Battery voltage — Confirm minimum

adjust friction as required. 25.7 volts for battery start.

21. ANTICOLL, POS and LDG lights 8. BATTERY COLD caution and BATT

switches — As required. HEATER ON advisory —

extinguished.

22. FUEL QTY — Sufficient.

9. Flight timer — Start.

23. OAT — Check.

10. ENGINE — START/RUN.

2-5. ENGINE START

11. PSI — Monitor start limitations.

12. START advisory — Extinguished at

CAUTION 50% NG (starter has disengaged).

13. Engine and transmission oil

IF ENGINE OIL LEVEL IS FOUND

pressures — Check.

LOW AND OIL MIGRATION FROM

THE ENGINE OIL TANK TO THE

ENGINE ACCESSORY GEARBOX IS NOTE

SUSPECTED, PERFORM DRY During cold temperature operations,

MOTORING RUN (PARAGRAPH normal transmission and engine oil

2-5-A) AND CONFIRM ENGINE OIL pressure limits may be exceeded

LEVEL PRIOR TO ENGINE START. during start. Stabilize engine at idle

until minimum temperature and

1. ANTICOLL, POS and LDG lights — pressure limits are attained.

As required.

14. IDLE — 63 ±1% NP.

2. Collective — Full down.

3. Cyclic and pedals — Centered. NOTE

If external power is connected, the

4. Rotors — Clear. generator will not provide power to

the bus until the external power is

NOTE disconnected. This also prevents the

Engine starts with THROTTLE switch charging of the external power

selected to FLY position are sources.

permitted provided that oil pressures

are monitored and kept within limits. 15. EXTERNAL POWER — Disconnect,

close the access door (if applicable).

NOTE 16. GEN — ON.

With dual controls installed, 17. Voltmeter — 28 ±0.5 volts.

selecting either pilot's THROTTLE

switch to FLY will command the NP to 2-5-A. DRY MOTORING RUN

104%.

The following procedure is used to reduce

5. THROTTLE — FLY. residual MGT and can only be performed if NG

Confirm DUAL FLY caution not is below 10%.

illuminated.

1. ENGINE — Hold CRANK up to 20

6. THROTTLE — IDLE. seconds, then release.

Export Classification C, ECCN EAR99 30 OCT 2019 Rev. 5 2-9

BHT-505-FM-1 TC APPROVED

2-6. SYSTEMS CHECK 2. NR and NP needles — Check

matching and indicating 104%.

2-6-A. PRELIMINARY HYDRAULIC

3. ELT (if installed) — Check for

SYSTEM CHECK

inadvertent transmission.

NOTE 4. Flight controls — Check freedom

with minimum friction.

Uncommanded control movement or

motoring with hydraulic system off 5. PITOT HEATER ON/OFF — Confirm

may indicate hydraulic system ammeter load variation.

malfunction.

2-6-D. HYDRAULIC SYSTEM CHECK

1. HYD SYS — OFF.

2. HYD SYS — ON. NOTE

Following a cold soak start, control

2-6-B. FLAME OUT PROTECTION

feedback could be felt during the

SYSTEM (FOPS) TEST hydraulic system check. Cycle the

cyclic and collective control with

Perform the FOPS test when required by

hydraulic system ON to warm the

maintenance prior to selecting THROTTLE to

hydraulic servos and repeat the

the FLY position. A stabilization time of 30

hydraulic system check as required.

seconds at idle and collective full down is

required prior to test initiation.

NOTE

1. THROTTLE — IDLE.

Hydraulic system check is to

2. Collective — Full down. determine proper operation of

hydraulic actuators for each flight

NOTE control system. If abnormal forces,

unequal forces, control binding, or

Go to ENGINE page/TEST page to motoring are encountered, it may be

access FOPS TEST softkey. an indication of a malfunctioning

flight control actuator.

3. FOPS TST softkey — Press ON.

4. FOPS TST INPRG advisory — ON. 1. Collective — Full down.

5. FOPS TST OK advisory — ON. 2. NR — 104% RPM.

6. CAS messages — Clear. 3. HYD SYS — OFF.

2-6-C. ENGINE RUN-UP 4. Cyclic — Centered.

5. Cyclic control — Check operation by

NOTE moving cyclic in an X pattern.

The governing N P reference when 6. Collective — Check operation by

FLY is selected is 104% NP. If dual moving collective (1 to 2 inches).

controls are installed, only the flying

pilot's THROTTLE switch shall be 7. HYD SYS — ON.

positioned to FLY.

8. Cyclic and collective friction — Set

1. THROTTLE — FLY. as desired.

2-10 Rev. 5 30 OCT 2019 Export Classification C, ECCN EAR99

TC APPROVED BHT-505-FM-1

2-6-E. AUXILIARY CONTROL UNIT 2-7. BEFORE TAKEOFF

(ACU) TEST

1. PITOT HEATER — ON in visible

NOTE moisture at or below 5°C (40°F) OAT.

Perform the ACU test when required 2. ANTICOLL, POS and LDG light — As

by maintenance. required.

1. Collective — Full down. 3. PNL LT and INTERIOR LT — As

desired.

2. NR — 104% RPM.

4. Radio(s) and altimeter(s) — Set as

NOTE required.

Go to ENGINE page/TEST page to 5. Flight controls — Position and adjust

access ACU TEST softkey. To frictions for takeoff.

prevent automatic de-activation,

complete procedure within 30 sec of 6. Warnings and cautions — Clear.

ACU TEST activation.

7. Engine, transmission, and electrical

3. ACU TST softkey — Press ON. instruments — Within limits.

4. HMU AUX CTRL caution — 8. Flight and navigation instruments —

Illuminated. Check.

5. NR — Verify decreasing to 102% ±1% 9. Standby instrument battery level —

RPM. Minimum 50% for night operation.

6. Collective — Increase to

10. Altimeters — Set.

approximately 40% TQ.

7. NG — Verify increase. 11. FUEL QTY — Note indication.

8. NR — Verify stabilizing 102% ±1% 2-8. TAKEOFF

RPM.

1. Collective — Increase to hover.

9. Collective — Decrease to flat pitch.

2. Directional control — As required to

10. NR — Verify stabilizing 102% ±1%

maintain desired heading.

RPM.

11. ACU TST softkey — Press OFF. 3. Cyclic — Apply as required to

accelerate smoothly.

12. NR — 104% RPM.

4. Collective — Increase collective, up

13. HMU AUX CTRL caution — to 5% torque above hover.

Extinguished.

5. Airspeed altitude — Avoid HV

2-6-F. POWER ASSURANCE CHECK diagram shaded areas.

(PAC)

P e r f o r m t h e PA C a s p e r S e c t i o n 4 ,

Paragraph 4-2 when required by

maintenance; Turbomeca recommends every

25 hours.

Export Classification C, ECCN EAR99 6 NOV 2017 2-11

BHT-505-FM-1 TC APPROVED

2-9. IN-FLIGHT OPERATIONS NOTE

1. AIRSPEED — As desired (not to The MGT cool down stabilization

exceed VNE at flight altitude). may be performed with the collective

down with the THROTTLE switch in

2. PITOT HEATER — ON in visible the FLY or IDLE position.

moisture at or below 5°C (40°F) OAT.

1. Collective — Full down.

3. TA MUTE (if installed) — As required 2. Cyclic and pedals — Centered.

to mute the traffic/terrain advisory

audio. 3. Cyclic friction — Increase so that

cyclic maintains position.

4. Altimeters — Set.

4. LDG LTS — OFF.

2-9-A. IN-FLIGHT - TRANSFER OF

5. THROTTLE — IDLE.

CONTROL FROM PILOT A TO

PILOT B (DUAL CONTROLS 6. RPM warning — Activated.

INSTALLED)

7. Master W/C acknowledgement

softkey — Push to mute audio.

1. Pilot Not Flying (Pilot B) - THROTTLE

— FLY. 8. MGT — Stabilized for 30 seconds.

2. DUAL FLY caution — Confirm 9. OK TO SHUTDOWN advisory —

Illuminated. Confirm Illuminated.

3. Pilot A - THROTTLE — IDLE. 10. ELT (if installed) — Check for

inadvertent transmission.

4. DUAL FLY caution — Confirm 11. GEN — OFF.

Extinguished.

12. ENGINE — OFF.

2-10. DESCENT AND LANDING

13. MGT and NG — Check decreasing.

1. Warnings and cautions — Clear. 14. W/C softkey — Press to acknowledge

messages and mute warnings.

2. Engine, transmission, and electrical

instruments — Within limits. 15. Rotor brake (if installed) — Apply

fully at or below 38% NR.

3. Flight path — As required for type of

approach. 16. Flight controls — Guarded.

17. Rotor brake (if installed) — Release

4. LDG LTS — As desired.

before rotor stops.

2-11. ENGINE SHUTDOWN 18. Rotor brake handle (if installed) —

Secured.

19. ANTI COLL LT — As desired.

CAUTION

20. All switches, except HYD SYS and

DO NOT INCREASE COLLECTIVE OR BATTERY switches — OFF/NORM.

APPLY LEFT TAIL ROTOR PEDAL 21. BATT — OFF.

TO SLOW ROTOR DURING

COASTDOWN. 22. Standby instrument — OFF.

2-12 6 NOV 2017 Export Classification C, ECCN EAR99

TC APPROVED BHT-505-FM-1

2-12. POSTFLIGHT CHECK - Winds in excess of 20 knots or a

gust spread of 15 knots exists or is

forecasted.

NOTE

To prevent over filling and oil - Helicopter is parked within 150 feet

venting, it is recommended to verify of hovering or taxiing aircraft that are

oil level and replenish oil within 15 in excess of basic GW of helicopter.

minutes of engine shutdown while oil - Helicopter to be left unattended.

temperature is warm.

Do as follows:

1. Engine oil reservoir — Check oil

level. a. Install main rotor blade

tie-downs.

NOTE

b. Secure tail rotor loosely to

Refer to BHT-505-MD-1, Section 2 for tailboom with tie-down strap to

additional tie-down data. prevent excessive flapping.

2. If any of following conditions exist: c. Install exhaust cover, engine air

inlet cover, and pitot tube cover.

- Thunderstorms are in local area or

forecasted.

Export Classification C, ECCN EAR99 6 NOV 2017 2-13/2-14

You might also like

- Big Bright Ideas 3 Unit 1 Activity BookDocument10 pagesBig Bright Ideas 3 Unit 1 Activity Bookjesusito gonzalo100% (3)

- Boeing 717-200 - NORMAL CHECKLIST: Start SkytrackDocument1 pageBoeing 717-200 - NORMAL CHECKLIST: Start SkytrackSam Alcalá100% (2)

- BE20 CAE Operating HandbookDocument174 pagesBE20 CAE Operating HandbookGabedi MoNo ratings yet

- A109e Normal Checklist Rev 2Document2 pagesA109e Normal Checklist Rev 2MD Air Ops LLCNo ratings yet

- Flight Manual A109S PDFDocument290 pagesFlight Manual A109S PDFVishwadeep BargeNo ratings yet

- Aircraft Tires and Tubes: NAVAIR 04-10-506Document70 pagesAircraft Tires and Tubes: NAVAIR 04-10-506adulfo03455No ratings yet

- 206 MM CH63Document60 pages206 MM CH63VALENTINA BUITRAGO GUERRERONo ratings yet

- Weight-Balance R66 V5Document694 pagesWeight-Balance R66 V5IjoeljuliantNo ratings yet

- Section 13F - Engine Electrical System PDFDocument14 pagesSection 13F - Engine Electrical System PDFrobbertmdNo ratings yet

- VK-53 (ВК-53) Erecting Cut-Out Switch: Maintenance ManualDocument76 pagesVK-53 (ВК-53) Erecting Cut-Out Switch: Maintenance ManualhaileNo ratings yet

- Inventors Who Revolutionised Our LivesDocument214 pagesInventors Who Revolutionised Our Liveshehena100% (4)

- PD Comparison of BS 8110 With en 1992Document40 pagesPD Comparison of BS 8110 With en 1992Paul Devine100% (1)

- Ica 19001 05 Opt 1 Rev A PDFDocument12 pagesIca 19001 05 Opt 1 Rev A PDFtayo_bNo ratings yet

- BELL 505: Five Seats. Innumerable BenefitsDocument2 pagesBELL 505: Five Seats. Innumerable BenefitsHasan Özgen100% (1)

- JMB VL3 915 PohDocument51 pagesJMB VL3 915 PohnaindejardinNo ratings yet

- Kodiak AimDocument606 pagesKodiak AimricardozafraNo ratings yet

- 04-00-00 Compressed CompressedDocument157 pages04-00-00 Compressed Compresseddarwin galindez100% (1)

- A109S RFM (109G0040A013) Part I - Issue 2Document374 pagesA109S RFM (109G0040A013) Part I - Issue 2Seimon Tamayo GonzalesNo ratings yet

- 18 - Vibration and Noise Analysis and AttenuationDocument28 pages18 - Vibration and Noise Analysis and AttenuationEsang Akan100% (1)

- Flight Timer ManualDocument16 pagesFlight Timer ManualLucas SAINENo ratings yet

- BK117 D2m-HELIONIX-STEP2 FLM EN 2022.11.04 D1Document48 pagesBK117 D2m-HELIONIX-STEP2 FLM EN 2022.11.04 D1Dejan ZlatanovicNo ratings yet

- Checklist SenecaDocument2 pagesChecklist SenecaPedro Henrique PecorariNo ratings yet

- LW224ADocument68 pagesLW224Abujin.gym.essen100% (1)

- Certificado Tipo Bell 204Document10 pagesCertificado Tipo Bell 204maocartoNo ratings yet

- 206 MM CH04Document12 pages206 MM CH04AngelilloRamirez100% (2)

- Chapter 71 - Power Plant: BHT-206L4-MM-9Document54 pagesChapter 71 - Power Plant: BHT-206L4-MM-9Raisa RabeyaNo ratings yet

- Check Sistemas King Air E90-1Document4 pagesCheck Sistemas King Air E90-1sergio leivaNo ratings yet

- EC120 Transition Pilot - POIDocument7 pagesEC120 Transition Pilot - POI唐波100% (1)

- H7EU Rev 25Document43 pagesH7EU Rev 25Emanuel PerezNo ratings yet

- Installation and Rigging ProceduresDocument40 pagesInstallation and Rigging ProceduresRichard BaileyNo ratings yet

- Rapport Technique D'Evaluation: Technical ReportDocument46 pagesRapport Technique D'Evaluation: Technical ReportrajaNo ratings yet

- CE525A CJ2 PTM Vol 1 2nd Edition Mar2007 EpubDocument404 pagesCE525A CJ2 PTM Vol 1 2nd Edition Mar2007 EpubO MENo ratings yet

- FS2Crew ATR Main OpsDocument73 pagesFS2Crew ATR Main Opsstilllife87No ratings yet

- Cost-Effective, Off-the-Shelf Commercial Re-Engining: Turbofan EngineDocument2 pagesCost-Effective, Off-the-Shelf Commercial Re-Engining: Turbofan EngineStrawichDanielNo ratings yet

- NCC Operations ManualDocument24 pagesNCC Operations Manuala320100% (1)

- Type Certificate Data Sheet: No. EASA - IM.R.520Document8 pagesType Certificate Data Sheet: No. EASA - IM.R.520Oleksandr BalychevNo ratings yet

- 412 Bell ELEC SPM CH11Document40 pages412 Bell ELEC SPM CH11felix magdalenoNo ratings yet

- European Aviation Safety Agency: Easa Restricted-Type Certificate Data Sheet EASA - IM.A.351Document22 pagesEuropean Aviation Safety Agency: Easa Restricted-Type Certificate Data Sheet EASA - IM.A.351Dan CaragicaNo ratings yet

- AWBCMM0001 Maintenance ManualDocument92 pagesAWBCMM0001 Maintenance ManualCristhian342No ratings yet

- Cabina Ska 350Document136 pagesCabina Ska 350C. CONTRERAS100% (1)

- AW169 Executive and Private Transport Brochure - Gen2020Document8 pagesAW169 Executive and Private Transport Brochure - Gen2020Lavern P. Sipin100% (1)

- FPD 500 EfisDocument65 pagesFPD 500 EfispmthompNo ratings yet

- Tecnam P2010 AFMDocument234 pagesTecnam P2010 AFMMike BaldwinNo ratings yet

- BD-700 MMEL Ver9Document165 pagesBD-700 MMEL Ver9ShinYamaNo ratings yet

- Checklist & Procedures For Ms Flight Simulator by Jaydee V1.217.1Document2 pagesChecklist & Procedures For Ms Flight Simulator by Jaydee V1.217.1wiktor200834No ratings yet

- EASA TCDS - DHC-8 - Iss 12Document34 pagesEASA TCDS - DHC-8 - Iss 12bittekeinspam123100% (1)

- Bell Uh-1 Iroquois & Ah-1 HueycobraDocument21 pagesBell Uh-1 Iroquois & Ah-1 HueycobraGiora MinorNo ratings yet

- Pt6-42a Comp Turbine WashDocument8 pagesPt6-42a Comp Turbine WashSky SoccerNo ratings yet

- Main A320 FCOM FCTM Change November 2023Document17 pagesMain A320 FCOM FCTM Change November 2023j.crzgoNo ratings yet

- AvionicaSPA Company Profile - Aug 2012 enDocument55 pagesAvionicaSPA Company Profile - Aug 2012 enเสริมศักดิ์ ยิ่งสมสุขNo ratings yet

- Hawker 00XPC-Engines PDFDocument44 pagesHawker 00XPC-Engines PDFwasser75No ratings yet

- 206B3CRO206B3CROCH62Document144 pages206B3CRO206B3CROCH62camiloguayazanNo ratings yet

- Search Light WDMDocument52 pagesSearch Light WDMAbdallah MhairatNo ratings yet

- C700 Checklist GRiMDocument2 pagesC700 Checklist GRiMBaptiste Le PageNo ratings yet

- AW139 October 2020Document30 pagesAW139 October 2020paolo100% (1)

- SMFD UH-1 OPERATORS MANUAL Nov 2012Document93 pagesSMFD UH-1 OPERATORS MANUAL Nov 2012Slendrei100% (1)

- DA42 NG AFM r1 CompleteDocument400 pagesDA42 NG AFM r1 Completemacario28No ratings yet

- Clearance Bae AVRO-146-RJ85 - V.3 (October 25, 2013)Document1 pageClearance Bae AVRO-146-RJ85 - V.3 (October 25, 2013)Rodrigo ArgoteNo ratings yet

- G RedlDocument209 pagesG RedlHeiriNo ratings yet

- EASA MMEL Bell Helicopter 429-00-14032011Document41 pagesEASA MMEL Bell Helicopter 429-00-14032011Matei CiprianNo ratings yet

- A1NM Rev 30 TYPE CERTIFICATE DATA SHEET A1NM 767Document16 pagesA1NM Rev 30 TYPE CERTIFICATE DATA SHEET A1NM 767MuseNo ratings yet

- G550 MX QuizcardsDocument816 pagesG550 MX QuizcardsstiveNo ratings yet

- Section 2: Normal ProceduresDocument16 pagesSection 2: Normal Proceduresandres felipe sandoval porrasNo ratings yet

- 1.additional FI RatingsDocument1 page1.additional FI RatingshaileNo ratings yet

- 5. Đặc quyền của FI theo Phần 10 CAAVDocument1 page5. Đặc quyền của FI theo Phần 10 CAAVhaileNo ratings yet

- Bảng điện Mi-17-1VDocument20 pagesBảng điện Mi-17-1VhaileNo ratings yet

- 3. Yêu cầu của Airbus Helicopter đối với TRI (H)Document1 page3. Yêu cầu của Airbus Helicopter đối với TRI (H)haileNo ratings yet

- 091 VFR Communication Answer BRISTOLDocument8 pages091 VFR Communication Answer BRISTOLhaileNo ratings yet

- Section 1: LimitationsDocument20 pagesSection 1: LimitationshaileNo ratings yet

- 091 VFR Communication BRISTOLDocument18 pages091 VFR Communication BRISTOLhaileNo ratings yet

- Nội dung thực hành chuyển loạiDocument7 pagesNội dung thực hành chuyển loạihaileNo ratings yet

- Instructor's Training CoursesDocument5 pagesInstructor's Training CourseshaileNo ratings yet

- 2 Math and Study CourseDocument130 pages2 Math and Study CoursehaileNo ratings yet

- 13 - Question Template (Level 3)Document7 pages13 - Question Template (Level 3)haileNo ratings yet

- VK-53 (BK-53) : Maintenance ManualDocument1 pageVK-53 (BK-53) : Maintenance ManualhaileNo ratings yet

- P-503 (П-503) Airborne Recorder: Maintenance Schedule СЫ1.740.015 РОDocument24 pagesP-503 (П-503) Airborne Recorder: Maintenance Schedule СЫ1.740.015 РОhaileNo ratings yet

- схемыDocument23 pagesсхемыhaileNo ratings yet

- High Hour Runner Caterpillar 3412 DIT 540HP Diesel Marine EngineDocument2 pagesHigh Hour Runner Caterpillar 3412 DIT 540HP Diesel Marine EngineAnoop VijayakumarNo ratings yet

- 330 GC ExcavadoraDocument13 pages330 GC ExcavadoraAndres Felipe Marquez GiraldoNo ratings yet

- 234348199-Plasma-Spray-Coating - 2024-02-23T001110.506Document153 pages234348199-Plasma-Spray-Coating - 2024-02-23T001110.506hinhhits07No ratings yet

- VLSIDocument3 pagesVLSINuniwal JyotiNo ratings yet

- CSG3X5 4707858 PDFDocument31 pagesCSG3X5 4707858 PDFSorin - Viorel MaresNo ratings yet

- Unconventional ResourcesDocument8 pagesUnconventional ResourcesjuckyrNo ratings yet

- TANDO 700: High-Precision Measuring and Analysis System For Dissipation/power Factor and CapacitanceDocument8 pagesTANDO 700: High-Precision Measuring and Analysis System For Dissipation/power Factor and CapacitanceAndrew SetiawanNo ratings yet

- 10 1108 - Yc 03 2016 00590Document13 pages10 1108 - Yc 03 2016 00590AreebaNo ratings yet

- CH 1 VPO - Guest Weekly BillDocument17 pagesCH 1 VPO - Guest Weekly BillKhushali OzaNo ratings yet

- Mist Elimation in SpearatorDocument14 pagesMist Elimation in SpearatorMohamadIbnuHassanNo ratings yet

- Actix Spotlight Desktop User GuideDocument276 pagesActix Spotlight Desktop User GuidetelwindNo ratings yet

- GFHGDocument5 pagesGFHGjoshua espiritu0% (1)

- Education UcspDocument3 pagesEducation UcspzhareiNo ratings yet

- Rational Consumer Choice - IBDP Economics HL FE2022 - KognityDocument9 pagesRational Consumer Choice - IBDP Economics HL FE2022 - Kognity김채빈No ratings yet

- Evangelista, NathanS MET Activity1Document9 pagesEvangelista, NathanS MET Activity1Nathan EvangelistaNo ratings yet

- Oral Communication GR 11Document2 pagesOral Communication GR 11明 志No ratings yet

- Final Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Document21 pagesFinal Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Shenzhen Yanse Intelligent Technology Q5 Low-Power Starlight Full Color Solar Camera User Guide - Manuals+Document22 pagesShenzhen Yanse Intelligent Technology Q5 Low-Power Starlight Full Color Solar Camera User Guide - Manuals+marbin djokoNo ratings yet

- Cartaz-SeminárioTécnico Miskimins Jennifer 10-06-2011Document1 pageCartaz-SeminárioTécnico Miskimins Jennifer 10-06-2011luizlimaroqueNo ratings yet

- FRP Construction With DERAKANE Epoxy Vinylester ResinsDocument65 pagesFRP Construction With DERAKANE Epoxy Vinylester ResinstyNo ratings yet

- Sapa Meaning - Google SearchDocument1 pageSapa Meaning - Google SearchQueen JessicaNo ratings yet

- A Preliminary Assessment of Ndoola (Ndoro)Document16 pagesA Preliminary Assessment of Ndoola (Ndoro)Samuel EkpoNo ratings yet

- Ludwig Witt Gen Stein Tractatus LogicoPhilosophicusDocument196 pagesLudwig Witt Gen Stein Tractatus LogicoPhilosophicusErinNo ratings yet

- Alien Agenda InvestigatingDocument1 pageAlien Agenda InvestigatingImmigg AnationNo ratings yet

- Purnanga Pranjal A4Document1 pagePurnanga Pranjal A4api-337625785No ratings yet

- Library Guideline DOC v10 en PDFDocument79 pagesLibrary Guideline DOC v10 en PDFMai Hương VănNo ratings yet

- Offshore ANSYSDocument96 pagesOffshore ANSYSUtkarsh Ramayan100% (2)