Professional Documents

Culture Documents

Freebird PDF

Freebird PDF

Uploaded by

ninonunezCopyright:

Available Formats

You might also like

- Penny Plane by John BarkerDocument11 pagesPenny Plane by John Barkerdcloin100% (4)

- Catalogo de Peças 318D2Document472 pagesCatalogo de Peças 318D2norte hidraulicaNo ratings yet

- CommScope ION-M DAS TrainingDocument108 pagesCommScope ION-M DAS Trainingpzernik50% (2)

- Guppy Assembly ManualDocument11 pagesGuppy Assembly ManualAlfredo Arnéz Paz SoldánNo ratings yet

- Super Sweet Stik 60 Oz14406 InstructionsDocument3 pagesSuper Sweet Stik 60 Oz14406 InstructionsjuanenriquefariasrubioNo ratings yet

- Elastic-Powered Duck: Assembly InstructionsDocument5 pagesElastic-Powered Duck: Assembly Instructionsmohammad hamzaNo ratings yet

- Ornithopter 2 PDFDocument1 pageOrnithopter 2 PDFMarco Antônio Gomes ApolinarioNo ratings yet

- Elastic-Powered Turtle: Assembly InstructionsDocument5 pagesElastic-Powered Turtle: Assembly InstructionsYohana LupitaNo ratings yet

- Korean Bird Kite Instruction-NEWDocument4 pagesKorean Bird Kite Instruction-NEWAmelia Laing0% (1)

- CNT 0010494 02 PDFDocument4 pagesCNT 0010494 02 PDFNachoNo ratings yet

- Notice 5500003Document43 pagesNotice 5500003cruzetNo ratings yet

- FVT3 InstructionsDocument18 pagesFVT3 InstructionsFlash AnimationsNo ratings yet

- Sumo 3d Build LogDocument5 pagesSumo 3d Build LogbennetjeNo ratings yet

- Scraps!: J&H AerospaceDocument21 pagesScraps!: J&H AerospaceJosh TerrazasNo ratings yet

- 1:144 Space Shuttle Paper Model AssemblyDocument16 pages1:144 Space Shuttle Paper Model AssemblyjoseNo ratings yet

- BD5 Build Instructions - Stab - Wings - CoverDocument6 pagesBD5 Build Instructions - Stab - Wings - Coverandyroads2No ratings yet

- Paperformer SkyfireDocument4 pagesPaperformer SkyfireJeancraft219No ratings yet

- How To Re-String & Re-Cable The Genesis Compound Bow.: Step by Step, Picture by Picture Right Hand Models ONLYDocument61 pagesHow To Re-String & Re-Cable The Genesis Compound Bow.: Step by Step, Picture by Picture Right Hand Models ONLYEdgars MurnieksNo ratings yet

- Super DecathlonDocument22 pagesSuper DecathlonIwan MaspaitellaNo ratings yet

- Assembling A Can SealerDocument12 pagesAssembling A Can SealerPlantain frankyNo ratings yet

- Assembly Manual: SpecificationsDocument19 pagesAssembly Manual: SpecificationsParpala BogdanNo ratings yet

- Super Chipmunk Goldberg 64in Oz7614 InstructionsDocument35 pagesSuper Chipmunk Goldberg 64in Oz7614 InstructionsMatNo ratings yet

- Munchkin: Assembly Instructions: Assemble The HeadDocument10 pagesMunchkin: Assembly Instructions: Assemble The HeadvistablancaNo ratings yet

- ME262 Build Log Rev ADocument26 pagesME262 Build Log Rev AJuan QuintanaNo ratings yet

- Toxic & Enigma Crossbow Owner'S Guide Theory Recurve Owner'S GuideDocument13 pagesToxic & Enigma Crossbow Owner'S Guide Theory Recurve Owner'S GuidePak Cik FauzyNo ratings yet

- Specifications: Assembly ManualDocument23 pagesSpecifications: Assembly ManualTitanium PenNo ratings yet

- Universal Auto Feed Reel Easy String Head: WarningDocument6 pagesUniversal Auto Feed Reel Easy String Head: WarningElena CMNo ratings yet

- Freebird PDFDocument5 pagesFreebird PDFHHOLINo ratings yet

- Trilobite WatchbandDocument4 pagesTrilobite Watchbandkleinschmidt.ryan28No ratings yet

- Wing Installation Section VDocument36 pagesWing Installation Section Vmohamed sidkyNo ratings yet

- Dalmatian: Assembly Instructions: Assemble The HeadDocument4 pagesDalmatian: Assembly Instructions: Assemble The HeadCesar De la FuenteNo ratings yet

- Flow Hive US-WRC Assembly Guide 250216 PDFDocument5 pagesFlow Hive US-WRC Assembly Guide 250216 PDFJosepNo ratings yet

- CC Edge 540 - WingbuildDocument17 pagesCC Edge 540 - WingbuildHusein HabsyiNo ratings yet

- Fly Fishing Basic SetupDocument8 pagesFly Fishing Basic SetupVop MirNo ratings yet

- Tyrannosaurus Rex InstructionsDocument5 pagesTyrannosaurus Rex InstructionsClick MediaNo ratings yet

- Rope MachineDocument4 pagesRope Machineamanda grovesNo ratings yet

- Winter Wool Cape: Sewing School InstructionsDocument1 pageWinter Wool Cape: Sewing School InstructionsGary RojasNo ratings yet

- Ukulele Kit Assembly Instructions: Getting Started Supplies ContinuedDocument10 pagesUkulele Kit Assembly Instructions: Getting Started Supplies ContinuedPablo PolettoNo ratings yet

- CNT 0011614 02Document5 pagesCNT 0011614 02Kuki34 RetNo ratings yet

- Pelicano Dalmata InstDocument9 pagesPelicano Dalmata InstEsteban NichoNo ratings yet

- BH64-Instruction Manual COSAIRDocument32 pagesBH64-Instruction Manual COSAIRDougNo ratings yet

- Accu Link Belt InstructionsDocument1 pageAccu Link Belt InstructionsewintersNo ratings yet

- PakCanoe Assembly 2016Document6 pagesPakCanoe Assembly 2016macbeni1969No ratings yet

- Lockheed SR-71 BlackbirdDocument4 pagesLockheed SR-71 BlackbirdAviation/Space History Library0% (1)

- F-22 Construction Guide-Scratchbuild 13Document14 pagesF-22 Construction Guide-Scratchbuild 13Mar PopNo ratings yet

- BD 5 InstructionsDocument13 pagesBD 5 InstructionskokiskoNo ratings yet

- CNT 0010308 04Document5 pagesCNT 0010308 04thaisonjpoNo ratings yet

- PDF Notes and Tips: Plane RequirementsDocument20 pagesPDF Notes and Tips: Plane RequirementsCarlos F programaciónNo ratings yet

- I5399 Neckjig instxRGB PDFDocument9 pagesI5399 Neckjig instxRGB PDFPaulNo ratings yet

- Polytarp Junk SailDocument10 pagesPolytarp Junk SailScott GieferNo ratings yet

- Guppyassemblymanual PDFDocument11 pagesGuppyassemblymanual PDFmarianospenza100% (1)

- Freedom Flyer: For Single & Double Treadle Joy Spinning WheelsDocument2 pagesFreedom Flyer: For Single & Double Treadle Joy Spinning WheelsSad ElfNo ratings yet

- Assembly Instructions: Arh TigerDocument12 pagesAssembly Instructions: Arh TigerHewertonMenezesNo ratings yet

- FreebirdDocument5 pagesFreebirdLucas Nahuel AsiainNo ratings yet

- Replacement Plumb Bobs Manual ME 9868ADocument3 pagesReplacement Plumb Bobs Manual ME 9868A이지민No ratings yet

- Manual pt19Document28 pagesManual pt19ricardoNo ratings yet

- Sportster Bipe 40 ManualDocument32 pagesSportster Bipe 40 ManualMolocromNo ratings yet

- The Duck - A Free-Flight Model AirplaneDocument6 pagesThe Duck - A Free-Flight Model AirplaneBob Kowalski100% (1)

- Ornitoptero PDFDocument5 pagesOrnitoptero PDFninonunezNo ratings yet

- A Model Boat Builder's Guide to Sail Making - A Collection of Historical Articles on the Planning and Construction of Model SailsFrom EverandA Model Boat Builder's Guide to Sail Making - A Collection of Historical Articles on the Planning and Construction of Model SailsNo ratings yet

- Beaded Bugs: Make 30 Moths, Butterflies, Beetles, and Other Cute CrittersFrom EverandBeaded Bugs: Make 30 Moths, Butterflies, Beetles, and Other Cute CrittersRating: 4.5 out of 5 stars4.5/5 (1)

- Trio System LuminaireDocument4 pagesTrio System LuminaireToto SukisnoNo ratings yet

- UPS DataDocument36 pagesUPS Datasumitsharma2010No ratings yet

- Encoder LIKA Catalogo GeneraleDocument24 pagesEncoder LIKA Catalogo Generalekuhn403825No ratings yet

- Danfoss Prop PDFDocument56 pagesDanfoss Prop PDFRicardo A. Custodio100% (1)

- Alcatel AT01 L2 Service ManualDocument22 pagesAlcatel AT01 L2 Service ManualEdgar Jose Aranguibel MorilloNo ratings yet

- PLC Seminar Report by SAIKRISHNADocument10 pagesPLC Seminar Report by SAIKRISHNASAIKRISHNA GUNDEMONINo ratings yet

- Bandas Industriales DAYCO PDFDocument70 pagesBandas Industriales DAYCO PDFdidi_carolaNo ratings yet

- lc090 2 Way Car Alarm System Host ManualDocument11 pageslc090 2 Way Car Alarm System Host Manualhebert.taypeNo ratings yet

- Cell Balancing in Electric Vehicle Battery Pack IJERTV11IS040239Document6 pagesCell Balancing in Electric Vehicle Battery Pack IJERTV11IS040239Praveen Kumar PandeyNo ratings yet

- Marantz 2245 Owner's ManualDocument28 pagesMarantz 2245 Owner's Manualnzerone691880No ratings yet

- Asr 9010Document98 pagesAsr 9010tiagomonsoresNo ratings yet

- Union Special 200-38 PDFDocument60 pagesUnion Special 200-38 PDFRobiyyanaNo ratings yet

- Discover 100Document40 pagesDiscover 100fsdfs100% (1)

- M126 - Datasheet 23423523Document2 pagesM126 - Datasheet 23423523Bagus FatkhurroziNo ratings yet

- Man Lifts: Trailer MountedDocument4 pagesMan Lifts: Trailer MountedPelonky ManiaNo ratings yet

- TCL L32D3260-MT10B-LA 1service Manual PDFDocument62 pagesTCL L32D3260-MT10B-LA 1service Manual PDFKornaek SaelimNo ratings yet

- DS0201Document9 pagesDS0201Dimitrios ChristodoulouNo ratings yet

- Annexure VI QAP For 30KW PMA and ControllerDocument27 pagesAnnexure VI QAP For 30KW PMA and Controllerrakesh bardepurNo ratings yet

- FYP Proposal (ARREY HAZIQ0Document7 pagesFYP Proposal (ARREY HAZIQ0LIEW HUI FANG UNIMAPNo ratings yet

- Especificaciones DVR PDFDocument1 pageEspecificaciones DVR PDFPascual DuqueNo ratings yet

- 66 Distance System, Cruise Control, Remote OperationDocument33 pages66 Distance System, Cruise Control, Remote OperationaterrohotmailNo ratings yet

- 4 - Midea VRF Unit DetailsDocument33 pages4 - Midea VRF Unit DetailsVenu GopalNo ratings yet

- NB BlocktypeDocument21 pagesNB BlocktypesunhuynhNo ratings yet

- Service Manual: Room Air ConditionerDocument114 pagesService Manual: Room Air Conditionernmo1122No ratings yet

- Technical Manual: Night Vision Equipment Data SheetsDocument33 pagesTechnical Manual: Night Vision Equipment Data SheetsVoltaireZeroNo ratings yet

- GBW15P 2022 10 25 22 12 29Document9 pagesGBW15P 2022 10 25 22 12 29Alfredo LechinNo ratings yet

- Firmware Functional Description MPH-03, MPB-03, MPD-03 R911308329 - 01 PDFDocument816 pagesFirmware Functional Description MPH-03, MPB-03, MPD-03 R911308329 - 01 PDFCristopher EntenaNo ratings yet

Freebird PDF

Freebird PDF

Uploaded by

ninonunezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Freebird PDF

Freebird PDF

Uploaded by

ninonunezCopyright:

Available Formats

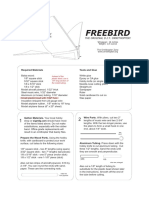

FREEBIRD

ORNITHOPTER - FLAPPING WING MODEL KIT

Congratulations on choosing The Ornithopter Zone's Freebird ornithopter kit designed

by Nathan Chronister. It's the perfect introduction to building your own ornithopters! To

build this kit, you will need scissors, a hobby knife, needle-nose pliers, straight pins,

white glue, and epoxy or CA instant glue. Read all instructions before you begin.

TAIL

Arrange wing and tail outlines on the

WING HINGE TUBES tissue sheet as shown. Carefully mark

front the centerline on the wing. Save the

view excess tissue for later.

ΠTrace the wing and tail outlines onto the tissue paper as shown and cut them out.

• Epoxy one of the 1/2" aluminum tubes to the 1/2" basswood spacer.

Fuselage: Make sure they are parallel. Be careful not to get any glue inside the tube.

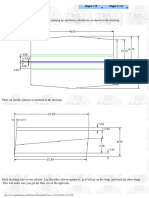

You can build Ž Locate the three balsawood pieces for the fuselage (body). Assemble with white glue.

this right on the Also cut and assemble the two balsa pieces for the tail. See tail diagram for more instructions.

plan sheet if you

• With pliers, bend the 2" wire pieces to make the two wing lever wires. You may want to practice

cover it with wax

paper first. first using a paperclip. Follow instructions below to attach wing lever wires to the wing spars.

TAIL WIRE front view of

assembled mechanism

SPACER Raise hook and hold

CRANK FRONT MOTOR HOOK REAR MOTOR HOOK pliers as shown to

BEARING make this bend.

• When the fuselage is dry, bend one of the 2-3/4" wire pieces to form the rear motor hook. Use a straight pin to make a

pilot hole, and then insert the wire through the fuselage, applying glue to the wire to coat the inside of the hole. Bend the

free end of the wire as shown. The last 1/8" at the end of the tail wire must be straight up and down.

‘ Crank assembly: Bend one of the 2-3/4" wires to form the front motor hook. Insert the wire through the bearing tube.

Add the small plastic bead. Bend the crank wire as shown in the front and side views. The crank radius should be 3/8"

or slightly less. Glue the crank assembly onto the fuselage. Glue the two aluminum wing hinge tubes to the top of the

fuselage, side by side. Be careful not to get any glue inside the tubes. Glue the tail to the tail wire as shown in the tail

diagram. Put something under the tail to support it while the glue dries.

’ Using a one-to-one mixture of glue and water, reinforce shaded areas with tissue. Cut the tissue strips narrow enough

so they don't stick out beyond the wood, and be careful not to get any glue in the wing hinge tubes. Apply four layers of

tissue around the crank assembly and three wraps elsewhere. ” Move the wings

“ Scrape excess glue from the wing lever wires. Fit the wing lever wires into the wing hinge tubes. to their lowest position. Apply

Then add the connecting rods. Support the wings from behind so you don't bend the glue/water mixture to the top of the wing spars. Glue the

wing lever wires. The first connecting rod goes past the first two bends in the crank, leading edge of the tissue in place and smooth out any wrinkles.

and it drives the left wing. The second connecting rod goes on the • Make sure the spars are all the way into the wing hinge tubes.

outermost part of the crank and drives the right wing. Glue the wing tissue to the top of the fuselage so that the

Wings should move freely when you turn the crank. marked centerline is parallel with the top of the fuselage.

Cut the plastic tubing into three sections and slide it To bend wire, grip

onto the wires to hold the connecting rods in place. with pliers and push Flight: Bend the tail up about 10°. Double the rubber band and hook it onto the

near the base. motor hooks with the knot in back. The band will last longer if you rub it with

Bend will fall about 1/32" from

vegetable oil before flying and store it away from light. You may also oil the crank

plier jaws. Position accordingly. WING wire. Wind up 80 turns and launch gently against the wind, pointing up 30°. If the

LEVER ornithopter dives, bend the tail up more. If it stalls, decrease the tail angle. To make

WIRE

CONNECTING RODS (2) it fly straighter, try winding the opposite direction or add a little weight to one wingtip.

make holes 2-5/16" apart with straight pin Wing lever wires: Bends must be

sharp and square. Use a straight pin to

make a pilot hole through the wing spar, Tail: You will need to cut an angle in the tail pieces so they fit together as shown.

fill hole with glue, then insert wire. The Assemble with white glue. Apply tissue to the tail frame using white glue and one part water.

middle part of the wire should be glued

© 2003 Nathan Chronister parallel with the spar.

TAIL WIRE see step five

You might also like

- Penny Plane by John BarkerDocument11 pagesPenny Plane by John Barkerdcloin100% (4)

- Catalogo de Peças 318D2Document472 pagesCatalogo de Peças 318D2norte hidraulicaNo ratings yet

- CommScope ION-M DAS TrainingDocument108 pagesCommScope ION-M DAS Trainingpzernik50% (2)

- Guppy Assembly ManualDocument11 pagesGuppy Assembly ManualAlfredo Arnéz Paz SoldánNo ratings yet

- Super Sweet Stik 60 Oz14406 InstructionsDocument3 pagesSuper Sweet Stik 60 Oz14406 InstructionsjuanenriquefariasrubioNo ratings yet

- Elastic-Powered Duck: Assembly InstructionsDocument5 pagesElastic-Powered Duck: Assembly Instructionsmohammad hamzaNo ratings yet

- Ornithopter 2 PDFDocument1 pageOrnithopter 2 PDFMarco Antônio Gomes ApolinarioNo ratings yet

- Elastic-Powered Turtle: Assembly InstructionsDocument5 pagesElastic-Powered Turtle: Assembly InstructionsYohana LupitaNo ratings yet

- Korean Bird Kite Instruction-NEWDocument4 pagesKorean Bird Kite Instruction-NEWAmelia Laing0% (1)

- CNT 0010494 02 PDFDocument4 pagesCNT 0010494 02 PDFNachoNo ratings yet

- Notice 5500003Document43 pagesNotice 5500003cruzetNo ratings yet

- FVT3 InstructionsDocument18 pagesFVT3 InstructionsFlash AnimationsNo ratings yet

- Sumo 3d Build LogDocument5 pagesSumo 3d Build LogbennetjeNo ratings yet

- Scraps!: J&H AerospaceDocument21 pagesScraps!: J&H AerospaceJosh TerrazasNo ratings yet

- 1:144 Space Shuttle Paper Model AssemblyDocument16 pages1:144 Space Shuttle Paper Model AssemblyjoseNo ratings yet

- BD5 Build Instructions - Stab - Wings - CoverDocument6 pagesBD5 Build Instructions - Stab - Wings - Coverandyroads2No ratings yet

- Paperformer SkyfireDocument4 pagesPaperformer SkyfireJeancraft219No ratings yet

- How To Re-String & Re-Cable The Genesis Compound Bow.: Step by Step, Picture by Picture Right Hand Models ONLYDocument61 pagesHow To Re-String & Re-Cable The Genesis Compound Bow.: Step by Step, Picture by Picture Right Hand Models ONLYEdgars MurnieksNo ratings yet

- Super DecathlonDocument22 pagesSuper DecathlonIwan MaspaitellaNo ratings yet

- Assembling A Can SealerDocument12 pagesAssembling A Can SealerPlantain frankyNo ratings yet

- Assembly Manual: SpecificationsDocument19 pagesAssembly Manual: SpecificationsParpala BogdanNo ratings yet

- Super Chipmunk Goldberg 64in Oz7614 InstructionsDocument35 pagesSuper Chipmunk Goldberg 64in Oz7614 InstructionsMatNo ratings yet

- Munchkin: Assembly Instructions: Assemble The HeadDocument10 pagesMunchkin: Assembly Instructions: Assemble The HeadvistablancaNo ratings yet

- ME262 Build Log Rev ADocument26 pagesME262 Build Log Rev AJuan QuintanaNo ratings yet

- Toxic & Enigma Crossbow Owner'S Guide Theory Recurve Owner'S GuideDocument13 pagesToxic & Enigma Crossbow Owner'S Guide Theory Recurve Owner'S GuidePak Cik FauzyNo ratings yet

- Specifications: Assembly ManualDocument23 pagesSpecifications: Assembly ManualTitanium PenNo ratings yet

- Universal Auto Feed Reel Easy String Head: WarningDocument6 pagesUniversal Auto Feed Reel Easy String Head: WarningElena CMNo ratings yet

- Freebird PDFDocument5 pagesFreebird PDFHHOLINo ratings yet

- Trilobite WatchbandDocument4 pagesTrilobite Watchbandkleinschmidt.ryan28No ratings yet

- Wing Installation Section VDocument36 pagesWing Installation Section Vmohamed sidkyNo ratings yet

- Dalmatian: Assembly Instructions: Assemble The HeadDocument4 pagesDalmatian: Assembly Instructions: Assemble The HeadCesar De la FuenteNo ratings yet

- Flow Hive US-WRC Assembly Guide 250216 PDFDocument5 pagesFlow Hive US-WRC Assembly Guide 250216 PDFJosepNo ratings yet

- CC Edge 540 - WingbuildDocument17 pagesCC Edge 540 - WingbuildHusein HabsyiNo ratings yet

- Fly Fishing Basic SetupDocument8 pagesFly Fishing Basic SetupVop MirNo ratings yet

- Tyrannosaurus Rex InstructionsDocument5 pagesTyrannosaurus Rex InstructionsClick MediaNo ratings yet

- Rope MachineDocument4 pagesRope Machineamanda grovesNo ratings yet

- Winter Wool Cape: Sewing School InstructionsDocument1 pageWinter Wool Cape: Sewing School InstructionsGary RojasNo ratings yet

- Ukulele Kit Assembly Instructions: Getting Started Supplies ContinuedDocument10 pagesUkulele Kit Assembly Instructions: Getting Started Supplies ContinuedPablo PolettoNo ratings yet

- CNT 0011614 02Document5 pagesCNT 0011614 02Kuki34 RetNo ratings yet

- Pelicano Dalmata InstDocument9 pagesPelicano Dalmata InstEsteban NichoNo ratings yet

- BH64-Instruction Manual COSAIRDocument32 pagesBH64-Instruction Manual COSAIRDougNo ratings yet

- Accu Link Belt InstructionsDocument1 pageAccu Link Belt InstructionsewintersNo ratings yet

- PakCanoe Assembly 2016Document6 pagesPakCanoe Assembly 2016macbeni1969No ratings yet

- Lockheed SR-71 BlackbirdDocument4 pagesLockheed SR-71 BlackbirdAviation/Space History Library0% (1)

- F-22 Construction Guide-Scratchbuild 13Document14 pagesF-22 Construction Guide-Scratchbuild 13Mar PopNo ratings yet

- BD 5 InstructionsDocument13 pagesBD 5 InstructionskokiskoNo ratings yet

- CNT 0010308 04Document5 pagesCNT 0010308 04thaisonjpoNo ratings yet

- PDF Notes and Tips: Plane RequirementsDocument20 pagesPDF Notes and Tips: Plane RequirementsCarlos F programaciónNo ratings yet

- I5399 Neckjig instxRGB PDFDocument9 pagesI5399 Neckjig instxRGB PDFPaulNo ratings yet

- Polytarp Junk SailDocument10 pagesPolytarp Junk SailScott GieferNo ratings yet

- Guppyassemblymanual PDFDocument11 pagesGuppyassemblymanual PDFmarianospenza100% (1)

- Freedom Flyer: For Single & Double Treadle Joy Spinning WheelsDocument2 pagesFreedom Flyer: For Single & Double Treadle Joy Spinning WheelsSad ElfNo ratings yet

- Assembly Instructions: Arh TigerDocument12 pagesAssembly Instructions: Arh TigerHewertonMenezesNo ratings yet

- FreebirdDocument5 pagesFreebirdLucas Nahuel AsiainNo ratings yet

- Replacement Plumb Bobs Manual ME 9868ADocument3 pagesReplacement Plumb Bobs Manual ME 9868A이지민No ratings yet

- Manual pt19Document28 pagesManual pt19ricardoNo ratings yet

- Sportster Bipe 40 ManualDocument32 pagesSportster Bipe 40 ManualMolocromNo ratings yet

- The Duck - A Free-Flight Model AirplaneDocument6 pagesThe Duck - A Free-Flight Model AirplaneBob Kowalski100% (1)

- Ornitoptero PDFDocument5 pagesOrnitoptero PDFninonunezNo ratings yet

- A Model Boat Builder's Guide to Sail Making - A Collection of Historical Articles on the Planning and Construction of Model SailsFrom EverandA Model Boat Builder's Guide to Sail Making - A Collection of Historical Articles on the Planning and Construction of Model SailsNo ratings yet

- Beaded Bugs: Make 30 Moths, Butterflies, Beetles, and Other Cute CrittersFrom EverandBeaded Bugs: Make 30 Moths, Butterflies, Beetles, and Other Cute CrittersRating: 4.5 out of 5 stars4.5/5 (1)

- Trio System LuminaireDocument4 pagesTrio System LuminaireToto SukisnoNo ratings yet

- UPS DataDocument36 pagesUPS Datasumitsharma2010No ratings yet

- Encoder LIKA Catalogo GeneraleDocument24 pagesEncoder LIKA Catalogo Generalekuhn403825No ratings yet

- Danfoss Prop PDFDocument56 pagesDanfoss Prop PDFRicardo A. Custodio100% (1)

- Alcatel AT01 L2 Service ManualDocument22 pagesAlcatel AT01 L2 Service ManualEdgar Jose Aranguibel MorilloNo ratings yet

- PLC Seminar Report by SAIKRISHNADocument10 pagesPLC Seminar Report by SAIKRISHNASAIKRISHNA GUNDEMONINo ratings yet

- Bandas Industriales DAYCO PDFDocument70 pagesBandas Industriales DAYCO PDFdidi_carolaNo ratings yet

- lc090 2 Way Car Alarm System Host ManualDocument11 pageslc090 2 Way Car Alarm System Host Manualhebert.taypeNo ratings yet

- Cell Balancing in Electric Vehicle Battery Pack IJERTV11IS040239Document6 pagesCell Balancing in Electric Vehicle Battery Pack IJERTV11IS040239Praveen Kumar PandeyNo ratings yet

- Marantz 2245 Owner's ManualDocument28 pagesMarantz 2245 Owner's Manualnzerone691880No ratings yet

- Asr 9010Document98 pagesAsr 9010tiagomonsoresNo ratings yet

- Union Special 200-38 PDFDocument60 pagesUnion Special 200-38 PDFRobiyyanaNo ratings yet

- Discover 100Document40 pagesDiscover 100fsdfs100% (1)

- M126 - Datasheet 23423523Document2 pagesM126 - Datasheet 23423523Bagus FatkhurroziNo ratings yet

- Man Lifts: Trailer MountedDocument4 pagesMan Lifts: Trailer MountedPelonky ManiaNo ratings yet

- TCL L32D3260-MT10B-LA 1service Manual PDFDocument62 pagesTCL L32D3260-MT10B-LA 1service Manual PDFKornaek SaelimNo ratings yet

- DS0201Document9 pagesDS0201Dimitrios ChristodoulouNo ratings yet

- Annexure VI QAP For 30KW PMA and ControllerDocument27 pagesAnnexure VI QAP For 30KW PMA and Controllerrakesh bardepurNo ratings yet

- FYP Proposal (ARREY HAZIQ0Document7 pagesFYP Proposal (ARREY HAZIQ0LIEW HUI FANG UNIMAPNo ratings yet

- Especificaciones DVR PDFDocument1 pageEspecificaciones DVR PDFPascual DuqueNo ratings yet

- 66 Distance System, Cruise Control, Remote OperationDocument33 pages66 Distance System, Cruise Control, Remote OperationaterrohotmailNo ratings yet

- 4 - Midea VRF Unit DetailsDocument33 pages4 - Midea VRF Unit DetailsVenu GopalNo ratings yet

- NB BlocktypeDocument21 pagesNB BlocktypesunhuynhNo ratings yet

- Service Manual: Room Air ConditionerDocument114 pagesService Manual: Room Air Conditionernmo1122No ratings yet

- Technical Manual: Night Vision Equipment Data SheetsDocument33 pagesTechnical Manual: Night Vision Equipment Data SheetsVoltaireZeroNo ratings yet

- GBW15P 2022 10 25 22 12 29Document9 pagesGBW15P 2022 10 25 22 12 29Alfredo LechinNo ratings yet

- Firmware Functional Description MPH-03, MPB-03, MPD-03 R911308329 - 01 PDFDocument816 pagesFirmware Functional Description MPH-03, MPB-03, MPD-03 R911308329 - 01 PDFCristopher EntenaNo ratings yet