Professional Documents

Culture Documents

16 MC324 Strength of Materials I - Unlocked

16 MC324 Strength of Materials I - Unlocked

Uploaded by

ultimatedroiidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16 MC324 Strength of Materials I - Unlocked

16 MC324 Strength of Materials I - Unlocked

Uploaded by

ultimatedroiidCopyright:

Available Formats

NATIONAL UNIVERSITY OF ENGINEERING

COLLEGE OF MECHANICAL ENGINEERING

MECHANICAL ENGINEERING PROGRAM

MC324 – STRENGTH OF MATERIALS I

I. GENERAL INFORMATION

CODE : MC324 Strength of Materials I

SEMESTER : 5

CREDITS : 5

HOURS PER WEEK : 6 (Theory, Practice)

PREREQUISITES : MC337 Statics

CONDITION : Compulsory

II. COURSE DESCRIPTION

This course provides students with basic concepts of the elastic body behavior. Concepts of stress, strain

and displacement as response to several types of solicitation (isolated or combined), and the application of

these provide the foundations for the development of the structure area courses. This course is made up of

topics such as axial solicitation, shear stress bending, bending moment, torsional moment and responses

in terms of stress and strain. In all the theory exposed, application problems are solved.

III. COURSE OUTCOMES

1. Identify the characteristics of deformable elastic bodies and interpret their properties.

2. Apply knowledge and skills in science and mathematics to solve problems.

3. Understand the behavior of an elastic body subject to external solicitations: Axial, shear, bending

and torsional.

4. Understand the proper use of materials, taking into consideration their characteristics of strength

and deformability.

5. Interpret the rigor and the objectivity of the theories exposed in the course and their applications.

6. Apply the knowledge given in class to the solution of related problems.

IV. LEARNING UNITS

1. AXIAL SOLICITATIONS / 18 HOURS

Elasticity / Traction and compression axial solicitations / Compression and tensile axial strain / Axial strain /

Normal stress / Hooke’s law / Stress-strain curve / Allowable stress / Transverse strain: Poisson’s ratio /

Nodes Displacement in structures / Isostatics / Stress and strain due to the own weight and to temperature

variations / Stresses and strains due to inertial forces / Analysis of statically indeterminate structures

subject to axial solicitation / Connections: Shear stress and shear strain unit / Stress in inclined planes.

2. STRESSES IN AN ELASTIC BODY POINT / 9 HOURS

Components of the stress in an elastic body point: / Stress tensor / Components of the strain in an elastic

body point: strain tensor / Generalized Hooke’s Law / The state of pure shear: Relationship between shear

stress and shear strain unit / Volumetric variation: Compressibility or expansion module.

3. STRESS AND STRAIN PLANE STATE / 9 HOURS

Plane stress state / Plane strain state / Stress calculation in a point of stress or strain plane state: Main

planes and stresses / Mohr’s stress circle / Strain calculation in a strain plane state point: Planes of main

unit strain / Mohr’s circle for strains.

4. TRIAXIAL STATE OF STRESS / 6 HOURS

Stress variation in an elastic body point / Normal stress variation / Stress ellipsoid / Determination of the

main stresses / Determination of the maximum and minimum shear stress planes / Strains in a elastic

body point / Main unit strains.

5. TORSION / 6 HOURS

Circular shafts torsion: fundamental hypotheses / Stresses and strains / Design of circular section / Power

transmission / Coupling of shafts subject to torsion by bolted flanges / Hyperstatic problems.

6. BENDING / 12 HOURS

Simple bending of prismatic bars / Fundamental hypotheses / Normal and shear stress / Stress and strain

distribution in the cross section / Design and testing of beams for bending and shear.

7. STRAIN IN BEAMS / 8 HOURS

Elastic shaft equation / Angular and linear displacement of a section / Strains and displacements in

isostatic beams / Double integration method.

8. REDUCED MOMENT-AREA METHOD / 8 HOURS

First and second theorem / Sign convention / Bending moment diagram by parts.

9. CONJUGATE BEAM METHOD / 8 HOURS

First and second proposition / Displacements in isostatic beams.

V. METHODOLOGY

This course is carried out in theory and practical sessions. In theory sessions, the instructor introduces

concepts of the theory in the teaching-learning process, in which students participate either individually or

in work groups. The instructor exposes and gives examples to complement students’ activities. Classroom

work is complemented with homework. The instructor provides students with theory and problem offprints.

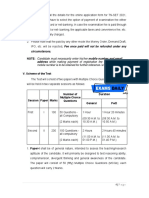

VI. EVALUATION FORMULA

The average grade PF is calculated as follows:

PF= 0.25 EP + 0.50 EF + 0.25 PP

EP: Mid-Term Exam EF: Final Exam

PP: Average of six quizzes

VII. BIBLIOGRAPHY

1. GERE, J.M. AND TIMOSHENKO, S.P.

Mechanics of Materials

Thomson Ed., 2006

2. BEER & JOHNSTON

Mechanics of Materials

Editorial McGrawHill, 2010

You might also like

- Sample Thesis Defense Questions and AnswersDocument6 pagesSample Thesis Defense Questions and AnswersMarjon Maurillo Lucero100% (8)

- MYP 2 IntegersDocument6 pagesMYP 2 IntegersYomna SherifNo ratings yet

- (07238) - ASCE 28-00 Standard Practice For Direct Design of Precast Concrete Box Sections For Jacking in Trenchless Construction - ASSCE StandardDocument63 pages(07238) - ASCE 28-00 Standard Practice For Direct Design of Precast Concrete Box Sections For Jacking in Trenchless Construction - ASSCE Standardรศ.ดร.เฉลิมเกียรติ วงศ์วนิชทวีNo ratings yet

- C5 ES531 Strength of Materials IDocument2 pagesC5 ES531 Strength of Materials IArturo AnticonaNo ratings yet

- BCE-14 Structural Mechanics - IDocument2 pagesBCE-14 Structural Mechanics - IUtkarsh ChaudharyNo ratings yet

- National University of Engineering College of Mechanical Engineering Mechanical-Electrical Engineering ProgramDocument2 pagesNational University of Engineering College of Mechanical Engineering Mechanical-Electrical Engineering ProgramMilton AguilarNo ratings yet

- Goods and Services Mech 101 Course Outline 2020Document8 pagesGoods and Services Mech 101 Course Outline 2020Teddy MukadzamboNo ratings yet

- C3 EC111 StaticsDocument2 pagesC3 EC111 StaticsAlexandro Paredes VillarNo ratings yet

- National University of Engineering College of Mechanical Engineering Mechanical Engineering ProgramDocument2 pagesNational University of Engineering College of Mechanical Engineering Mechanical Engineering Programjorge luisNo ratings yet

- 08 FI203 Physics I 1Document2 pages08 FI203 Physics I 1Riswan RiswanNo ratings yet

- Mech 101 Course Outline 2022Document8 pagesMech 101 Course Outline 2022teddiengadzeNo ratings yet

- MCE 205 Strength of MaterialsDocument2 pagesMCE 205 Strength of MaterialsKarthiNo ratings yet

- N201 CF121 Physics IDocument2 pagesN201 CF121 Physics IJuan EspejoNo ratings yet

- JSDO1asd 3n AsdDocument2 pagesJSDO1asd 3n AsdAnonimus290599No ratings yet

- CivilsyllDocument133 pagesCivilsyllManoj ReddyNo ratings yet

- Unit 1 Part 1Document32 pagesUnit 1 Part 1ramamurthiNo ratings yet

- Course Book,,STMDocument11 pagesCourse Book,,STMMariwan MirNo ratings yet

- L201 FI203 Physics IDocument2 pagesL201 FI203 Physics IghmoralesfNo ratings yet

- Course Outline: International Islamic University MalaysiaDocument6 pagesCourse Outline: International Islamic University Malaysiade_stanszaNo ratings yet

- Unit I-1Document44 pagesUnit I-1sanjaymagnetoooNo ratings yet

- Ciclo IIIDocument7 pagesCiclo IIIAlexandro Paredes VillarNo ratings yet

- Course Outcomes StaticDocument5 pagesCourse Outcomes StaticAsmadi YussufNo ratings yet

- S. E. Mech. Engg. June 2013 PDFDocument34 pagesS. E. Mech. Engg. June 2013 PDFDinesh PatilNo ratings yet

- BMEE202L - MECHANICS-OF-SOLIDS - TH - 1.0 - 70 - BMEE202L - Mechanics of SolidsDocument2 pagesBMEE202L - MECHANICS-OF-SOLIDS - TH - 1.0 - 70 - BMEE202L - Mechanics of SolidsShin ChanNo ratings yet

- General Physics SylabusDocument5 pagesGeneral Physics SylabusTadesse AbateNo ratings yet

- Course Handbook Mech 1054 2011-2012Document10 pagesCourse Handbook Mech 1054 2011-2012Ahmar RazaNo ratings yet

- ES 321 (Strength of Materials) SyllabusDocument2 pagesES 321 (Strength of Materials) SyllabusHarold TaylorNo ratings yet

- Lecture 1Document16 pagesLecture 1k.ghanemNo ratings yet

- Syllabus Mechanism of MaterialDocument3 pagesSyllabus Mechanism of Materialvikaskumar1986No ratings yet

- Strenght of Materials I enDocument2 pagesStrenght of Materials I ensarajevo96No ratings yet

- Course Title: Strength of Materials: Teaching Hours Revised Bloom's Taxonomy (RBT) LevelDocument21 pagesCourse Title: Strength of Materials: Teaching Hours Revised Bloom's Taxonomy (RBT) LevelSrinivas V RaoNo ratings yet

- MENG1003 Course Descriptor (1) - 54645703Document7 pagesMENG1003 Course Descriptor (1) - 54645703Gregory CameraNo ratings yet

- Strength of Material SugDocument8 pagesStrength of Material Sugspraveen123No ratings yet

- III Sem Course Handout Mos Mec 206Document11 pagesIII Sem Course Handout Mos Mec 206Dr Praveen KumarNo ratings yet

- CE 302 Mechanics of Materials SyllabusDocument2 pagesCE 302 Mechanics of Materials SyllabusAhmet TükenNo ratings yet

- 21CV33 SomDocument78 pages21CV33 SomFarhan AhmedNo ratings yet

- Phy-101 & 102Document3 pagesPhy-101 & 102syedsunnyshah321No ratings yet

- S - Y - B Tech - Mech - Sem-IIDocument17 pagesS - Y - B Tech - Mech - Sem-IIakshatraj875No ratings yet

- T6 - Course Specifications CE203 Version 2017Document9 pagesT6 - Course Specifications CE203 Version 2017bachour58No ratings yet

- E GN 3331 Strength Mat LsDocument1 pageE GN 3331 Strength Mat LsDominic GograNo ratings yet

- 4.80 S.E Mechanical EngineeringDocument2 pages4.80 S.E Mechanical Engineeringq8400No ratings yet

- RMD2508Document5 pagesRMD2508ismail douidiNo ratings yet

- ME231 Strength of MaterialsDocument5 pagesME231 Strength of MaterialsVedant GavhaneNo ratings yet

- Course Code Course Name L-T-P:C Year 04 CE 6103 3-1-0-4 2015Document2 pagesCourse Code Course Name L-T-P:C Year 04 CE 6103 3-1-0-4 2015Arun KumarNo ratings yet

- Mec107:Basic Engineering Mechanics: Course OutcomesDocument1 pageMec107:Basic Engineering Mechanics: Course OutcomesNarendra SripalasettiNo ratings yet

- Module 3 - Mechanical Properties of MaterialsDocument15 pagesModule 3 - Mechanical Properties of MaterialsNicole NimoNo ratings yet

- MAK206 Syllabus Spring 2017Document1 pageMAK206 Syllabus Spring 2017michaelNo ratings yet

- Engg Mechanics SyllabusDocument3 pagesEngg Mechanics Syllabuserrohitverma25No ratings yet

- Course Outline: Meng6302 Advanced Mechanics of SolidsDocument7 pagesCourse Outline: Meng6302 Advanced Mechanics of SolidsKKDhNo ratings yet

- MM222 LecturesDocument255 pagesMM222 LecturesabdurrafayzeNo ratings yet

- ME 3813-Su14Document4 pagesME 3813-Su14xxxtoyaxxxNo ratings yet

- Strength of MateriaLS Course Outline For Civil Engineer, TarchaDocument3 pagesStrength of MateriaLS Course Outline For Civil Engineer, TarchaKebede HaileNo ratings yet

- ME 201 Mechanics of SolidsDocument3 pagesME 201 Mechanics of SolidsSudeesh SudevanNo ratings yet

- FALL 2009-2010: E-MailDocument5 pagesFALL 2009-2010: E-MailMDR PRAPHUNo ratings yet

- Fundamental Structural Engineering TheoriesDocument13 pagesFundamental Structural Engineering TheoriesGirum MindayeNo ratings yet

- Bmee202l Mechanics-Of-Solids TH 1.0 67 Bmee202lDocument3 pagesBmee202l Mechanics-Of-Solids TH 1.0 67 Bmee202lKrijayNo ratings yet

- FEATI University, Civil Engineering Course Syllabus 1991-2002Document90 pagesFEATI University, Civil Engineering Course Syllabus 1991-2002Rebecca Perez100% (1)

- Course Code Category Hours / Week Credits Maximum Marks L T P C CIA SEE TotalDocument2 pagesCourse Code Category Hours / Week Credits Maximum Marks L T P C CIA SEE TotalideepujNo ratings yet

- 01ci1301 MosDocument4 pages01ci1301 MosPokar HardikNo ratings yet

- Solid Mechanics IIT DDocument1 pageSolid Mechanics IIT DVishalNo ratings yet

- BCEL 506 Strength of Materials COURSE FILEDocument18 pagesBCEL 506 Strength of Materials COURSE FILESanjay TiwariNo ratings yet

- XB298100 PreliminaryDocument7 pagesXB298100 Preliminaryjorge luisNo ratings yet

- Sea Jay 453 Bayseeker With F60Document1 pageSea Jay 453 Bayseeker With F60jorge luisNo ratings yet

- TSS DM8162 04 GS Epg 9355182 PDFDocument3 pagesTSS DM8162 04 GS Epg 9355182 PDFjorge luisNo ratings yet

- FR 90821Document2 pagesFR 90821jorge luisNo ratings yet

- KTA38-M1 900HP 2023-54687 - 27apr2023Document12 pagesKTA38-M1 900HP 2023-54687 - 27apr2023jorge luis100% (1)

- Dat V180tiDocument2 pagesDat V180tijorge luisNo ratings yet

- A043F870 - Rev - B UCDM274KDocument8 pagesA043F870 - Rev - B UCDM274Kjorge luisNo ratings yet

- Ul FirePumpsFlexibleConnectors PDFDocument2 pagesUl FirePumpsFlexibleConnectors PDFjorge luisNo ratings yet

- Marine Propulsion and Auxiliary Engines: Commercial and Recreational ApplicationsDocument2 pagesMarine Propulsion and Auxiliary Engines: Commercial and Recreational Applicationsjorge luisNo ratings yet

- QSK38 Epa 4 - Imo IiiDocument2 pagesQSK38 Epa 4 - Imo Iiijorge luisNo ratings yet

- Newage Stamford Avk PowerportfolioDocument40 pagesNewage Stamford Avk Powerportfoliojorge luisNo ratings yet

- Marine Propulsion and Auxiliary Engines: Recreational ApplicationsDocument2 pagesMarine Propulsion and Auxiliary Engines: Recreational Applicationsjorge luisNo ratings yet

- National University of Engineering College of Mechanical Engineering Mechanical Engineering Program Mn114 - Thermodynamics IDocument2 pagesNational University of Engineering College of Mechanical Engineering Mechanical Engineering Program Mn114 - Thermodynamics Ijorge luisNo ratings yet

- National University of Engineering College of Mechanical Engineering Mechanical Engineering ProgramDocument2 pagesNational University of Engineering College of Mechanical Engineering Mechanical Engineering Programjorge luisNo ratings yet

- 18 MN216 Fluid Mechanics IDocument2 pages18 MN216 Fluid Mechanics Ijorge luisNo ratings yet

- National University of Engineering Mechanical Engineering ProgramDocument4 pagesNational University of Engineering Mechanical Engineering Programjorge luisNo ratings yet

- Gate-Me-2023, V-IDocument418 pagesGate-Me-2023, V-Iyash guptaNo ratings yet

- P18 Probability in The CourtroomDocument14 pagesP18 Probability in The CourtroomYehiaNo ratings yet

- GR 8 Maths 2 in 1 ExtractsDocument16 pagesGR 8 Maths 2 in 1 ExtractsSophia StamatiadisNo ratings yet

- Test Planner - PDF OnlyDocument2 pagesTest Planner - PDF Onlypriyanka pratapNo ratings yet

- R Gid Solutions: Review School For Civil EngineeringDocument2 pagesR Gid Solutions: Review School For Civil EngineeringLenielle AmatosaNo ratings yet

- Asset Health & Probability of Failure: Calculations For Transformers and BreakersDocument19 pagesAsset Health & Probability of Failure: Calculations For Transformers and Breakerscarlos patrickNo ratings yet

- Electric Circuits 10th Edition Nilsson Solutions ManualDocument38 pagesElectric Circuits 10th Edition Nilsson Solutions Manualstephaniecervanteskiygptmsfb100% (43)

- Electric Motor - Parts of Motor, Working of Electric Motor & UsesDocument7 pagesElectric Motor - Parts of Motor, Working of Electric Motor & UsesmanjuNo ratings yet

- Math 201 Final TestDocument1 pageMath 201 Final TestMichael GbonehNo ratings yet

- ASTM A276 & A479 The DifferenceDocument3 pagesASTM A276 & A479 The DifferenceWaqas Waqas100% (4)

- Intro To Linear AlgebraDocument67 pagesIntro To Linear AlgebraBevold LineNo ratings yet

- ME8501 Metrology and MeasurementsDocument14 pagesME8501 Metrology and MeasurementsarulmuruguNo ratings yet

- Measuring Change: Differentiation: Essential UnderstandingsDocument24 pagesMeasuring Change: Differentiation: Essential UnderstandingsMath Student 1 -No ratings yet

- Unit-4 Gravity DamsDocument23 pagesUnit-4 Gravity Damssushanth kumar0% (1)

- 3rd of 19 Chapters) Kinetic Particle Theory - GCE O Level Chemistry LectureDocument19 pages3rd of 19 Chapters) Kinetic Particle Theory - GCE O Level Chemistry LectureDylanNo ratings yet

- Confi-Gel HT Product Data SheetDocument1 pageConfi-Gel HT Product Data SheetpaimanNo ratings yet

- De Tieng Anh 2776Document4 pagesDe Tieng Anh 2776Đức Thịnh NgôNo ratings yet

- Tle Lesson 1Document23 pagesTle Lesson 1Ma Kristina Cassandra LunorNo ratings yet

- Lesson 8: Points. Lines. Three Collinear Points: I. Basic KnowledgeDocument5 pagesLesson 8: Points. Lines. Three Collinear Points: I. Basic KnowledgeChristina TranNo ratings yet

- 3RD Quarter Exam Grade 7 ScienceDocument2 pages3RD Quarter Exam Grade 7 ScienceJUDITH M. MABAONo ratings yet

- Francesco Intravaia and Carsten Henkel - Can Surface Plasmons Tune The Casimir Forces Between Metamaterials?Document1 pageFrancesco Intravaia and Carsten Henkel - Can Surface Plasmons Tune The Casimir Forces Between Metamaterials?KorezmNo ratings yet

- Coded Orthogonal Frequency Division Multiplex: Bernard Le Floch, Michel Alard, Claude BerrouDocument15 pagesCoded Orthogonal Frequency Division Multiplex: Bernard Le Floch, Michel Alard, Claude BerrouFrank EbongNo ratings yet

- 9780 - Week 2 - Sound WavesDocument3 pages9780 - Week 2 - Sound Wavesvivianada683No ratings yet

- Lesson1Introduction To Social ScienceDocument59 pagesLesson1Introduction To Social ScienceShiarica Mae Neri100% (1)

- SSC12 X 1 - PresentationDocument19 pagesSSC12 X 1 - PresentationHoussem LoussifNo ratings yet

- Trigonometric Functions Class 11 Cbse SummaryDocument4 pagesTrigonometric Functions Class 11 Cbse SummaryChugger BabyNo ratings yet

- TNSET Syllabus PDFDocument6 pagesTNSET Syllabus PDFSrinivasaRao JJNo ratings yet