Professional Documents

Culture Documents

Integration of SAP ERP With SCM EWM Configuration Guide

Integration of SAP ERP With SCM EWM Configuration Guide

Uploaded by

MK SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Integration of SAP ERP With SCM EWM Configuration Guide

Integration of SAP ERP With SCM EWM Configuration Guide

Uploaded by

MK SinghCopyright:

Available Formats

Integration of SAP ERP with SCM

EWM

Configuration Guide

Configuration Guide Page 1 of 36

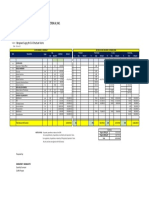

Contents

1 BASIS SETTINGS PRIOR TO ANY CUSTOMIZING IN ERP & EWM......................................3

1.1 Activating Business Functions in Switch Framework.......................................................3

1.2 Assigning a Logical System to a Client..............................................................................3

1.3 Naming the Logical System for the Connection to SAP EWM........................................3

1.4 Specifying the SAP APO Release......................................................................................3

1.5 Activating Business Transaction Events (BTEs)...............................................................3

1.6 Activating Business Functions in Switch Framework.......................................................3

1.7 Assigning a Logical System to a Client..............................................................................3

1.8 Naming the Logical System for the Connection to SAP ERP.........................................3

1.9 Checking the SAP APO Model and Planning Version.....................................................3

2 Configuration Settings for the ERP System..................................................................................3

2.1 Activating Business Functions in Switch Framework.......................................................3

2.2 Creating an RFC User in ERP.............................................................................................3

2.3 Naming the Logical System for the Connection to SAP EWM........................................3

2.4 Assigning a Logical System to a Client..............................................................................3

2.5 Specifying the SAP APO Release......................................................................................3

2.6 RFC Destinations..................................................................................................................3

2.6.1 Defining RFC Destinations in ERP.................................................................................3

2.6.2 Determining RFC Destinations for Method Calls in ERP.............................................3

2.6.3 Defining Internal Workflow Destinations........................................................................3

2.7 Setting the Target System and Queue Type.....................................................................3

2.8 qRFC Monitor Settings.........................................................................................................3

2.8.1 Maintaining qRFC Monitor (QIN Scheduler) Settings in ERP.....................................3

2.8.2 Maintaining qRFC Monitor (QOUT Scheduler) Settings in ERP.................................3

2.8.3 Registering Display Programs for Application Log in ERP..........................................3

2.9 Setting User Parameters for Data Transfer.......................................................................3

2.10 Checking Basic Table Entries..............................................................................................3

2.11 Additional Material Master Attributes..................................................................................3

2.11.1 Activating Additional Material Master Screens..............................................................3

Configuration Guide Page 2 of 36

2.11.2 Maintaining Additional Screen Sequences....................................................................3

2.11.3 Attributing Values to Additional Material Master Fields................................................3

2.12 Number Ranges for Deliveries............................................................................................3

2.12.1 Maintaining Number Ranges for Unchecked Deliveries..............................................3

2.12.2 Maintaining a Deviating Number Range for Unchecked Deliveries............................3

2.12.3 Maintaining Number Ranges for Temporary Inbound Deliveries................................3

2.13 Activating Enhancements for Service Parts Management (SPM)..................................3

2.14 Extended Inbound Delivery..................................................................................................3

2.14.1 Defining the Profile for Extended Inbound Delivery Processing (VL60) Users.........3

2.14.2 Assigning a User for Extended Inbound Delivery Processing (VL60)........................3

2.15 Assigning Warehouse Number to Plant and Storage Location.......................................3

2.16 Assigning Shipping Points to Plants...................................................................................3

2.17 Maintaining Shipping Point Assignment to Plant..............................................................3

2.18 Assigning Goods Receiving Points for Inbound Delivery.................................................3

2.19 Organizational Structures in the ERP System..................................................................3

2.19.1 Maintaining Extended Warehouse Management-Specific Parameters.....................3

2.19.2 Defining the Queue for Extended Warehouse Management......................................3

2.19.3 Logging Sent and Received Messages..........................................................................3

2.19.4 Registering the Navigation from the Queue..................................................................3

2.19.5 Generating the Distribution Model for ERP to EWM....................................................3

2.20 Defining Delivery Split by Warehouse Number.................................................................3

2.21 Maintenance of Object and Class Types...........................................................................3

2.21.1 Maintaining Object Types and Class Types in ERP.....................................................3

2.21.2 Maintaining Characteristics for Batches.........................................................................3

2.21.3 Creating Classes for Batches..........................................................................................3

2.22 Activating Business Configuration Sets (BC Sets)...........................................................3

3 Configuration Settings for SAP SCM..............................................................................................3

3.1 Activating Business Functions in Switch Framework.......................................................3

3.2 Creating an RFC User in SCM............................................................................................3

3.3 Assigning a Logical System to a Client..............................................................................3

3.4 Naming the Logical System for the Connection to SAP ERP.........................................3

3.5 Defining RFC Destinations...................................................................................................3

Configuration Guide Page 3 of 36

3.6 Maintaining Business System Groups................................................................................3

3.7 Assigning Logical System and Queue Types....................................................................3

3.8 Determining RFC Destinations for Method Calls in EWM...............................................3

3.9 Maintenance of the qRFC Monitor Settings.......................................................................3

3.9.1 Maintaining qRFC Monitor (QIN Scheduler) Settings in EWM....................................3

3.9.2 Maintaining qRFC Monitor (QOUT Scheduler) Settings in EWM...............................3

3.10 Defining a Separate Business System...............................................................................3

3.11 Defining the Business System.............................................................................................3

3.12 Defining Outbound Communication....................................................................................3

3.13 Setting Control Parameters for the ERP Version Control................................................3

3.14 Verifying Synchronization of the ERP System and EWM................................................3

3.15 Delivery Processing..............................................................................................................3

3.15.1 Defining Number Range Intervals...................................................................................3

3.15.2 Defining Number Ranges for ERP Documents.............................................................3

3.15.3 Defining the Delivery Priority...........................................................................................3

3.15.4 Defining Shipping Conditions..........................................................................................3

3.15.5 Defining Incoterms............................................................................................................3

3.16 Maintaining Object Types and Class Types in SCM........................................................3

3.17 Defining Warehouse Numbers............................................................................................3

3.18 Mapping Warehouse Numbers............................................................................................3

3.19 Activating User Exits.............................................................................................................3

3.20 Activating Business Add-Ins (BAdIs).............................................................................3

3.20.1 Activating BAdI: Inbound Processing for Location........................................................3

3.20.2 Activating BAdI: Inbound Processing for Product.........................................................3

3.20.3 Copying BAdI Method Source Code...............................................................................3

3.20.4 Activating BAdI: Inbound Processing for Partner..........................................................3

3.21 Defining Availability Groups.................................................................................................3

3.22 Defining the Transportation Group.....................................................................................3

3.23 Settings for the Logistic Inventory Management Engine (LIME).....................................3

3.23.1 Defining the Warehouse Management Process Type for LIME..................................3

3.23.2 Defining the Index Tables for LIME................................................................................3

3.23.3 Defining the Hierarchy for LIME......................................................................................3

Configuration Guide Page 4 of 36

3.24 Defining Warehouse Number Ranges................................................................................3

3.25 Defining Warehouse Number Ranges for HUs.................................................................3

3.26 Specifying Output Format of Product Number..................................................................3

3.27 Checking the SAP APO Model and Planning Version.....................................................3

Configuration Guide Page 5 of 36

Integration of SAP ERP with SCM EWM

This document provides you with the necessary information for configuring the integration of SAP ERP

and SAP Extended Warehouse Management (EWM).

In this integration scenario, SAP EWM is a component of SAP Supply Chain Management (SCM).

This document describes the complete configuration for integrating SAP ERP and SAP EWM, where SAP

EWM is a component of SAP SCM.

You must ensure that you follow the configuration steps exactly the order in which they are

presented in this document.

1 BASIS SETTINGS PRIOR TO ANY CUSTOMIZING IN ERP & EWM.

System administrators have to make specific settings for the integration of SAP ERP and SAP EWM

before any Customizing activity is carried out.

System administrators need to pay particular attention to the following activities:

All cross-client activities, such as:

In the ERP system:

Activating Business Functions in Switch Framework

Assigning a Logical System to a Client

Naming the Logical System for the Connection to SAP EWM

Specifying the SAP APO Release

Activating Business Transaction Events (BTEs)

In SAP SCM:

Assigning a Logical System to a Client

Naming the Logical System for the Connection to SAP ERP

Checking the SAP APO Model and Planning Version

All activities that relate to user exists or Business Add-Ins (BAdIs)

1.1 Activating Business Functions in Switch Framework

In the ERP system, on the SAP Easy Access screen, call transaction sfw5

Activate the business function that you want to use.

a. LOG_LE_INTEGRATION

b. LOG_PP_EWM_MAN

1.2 Assigning a Logical System to a Client

In Customizing for the ERP system, choose Integration with Other mySAP.com Components

Extended Warehouse Management Basic Settings for Setting Up the System Landscape

Assign Logical System to a Client .

Configuration Guide Page 6 of 36

Check whether the logical system for the ERP client exists, for example ERPCLNT001

If it does not exist, name the logical system for the ERP client first. For naming the logical system,

in Customizing for the ERP system, see Integration with Other mySAP.com Components

Extended Warehouse Management Basic Settings for Setting Up the System Landscape

Name Logical System .

1.3 Naming the Logical System for the Connection to SAP EWM

In Customizing for the ERP system, choose Integration with Other mySAP.com Components

Extended Warehouse Management Basic Settings for Setting Up the System Landscape

Name Logical System .

Define the logical system for SAP SCM, for example define SCMCLNT001.

1.4 Specifying the SAP APO Release

In Customizing for the ERP system, choose Integration with mySAP.com Components

Extended Warehouse Management Basic Settings for Setting Up the System Landscape

Specify SAP APO Release .

Check that an entry for your logical system exists or create the entry. Enter the values as

shown in the following table:

Field Value

Log. System <Logical System Name>, for example SCMCLNT001

Syst. type SAP_APO

Release <System Release>, for example 70

1.5 Activating Business Transaction Events (BTEs)

1. In the ERP system, on the SAP Easy Access screen, call transaction FIBF.

The SAP Business Framework:Business Transaction Events screen appears.

2. In the menu, choose Settings Identification SAP Applications .

3. Confirm the message.

4. Look for entries ND-APO and NDI.

5. Select theApplication Active checkbox.

6. Choose Save.

Configuration Guide Page 7 of 36

1.6 Activating Business Functions in Switch Framework

On the SAP Easy Access screen of EWM, call transaction SFW5.

Activate the business function that you want to use.

SCM_EWM_REV_LOG

SCM_EWM_TRANS_INT_1

1.7 Assigning a Logical System to a Client

In Customizing for SAP SCM, choose SCM Basis Integration Basic Settings for Creating

the System Landscape Assign Logical Systems to a Client .

Check whether the logical system for the SCM client exists, for example SCMCLNT001.

If it does not exist, define the logical system for the ERP client first. For more information about how

to define a logical system, see Naming the Logical System for the Connection to SAP ERP.

1.8 Naming the Logical System for the Connection to SAP ERP

In Customizing for SAP SCM, choose SCM Basis Integration Basic Settings for Creating

the System Landscape Name Logical Systems .

Define the logical systems for SAP SCM and SAP ERP, for

example SCMCLNT001 and ERPCLNT001.

1.9 Checking the SAP APO Model and Planning Version

In SAP SCM, on the SAP Easy Access screen, call transaction SE38.

In the Program field, enter /SAPAPO/VERSION_CREATE_NO_APO.

If a dialog box appears, choose Cancel and check if the planning version 000 and model 000 exist

by calling transaction /SAPAPO/MVN.

Choose Execute.

2 Configuration Settings for the ERP System

You can use this process to make configuration settings in the ERP system that are needed for the

integration with SAP SCM. By connecting the two applications you can transfer data from the ERP system

that is relevant for processes in SAP EWM.

Configuration Guide Page 8 of 36

Prerequisites:

You have installed and correctly configured the following systems on SAP enhancement package 2 for

SAP NetWeaver 7.0:

SAP ERP 6.0

SAP SCM 7.0 including SAP enhancement package 1 for SAP SCM 7.0

In the ERP system, you have created the following objects:

Plants

Storage location(s)

Warehouse numbers

Shipping points

Customer Master

Vendor Master

Materials

Process:

Ensure that you follow the steps in exactly the order in which they are given:

1. Activating Business Functions in Switch Framework

2. Creating an RFC User in ERP

3. Naming the Logical System for the Connection to SAP EWM

4. Assigning a Logical System to a Client

5. Specify the SAP APO Release

6. RFC Destinations

7. Setting the Target System and Queue Type

8. qRFC Monitor Settings

9. Setting User Parameters for Data Transfer

10. Checking Basic Table Entries

11. Additional Material Master Attributes

12. Number Ranges for Deliveries

13. Activating Enhancements for Service Parts Management (SPM)

14. Extended Inbound Delivery

15. Assigning Warehouse Number to Plant and Storage Location

16. Assigning Shipping Points to Plants

17. Maintaining Shipping Point Assignment to Plant

18. Assigning Goods Receiving Points for Inbound Delivery

19. Organizational Structures in the ERP System

20. Defining Delivery Split by Warehouse Number

21. Maintenance of Object and Class Types

22. Activate Business Configuration Sets (BC Sets)

2.1 Activating Business Functions in Switch Framework

REFER STEP 1.1

Configuration Guide Page 9 of 36

2.2 Creating an RFC User in ERP

In the ERP system, on the SAP Easy Access screen, choose Tools Administration User

Maintenance Users . Alternatively, call transaction SU01.

To create the RFC user for the integration of ERP and EWM, carry out the following steps:

1. In the User field, enter the name of the RFC user.

2. Choose Create.

Field Value

Name

Address tab page

Last Name ALEREMOTE

Logon Data tab page

User Type Communication (A)

Password <Password>

Profiles tab page

Choose profile.

For the integration with SAP SCM the following profile is recommended:

S_BI-WX_RFC

See SAP Notes 150315 and 784891.

CAUTION

Do not assign too many rights to this technical user. If, for example, technical users for RFC

connections have too many authorizations, RFC administrators from the calling system can

easily log on to the called system and abuse the technical user’s authorizations. 70% of all

attacks on systems come from within the attacked company. Use the profile generator

(transaction PFCG) to define an appropriate profile. See also SAP Note 727839.

Defaults tab page

Logon EN

Language

3. In the Maintain User screen, enter the following data:

To create the RFC user for the internal workflow, carry out the following steps:

4. In the User field, enter the name of the RFC user.

5. Choose Create.

6. In the Maintain User screen, enter the following data:

Configuration Guide Page 10 of 36

Field Value

Name

Address tab page

Last Name WF-Batch

Logon Data tab page

User Type System (B)

Password <Password>

Profiles tab page

Choose profile.

For the integration with SAP SCM the following profile is recommended:

S_BI-WX_RFC

See SAP Notes 150315 and 784891.

CAUTION

Do not assign too many rights to this technical user. If, for example, technical users for RFC

connections have too many authorizations, RFC administrators from the calling system can

easily log on to the called system and abuse the technical user’s authorizations. 70% of all

attacks on systems come from within the attacked company. Use the profile generator

(transaction PFCG) to define an appropriate profile. See also SAP Note 727839.

Defaults tab page

Logon EN

Language

2.3 Naming the Logical System for the Connection to SAP EWM

REFER STEP 1.3

2.4 Assigning a Logical System to a Client

REFER STEP 1.2

2.5 Specifying the SAP APO Release

REFER STEP 1.4

2.6 RFC Destinations

2.6.1 Defining RFC Destinations in ERP

Configuration Guide Page 11 of 36

In the ERP system, on the SAP Easy Access screen, choose Tools Administration

Administration Network RFC Destinations . Alternatively, call transaction SM59.

Select ABAP Connections.

Choose Create.

Enter the data as shown in the table:

Field Name User Action and Default Values

RFC Destination <SAP SCM system name>CLNT<client>

For example: SCMCLNT001

Connection Type 3 (Connection to SAP R/3)

Description SCM

Technical Settings tab page

Load Balancing Yes or No (preselected)

Target Host <Target Host Name>

For example: iwdf9199.wdf.sap.corp

System Number <Target System Number>

For example: 00

Logon & Security tab page

Trusted System Yes or No (preselected)

SNC Active or Inactive (preselected)

Language EN (optional)

Client For example: 001

User ALEREMOTE

Password <Password>

The password you created in Creating an RFC User in ERP.

Current User Not selected

Unencrypted Password Not selected

Save your RFC destination.

2.6.2 Determining RFC Destinations for Method Calls in ERP

Configuration Guide Page 12 of 36

In Customizing for the ERP system, choose SAP NetWeaver Application Server IDoc

Interface/Application Link Enabling (ALE) Communication Determine RFC Destinations for

Method Calls . Alternatively, call transaction BD97.

Position the cursor on the relevant logical system, for example SCMCLNT001

Choose Standard BAPI Destination.

Enter the RFC destination created previously

Press Enter.

2.6.3 Defining Internal Workflow Destinations

In the ERP system, on the SAP Easy Access screen, choose Tools Administration

Administration Network RFC Destinations . Alternatively, call transaction SM59.

Choose Create.

Enter the data as shown in the table:

Field Name User Action and Default Values

RFC Destination <workflow_local_client number>, for example workflow_local_001

Where 001 is the ERP client you are working in.

Connection Type L

Description Local workflow

Logon & Security tab page

Authorization for Destination - leave blank -

Language EN (optional)

Client For example, 001

User For example, WF-Batch

PW Status <Password>

The password you created in Creating an RFC User in ERP.

Save your internal workflow destination.

2.7 Setting the Target System and Queue Type

In Customizing for the ERP system, choose Integration with mySAP.com Components

Extended Warehouse Management Basic Settings for Setting Up the System Landscape Set

Target System and Queue Type .

Check that the data for the relevant logical system exists or enter the data as shown in the

following table:

Configuration Guide Page 13 of 36

Field Description Value

Log.System Logical System For example, SCMCLNT001

Q-Type Queue type I (Inbound queue)

2.8 qRFC Monitor Settings

2.8.1 Maintaining qRFC Monitor (QIN Scheduler) Settings in ERP

In the ERP system, on the SAP Easy Access screen, call transaction SMQR.

1. On the qRFC Monitor (QIN Scheduler) screen, choose Register without activation.

2. Enter the data as shown in the following table:

Field Value

Queue <used queue name>, we recommend that you use either * or any of the

Name following: CF*, DLV*, QI*, EWM*, WRCF*, X*

Mode D

Max. 60

Runtime

USERDEST - leave blank -

Attempts 30

Pause 300

3. Choose Continue.

2.8.2 Maintaining qRFC Monitor (QOUT Scheduler) Settings in ERP

1. In the ERP system, on the SAP Easy Access screen, call transaction SMQS.

2. On the qRFC Monitor (QOUT Scheduler) screen, choose Register without activation.

3. Enter the data as shown in the following table:

Field Value

Destination <RFC Destination>, for example SCMCLNT001

Max.Conn. 10

Max. Runtime 60

Configuration Guide Page 14 of 36

Field Value

W/o Trfc - leave blank -

4. Choose Continue.

2.8.3 Registering Display Programs for Application Log in ERP

1. In SAP ERP, on the SAP Easy Access screen, call transaction SMQE.

2. Choose Edit Register Display Program .

3. Enter the queue and program names as shown in the following table.

Queue Name Program Name

CF* CIFQEV02

DLV* /SPE/QUEUE_DISPLAY_TOOLS

DLW* /SPE/QUEUE_DISPLAY_TOOLS

EWM* /SPE/QUEUE_DISPLAY_TOOLS

QI* /SPE/QUEUE_DISPLAY_TOOLS

QM* /SPE/QUEUE_DISPLAY_TOOLS

X* RSXMB_SHOW_ENTRY

2.9 Setting User Parameters for Data Transfer

1. In Customizing for the ERP system, choose Integration with mySAP.com Components

Extended Warehouse Management Basic Settings for Data Transfer Set User Parameters .

Alternatively, call transaction CFC2.

2. Check the entries. If necessary, create an entry with the following data:

Field Value

User Name *, ALEREMOTE

RFC Mode Q

Logging D

Debug - leave blank -

2.10 Checking Basic Table Entries

Configuration Guide Page 15 of 36

1. On the SAP Easy Access screen, execute transaction code SCMP.

2. Compare the information in the following tables in all of the systems, for example SAP

ERP and SAP SCM:

Table Field Description

T006 ISOCODE Unit of measure

T002 LAISO Language keys

TCURC ISOCD Currency codes

T005 INTCA Countries

2.11 Additional Material Master Attributes

2.11.1 Activating Additional Material Master Screens

1. In the ERP system, on the SAP Easy Access screen, choose Tools Customizing

Business Configuration Sets Activation of BC Sets . Alternatively, call transaction SCPR20.

2. Choose BC set /SPE/MATERIAL_SCREENS.

3. On the menu, choose BC Set Activate .

The Activation Options screen appears.

4. Check that the following fields are selected:

Overwrite All Data

Default Mode (Recommended)

5. Choose Continue Activation.

2.11.2 Maintaining Additional Screen Sequences

1. In Customizing for the ERP system, choose Logistics - General Material Master

Configuring the Material Master Maintain Order of Main and Additional Screens . Alternatively,

call transaction OMT3R.

2. Select sequence 21 and display the details by choosing Goto Details in the menu.

3. For screen number 56, enter 300.

4. For screen number 57, enter 310.

5. Choose Save.

2.11.3 Attributing Values to Additional Material Master Fields

In Customizing for the ERP system, choose Integration with Other mySAP.com Components

Extended Warehouse Management Additional Material Attributes Attribute Values for Additional

Material Master Fields .

1. In the following Customizing activities, define and save attributes for additional material master

fields:

Define Handling Unit Type

Configuration Guide Page 16 of 36

Define Warehouse Storage Condition

Define Warehouse Material Group

Define Handling Indicator

Define Serial Number Profile

Define Quality Inspection Group

2.12 Number Ranges for Deliveries

2.12.1 Maintaining Number Ranges for Unchecked Deliveries

In the ERP system, on the SAP Easy Access screen, call transaction SNRO.

1. In the Object field, enter RV_BELEG and check whether it already exists.

If it does not exist, choose Create to create the entry.

2. Choose Number Ranges.

3. Choose Change Intervals and check that entries for the number range numbers 24 and 45 have

been defined.

If they have not been defined, define the entries and the number range intervals as shown in

the following table:

No From number To number Current number

24 0083000000 0083999999 0

45 0183000000 0183999999 0

5. Choose Save.

2.12.2 Maintaining a Deviating Number Range for Unchecked Deliveries

1. In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Outbound Process (SPM) Unchecked Deliveries Maintain Deviating Number Range

for Unchecked Deliveries .

2. For the delivery type LF, enter number range 24 in the TmpNr field.

3. To activate the reuse of numbers for unchecked deliveries, select the Reuse checkbox.

2.12.3 Maintaining Number Ranges for Temporary Inbound Deliveries

1. In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Extended Inbound Delivery Processing (SPM) Settings for SPM Inbound Delivery

Processing .

2. Create a new entry.

3. Set EL as the delivery type.

4. Select the entry and choose Details.

5. In the Temporary Delivery frame, enter 45 in the Number Ranges for Temporary Inb.

Deliveries field.

6. Choose Save.

Configuration Guide Page 17 of 36

2.13 Activating Enhancements for Service Parts Management (SPM)

1. In Customizing for the ERP system, choose Logistics Execution Service Parts

Management Activate Enhancements for Service Parts Management (SPM) Activate

Enhancements for Service Parts Management .

2. Create a new entry.

3. In the Customer Type field, choose Service Parts Management active (SPM).

4. Choose Save.

A system message appears.

5. Confirm the message.

2.14 Extended Inbound Delivery

2.14.1 Defining the Profile for Extended Inbound Delivery Processing (VL60) Users

1. In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Extended Inbound Delivery Processing (SPM) UI Profiles Maintain Profile Assign

Users . Alternatively, call transaction VL60P2.

2. Choose New Entries.

3. Create a user group, for example VL60ALL, and press Enter.

4. Select the user group you created.

5. In the Dialog Structure, do the following:

1. Double-click Assignment User - User Groups.

2. Choose New Entries.

3. Enter all users.

4. For each user, select the Default Group checkbox.

5. In the Dialog Structure, double-click Assignment Profiles - User Groups.

6. Choose New Entries.

7. Assign profile VL60ALL and select the Default Profile checkbox.

6. Choose Save.

2.14.2 Assigning a User for Extended Inbound Delivery Processing (VL60)

1. In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Extended Inbound Delivery Processing (SPM) UI Profiles Maintain Profile Assign

Users .

2. Select the user group assigned to profile VL60ALL, for example select user group VL60ALL.

3. In the Dialog Structure, double-click Assignment User - User Groups.

4. Choose New Entries.

5. Enter the RFC user, for example ALEREMOTE, and select the Default Group checkbox.

6. Choose Save.

Configuration Guide Page 18 of 36

2.15 Assigning Warehouse Number to Plant and Storage Location

In Customizing for the ERP system, choose Enterprise Structure Assignment Logistics

Execution Assign warehouse number to plant/storage location .

2.16 Assigning Shipping Points to Plants

In Customizing for the ERP system, choose Enterprise Structure Assignment Logistics

Execution Assign shipping point to plant .

2.17 Maintaining Shipping Point Assignment to Plant

In Customizing for the ERP system, choose Logistics Execution Shipping Basic Shipping

Functions Shipping Point and Goods Receiving Point Determination Assign Shipping

Points .

2.18 Assigning Goods Receiving Points for Inbound Delivery

In Customizing for the ERP system, choose Logistics Execution Shipping Basic Shipping

Functions Shipping Point and Goods Receiving Point Determination Assign Goods Receiving

Points for Inbound Deliveries .

2.19 Organizational Structures in the ERP System

2.19.1 Maintaining Extended Warehouse Management-Specific Parameters

In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Integrate SPM with Other Components Maintain Extended WM-Specific Parameters .

2.19.2 Defining the Queue for Extended Warehouse Management

In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Integrate SPM with Other Components Define Queue for Transfer to Extended WM .

2.19.3 Logging Sent and Received Messages

In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Integrate SPM with Other Components Log Sent and Received Messages .

2.19.4 Registering the Navigation from the Queue

In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Integrate SPM with Other Components Register Navigation from Queue .

Configuration Guide Page 19 of 36

2.19.5 Generating the Distribution Model for ERP to EWM

In Customizing for the ERP system, choose Logistics Execution Service Parts Management

(SPM) Integrate SPM with Other Components Generate Distribution Model ERP => EWM .

2.20 Defining Delivery Split by Warehouse Number

In Customizing for the ERP system, choose Logistics Execution Shipping Deliveries

Define Split Criteria for Deliveries Delivery Split by Warehouse Number .

2.21 Maintenance of Object and Class Types

2.21.1 Maintaining Object Types and Class Types in ERP

In Customizing for the ERP system, choose Cross-Application Components Classification

System Classes Maintain Object Types and Class Types .

2.21.2 Maintaining Characteristics for Batches

In the ERP system, on the SAP Easy Access screen, choose Cross-Application

Components Classification System Master Data

Create the following characteristics if you need them:

1. LOBM_HERKL - country of origin

2. LOBM_VFDAT - expiration date, shelf life

3. LOBM_ZUSTD - status of batch

4. LOBM_HSDAT - date when batch was produced

5. LOBM_QNDAT - next insp. date for batch

6. LOBM_LVORM - deletion ind. for batches

7. LOBM_VERAB - availability date

2.21.3 Creating Classes for Batches

In the ERP system, on the SAP Easy Access screen, choose Cross-Application Components

Classification System Master Data Classes . Alternatively, call transaction CL02.

1. In the Class field, enter the name of the class, for example SPE_COO.

2. In the Class type field, enter 023.

3. Choose Create.

4. On the Basic Data tab, enter the following values:

Field Value

Description COO

Configuration Guide Page 20 of 36

Field Value

Status Released

Organizational Area A

5. On the Keywords tab, enter SPE_COO as a keyword.

6. On the Char tab, enter the characteristics specified and attribute Org. Area A to all of them.

2.22 Activating Business Configuration Sets (BC Sets)

1. In the ERP system, on the SAP Easy Access screen, choose Tools Customizing

Business Configuration Sets Activation of BC Sets . Alternatively, call transaction SCPR20.

2. In the BC Set input field, enter /SPE/COMPLETE and choose Enter. This BC Set comprises

the BC sets named in the following table.

BC Set Description

/SPE/MATERIAL_SCREENS Material master setup for additional EWM fields

/SPE/TVSHP Global shipping setup for EWM

/SPE/SPM_RETURNS_SHIPPED_IMG Complaints & Returns Customizing including QM catalogs

and ALE process codes for communication with SCM-SNC

/SPE/STO_DISCREPANCIES POD Customizing and output control

/ TCD Customizing and output control

SPE/TRANSPORTATION_CROSS_DOCK

/SPE/TNAPR Output types for POD, TCD, and STO processes

3. In the menu, choose BC Set Activate . The Activation Options screen appears.

4. Check that the following fields are selected:

Overwrite All Data

Default Mode (Recommend)

5. Choose Continue Activation.

For technical reasons, we recommend that you activate the BC Sets more than once.

6. Repeat steps 2-5 for the following BC-Sets if you use the corresponding special processes

in EWM:

BC Set Description

/SPE/DIRECT_OUTBOUND_DELIVERIES Customizing for Direct Outbound Deliveries

/SPE/KIT_TO_ORDER Kit-to-Order

Configuration Guide Page 21 of 36

3 Configuration Settings for SAP SCM

You have installed and correctly configured the following systems on SAP enhancement package 2 for

SAP NetWeaver 7.0:

SAP ERP 6.0

SAP SCM 7.0 including SAP enhancement package 1 for SAP SCM 7.0

You have configured the ERP system for connection to SAP SCM,

Process

Ensure that you follow the steps in exactly the order in which they are presented:

1. Activating Business Functions in Switch Framework

2. Creating an RFC User in SCM

3. Naming the Logical System for the Connection to SAP ERP

4. Assigning a Logical System to a Client

5. Define RFC Destinations

6. Maintaining Business hSystem Groups

7. Assigning Logical System and Queue Types

8. Determining RFC Destinations for Method Calls in EWM

9. Maintenance of qRFC Monitor Settings

10. Defining a Separate Business System

11. Defining the Business System

12. Defining Outbound Communication

13. Setting Control Parameters for the ERP Version Control

14. Verifying Synchronization of the ERP System and EWM

15. Delivery Processing

16. Maintaining Object Types and Class Types in SCM

17. Defining Warehouse Numbers

18. Mapping Warehouse Numbers

19. Activating User Exists

20. Activating Business Add-Ins (BAdIs) (optional)

21. Defining Availability Groups.

22. Defining the Transportation Group (optional)

23. Settings for the Logistic Inventory Management Engine (LIME)

24. Defining Warehouse Number Ranges

25. Defining Warehouse Number Ranges for HUs

26. Specifying Output Format of Product Number

27. Checking the SAP APO Model and Planning Version

3.1 Activating Business Functions in Switch Framework

Configuration Guide Page 22 of 36

REFER TO STEP 1.6

3.2 Creating an RFC User in SCM

1. In SAP SCM, on the SAP Easy Access screen, choose Tools Administration User

Maintenance Users .

2. In the User field, enter ALEREMOTE.

3. Choose Create.

4. In the Maintain User screen, enter the following data:

Field Value

Name

Address tab page

Last Name ALEREMOTE

Logon Data tab page

User Type Communication (C)

If you are connecting SAP EWM to an ERP system, you have to use a User Type D for

debugging purposes.

Password <Password>

Profile tab page

Profiles Choose profile.

For the integration with the ERP system the following profiles are recommended:

SAP_APP

S_BI-WX_RFC

See SAP Notes 150315 and 784891.

CAUTION

Do not assign too many rights to this technical user. If, for example, technical users for

RFC connections have too many authorizations, RFC administrators from the calling

system can easily log on to the called system and abuse the technical user's

authorizations. 70% of all attacks on systems come from within the attacked company.

Use the profile generator (transaction PFCG) to define an appropriate profile.

See also SAP Note 727839.

Roles tab Enter role SAP_RFC_ALEREMOTE

page

Defaults tab page

Logon EN

Language

5. Choose Save.

CAUTION

Do not change the password of this user because it is used in RFC connections.

Configuration Guide Page 23 of 36

3.3 Assigning a Logical System to a Client

REFER STEP 1.7

3.4 Naming the Logical System for the Connection to SAP ERP

REFER STEP 1.8

3.5 Defining RFC Destinations

In Customizing for SAP SCM, choose SCM Basis Integration Basic Settings for Creating

the System Landscape Set Up RFC Destination . Alternatively, call transaction SM59.

Select ABAP Connections.

Choose Create.

Enter the data as shown in the table:

Field Name User Action and Default Values

RFC Destination <ERP system name>CLNT<client>, for example ERPCLNT001

Connection Type 3 (Connection to ERP system)

Description ERP system

Technical Settings tab page

Load Balancing Yes or No (preselected)

Target Host <Target Host Name>

System Number <Target System Number>

Logon & Security tab page

Trusted System Yes or No (preselected)

SNC Active or Inactive (preselected)

Language EN

Client For example: 001

User ALEREMOTE

Configuration Guide Page 24 of 36

Field Name User Action and Default Values

Password <Password>

The password you have created in Creating an RFC User in SCM.

Current User Not selected

Unencrypted Password Not selected

Save your RFC destination.

3.6 Maintaining Business System Groups

In Customizing for SAP SCM, choose SCM Basis Integration Basic Settings for Creating

the System Landscape Maintain Business System Group .

3.7 Assigning Logical System and Queue Types

In Customizing for SAP SCM, choose SCM Basis Integration Basic Settings for Creating

the System Landscape Assign Logical System and Queue Type .

Create entries using inbound queues in the Assignment of Logical System to Business System

Group table, for example, for the two-client scenario for SAP SCM:

Business System Logical System SAP System Release Queue Type

Group

ERP001 SCMCLNT001 <ERP Release, for example Inbound

51> Queues

ERP001 ERPCLNT001 x <EWM Release, for example Inbound

600> Queues

3.8 Determining RFC Destinations for Method Calls in EWM

1. In Customizing for SAP SCM, choose SAP NetWeaver Application Server IDoc

Interface/Application Link Enabling (ALE) Communication Determine RFC Destination for

Method Calls . Alternatively, call transaction BD97.

The Assign RFC Destinations for Synchronous Method Calls screen appears.

2. Select the logical system, for example ERPCLNT001, and choose Standard BAPI destination.

3. In the RFC destination for BAPI calls field, enter the name of the RFC destination.

4. Choose Save.

3.9 Maintenance of the qRFC Monitor Settings

Configuration Guide Page 25 of 36

3.9.1 Maintaining qRFC Monitor (QIN Scheduler) Settings in EWM

In SAP SCM, on the SAP Easy Access screen, call transaction SMQR.

On the qRFC Monitor (QIN Scheduler) screen, choose Register without activation.

Enter the data as shown in the following table:

Field Value

Queue name <used queue name>

We recommend that you use *

Mode D

Max. Runtime 60

USERDEST - leave blank -

Attempts 30

Pause 300

3.9.2 Maintaining qRFC Monitor (QOUT Scheduler) Settings in EWM

In SAP SCM, on the SAP Easy Access screen, call transaction SMQS.

On the qRFC Monitor (QOUT Scheduler)screen, choose Register without activation.

Enter the data as shown in the following table:

Field Value

Destination <RFC Destination>, for example ERPCLNT001

Max.Conn. 10

Max. Runtime 60

W/o tRFC - leave blank -

3.10 Defining a Separate Business System

In Customizing, choose SCM Extended Warehouse Management Extended Warehouse

Management Interfaces ERP Integration General Settings Define Own Business

System .

This is SCM system

Configuration Guide Page 26 of 36

3.11 Defining the Business System

In Customizing for SAP SCM, choose Extended Warehouse Management Interfaces ERP

Integration General Settings Define Business System .

Field Value

Business System <Bus System name>,

Logical System <Log System name>

Manual Maint. Flag set. Event has occurred.

Maintain for your ERP and SCM systems

3.12 Defining Outbound Communication

1. In Customizing for SAP SCM, choose Extended Warehouse Management Interfaces ERP

Integration General Settings Control for RFC Queue .

2. Enter or select your Business System for outbound queues (ERP system)

3. Choose No Aggregation and Mass Queue Deactivated (=> Individual Queue).

4. Define Queue Type for connection to the ERP system.

5. Choose Save.

3.13 Setting Control Parameters for the ERP Version Control

1. In Customizing for SAP SCM, choose Extended Warehouse Management Interfaces ERP

Integration General Settings Set Control Parameters for ERP Version Control .

2. Choose New Entries.

3. Enter data in the following fields:

Business System, for example ERP system

SAP Release

4. Choose Save.

3.14 Verifying Synchronization of the ERP System and EWM

1. In SAP SCM, on the SAP Easy Access screen, call transaction SM30.

2. In the Table/View field, enter the name of the SAP SCM table as shown in the table below and

choose Customizing.

If the Choose Customizing Project dialogue box appears, choose Continue w/o Specifiying Project.

3. Check whether the table entries in SAP SCM are the same as those you defined in the ERP

system.

Customizing Entries

Configuration Guide Page 27 of 36

Table Item Table in SAP SCM Table in SAP ERP

Handling ID /SCMB/THNDLCD THNDLCD

Handling Unit Type /SCWM/THUTYP THUTYP

PkMtT /SCWM/TPMTYP V_TVTY

PackGrp /SCWM/TPACKGR V_TVEGR

Warehouse Product Group /SCMB/TWHMATGR TWHMATGR

Warehouse Storage Condition /SCMB/TWHSTC TWHSTC

No Customizing Entries

Table Item Table in SAP SCM Table in SAP ERP

QualInsGrp /SCWM/TQGRP TQGRP

3.15 Delivery Processing

3.15.1 Defining Number Range Intervals

1. In Customizing for SAP SCM, define the intervals for the following items:

1. Technical keys: Choose Extended Warehouse Management Cross-Process

Settings Delivery Processing Number Ranges Define Number Range Intervals for

Technical Keys and define the intervals.

2. Outbound deliveries: Choose Extended Warehouse Management Cross-Process

Settings Delivery Processing Number Ranges Define Number Range Intervals for

Outbound Deliveries and define the intervals.

3. Inbound deliveries and outbound delivery orders: Choose Extended Warehouse

Management Cross-Process Settings Delivery Processing Number Ranges Define

No. Range Intervals for Inbound Deliveries and Outbound Del. Orders and define the

intervals.

3.15.2 Defining Number Ranges for ERP Documents

1. In Customizing for SAP SCM, choose SCM Extended Warehouse Management Extended

Warehouse Management Interfaces ERP Integration Delivery Processing Define

Number Ranges for ERP Documents .

2. Choose Change Intervals.

3. Enter number range from for example 1000000001 and number range to for

example 2000000000.

4. Choose Save.

Configuration Guide Page 28 of 36

3.15.3 Defining the Delivery Priority

In Customizing for SAP SCM, choose Extended Warehouse Management Cross-Process

Settings Delivery Processing General Settings Define Delivery Priority .

3.15.4 Defining Shipping Conditions

In Customizing for SAP SCM, choose Extended Warehouse Management Cross-Process

Settings Delivery Processing General Settings Define Shipping Conditions .

3.15.5 Defining Incoterms

In Customizing for SAP SCM, choose Extended Warehouse Management Cross Process

Settings Delivery Processing General Settings Define Incoterms .

3.16 Maintaining Object Types and Class Types in SCM

1. In Customizing for SAP SCM, choose Cross-Application Components Classification

System Classes Maintain Object Types and Class Types .

2. Enter the following values:

Table: /SAPAPO/VERSKEY

Class type: 230

Org. Area: A

Org. Area Description: for example, SPE_COO

3. Choose Save.

3.17 Defining Warehouse Numbers

In Customizing for SAP SCM, choose Extended Warehouse Management Master Data

Define Warehouse Numbers .

3.18 Mapping Warehouse Numbers

1. In Customizing for SAP SCM, choose Extended Warehouse Management Interfaces ERP

Integration General Settings Map Warehouse Numbers from ERP system to EWM Syste .

2. Choose New Entries.

3. Enter data in the following fields:

Business System,

WNoERP,

Warehouse Number,

4. Choose Save.

Configuration Guide Page 29 of 36

3.19 Activating User Exits

Prerequisites

Before activating the user exit for material data, refer to SAP Notes number 746982 and 458914.

1. In SAP SCM, on the SAP Easy Access screen, choose Tools ABAP Workbench

Utilities Enhancements Project Management . Alternatively, call transaction CMOD.

2. Search for project APO_CIF.

3. Choose Enhancements assignment to check that the following enhancements have been

entered:

APOCF005 for inbound processing of product data

APOCF001 for inbound processing of location data

4. Activate the following user exits:

ZXCIFUSERU08 for material data

ZXCIFUSERU06 for location data

SAP SCM stores location data with a different prefix depending on the location type.

For more information about the prefixes, see the following table:

Location Type Name Prefix Added

1001 Plant PL

1002 Distribution Center DC

1003 Shipping Point SP

1005 Transportation Zone - no prefix -

1007 MRP Area MR

1010 Customer CU

1011 Supplier SU

1020 Carrier CA

1040 Store ST

3.20 Activating Business Add-Ins (BAdIs)

3.20.1 Activating BAdI: Inbound Processing for Location

1. In Customizing for SAP SCM, choose SCM Basis Integration BAdIs for Specific

Applications Location and Business Partner BAdI: Inbound Processing for Location .

2. Select the APOCF001_TYPEDIF implementation.

Configuration Guide Page 30 of 36

3. Choose Create.

4. In the Implementation Name field, enter a name for your implementation, for

example Z_APOCF001_TYPEDIF.

5. Choose Continue.

6. In the Implementation Short Text field, enter a description for your implementation.

7. In the menu, choose Implementation Activate .

The Create Object Directory Entry window opens.

8. Do one of the following:

Enter your package and choose Save.

Save the object as a local object by choosing Local Object.

9. You can copy the source code of the BAdI method delivered in the standard system to your BAdI

implementation. For more information about copying the method source code, see Copying the

BAdI Method Source Code.

3.20.2 Activating BAdI: Inbound Processing for Product

1. In Customizing for SAP SCM, choose SCM Basis Integration BAdIs for Specific

Applications Product BAdI: Inbound Processing for Product .

2. Select the APOCF005_SYSDIF implementation.

3. Choose Create.

4. In the Implementation Name field, enter a name for your implementation, for

example Z_APOCF005_SYSDIF.

5. Choose Continue.

6. In the Implementation Short Text field, enter a description for your implementation.

7. In the menu, choose Implementation Activate .

The Create Object Directory Entry window appears.

8. Do one of the following:

Enter your package and choose Save.

Save the object as a local object by choosing Local Object.

9. You can copy the source code of the BAdI method delivered in the standard system to your BAdI

implementation. For more information about copying the method source code, see Copying the

BAdI Method Source Code.

3.20.3 Copying BAdI Method Source Code

1. In Customizing for SAP SCM, choose SCM Basis Integration BAdIs for Specific

Applications Location and Business Partner BAdI: Inbound Processing for Location .

2. Select one of the following BAdI implementations:

APOCF001_TYPEDIF

APOCF005_SYSDIF

3. Choose Display.

4. On the Interface tab, double-click the BAdI method.

5. Select the source code and copy it.

6. Access the corresponding BAdI implementation you created. For more information, see Activating

BAdI: Inbound Processing for Location or Activating BAdI: Inbound Processing for Product.

7. On the Interface tab, double-click the BAdI method and paste the copied source code into it.

Configuration Guide Page 31 of 36

8. Save and activate the BAdI implementation.

3.20.4 Activating BAdI: Inbound Processing for Partner

1. In Customizing for EWM, choose Cross-Application Components SAP Business Partner

Business Partner Basic Settings Number Ranges and Groupings Define Number

Ranges to create an internal or an external number range interval for business partners,

depending on the option you have chosen.

Alternatively, do the following:

1. Call transaction SNUM.

2. Display object BU_PARTNER.

3. Choose Goto Number Ranges .

4. Choose the Change intervals button to create a new number range.

2. In Customizing for EWM, choose Cross-Application Components SAP Business Partner

Business Partner Basic Settings Number Ranges and Groupings Define Groupings and

Assign Number Ranges , assign the number range to a business partner grouping and set the

grouping as standard grouping for internal or external number assignment.

3. In Customizing for EWM, choose SCM Basis Integration BAdIs for Specific

Applications Location and Business Partner BAdI: Inbound Processing for Business

Partner . Create an implementation for classic BAdI SMOD_APOCF038 and activate it. SAP

does not provide an example implementation as several options are possible. For more information,

see the BAdI documentation. The ERP business partner numbers are contained in

table IT_CIF_BP (field PARTNER_ID for business partner number, field TYPE=CRM004 for

vendors, field TYPE=CRM002 for customers). The changed number must be filled in

table ET_BPMAP. Field EF_MAP_USE must be set to X for the changes to be taken into account.

3.21 Defining Availability Groups

1. In Customizing for SAP SCM, choose Extended Warehouse Management Goods Receipt

Process Configure Availability Group for Putaway .

2. Choose Define availability groups.

3. Assign the availability group to the warehouse number and enter the date and time type of the

ERP system in the DtypeERP field.

STANDARD SETTINGS

3.22 Defining the Transportation Group

If you do define the transportation group, you have to ensure that the settings in both systems are the

same.

1. In Customizing for SAP SCM, choose SCM Basis Master Data Product Maintain

Transportation Group .

2. Check that the data shown in the table below exists or enter the data as shown:

Transportation Group Description

0001 On pallets

Configuration Guide Page 32 of 36

Transportation Group Description

0002 In liquid form

3. Choose Save.

3.23 Settings for the Logistic Inventory Management Engine (LIME)

3.23.1 Defining the Warehouse Management Process Type for LIME

1. In Customizing for SAP SCM, choose SCM Basis Logistic Inventory Management Engine

(LIME) Basic Settings Features of Calling Application Process Type of Calling

Application Determine Process Type of Calling Application .

2. Check that a process type named SCM Warehouse Management exists. If it does not exist,

define one by choosing New Entries.

1. Create an entry with the following values:

Field Value

Process Type SCM Warehouse Management

Coll S Collector Active

PN - do not select this checkbox -

Dated Stock Do not take (external) timestamps into account

3. Select the entry and in the Dialog Structure, under Applications, double-click Control Collector.

A new screen appears.

4. Check that a process type SCWM exists. If it does not exist, define one by choosing New Entries.

1. Create an entry with the following values:

Field Value

Process Type SCWM

Coll W2IM

actve - select the checkbox -

5. Choose Save.

3.23.2 Defining the Index Tables for LIME

1. In Customizing for SAP SCM, choose SCM Basis Logistic Inventory Management Engine

(LIME) Basic Settings Index Tables and Hierarchy Determine Index Tables .

2. Check that entries for ObjectTypeLocation, Stock and Handling Unit have been defined. If not,

define them by choosing New Entries.

You have to define multiple entries.

Configuration Guide Page 33 of 36

3. For the object type Location, choose Key Tables W01, W02, W03, and W04.

4. Deselect the Create checkbox for these entries.

5. For the object type Stock, chooseKey Tables W01, W02, W03, and W04.

6. Select the Create checkbox for these entries.

7. For the object type Handling Unit, choose Key Tables W01.

8. Deselect the Create checkbox for these entries.

9. Choose Save.

3.23.3 Defining the Hierarchy for LIME

1. In Customizing for SAP SCM, choose SCM Basis Logistic Inventory Management Engine

(LIME) Basic Settings Index Tables and Hierarchy Determine Hierarchy .

2. Check that the hierarchy index tables have been defined for Location, Stock, and Handling Unit. If

they do not exist, define them by choosing New Entries and enter the data as shown in the

following table.

Parent Key Table Child Key Tab

Root 000 Location W01

Root 000 Location W02

Root 000 Location W03

Root 000 Location W04

Location W01 Handling Unit W01

Location W02 Handling Unit W01

Location W03 Handling Unit W01

Location W03 Stock W01

Location W03 Stock W02

Location W03 Stock W03

Location W03 Stock W04

Location W04 Handling Unit W01

Handling Unit W01 Handling Unit W01

Handling Unit W01 Stock W01

Handling Unit W01 Stock W02

Configuration Guide Page 34 of 36

Parent Key Table Child Key Tab

Handling Unit W01 Stock W03

Handling Unit W01 Stock W04

3. Choose Save.

3.24 Defining Warehouse Number Ranges

1. In Customizing for SAP SCM, choose Extended Warehouse Management Master Data

Define Number Ranges .

The Choose Activity window opens. You can choose from the following activities:

Define Number Range Intervals for Warehouse Task/Warehouse Document

Define Number Range Intervals for Wave

Define Number Range Intervals for Warehouse Order

Define Number Range Intervals for Slotting Run

Define Number Range Intervals for Consolidation Group

Number Ranges for VAS Order

2. Place the cursor on the activity you want to perform.

3. Click Choose.

The relevant Customizing view opens.

4. In the Warehouse No. field, enter the warehouse number.

5. In the menu, choose Interval Change .

6. Define the number ranges and number range intervals by entering data in the following fields:

No.

From No.

To No.

7. In the Assign Number Range Intervals to Warehouse Number activity, enter the number range

numbers you created in the previous activities.

3.25 Defining Warehouse Number Ranges for HUs

1. In Customizing for SAP SCM, choose Extended Warehouse Management Cross-Process

Settings Handling Units External Identification Define Number Range for HU Identification

. Alternatively, call transaction SNRO.

2. In the Object field, enter /SCWM/HUID.

3. Choose Number Ranges.

Configuration Guide Page 35 of 36

3.26 Specifying Output Format of Product Number

In Customizing for EWM, choose SCM Basis Master Data Product Specify Output Format of

Product Number . For more information

3.27 Checking the SAP APO Model and Planning Version

REFER STEP 1.9

Configuration Guide Page 36 of 36

You might also like

- SAP S/4HANA Retail: Processes, Functions, CustomisingFrom EverandSAP S/4HANA Retail: Processes, Functions, CustomisingRating: 3 out of 5 stars3/5 (1)

- The Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemFrom EverandThe Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemNo ratings yet

- Decentralized Ewm: Setup Reports For Configuration of Idoc CommunicationDocument7 pagesDecentralized Ewm: Setup Reports For Configuration of Idoc CommunicationkamalrajNo ratings yet

- Pick by Voice CookbookDocument26 pagesPick by Voice CookbookDevi Konda100% (1)

- SAP EWM Deconsolidation ProcessDocument2 pagesSAP EWM Deconsolidation ProcessKebasot100% (2)

- SAP IS-Retail Interview Questions, Answers, and ExplanationsFrom EverandSAP IS-Retail Interview Questions, Answers, and ExplanationsRating: 3 out of 5 stars3/5 (11)

- SAP EWM-MFS - Master Data - Processing TelegramDocument23 pagesSAP EWM-MFS - Master Data - Processing TelegramMahesh Babu Malepati100% (1)

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesFrom EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo ratings yet

- 301 Dock Appointment SchedulingDocument35 pages301 Dock Appointment SchedulingraviNo ratings yet

- Configuration Guide For Outsourced Transportation PDFDocument118 pagesConfiguration Guide For Outsourced Transportation PDFHemanth Kumar PanagamNo ratings yet

- SAP Integration - SAP ERP - SAP - EWM PDFDocument17 pagesSAP Integration - SAP ERP - SAP - EWM PDFlostrider_991No ratings yet

- Sap Ewm Configuration GuideDocument11 pagesSap Ewm Configuration Guidebalajee nimmalaNo ratings yet

- Understanding Transportation Unit in SAP EWM - Programmer SoughtDocument15 pagesUnderstanding Transportation Unit in SAP EWM - Programmer SoughthalwanvNo ratings yet

- C - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 9Document4 pagesC - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 9Padma Raju0% (1)

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- Final MP WORK DESIGNDocument19 pagesFinal MP WORK DESIGNVita RetiNo ratings yet

- SAP TM Course ContentDocument4 pagesSAP TM Course ContentRahul SinghNo ratings yet

- Appointment Scheduling (DAS) ADMIN GUIDE EWM940Document19 pagesAppointment Scheduling (DAS) ADMIN GUIDE EWM940raviNo ratings yet

- Comparison Between SAP IM - WM - Lean WM - DWM - EWMDocument4 pagesComparison Between SAP IM - WM - Lean WM - DWM - EWMSebastian BravoNo ratings yet

- Fixed Bin Replenishment in SAPDocument5 pagesFixed Bin Replenishment in SAPMohan NaiduNo ratings yet

- Sap SCM Ewm Vs Sap Ecc WMDocument5 pagesSap SCM Ewm Vs Sap Ecc WMJP49466No ratings yet

- Wave Creation in EWM - SAPSPOTDocument23 pagesWave Creation in EWM - SAPSPOTLuis AlonsoNo ratings yet

- SCM EWM A Detailed Overview of Processes and FunctionalityDocument35 pagesSCM EWM A Detailed Overview of Processes and Functionalityrohit dwevediNo ratings yet

- Connectivity Set Up - SAP EWM and S4 HANADocument5 pagesConnectivity Set Up - SAP EWM and S4 HANAAruna DasNo ratings yet

- Ewm Config ContentsDocument4 pagesEwm Config ContentsKumarArunNo ratings yet

- How - To - Guide - List - Classic - Cloud - S4 - Solution ManagerDocument11 pagesHow - To - Guide - List - Classic - Cloud - S4 - Solution ManagerEkrem ErdoganNo ratings yet

- Differences Between IM - WM and EWM - LinkedInDocument5 pagesDifferences Between IM - WM and EWM - LinkedInolivier laroche100% (1)

- Sap EwmDocument2 pagesSap EwmsirivirishiNo ratings yet

- Restrictions For SAP CWM in SAP S/4HANADocument11 pagesRestrictions For SAP CWM in SAP S/4HANATuấn Nguyễn Khắc MinhNo ratings yet

- Function Modules Available in MM & EWMDocument3 pagesFunction Modules Available in MM & EWMgopalaaraoNo ratings yet

- En Flyer Produkt Dematic SAP 001Document16 pagesEn Flyer Produkt Dematic SAP 001srikanthsreeNo ratings yet

- EWM USer ManualDocument16 pagesEWM USer ManualSathish JNo ratings yet

- SAP Plant Connectivity Configuration Guide For SAP Extended Warehouse ManagementDocument19 pagesSAP Plant Connectivity Configuration Guide For SAP Extended Warehouse ManagementHiếu Phạm QuangNo ratings yet

- Rohela Tech It Solutions Pvt. LTDDocument24 pagesRohela Tech It Solutions Pvt. LTDJosé RoblesNo ratings yet

- Embedded Ewm in Sap s4 Hana A PDFDocument12 pagesEmbedded Ewm in Sap s4 Hana A PDFhalwanv100% (1)

- Sap-Ewm ResumeDocument3 pagesSap-Ewm Resumemahaboobpasha.ewmNo ratings yet

- Training For SAP Supply Chain Management (SCM) in Extended Warehouse Management (EWM) For ApplicationsDocument2 pagesTraining For SAP Supply Chain Management (SCM) in Extended Warehouse Management (EWM) For Applicationssamm19820% (1)

- Check of ERP-EWM ConfigurationDocument6 pagesCheck of ERP-EWM Configurationchandra9000No ratings yet

- SAP Transportation ManagementDocument5 pagesSAP Transportation ManagementSrinivas SomisettyNo ratings yet

- EWM - Quick Guide ManualDocument16 pagesEWM - Quick Guide Manualprimegem0% (1)

- 1VD S4hana2021 BPD en UsDocument74 pages1VD S4hana2021 BPD en UsMAYANK JAINNo ratings yet

- EWM - Auto Create Warehouse Task From Inbound & OutboundDocument9 pagesEWM - Auto Create Warehouse Task From Inbound & Outboundwaseem abbasNo ratings yet

- Sap Ewm For FSHN MG EnenDocument33 pagesSap Ewm For FSHN MG EnenmizraimNo ratings yet

- Fernando Vladimir Soliz Mejia: Contact InformationDocument16 pagesFernando Vladimir Soliz Mejia: Contact InformationfsolizmNo ratings yet

- Integration Between SAP, 3rd Party Logistics Providers, and Legacy Systems PDFDocument21 pagesIntegration Between SAP, 3rd Party Logistics Providers, and Legacy Systems PDFchennakrishnaramesh100% (1)

- SAP Transportation Management - Freight Unit (FU)Document11 pagesSAP Transportation Management - Freight Unit (FU)Hruday TNo ratings yet

- EWM Transaction Codes - Supply Chain Management (SCM) - SCN WikiDocument16 pagesEWM Transaction Codes - Supply Chain Management (SCM) - SCN WikiChityala Jeevan Reddy100% (1)

- What Happens During Inbound Processing in SAP Embedded EWM?: External ProcurementDocument8 pagesWhat Happens During Inbound Processing in SAP Embedded EWM?: External ProcurementMohanish MurkuteNo ratings yet

- Sap Ewm Img Key Access MfsDocument19 pagesSap Ewm Img Key Access Mfsbalajee nimmalaNo ratings yet

- Ewm QuestionsDocument3 pagesEwm QuestionsnilackappillilNo ratings yet

- 10 Things To Consider When Deciding If You Should Switch: From SAP WM To EWMDocument11 pages10 Things To Consider When Deciding If You Should Switch: From SAP WM To EWMhalwanvNo ratings yet

- 1v9 S4hana2021 BPD en UsDocument35 pages1v9 S4hana2021 BPD en UsssNo ratings yet

- EwmDocument6 pagesEwmWalid Amin MahmodNo ratings yet

- Yard Management-Sap HelpDocument99 pagesYard Management-Sap HelpBLNo ratings yet

- SBN Car Project 23april 2018 001Document9 pagesSBN Car Project 23april 2018 001Vijay Kamath100% (1)

- Ewm Putaway RulesDocument22 pagesEwm Putaway RulesbirojivenkatNo ratings yet

- RN Ewm 900 enDocument16 pagesRN Ewm 900 enAakriti ChNo ratings yet

- SAP TM DocumentDocument4 pagesSAP TM DocumentsreenusrNo ratings yet

- Deed of Sale With Assumption of MortgageDocument3 pagesDeed of Sale With Assumption of MortgageReb Reymund Castillo100% (1)

- Disinfection-Tunnel Taytay PalawanDocument8 pagesDisinfection-Tunnel Taytay PalawanNico Rivera CallangNo ratings yet

- DFM ProcessDocument7 pagesDFM ProcessDaniel SianturiNo ratings yet

- Megawide GMR Construction JV, Inc.: Manpower Supply For Civil Structural WorksDocument1 pageMegawide GMR Construction JV, Inc.: Manpower Supply For Civil Structural WorksChristian Jay ValdezNo ratings yet

- Class Ir Under EUMDRDocument2 pagesClass Ir Under EUMDRhithamextrastepNo ratings yet

- SRL - CBR FinalDocument19 pagesSRL - CBR FinalheebaNo ratings yet

- 3i Research Paper Noriels GroupDocument76 pages3i Research Paper Noriels GroupMICHELLE LENDESNo ratings yet

- What Money Can'T Buy: The Moral Limits of Markets: Book ForumDocument9 pagesWhat Money Can'T Buy: The Moral Limits of Markets: Book ForumIshtar CardonaNo ratings yet

- Urban RenewalDocument6 pagesUrban RenewalashimaNo ratings yet

- Shubham Moon Marketing 4.0 Final Assignment MBA 1Document26 pagesShubham Moon Marketing 4.0 Final Assignment MBA 1shubham moonNo ratings yet

- Idirect Remotes MTBF & MTTR DeclarationDocument3 pagesIdirect Remotes MTBF & MTTR DeclarationАнатолий МаловNo ratings yet

- IQP Final Report PDFDocument135 pagesIQP Final Report PDFmalingyee100% (1)

- Chapter 3: Forecasting: Anne Liah D. Romero BSA2205 - BSMA 1E Activity 3Document11 pagesChapter 3: Forecasting: Anne Liah D. Romero BSA2205 - BSMA 1E Activity 3Aliah RomeroNo ratings yet

- Make in India 2Document7 pagesMake in India 2Hcs OnlineNo ratings yet

- NSTP Module - Lesson 5Document5 pagesNSTP Module - Lesson 5Maira Garcia C.No ratings yet

- Rural Marketing: Prof Sugandha Sinha, Assistant Professor Parul Institute of Management and ResearchDocument28 pagesRural Marketing: Prof Sugandha Sinha, Assistant Professor Parul Institute of Management and ResearchSugandhaNo ratings yet

- Career Profiles: Berlin Insan Pratiwi S.PD., M.HumDocument11 pagesCareer Profiles: Berlin Insan Pratiwi S.PD., M.HumAyu RestianahNo ratings yet

- Universiti Teknologi MaraDocument5 pagesUniversiti Teknologi Mararaihana abdulkarimNo ratings yet

- 1 s2.0 S2214785320316102 MainDocument6 pages1 s2.0 S2214785320316102 MainmonicaNo ratings yet

- PGPF 04 019 Kancharapu Akhil Kumar CF AssignmnetDocument59 pagesPGPF 04 019 Kancharapu Akhil Kumar CF Assignmnetak kancharapuNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument2 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalancePriyanka SangleNo ratings yet

- Tieng Anh 10 Friends Global - Unit 5&6 - Test 1Document6 pagesTieng Anh 10 Friends Global - Unit 5&6 - Test 1Nguyễn ĐăngNo ratings yet

- Zanini, Curtis & Company - August 2022Document27 pagesZanini, Curtis & Company - August 2022fredNo ratings yet

- Quality Services of Manufacturing of Automobiles IDocument2 pagesQuality Services of Manufacturing of Automobiles ITanzeel HassanNo ratings yet

- Edited Bestari Business PlanDocument26 pagesEdited Bestari Business PlanJohn SonNo ratings yet

- Humanity's Unsustainable Environmental Footprint - Hoekstra - 2014Document5 pagesHumanity's Unsustainable Environmental Footprint - Hoekstra - 2014David RemolinaNo ratings yet

- GPRO - 330 - 1 - Monthly Process AuditDocument1 pageGPRO - 330 - 1 - Monthly Process Auditsantosh kumarNo ratings yet

- Uniwash UW Series SpecificationsDocument4 pagesUniwash UW Series Specificationsmairimsp2003No ratings yet

- LMN Piggery Together We Can Business Plan Prepared 10/03/2021Document14 pagesLMN Piggery Together We Can Business Plan Prepared 10/03/2021Malinga Lunga100% (1)