Professional Documents

Culture Documents

KTR 019 PDF

KTR 019 PDF

Uploaded by

L.kolekarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KTR 019 PDF

KTR 019 PDF

Uploaded by

L.kolekarCopyright:

Available Formats

Tyre couplings

REVOLEX KX

ROTEX® Torsionally flexible couplings

POLY-NORM

For advanced

drive

ROTEX

technology

POLY

Spider types

el;

ste

r ial

te A

ma Sh

r ial hub r 92

te h ide

A ma ns F wit sp

Sh erial l

s A h ub tio h D- ation 40) of

2 h ra S n G e

r 9 mat nera S ith vib 4 bi (GG orqu

ide °C /98 h A nw )

40 ping 0 °C r6 om t

d sp ll hub in ge + 90

e r 95 98 S natio );

i G m 9 s pide um c 0-15 e the

riv

es

ar r a ns s to id 5 / b 25 G G da + ■ im -4 0 ic ld

nd fo atio ulic s °C s p r 9 o m G 5 ( et to p t JS tw gle c a

a e c -1 y °C o g an crit i

st able plic ydra er tie – 40 ■ id (G s ■ -G tin

■ it sp imum 250 -400 rque – 30 EN smit sting for

■

su all ap ring/h prop from ■

pt J L- JS to om a n twi le olysi

s

c o G h tr b

■

for inee ami nge ■ G

N- ; EN- g hig ge f

r ■

m all suita hydr

g n a E r

en d dy ure r el tin an ■

s

ide t to

o t ste smit ure r sp istan

■

go pera ran erat ■ s

t re

tem ■ p ■

■ tem ■

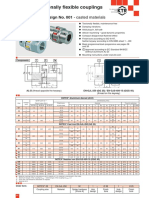

Spider types – Materials, physics, properties

Standard spiders

Spider Perm. temperature range (°C) Available for

type Identification Material coupling size Typical

hardness- Continuous Max. temperature applications

(Shore) colour temperature short time

– for all applications in general engineering

92 Sh A yellow polyurethane – 40 to + 90 – 50 to + 120 size 14 – 180 and hydraulics

– Standard applications with average elasticity

– good torque transmission

95/98 Sh A red polyurethane – 30 to + 90 – 40 to + 120 size 14 – 180

with good damping properties

natural white – I.C. - engines

64 Sh D-F with green polyurethane – 30 to + 110 – 30 to + 130 size 14 – 180 – high air moisture, resistant to hydrolysis

tooth flanks – displacement of critical speeds

Spiders for special applications on request for:

Spider type Identification Material Perm. temperature range (°C)

hardness

Typical (Shore) colour Continuous Max. temperature

applications temperature short time

I.C.-engines, for high dynamic load, blue with yellow

high air moisture/resistant to hydrolysis 94 Sh A-T polyurethane – 50 to + 110 – 60 to + 130

tooth flanks

Drives with higher loads, small twisting angles -

torsionally rigid, high ambient temperatures 64 Sh D-H green hytrel – 50 to + 110 – 60 to + 150

Small twisting angles and high torsion spring stiffness,

high ambient temperature, good resistance to chemicals polyamide - PA –20 to +130 –30 to +150

Small twisting angles and high torsion spring stiffness, up to +180

very high ambient temperature, good resistance to chemicals, PEEK light grey PEEK (ATEX release up to +250

resistant to hydrolysis to a max. +160)

1) Different properties depending on compound

Comparison of loads Twisting angle Damping

= Dampings- [AD] stat. charact.

curve

Flex. deformation [Ae]

torque T

CTstat.

torque T

operation

torque T

w/o damping

dyn. charact.

curve CTdyn.

with damping

twisting angle

operating point

period Twisting angle

19

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- List of Koc Standards & Specifications Applicable For JPF-4 & JPF-5 PDFDocument5 pagesList of Koc Standards & Specifications Applicable For JPF-4 & JPF-5 PDFL.kolekar25% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Thermodynamic-BasicDocument136 pagesThermodynamic-BasicAhmad Abdullahi TijjaniNo ratings yet

- Storage TankDocument2 pagesStorage TankL.kolekarNo ratings yet

- Extract of HEIL Old Manual Valve SectionsDocument10 pagesExtract of HEIL Old Manual Valve SectionsL.kolekar100% (1)

- Motion in One DimensionDocument12 pagesMotion in One DimensionShinji50% (2)

- Assembly Line BalancingDocument54 pagesAssembly Line BalancingKoushik Rao100% (1)

- Ipe 450Document2 pagesIpe 450L.kolekarNo ratings yet

- Bep StandardDocument64 pagesBep StandardL.kolekarNo ratings yet

- Hydraulics The ReservoirDocument2 pagesHydraulics The ReservoirL.kolekarNo ratings yet

- CircuitDocument1 pageCircuitL.kolekarNo ratings yet

- 875c Series Api Dust Cap Data SheetDocument2 pages875c Series Api Dust Cap Data SheetL.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Tozen Flex JTDocument16 pagesTozen Flex JTL.kolekarNo ratings yet

- 108" CA Body and Other Optional Equipment ShownDocument2 pages108" CA Body and Other Optional Equipment ShownL.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- 2021 Calendar - India: January 2021 February 2021 March 2021Document1 page2021 Calendar - India: January 2021 February 2021 March 2021L.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- MK Series User ManualDocument24 pagesMK Series User ManualL.kolekarNo ratings yet

- ENG7cranesgen Volvo Body Builder Cat Crane MountingDocument13 pagesENG7cranesgen Volvo Body Builder Cat Crane MountingL.kolekar0% (1)

- Blackmer Parts List: T-Type Truck Pump Strainers FOR PUMP SIZES: 2, 2.5, 3Document2 pagesBlackmer Parts List: T-Type Truck Pump Strainers FOR PUMP SIZES: 2, 2.5, 3L.kolekarNo ratings yet

- JIS-G-3302 Specifications For GI PlatesDocument11 pagesJIS-G-3302 Specifications For GI PlatesL.kolekarNo ratings yet

- Science Interactive TextDocument112 pagesScience Interactive Textaapirzado100% (12)

- Resume - Sachin RavindranDocument1 pageResume - Sachin RavindranJosh pokeNo ratings yet

- 2 Computing More Limits: Math 180 WorksheetsDocument5 pages2 Computing More Limits: Math 180 WorksheetsDeep PrajapatiNo ratings yet

- IEEEpaper Feb 2005Document9 pagesIEEEpaper Feb 2005NicovDijkNo ratings yet

- Question Bank (4ec6a-Advanced Engg. Mathematics-II)Document6 pagesQuestion Bank (4ec6a-Advanced Engg. Mathematics-II)govindcoolNo ratings yet

- Intro Emb SysDocument294 pagesIntro Emb SysSanjay YadavNo ratings yet

- Visual Inspection of Crimped ConnectionsDocument1 pageVisual Inspection of Crimped Connectionsvinay gayateNo ratings yet

- Amwell Standard Protocol V2.02!14!11 - 11Document30 pagesAmwell Standard Protocol V2.02!14!11 - 11Aziz AzizNo ratings yet

- Jeppview For Windows: General Information General InformationDocument52 pagesJeppview For Windows: General Information General InformationAfner OtnielNo ratings yet

- DEXTREMEL Final ReportDocument75 pagesDEXTREMEL Final ReportalfavectorNo ratings yet

- Sa 20 Instruction 20 Sheetenglish 20060112Document2 pagesSa 20 Instruction 20 Sheetenglish 200601122i Eletrônica Industrial LTDANo ratings yet

- ESP8089 Driver Release Description: Produkt Dostpny W Sklepie WWW - Soyter.pl - KliknijDocument10 pagesESP8089 Driver Release Description: Produkt Dostpny W Sklepie WWW - Soyter.pl - KliknijGleyton BezerraNo ratings yet

- Goldengate12 2 X Cert Matrix 2769360Document18 pagesGoldengate12 2 X Cert Matrix 2769360repakulakishoreNo ratings yet

- Optical Fiber Communication-1finalDocument39 pagesOptical Fiber Communication-1finalTanima ChakrabortyNo ratings yet

- Plan and DesignDocument4 pagesPlan and Designsanique peterkinNo ratings yet

- Chapter 2-4 To 2-6 With AnswersDocument12 pagesChapter 2-4 To 2-6 With Answersapi-235135985No ratings yet

- 07 KT 97Document54 pages07 KT 97max_ingNo ratings yet

- FEMAP-155 508 Cortado (01-13)Document13 pagesFEMAP-155 508 Cortado (01-13)Karolayn VenturaNo ratings yet

- USP-NF AcetaminophenDocument4 pagesUSP-NF AcetaminophenStalin VacaNo ratings yet

- Simulink Control DesignDocument4 pagesSimulink Control DesignjimakosjpNo ratings yet

- Downloading The User's Guide Scope: EnglishDocument10 pagesDownloading The User's Guide Scope: EnglishCesar Oseguera CabreraNo ratings yet

- CANcaseXL Manual enDocument38 pagesCANcaseXL Manual enHemanth RasineniNo ratings yet

- Proud As A Kumon CompleterDocument3 pagesProud As A Kumon CompleterYuh-Lin GanNo ratings yet

- Gaurav Singh - Equilibrium of Parallel Forces and MomentsDocument13 pagesGaurav Singh - Equilibrium of Parallel Forces and Momentsgaurav singhNo ratings yet

- Igbt Irg 4p254sDocument9 pagesIgbt Irg 4p254sMilagros Mendieta VegaNo ratings yet

- Inhemeter Smart Grid Solution-InheGrid-DA 180312Document63 pagesInhemeter Smart Grid Solution-InheGrid-DA 180312chykemanNo ratings yet

- Fsd36 Combination Fire and Smoke DamperDocument4 pagesFsd36 Combination Fire and Smoke Damperkprasad_56900No ratings yet