Professional Documents

Culture Documents

Rotex: Torsionally Flexible Couplings

Rotex: Torsionally Flexible Couplings

Uploaded by

L.kolekar0 ratings0% found this document useful (0 votes)

150 views1 pageKTR cOPU_5

Original Title

KTR_024

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKTR cOPU_5

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

150 views1 pageRotex: Torsionally Flexible Couplings

Rotex: Torsionally Flexible Couplings

Uploaded by

L.kolekarKTR cOPU_5

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

ROTEX® Torsionally flexible couplings For advanced

drive

technology

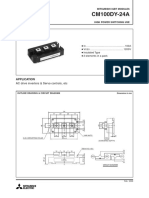

Shaft coupling design No. 001 - casted materials

● Torsionally flexible, maintenance-free

● Damping vibrations

● Axial plug-in, fail-safe

● Allover machining – good dynamic properties

● Compact design/small flywheel effect

● Finish bore according to ISO fit H7,

feather keyway according to DIN 6885 sheet 1 - JS9

● Basic programme/stock programme see pages 38

and 39

● Approved according to EC Standard 94/9/EC

(without aluminium AL-D)

● Mounting instructions under www.ktr.com

Components 1 2 1a 1 2 1a

AL-D (thread opposite the keyway) EN-GJL-250 (GG 25) / EN-GJS-400-15 (GGG 40)

(thread on the keyway)

ROTEX® Aluminium diecast (AI-D)

Spider (part 2) 1) Dimensions [mm]

Size Compo- Rated torque [Nm] Finish bore General Thread for setscrews

nent

92 Sh A 98 Sh A 64 Sh D d (min-max) L l1; l2 E b s DH dH D; D1 N G t TA [Nm]

143) 1a 7,5 12,5 – 6-16 35 11 13 10 1,5 30 10 30 – M4 5 1,5

1 6-19 32

19 10 17 – 66 25 16 12 2 41 18 20 M5 10 2

1a 19-24 41

1 9-24 40

24 35 60 – 78 30 18 14 2 56 27 24 M5 10 2

1a 22-28 56

1 10-28 48

28 95 160 – 90 35 20 15 2,5 67 30 28 M8 15 10

1a 28-38 67

ROTEX® Cast iron EN-GJL-250 (GG 25)

1 12-38 66

114 45 37

38 1a 190 325 405 24 18 3 80 38 M8 15 10

38-45 78

1b 164 70 62

1 14-42 75

126 50 40

42 1a 265 450 560 26 20 3 95 46 M8 20 10

42-55 94

1b 176 75 65

1 15-48 85

140 56 45

48 1a 310 525 655 28 21 3,5 105 51 M8 20 10

48-60 104

1b 188 80 69

1 20-55 98

55 410 685 825 160 65 30 22 4 120 60 52 M10 20 17

1a 55-70 118

65 1 625 940 1175 22-65 185 75 35 26 4,5 135 68 115 61 M10 20 17

75 1 1280 1920 2400 30-75 210 85 40 30 5 160 80 135 69 M10 25 17

90 1 2400 3600 4500 40-90 245 100 45 34 5,5 200 100 160 81 M12 30 40

ROTEX® Nodular iron EN-GJS-400-15 (GGG 40)

100 1 3300 4950 6185 50-115 270 110 50 38 6 225 113 180 89 M12 30 40

110 1 4800 7200 9000 60-125 295 120 55 42 6,5 255 127 200 96 M16 35 80

125 1 6650 10000 12500 60-145 340 140 60 46 7 290 147 230 112 M16 40 80

140 1 8550 12800 16000 60-160 375 155 65 50 7,5 320 165 255 124 M20 45 140

160 1 12800 19200 24000 80-185 425 175 75 57 9 370 190 290 140 M20 50 140

180 1 18650 28000 35000 85-200 475 195 85 64 10,5 420 220 325 156 M20 50 140

= Material marking that the calculation/order is based on if no material is mentioned in the order.

1) Maximum torque of the coupling TKmax. = rated torque of the coupling TK Nenn. x 2

2) From size 125 thread for setscrews on request.

3) Material Al-H.

Order form: ROTEX® - 38 EN-GJL-250 92 1 – Ø 38 1 – Ø 25

Coupling size Material Spider hardness Hub Finish Hub Finish

[Shore A] design bore design bore

24

You might also like

- List of Koc Standards & Specifications Applicable For JPF-4 & JPF-5 PDFDocument5 pagesList of Koc Standards & Specifications Applicable For JPF-4 & JPF-5 PDFL.kolekar25% (4)

- HLX5 Kataloğu - 2016Document22 pagesHLX5 Kataloğu - 2016Alma100% (1)

- Storage TankDocument2 pagesStorage TankL.kolekarNo ratings yet

- Extract of HEIL Old Manual Valve SectionsDocument10 pagesExtract of HEIL Old Manual Valve SectionsL.kolekar100% (1)

- Flylinktech 6000mah Jump Starter ManualDocument5 pagesFlylinktech 6000mah Jump Starter ManualBenjamin Dover0% (1)

- Acoplamentos KTR 024 PDFDocument1 pageAcoplamentos KTR 024 PDF3DLAB CAD/CAMNo ratings yet

- Rotex Torsionally Flexible Coupling: Shaft Coupling Design No. 001 - Material SteelDocument1 pageRotex Torsionally Flexible Coupling: Shaft Coupling Design No. 001 - Material SteelСергей КолесниковNo ratings yet

- Instruccionesaacoples KTRDocument16 pagesInstruccionesaacoples KTRDênis DáyolNo ratings yet

- DMT280H редукторDocument2 pagesDMT280H редукторkamran mamedovNo ratings yet

- ROTEX Flex Coupling GR Instruction ManualDocument21 pagesROTEX Flex Coupling GR Instruction ManualIzzi Al-AkbarNo ratings yet

- TYPE 8B1/8B1T: Elastomer O-Ring SealsDocument6 pagesTYPE 8B1/8B1T: Elastomer O-Ring SealshukNo ratings yet

- Mini Ratchet Set Accessory: 2335M 5, 5.5, 6, 7, 8 1025P PH1, PH2 1025T T10, T15, T20 1025H H3, H4, H5, H6Document1 pageMini Ratchet Set Accessory: 2335M 5, 5.5, 6, 7, 8 1025P PH1, PH2 1025T T10, T15, T20 1025H H3, H4, H5, H6hudsonNo ratings yet

- Monninghoff 546 - DatasheetDocument11 pagesMonninghoff 546 - DatasheetirfannadineNo ratings yet

- 546 DatasheetDocument11 pages546 Datasheetwilfredo mercedesNo ratings yet

- Limitador de TorqueDocument1 pageLimitador de TorquenoonesthereNo ratings yet

- Lineaarijohteiden RullatDocument1 pageLineaarijohteiden RullatAntti KoskiniemiNo ratings yet

- Matryx Vane Actuator Technical DataDocument5 pagesMatryx Vane Actuator Technical DataWise SoNo ratings yet

- Flender Coupling N-BWNDocument1 pageFlender Coupling N-BWNCharles ChengNo ratings yet

- Barra Estabilizadora, D5N CaterpillarDocument2 pagesBarra Estabilizadora, D5N CaterpillarLuisNo ratings yet

- Marine-Transmission DMT170HL BrochureDocument2 pagesMarine-Transmission DMT170HL BrochureChocolateNo ratings yet

- Marine-Transmission DMT260HL BrochureDocument2 pagesMarine-Transmission DMT260HL BrochureEduardo Uquiza HuamanNo ratings yet

- Permanent Magnet Brake. PMB SeriesDocument8 pagesPermanent Magnet Brake. PMB SeriesAshok BhatNo ratings yet

- Gerwah DiskDocument4 pagesGerwah DiskThai TrangNo ratings yet

- Hydraulic Rock Drill HLX 5 Water FlushinDocument19 pagesHydraulic Rock Drill HLX 5 Water FlushinSales Aydinkaya100% (1)

- Sello 8-1Document6 pagesSello 8-1joel galvanNo ratings yet

- S02 Rock DrillDocument22 pagesS02 Rock DrillEver Jhonatan Mellisho CanoNo ratings yet

- Cm200du 12FDocument4 pagesCm200du 12FAna Cuahutli Sanchez MartinezNo ratings yet

- Marine-Transmission DMT180HL BrochureDocument2 pagesMarine-Transmission DMT180HL BrochureChocolateNo ratings yet

- Microphone PreamplifierDocument3 pagesMicrophone Preamplifierkholid0150% (2)

- Gibault Joint: Ref: RF25Document1 pageGibault Joint: Ref: RF25Glee ZiEoNo ratings yet

- Dimension DB 611Document3 pagesDimension DB 611Ugo MorelliNo ratings yet

- Z5 Parker-Praedifa GBDocument2 pagesZ5 Parker-Praedifa GBArun51092No ratings yet

- DRIVE CLiQ ConnectionDocument1 pageDRIVE CLiQ ConnectionAnh HoàngNo ratings yet

- DRIVE CLiQ ConnectionDocument1 pageDRIVE CLiQ ConnectionAnh HoàngNo ratings yet

- Oyf24-1a - 36312Document1 pageOyf24-1a - 36312geradNo ratings yet

- DRIVE CLiQ ConnectionDocument1 pageDRIVE CLiQ ConnectionAnh HoàngNo ratings yet

- DRIVE CLiQ ConnectionDocument1 pageDRIVE CLiQ ConnectionAnh HoàngNo ratings yet

- D4N Mini Safety Limit Switch C130 E1 01 DsDocument24 pagesD4N Mini Safety Limit Switch C130 E1 01 DsciprianNo ratings yet

- CM100DY-24NF MitsubishiElectricSemiconductorDocument4 pagesCM100DY-24NF MitsubishiElectricSemiconductorJerry LeeNo ratings yet

- XJ Aluminium Butterfly ValveDocument7 pagesXJ Aluminium Butterfly ValveNguyễn Thành ChungNo ratings yet

- NCS CatalogDocument27 pagesNCS Catalogminhdoan00No ratings yet

- Cm400dy 66HDocument3 pagesCm400dy 66HMiguel GalvánNo ratings yet

- Bearing Isolator: Vb45-S Technical DataDocument1 pageBearing Isolator: Vb45-S Technical DataDAVID SOTONo ratings yet

- 1232Xl Lawn Tractor: Parts CatalogDocument36 pages1232Xl Lawn Tractor: Parts CatalogjanNo ratings yet

- d14.001.1 IS TS VBXX-D ENUSDocument1 paged14.001.1 IS TS VBXX-D ENUSbincoleto5536No ratings yet

- GTO StationaryChuckDocument1 pageGTO StationaryChuckweslley.luzNo ratings yet

- Cm200dy-24nf eDocument4 pagesCm200dy-24nf eWesamNo ratings yet

- RPT GERWAH Backlash-Free Metal Bellows Coupling AKD H ENDocument2 pagesRPT GERWAH Backlash-Free Metal Bellows Coupling AKD H ENjohnNo ratings yet

- Delta Ia-Plc Dvp-Sa2 I Tse 20210121Document19 pagesDelta Ia-Plc Dvp-Sa2 I Tse 20210121tungdohmeNo ratings yet

- DA32UQ User Manual: FeaturesDocument12 pagesDA32UQ User Manual: FeaturesMBAHWIERNo ratings yet

- YU-UL18 (Inch) Indexable InsertsDocument38 pagesYU-UL18 (Inch) Indexable InsertsLuis CoolNo ratings yet

- DA32UQ User Manual: FeaturesDocument12 pagesDA32UQ User Manual: FeaturesMBAHWIERNo ratings yet

- Rexroth: Spare Parts ListDocument35 pagesRexroth: Spare Parts Listadelmomoura100% (1)

- Nema Nomenclature RolesDocument9 pagesNema Nomenclature RolesRicardo LaraNo ratings yet

- Remmen Voor ElektromotorenDocument3 pagesRemmen Voor ElektromotorenThierry HeldenberghNo ratings yet

- ER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BDocument10 pagesER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BdavicocasteNo ratings yet

- DCU SeriesDocument4 pagesDCU SeriesSupakanit LimsowanNo ratings yet

- Cm100dy-24a eDocument5 pagesCm100dy-24a eDamian MadryNo ratings yet

- Re 17327 - 2022-12Document36 pagesRe 17327 - 2022-12Abner TortoreliNo ratings yet

- Re 17327 - 2022-10Document36 pagesRe 17327 - 2022-10ashfaq shaikhNo ratings yet

- BOM List Converter 60VDC-12VDC 12 - 06 - 2020 ThôDocument2 pagesBOM List Converter 60VDC-12VDC 12 - 06 - 2020 ThôNguyễn TínNo ratings yet

- Datasheet CM100DU-34KADocument4 pagesDatasheet CM100DU-34KAOscar Ortega EstarriagaNo ratings yet

- Ipe 450Document2 pagesIpe 450L.kolekarNo ratings yet

- Bep StandardDocument64 pagesBep StandardL.kolekarNo ratings yet

- Hydraulics The ReservoirDocument2 pagesHydraulics The ReservoirL.kolekarNo ratings yet

- CircuitDocument1 pageCircuitL.kolekarNo ratings yet

- 875c Series Api Dust Cap Data SheetDocument2 pages875c Series Api Dust Cap Data SheetL.kolekarNo ratings yet

- 2021 Calendar - India: January 2021 February 2021 March 2021Document1 page2021 Calendar - India: January 2021 February 2021 March 2021L.kolekarNo ratings yet

- Blackmer Parts List: T-Type Truck Pump Strainers FOR PUMP SIZES: 2, 2.5, 3Document2 pagesBlackmer Parts List: T-Type Truck Pump Strainers FOR PUMP SIZES: 2, 2.5, 3L.kolekarNo ratings yet

- Tozen Flex JTDocument16 pagesTozen Flex JTL.kolekarNo ratings yet

- 108" CA Body and Other Optional Equipment ShownDocument2 pages108" CA Body and Other Optional Equipment ShownL.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- JIS-G-3302 Specifications For GI PlatesDocument11 pagesJIS-G-3302 Specifications For GI PlatesL.kolekarNo ratings yet

- ENG7cranesgen Volvo Body Builder Cat Crane MountingDocument13 pagesENG7cranesgen Volvo Body Builder Cat Crane MountingL.kolekar0% (1)

- MK Series User ManualDocument24 pagesMK Series User ManualL.kolekarNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 030235-0Document19 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 030235-0Chris HendonNo ratings yet

- Electric Drive Drilling Equipment: Emeri InternationalDocument185 pagesElectric Drive Drilling Equipment: Emeri InternationalKhedr HamoudNo ratings yet

- PC Rotary - Oil Free NirvanaDocument1 pagePC Rotary - Oil Free NirvanaBùi ViệtNo ratings yet

- G. Ford Motor Company - 2021 Q4 Earnings Transcript 20220203Document17 pagesG. Ford Motor Company - 2021 Q4 Earnings Transcript 20220203nguyenhoangNo ratings yet

- Apollo Tyres LTDDocument27 pagesApollo Tyres LTDamal roiNo ratings yet

- The All New Lexus RZ Digital BrochureDocument15 pagesThe All New Lexus RZ Digital BrochureReza MaulanaNo ratings yet

- Regenerative Braking System Full ProjectDocument24 pagesRegenerative Braking System Full ProjectĨ Åm MoħănNo ratings yet

- Operator'S Manual: Do Not Remove This Manual From This VehicleDocument83 pagesOperator'S Manual: Do Not Remove This Manual From This VehiclePablo Martínez H.No ratings yet

- SM-664 Blowby Test ReportDocument6 pagesSM-664 Blowby Test ReportSandeep NikhilNo ratings yet

- Nara Ana Wind Power PVT - LTD: Service Inspection ReportDocument7 pagesNara Ana Wind Power PVT - LTD: Service Inspection ReportAkash RockNo ratings yet

- Harvard Business Review Analytic - Ducati: January 2017Document10 pagesHarvard Business Review Analytic - Ducati: January 2017Vaibhav ShuklaNo ratings yet

- Value Advantage: A/C CompressorsDocument2 pagesValue Advantage: A/C CompressorsСергей Че100% (1)

- Nike Case StudyDocument5 pagesNike Case Studyaditya kothekarNo ratings yet

- New Mechanical ProjectDocument10 pagesNew Mechanical Projectवैज्ञानिक बाबाNo ratings yet

- Foreign Object Damage Uneven Wear Normal Wear: Radial and Bias TiresDocument1 pageForeign Object Damage Uneven Wear Normal Wear: Radial and Bias Tireshpulido33_390009144100% (1)

- VORON2.2 ManualDocument120 pagesVORON2.2 ManualSsZzliMmNo ratings yet

- Atc TRT2221 (Ver 00)Document43 pagesAtc TRT2221 (Ver 00)sandyNo ratings yet

- 2010 ATRA Technical SeminarDocument35 pages2010 ATRA Technical Seminartambache69100% (1)

- C640D-305-192 Data SheetDocument12 pagesC640D-305-192 Data SheetFlavio PinhoNo ratings yet

- Mxu 50 Reverse PDFDocument122 pagesMxu 50 Reverse PDFtestiNo ratings yet

- SCV Digital Catalogue 26 June - 01Document58 pagesSCV Digital Catalogue 26 June - 01Prateesh DeepankarNo ratings yet

- TF April 2014 WebDocument20 pagesTF April 2014 Webjaskaran singhNo ratings yet

- IsuzuDocument1 pageIsuzuFarhan Sheikh100% (1)

- Morgan Olson Ford F59 FOUNDATION Food TruckDocument2 pagesMorgan Olson Ford F59 FOUNDATION Food TruckLeyner NúñezNo ratings yet

- Lecture Notes ON Internal Combustion Engine: Course Code: Me 4101Document10 pagesLecture Notes ON Internal Combustion Engine: Course Code: Me 4101MahiNo ratings yet

- CNH - 87354249 - National & International Standard PartsDocument156 pagesCNH - 87354249 - National & International Standard PartsLucaNo ratings yet

- GPS and GSM Based Smart TaximeterDocument5 pagesGPS and GSM Based Smart TaximeterIJIERT-International Journal of Innovations in Engineering Research and Technology100% (1)

- WWME BrochureDocument3 pagesWWME BrochurebahlakeNo ratings yet

- FerrariDocument38 pagesFerrariJirayu MmNo ratings yet