Professional Documents

Culture Documents

Effect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant Efficiency

Effect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant Efficiency

Uploaded by

Manish Gautam0 ratings0% found this document useful (0 votes)

111 views2 pagesChanging the steam to carbon ratio (S/C ratio) in an ammonia plant's primary reformer impacts the plant's efficiency. Specifically:

1) Increasing the S/C ratio from 3.61 to 3.71 increases fuel requirements, steam generation, and pressure drops, while decreasing synthesis loop purge rates and secondary reformer methane slip.

2) Decreasing the S/C ratio from 3.71 to 3.61 produces the opposite effects.

3) Calculations estimate that decreasing the S/C ratio by 0.1 would save 0.51 Gcal/hr of heat, equating to annual savings of 0.95 crore rupees with India's current energy costs

Original Description:

Original Title

SC calculation

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentChanging the steam to carbon ratio (S/C ratio) in an ammonia plant's primary reformer impacts the plant's efficiency. Specifically:

1) Increasing the S/C ratio from 3.61 to 3.71 increases fuel requirements, steam generation, and pressure drops, while decreasing synthesis loop purge rates and secondary reformer methane slip.

2) Decreasing the S/C ratio from 3.71 to 3.61 produces the opposite effects.

3) Calculations estimate that decreasing the S/C ratio by 0.1 would save 0.51 Gcal/hr of heat, equating to annual savings of 0.95 crore rupees with India's current energy costs

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

111 views2 pagesEffect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant Efficiency

Effect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant Efficiency

Uploaded by

Manish GautamChanging the steam to carbon ratio (S/C ratio) in an ammonia plant's primary reformer impacts the plant's efficiency. Specifically:

1) Increasing the S/C ratio from 3.61 to 3.71 increases fuel requirements, steam generation, and pressure drops, while decreasing synthesis loop purge rates and secondary reformer methane slip.

2) Decreasing the S/C ratio from 3.71 to 3.61 produces the opposite effects.

3) Calculations estimate that decreasing the S/C ratio by 0.1 would save 0.51 Gcal/hr of heat, equating to annual savings of 0.95 crore rupees with India's current energy costs

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

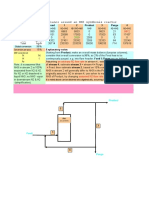

Effect of Primary Reformer Steam to Carbon ratio on Ammonia plant

Efficiency

Steam rate in any ammonia plant should be enough to meet certain requirements which are as

follow

1) Steam is one of the reactant in the reforming reaction and water shift reaction therefore it

should be more than stoichiometric requirement.

Theoretical requirement of S/C

S/C 1.5 To prevent carbon formation zone in Primary Reformer tube

S/C 2 To maintain High temperature shift catalyst in proper reduction state

2) Condensing steam should be enough to provide heat of regeneration in CO2 removal

system.

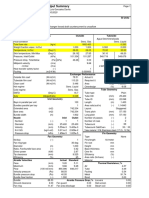

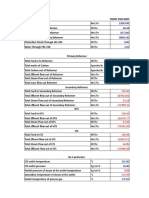

Change occurring for a steady plant operation by changing S/C ratio by 0.1.

S/C 3.71 3.61

1) Fuel Requirement Increase Decrease

2) Synthesis loop purge rate Decrease Increase

3) Steam generation in HP boiler Increase Decrease

4) Pressure drop through Front End Increase Decrease

5) Supply of heat of regeneration in No 2 HPC reboiler Decrease Increase

Calculation for change in specific energy consumption

Following are the assumptions taken while doing the calculation for change in specific energy

consumption

1) PFD data is considered as base case.

2) Primary Reformer efficiency is constant while changing the S/C

3) Cost of energy is considered to be 2400 INR/Mkcal.

4) Approach to Equilibruim for all catalyst reactor is same.

Inlet steam to Primary Reformer MT/hr 66.68 64.80

Inlet steam temperature Kg/cm2G 36 36

Inlet steam temperature O

C 245 245

Enthalpy of steam at inlet kcal/kg 671 671

Outlet pressure Kg/cm2G 30.4 30.4

Outlet temperature O

C 761 761

Enthaply of steam at outlet kcal/kg 970 970

Heat duty Gcal/hr 20 19

heat of regeneration kcal/Nm3 1075 1075

Steam input to No 2 HPC reboiler MT/hr 9.90 10.08

Enthalpy of steam to No 2 HPC reboiler kcal/kg 667 667

Steam Saving MT/hr 1.70

Heat Saving Gcal/hr 0.51

Secondary Reformer CH4 slip % 1.05 1.11

Primary Reformer efficiency % 82 82

Reformer fuel Flow 3635 3569

Fuel Saving 66.1

Speicific Energy Consumption (Gcal/MTNH3) Gcal/MT 0.02

Speicific Energy Consumption (Gcal/MT Urea) Gcal/MT 0.010

Cost of Energy Rs/Gcal 2400

RS/MT of

Urea 25.13

Yearly Saving Crore 0.95

If S/C ratio is changed by 0.1 then energy saving of 0.02 Gcal/MT of NH 3 can be achieved which is

equivalent to INR 0.95 Crore annually with the current energy cost.

Please note that there is a source of error.

1) Change in SC ratio will alter the conversion rate and rate kinetics of Methane reforming in Primary

Reformer which is not considered in the calculation.

2) Change in SC ratio will alter the conversion rate for water shift reaction which is not considered in

the calculation.

You might also like

- Natural Gas Composition (Mol%)Document37 pagesNatural Gas Composition (Mol%)tauseefaroseNo ratings yet

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Document26 pagesUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- Purifier Ammonia ProcessDocument4 pagesPurifier Ammonia ProcessGajanan PadamwarNo ratings yet

- Operating Manual Ammonia Synthesis Jan 08Document20 pagesOperating Manual Ammonia Synthesis Jan 08Gaurav GuptaNo ratings yet

- Mole BalancesDocument8 pagesMole BalancesKvspavan KumarNo ratings yet

- Ammonia Synthesis and Molecular SieveDocument25 pagesAmmonia Synthesis and Molecular Sieveaehque04No ratings yet

- Process DescriptionDocument6 pagesProcess Descriptionافكر اشتري كورياNo ratings yet

- Ammonia Synthesis Catalyst OperationDocument19 pagesAmmonia Synthesis Catalyst OperationMuhammad Junaid0% (1)

- Diseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesDocument25 pagesDiseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesLuis AlexanderNo ratings yet

- Improved Efficiency in Ammonia Synthesis: John Brightling October 2015Document43 pagesImproved Efficiency in Ammonia Synthesis: John Brightling October 2015Muhammad JunaidNo ratings yet

- Correctly Modeling and Calculating Combustion Efficiencies in Fired EquipmentDocument23 pagesCorrectly Modeling and Calculating Combustion Efficiencies in Fired Equipmentfawmer61No ratings yet

- Ammonia ReactorDocument11 pagesAmmonia ReactorRh GladysNo ratings yet

- A Guide of Refinery ProcessDocument32 pagesA Guide of Refinery ProcessSaidFerdjallahNo ratings yet

- UhdeDocument9 pagesUhdeibkhiNo ratings yet

- Knovel Charts For Water & Steam, SI & English Units, 2006, Norwich, 26pgDocument26 pagesKnovel Charts For Water & Steam, SI & English Units, 2006, Norwich, 26pgVlad ElenaNo ratings yet

- Ammonia Synthesis ConverterDocument26 pagesAmmonia Synthesis ConverterKvspavan Kumar100% (1)

- Acid Gas EnrichmentDocument7 pagesAcid Gas EnrichmentkusdiyantaNo ratings yet

- A An ND D Ffo Orr: Increase CapacityDocument7 pagesA An ND D Ffo Orr: Increase CapacityLuis Enrique Leyva OvalleNo ratings yet

- Ammonia Synthesis Material Balence CalulDocument1 pageAmmonia Synthesis Material Balence CalulDhruv RanaNo ratings yet

- Ammonia Absorption Tower Equilibrium Curves EstimationDocument3 pagesAmmonia Absorption Tower Equilibrium Curves EstimationKvspavan KumarNo ratings yet

- Topsoe Sec Ref Cat RKS 2Document5 pagesTopsoe Sec Ref Cat RKS 2Vo Duc Minh MinhNo ratings yet

- CHE 165A L11 - Heat Exchanger Design PDFDocument61 pagesCHE 165A L11 - Heat Exchanger Design PDFLi ChNo ratings yet

- Major Risks in Ammonia PlantsDocument17 pagesMajor Risks in Ammonia PlantsrobertionNo ratings yet

- HDS CatalystDocument8 pagesHDS CatalystBạch Trung PhúNo ratings yet

- Simulation of Ammonia Production From Synthesis GaDocument12 pagesSimulation of Ammonia Production From Synthesis Gasagar dasguptaNo ratings yet

- Paper 10 - Catalyst CatastrophesDocument16 pagesPaper 10 - Catalyst CatastrophesArsalan QadirNo ratings yet

- Four Challenges For Nickel Steam-Reforming CatalystsDocument8 pagesFour Challenges For Nickel Steam-Reforming CatalystsReza Rhi100% (2)

- Catacarb Section, Dawood Hercules Fertilizers LimitedDocument16 pagesCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (1)

- Ammonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEODocument33 pagesAmmonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOAkil PrabhuNo ratings yet

- Prico Process PDFDocument13 pagesPrico Process PDFcorkynhoNo ratings yet

- HRSG Understand The BasicsDocument14 pagesHRSG Understand The BasicsMazen Darwish100% (1)

- Ammonia Absorber CalculationDocument5 pagesAmmonia Absorber CalculationKvspavan KumarNo ratings yet

- Steam Reforming Carbon FormationDocument26 pagesSteam Reforming Carbon FormationBilalNo ratings yet

- Extended Functionality and Validation of Sulsim Sulfur Recovery in Aspen HYSYSDocument16 pagesExtended Functionality and Validation of Sulsim Sulfur Recovery in Aspen HYSYSIffatNo ratings yet

- LP Steam Hysys-PrintDocument2 pagesLP Steam Hysys-PrintamiyachemNo ratings yet

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDocument8 pagesA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- Ammonia Plant Simulation 25.08.2016Document81 pagesAmmonia Plant Simulation 25.08.2016Manish Gautam100% (1)

- Choudari Et Al. (2012) - Distillation Optimization Vapor RecompressionDocument5 pagesChoudari Et Al. (2012) - Distillation Optimization Vapor Recompressionvazzoleralex6884No ratings yet

- Flare Gas Recovery PDFDocument13 pagesFlare Gas Recovery PDFSadad MohamadNo ratings yet

- Aist 2018 ZR and Hyl Iii PDFDocument28 pagesAist 2018 ZR and Hyl Iii PDFteresaNo ratings yet

- PFD - Nitrogen Plant UTL Plaju (Cold Box)Document1 pagePFD - Nitrogen Plant UTL Plaju (Cold Box)Arga YudhaNo ratings yet

- Pressure Drop Improvements in A Fixed Bed ReactorDocument10 pagesPressure Drop Improvements in A Fixed Bed Reactorvaratharajan g rNo ratings yet

- Gas Processing I - Chapter 3 Rev 1Document26 pagesGas Processing I - Chapter 3 Rev 1ABULARA2K6No ratings yet

- Modeling and Simulation of Methanation Catalytic Reactor in Ammonia UnitDocument8 pagesModeling and Simulation of Methanation Catalytic Reactor in Ammonia UnitMartin NizNo ratings yet

- Chemical Cleaning and FoulingDocument4 pagesChemical Cleaning and FoulingoswaldoNo ratings yet

- Callidus Low Nox Staged Gas Burner CSGL PDFDocument3 pagesCallidus Low Nox Staged Gas Burner CSGL PDFReyes SanchezNo ratings yet

- Mass BalancekkkkkkkkDocument22 pagesMass BalancekkkkkkkkSukirtha GaneshanNo ratings yet

- Effect of Reactor Inlet Temperature in A HydrotreaterDocument5 pagesEffect of Reactor Inlet Temperature in A HydrotreaterAlexNo ratings yet

- The Theory and Practice of Steam Reforming: By: Gerard B. Hawkins Managing Director, CEODocument0 pagesThe Theory and Practice of Steam Reforming: By: Gerard B. Hawkins Managing Director, CEOBalaji RamanNo ratings yet

- Xu and FromentDocument9 pagesXu and FromentJhimmy Terceros100% (1)

- The Hot Bypass Pressure Control Rev. Agosto 2018Document12 pagesThe Hot Bypass Pressure Control Rev. Agosto 2018luiz.henriqueNo ratings yet

- Methanol DistillationDocument6 pagesMethanol DistillationNaseeb AliNo ratings yet

- GBH Enterprises, LTD.: GBHE-PEG-MAS-608Document79 pagesGBH Enterprises, LTD.: GBHE-PEG-MAS-608arch0wnzNo ratings yet

- Characterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSDocument183 pagesCharacterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSGianmarco Corticelli100% (1)

- Room Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFDocument11 pagesRoom Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFAshpavi ArunNo ratings yet

- Kettle Reboilers Chemical Engineering Design Ray SinnoyDocument6 pagesKettle Reboilers Chemical Engineering Design Ray SinnoyFederico BogettiNo ratings yet

- IONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 TransmittalDocument10 pagesIONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 Transmittalyusuf.yuzuakNo ratings yet

- Materials and Processes for CO2 Capture, Conversion, and SequestrationFrom EverandMaterials and Processes for CO2 Capture, Conversion, and SequestrationNo ratings yet

- Impact of SC On Specific EnergyDocument33 pagesImpact of SC On Specific EnergyManish GautamNo ratings yet

- Conversion FactorDocument3 pagesConversion FactorAniket AngreNo ratings yet

- Performance Evaluation of An Oil Fired Boiler A Case Study in Dairy Industry.Document8 pagesPerformance Evaluation of An Oil Fired Boiler A Case Study in Dairy Industry.atul100% (8)

- TEMA Datasheet-Carbamate CondeserDocument1 pageTEMA Datasheet-Carbamate CondeserManish GautamNo ratings yet

- Ammonia Plant Simulation 25.08.2016Document81 pagesAmmonia Plant Simulation 25.08.2016Manish Gautam100% (1)

- Stock AnalysisDocument16 pagesStock AnalysisManish GautamNo ratings yet

- Sop Covid 19 - 12.04.21Document53 pagesSop Covid 19 - 12.04.21Manish GautamNo ratings yet

- Rich Gas and Lean GasDocument7 pagesRich Gas and Lean GasManish GautamNo ratings yet

- Ammona Plant Parameters CO2 BalanceDocument16 pagesAmmona Plant Parameters CO2 BalanceManish Gautam0% (1)

- HRU Unit Base Working FinalDocument8 pagesHRU Unit Base Working FinalManish GautamNo ratings yet

- Impact of SC On Specific EnergyDocument33 pagesImpact of SC On Specific EnergyManish GautamNo ratings yet

- Regenerator Shut Down ReportDocument2 pagesRegenerator Shut Down ReportManish GautamNo ratings yet

- Alarm Management - Ammonia Plants Experience in Improving Alarm Systems With Focus On Process and Human FactorsDocument12 pagesAlarm Management - Ammonia Plants Experience in Improving Alarm Systems With Focus On Process and Human FactorsManish GautamNo ratings yet

- Reflux Preheater Fluid Allocation Shell Side Tube Side Fluid Name Fuild Quantity Liquid Vapor Water K CODocument1 pageReflux Preheater Fluid Allocation Shell Side Tube Side Fluid Name Fuild Quantity Liquid Vapor Water K COManish GautamNo ratings yet

- Syn CompressorDocument23 pagesSyn CompressorManish GautamNo ratings yet

- DCM PFD CalculationDocument8 pagesDCM PFD CalculationManish GautamNo ratings yet

- % Excess Air in Combnustion Air GasDocument2 pages% Excess Air in Combnustion Air GasManish GautamNo ratings yet

- Explosive Limits CalculationDocument3 pagesExplosive Limits CalculationManish GautamNo ratings yet

- Carbon Hydrogen Ratio of Natural GasDocument10 pagesCarbon Hydrogen Ratio of Natural GasManish GautamNo ratings yet

- MT/HR NM /HR NM /HR NM /HRDocument11 pagesMT/HR NM /HR NM /HR NM /HRManish GautamNo ratings yet

- PCI End Semester NIT Jalandhar M.TechDocument5 pagesPCI End Semester NIT Jalandhar M.Techom prakash vermaNo ratings yet

- StructureDocument13 pagesStructureAnshul SharmaNo ratings yet

- Effect of Admixtures On Properties of Alkali-Activated Slag ConcreteDocument8 pagesEffect of Admixtures On Properties of Alkali-Activated Slag ConcreteZhu PengfeiNo ratings yet

- Schott Borofloat Technical Data Sheet EnglishDocument1 pageSchott Borofloat Technical Data Sheet Englishlilian.agenaisNo ratings yet

- Phase DiagramDocument5 pagesPhase DiagramBunnimit panyacheewathonNo ratings yet

- Prince CPVC Pipes and Fittings PricelistDocument1 pagePrince CPVC Pipes and Fittings PricelistAlok KapoorNo ratings yet

- Floor SlabsDocument37 pagesFloor SlabsLuis BeduschiNo ratings yet

- MK003 - Why Use ICE Solair Over OthersDocument2 pagesMK003 - Why Use ICE Solair Over OthersFatmir KelmendiNo ratings yet

- How and Why To Specify Cast Connex Universal Pin ConnectorsDocument6 pagesHow and Why To Specify Cast Connex Universal Pin Connectorsaams_sNo ratings yet

- NuaireHousebuilderCatalogue MVHRDocument85 pagesNuaireHousebuilderCatalogue MVHRreplicaderNo ratings yet

- The Use of Coal As Fuel For Cement Rotary KilnDocument23 pagesThe Use of Coal As Fuel For Cement Rotary KilnDheo Ebhee LouVeNo ratings yet

- (A3) Cementitious Waterproofing Applicator ListDocument1 page(A3) Cementitious Waterproofing Applicator ListjimdabrondNo ratings yet

- Boilers EmissionDocument2 pagesBoilers EmissionGopinath KaliyaperumalNo ratings yet

- Eddy Current Testing ApplicationsDocument21 pagesEddy Current Testing ApplicationsvibinkumarsNo ratings yet

- JMC FORMAT FOR RCC Cable TrenchDocument1 pageJMC FORMAT FOR RCC Cable TrenchKuldeep KumarNo ratings yet

- Drude Model PDFDocument5 pagesDrude Model PDFkeshav sharmaNo ratings yet

- Customer of CrgoDocument18 pagesCustomer of CrgoGupta GuptaNo ratings yet

- Manual CarrierDocument220 pagesManual CarrierJuan Carlos Chapoñan SilvaNo ratings yet

- .4 Minimum Necessary Preheat TemperatureDocument5 pages.4 Minimum Necessary Preheat Temperatureromanosky11No ratings yet

- Ymvk-Mb Ss Powerflex: ConstructionDocument2 pagesYmvk-Mb Ss Powerflex: ConstructionAnamulKabirNo ratings yet

- Lecture 18-19Document25 pagesLecture 18-19Ahmed SFNo ratings yet

- Chapter-i-Introduction To Soil MechanicsDocument27 pagesChapter-i-Introduction To Soil MechanicsVijaykumar Nagnaik100% (2)

- Subsea Systems: Gs Ep Sps 006 Service Valves in Subsea Stations 01 / 2012 08Document2 pagesSubsea Systems: Gs Ep Sps 006 Service Valves in Subsea Stations 01 / 2012 08Nader GhrabNo ratings yet

- Suspencion 930E KOMATSUDocument37 pagesSuspencion 930E KOMATSUBryan Rafael Coronado Pinto100% (1)

- Cummins SB 4022060-Oil Analysis Techniques For High Horsepower Diesel Engines-UpdateDocument34 pagesCummins SB 4022060-Oil Analysis Techniques For High Horsepower Diesel Engines-Updategilar herliana putraNo ratings yet

- LAOAC Solid WasteDocument5 pagesLAOAC Solid WasteMark Roed Onofre LuceroNo ratings yet

- USP-NF 621 ChromatographyDocument14 pagesUSP-NF 621 ChromatographyNur AcarNo ratings yet

- Engine Tune-Up: Ii. Tools and MaterialsDocument6 pagesEngine Tune-Up: Ii. Tools and MaterialsdrakuleeNo ratings yet

- Composite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingDocument6 pagesComposite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingKarrar MonarchNo ratings yet