Professional Documents

Culture Documents

Fire Safe Isolation Kit: Seal Tight. Seal Safe

Fire Safe Isolation Kit: Seal Tight. Seal Safe

Uploaded by

Anonymous Dp4DdscGSCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Yamaha MT-25 - 1rb04460e1Document70 pagesYamaha MT-25 - 1rb04460e1Restu PebrianaNo ratings yet

- MODELS-2030 Series: All Stainless Steel Construction Chemical Seal Pressure GaugesDocument4 pagesMODELS-2030 Series: All Stainless Steel Construction Chemical Seal Pressure GaugesAnonymous Dp4DdscGSNo ratings yet

- Process Interlocking: NetherlocksDocument2 pagesProcess Interlocking: NetherlocksAnonymous Dp4DdscGSNo ratings yet

- Terminal-Series Bro AuDocument8 pagesTerminal-Series Bro AuAnonymous Dp4DdscGSNo ratings yet

- Design Criteria Brochure - 5 15 2019 Low ResDocument74 pagesDesign Criteria Brochure - 5 15 2019 Low ResAnonymous Dp4DdscGSNo ratings yet

- Process Interlocking: NetherlocksDocument1 pageProcess Interlocking: NetherlocksAnonymous Dp4DdscGSNo ratings yet

- CCI Pipeline Systems: Wrap-It Link Mechanical Seal Model WLDocument1 pageCCI Pipeline Systems: Wrap-It Link Mechanical Seal Model WLAnonymous Dp4DdscGSNo ratings yet

- Process Interlocking: NetherlocksDocument2 pagesProcess Interlocking: NetherlocksAnonymous Dp4DdscGSNo ratings yet

- Process Interlocking: NetherlocksDocument1 pageProcess Interlocking: NetherlocksAnonymous Dp4DdscGSNo ratings yet

- Innerlynx Installation Instructions: Advance Products & Systems, Inc. at 800-315-6009Document1 pageInnerlynx Installation Instructions: Advance Products & Systems, Inc. at 800-315-6009Anonymous Dp4DdscGSNo ratings yet

- Literature For Hy-Drop Blowdown ValveDocument8 pagesLiterature For Hy-Drop Blowdown ValveAnonymous Dp4DdscGSNo ratings yet

- S P P ... F: Eals IPE Enetrations ASTDocument12 pagesS P P ... F: Eals IPE Enetrations ASTAnonymous Dp4DdscGSNo ratings yet

- Worldwide Equivalent GradesDocument1 pageWorldwide Equivalent GradesAnonymous Dp4DdscGSNo ratings yet

- Literature For Blow-Off Valve PDFDocument16 pagesLiterature For Blow-Off Valve PDFAnonymous Dp4DdscGSNo ratings yet

- Terminal Boxes 8146 PDFDocument14 pagesTerminal Boxes 8146 PDFAnonymous Dp4DdscGSNo ratings yet

- FastenersDocument56 pagesFastenersAnonymous Dp4DdscGSNo ratings yet

- Legrand UK Swifts Cable Ladder Tech Guide PDFDocument148 pagesLegrand UK Swifts Cable Ladder Tech Guide PDFAnonymous Dp4DdscGSNo ratings yet

- Blind Rivets Application ConsiderationsDocument3 pagesBlind Rivets Application ConsiderationsAnonymous Dp4DdscGSNo ratings yet

- NXF Supports en 2017Document55 pagesNXF Supports en 2017Anonymous Dp4DdscGSNo ratings yet

- BV3D BV3DZDocument4 pagesBV3D BV3DZYOGESH GOPALNo ratings yet

- Pressure Vessel Design Without Seismic Loads PDFDocument21 pagesPressure Vessel Design Without Seismic Loads PDFMas afjalNo ratings yet

- Priced Bill of Quantities: Boq Mechanical InstalationDocument8 pagesPriced Bill of Quantities: Boq Mechanical InstalationHayri Bahadır UzunoğluNo ratings yet

- B2a ElDocument5 pagesB2a ElBALAKRISHNANNo ratings yet

- 1000CUM Main Fuel Storage Tanks SepchDocument3 pages1000CUM Main Fuel Storage Tanks SepchBTENo ratings yet

- FRP Pipes & Fitting PDFDocument10 pagesFRP Pipes & Fitting PDFAbbasNo ratings yet

- Modulate ActionDocument97 pagesModulate ActionSyarip HidayatNo ratings yet

- ASME B16-48 - Edtn - 2005Document50 pagesASME B16-48 - Edtn - 2005eceavcmNo ratings yet

- SIIT ReportDocument50 pagesSIIT ReportAnderson JoeNo ratings yet

- N 4.16.5.3 Automated Valves. N 4.16.5.3.1 N 4.16.5.3.2: Installation of Stationary Pumps For Fire ProtectionDocument2 pagesN 4.16.5.3 Automated Valves. N 4.16.5.3.1 N 4.16.5.3.2: Installation of Stationary Pumps For Fire Protectionbhima irabattiNo ratings yet

- 8) Tss-Glycol Surge DrumDocument1 page8) Tss-Glycol Surge DrumKiran KumarNo ratings yet

- Fisher ET, EAT, and ETR Sliding - Stem Control Valves: ET Valve Product BulletinDocument28 pagesFisher ET, EAT, and ETR Sliding - Stem Control Valves: ET Valve Product BulletinbalajiNo ratings yet

- Technical Data: Concentrate Control Valve Applications, Priming Connections, and TrimsDocument6 pagesTechnical Data: Concentrate Control Valve Applications, Priming Connections, and TrimsAhmed ElbarbaryNo ratings yet

- Proportional Pressure Reducing Valve Flange and Sandwich Construction - Pilot Operated - Q 60 L/min - P 400 Bar - P 350 BarDocument2 pagesProportional Pressure Reducing Valve Flange and Sandwich Construction - Pilot Operated - Q 60 L/min - P 400 Bar - P 350 BarDavidson GattoniNo ratings yet

- Z1186-Oil Int. SpecsDocument1 pageZ1186-Oil Int. SpecsRawan Alwan ZarifNo ratings yet

- Xav 545Document4 pagesXav 545ALINo ratings yet

- ACTAIR - NG240 To NG700 DYNACTAIR - NG120 To NG350Document48 pagesACTAIR - NG240 To NG700 DYNACTAIR - NG120 To NG350tommyNo ratings yet

- DTI S FCC-comprimido - 092932 - 093829Document333 pagesDTI S FCC-comprimido - 092932 - 093829irvingjaircarmonavaldesNo ratings yet

- 3L Filters CompleteDocument56 pages3L Filters Completekmodihm100% (1)

- SRI Trunnion Ball ValvesDocument40 pagesSRI Trunnion Ball ValvesFaizan AbbasiNo ratings yet

- Parts Manual KX250F11Document78 pagesParts Manual KX250F11Tony RouillonNo ratings yet

- Design of Reduced Beam Section Moment Frame ConnectionDocument40 pagesDesign of Reduced Beam Section Moment Frame Connectionhamze hosseiniNo ratings yet

- Installation & Maintenance Instructions: Brands You TrustDocument16 pagesInstallation & Maintenance Instructions: Brands You Trusthata_562026No ratings yet

- Valve Tender PDFDocument35 pagesValve Tender PDFMohd Hassanudin100% (1)

- Dismantling Joints With 3 Flanges, PN 64Document2 pagesDismantling Joints With 3 Flanges, PN 64Mohd AmirNo ratings yet

- Tubular and Process Assemblies: W A T L O WDocument34 pagesTubular and Process Assemblies: W A T L O WEliasNo ratings yet

- F-3061 Jis 5K/Jis 10K: No Part Material CodeDocument1 pageF-3061 Jis 5K/Jis 10K: No Part Material CodeSergio Jesus SanjurjoNo ratings yet

- Catalogo Ini InglesDocument15 pagesCatalogo Ini InglesJarlissonmartinsNo ratings yet

- Vessel Design CalculationDocument54 pagesVessel Design CalculationPohn Myint Han50% (2)

Fire Safe Isolation Kit: Seal Tight. Seal Safe

Fire Safe Isolation Kit: Seal Tight. Seal Safe

Uploaded by

Anonymous Dp4DdscGSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Safe Isolation Kit: Seal Tight. Seal Safe

Fire Safe Isolation Kit: Seal Tight. Seal Safe

Uploaded by

Anonymous Dp4DdscGSCopyright:

Available Formats

Fire Safe Isolation Kit

SEAL TIGHT. SEAL SAFE.

With more than 80 years’ combined experience together the very best of industry design and manufacturing.

in isolation kits, our technical team is continually This design also allows for a lower bolt load requirement than

approached by oil and gas operators looking for high- other Isolation kits, meaning less stress is required on the bolts

performing, cost effective solutions, which demonstrate to achieve a seal.

exceptional levels of mechanical integrity in high-

Moreover our IsoShield FS™ is made with combination of

pressure day-to-day operating conditions.

Glass Reinforced Epoxy (GRE) and steel core offering the

Our leak-free, tight-sealing corrosion control range not only strength and integrity of a metal gasket but which also

provides robust and reliable isolation kits which mitigate maintains the Isolation characteristics of traditional GRE

against the costly effects of flange and pipeline corrosion, designs. This in turn ensures the highest levels of electrical

but also demonstrates ZERO leakage in industry fire tests, isolation.

preventing further hydrocarbon releases and therefore the

We can supply all size and pressure classes on both Raised

spread of fire.

face and RTJ flanges - ½” to 24”, ASME B16.5 class 150-2500,

In particular, our IsoShield FS™ uses a unique combination API up to 10k pressure class, thereby offering the only fire-safe

of pressure-activated spring-energised Teflon seals with kit with spring-energised seals which caters for all sizes and

a Kammpro Phyllosillicate fire-safe back-up seal, bringing pressure classes.

Block 1, Units 10 and 11, Souterhead Industrial

Estate, Altens, Aberdeen, United Kingdom AB12 3LF

T: 01224 249414 E: sales@albagaskets.co.uk

www.albagaskets.com OHS621780 EMS621779 FS 544395

Fire Safe Isolation Kit

SEAL TIGHT. SEAL SAFE.

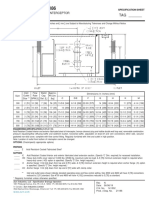

FEATURES OF THE ISOSHIELD FS

• Supplied in all size and pressure classes:

• ½” to 24”

• ASME B16.5 class 150-2500 – RF and RTJ flanges

• API up to 10k pressure class

• Suitable for mismatched RTJ to RF

• Rated to 205°c operating temperature

• All applications including high pressures (up to 1000 bar)

and medias (including H2s and Co2) ensures high level of

Mechanical integrity

• Zero leakage in API 6FB fire tests

• Utilizes spring energized teflon seals ensuring optimum

tightness levels at low bolt load

• High strength metal core gasket bonded with glass

reinforced epoxy ensuring high levels of isolation

APPLICATIONS

• Dissimilar metal flange connections to mitigate galvanic

corrosion

• High pressure flowlines/wellheads for isolation

• Flange isolation in conjunction with cathodic protection

systems

• Mismatched flange assemblies – RF/RTJ

• Critical service, fire safe sealing requirements

• Flange protection against crevice corrosion

As the companies products are used in multiple applications and as the company

has no control over the method of their use, the company excludes all conditions or

warranties, expressed or implied by statute or otherwise. Any technical cooperation is

given for customers assistance only and without liability on the part of the company.

Block 1, Units 10 and 11, Souterhead Industrial

Estate, Altens, Aberdeen, United Kingdom AB12 3LF

T: 01224 249414 E: sales@albagaskets.co.uk

www.albagaskets.com OHS621780 EMS621779 FS 544395

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Yamaha MT-25 - 1rb04460e1Document70 pagesYamaha MT-25 - 1rb04460e1Restu PebrianaNo ratings yet

- MODELS-2030 Series: All Stainless Steel Construction Chemical Seal Pressure GaugesDocument4 pagesMODELS-2030 Series: All Stainless Steel Construction Chemical Seal Pressure GaugesAnonymous Dp4DdscGSNo ratings yet

- Process Interlocking: NetherlocksDocument2 pagesProcess Interlocking: NetherlocksAnonymous Dp4DdscGSNo ratings yet

- Terminal-Series Bro AuDocument8 pagesTerminal-Series Bro AuAnonymous Dp4DdscGSNo ratings yet

- Design Criteria Brochure - 5 15 2019 Low ResDocument74 pagesDesign Criteria Brochure - 5 15 2019 Low ResAnonymous Dp4DdscGSNo ratings yet

- Process Interlocking: NetherlocksDocument1 pageProcess Interlocking: NetherlocksAnonymous Dp4DdscGSNo ratings yet

- CCI Pipeline Systems: Wrap-It Link Mechanical Seal Model WLDocument1 pageCCI Pipeline Systems: Wrap-It Link Mechanical Seal Model WLAnonymous Dp4DdscGSNo ratings yet

- Process Interlocking: NetherlocksDocument2 pagesProcess Interlocking: NetherlocksAnonymous Dp4DdscGSNo ratings yet

- Process Interlocking: NetherlocksDocument1 pageProcess Interlocking: NetherlocksAnonymous Dp4DdscGSNo ratings yet

- Innerlynx Installation Instructions: Advance Products & Systems, Inc. at 800-315-6009Document1 pageInnerlynx Installation Instructions: Advance Products & Systems, Inc. at 800-315-6009Anonymous Dp4DdscGSNo ratings yet

- Literature For Hy-Drop Blowdown ValveDocument8 pagesLiterature For Hy-Drop Blowdown ValveAnonymous Dp4DdscGSNo ratings yet

- S P P ... F: Eals IPE Enetrations ASTDocument12 pagesS P P ... F: Eals IPE Enetrations ASTAnonymous Dp4DdscGSNo ratings yet

- Worldwide Equivalent GradesDocument1 pageWorldwide Equivalent GradesAnonymous Dp4DdscGSNo ratings yet

- Literature For Blow-Off Valve PDFDocument16 pagesLiterature For Blow-Off Valve PDFAnonymous Dp4DdscGSNo ratings yet

- Terminal Boxes 8146 PDFDocument14 pagesTerminal Boxes 8146 PDFAnonymous Dp4DdscGSNo ratings yet

- FastenersDocument56 pagesFastenersAnonymous Dp4DdscGSNo ratings yet

- Legrand UK Swifts Cable Ladder Tech Guide PDFDocument148 pagesLegrand UK Swifts Cable Ladder Tech Guide PDFAnonymous Dp4DdscGSNo ratings yet

- Blind Rivets Application ConsiderationsDocument3 pagesBlind Rivets Application ConsiderationsAnonymous Dp4DdscGSNo ratings yet

- NXF Supports en 2017Document55 pagesNXF Supports en 2017Anonymous Dp4DdscGSNo ratings yet

- BV3D BV3DZDocument4 pagesBV3D BV3DZYOGESH GOPALNo ratings yet

- Pressure Vessel Design Without Seismic Loads PDFDocument21 pagesPressure Vessel Design Without Seismic Loads PDFMas afjalNo ratings yet

- Priced Bill of Quantities: Boq Mechanical InstalationDocument8 pagesPriced Bill of Quantities: Boq Mechanical InstalationHayri Bahadır UzunoğluNo ratings yet

- B2a ElDocument5 pagesB2a ElBALAKRISHNANNo ratings yet

- 1000CUM Main Fuel Storage Tanks SepchDocument3 pages1000CUM Main Fuel Storage Tanks SepchBTENo ratings yet

- FRP Pipes & Fitting PDFDocument10 pagesFRP Pipes & Fitting PDFAbbasNo ratings yet

- Modulate ActionDocument97 pagesModulate ActionSyarip HidayatNo ratings yet

- ASME B16-48 - Edtn - 2005Document50 pagesASME B16-48 - Edtn - 2005eceavcmNo ratings yet

- SIIT ReportDocument50 pagesSIIT ReportAnderson JoeNo ratings yet

- N 4.16.5.3 Automated Valves. N 4.16.5.3.1 N 4.16.5.3.2: Installation of Stationary Pumps For Fire ProtectionDocument2 pagesN 4.16.5.3 Automated Valves. N 4.16.5.3.1 N 4.16.5.3.2: Installation of Stationary Pumps For Fire Protectionbhima irabattiNo ratings yet

- 8) Tss-Glycol Surge DrumDocument1 page8) Tss-Glycol Surge DrumKiran KumarNo ratings yet

- Fisher ET, EAT, and ETR Sliding - Stem Control Valves: ET Valve Product BulletinDocument28 pagesFisher ET, EAT, and ETR Sliding - Stem Control Valves: ET Valve Product BulletinbalajiNo ratings yet

- Technical Data: Concentrate Control Valve Applications, Priming Connections, and TrimsDocument6 pagesTechnical Data: Concentrate Control Valve Applications, Priming Connections, and TrimsAhmed ElbarbaryNo ratings yet

- Proportional Pressure Reducing Valve Flange and Sandwich Construction - Pilot Operated - Q 60 L/min - P 400 Bar - P 350 BarDocument2 pagesProportional Pressure Reducing Valve Flange and Sandwich Construction - Pilot Operated - Q 60 L/min - P 400 Bar - P 350 BarDavidson GattoniNo ratings yet

- Z1186-Oil Int. SpecsDocument1 pageZ1186-Oil Int. SpecsRawan Alwan ZarifNo ratings yet

- Xav 545Document4 pagesXav 545ALINo ratings yet

- ACTAIR - NG240 To NG700 DYNACTAIR - NG120 To NG350Document48 pagesACTAIR - NG240 To NG700 DYNACTAIR - NG120 To NG350tommyNo ratings yet

- DTI S FCC-comprimido - 092932 - 093829Document333 pagesDTI S FCC-comprimido - 092932 - 093829irvingjaircarmonavaldesNo ratings yet

- 3L Filters CompleteDocument56 pages3L Filters Completekmodihm100% (1)

- SRI Trunnion Ball ValvesDocument40 pagesSRI Trunnion Ball ValvesFaizan AbbasiNo ratings yet

- Parts Manual KX250F11Document78 pagesParts Manual KX250F11Tony RouillonNo ratings yet

- Design of Reduced Beam Section Moment Frame ConnectionDocument40 pagesDesign of Reduced Beam Section Moment Frame Connectionhamze hosseiniNo ratings yet

- Installation & Maintenance Instructions: Brands You TrustDocument16 pagesInstallation & Maintenance Instructions: Brands You Trusthata_562026No ratings yet

- Valve Tender PDFDocument35 pagesValve Tender PDFMohd Hassanudin100% (1)

- Dismantling Joints With 3 Flanges, PN 64Document2 pagesDismantling Joints With 3 Flanges, PN 64Mohd AmirNo ratings yet

- Tubular and Process Assemblies: W A T L O WDocument34 pagesTubular and Process Assemblies: W A T L O WEliasNo ratings yet

- F-3061 Jis 5K/Jis 10K: No Part Material CodeDocument1 pageF-3061 Jis 5K/Jis 10K: No Part Material CodeSergio Jesus SanjurjoNo ratings yet

- Catalogo Ini InglesDocument15 pagesCatalogo Ini InglesJarlissonmartinsNo ratings yet

- Vessel Design CalculationDocument54 pagesVessel Design CalculationPohn Myint Han50% (2)