Professional Documents

Culture Documents

Vickers: Constant Pressure Reversible Power Transfer Unit

Vickers: Constant Pressure Reversible Power Transfer Unit

Uploaded by

Jivendra KumarCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pressure Test, Flushing & Air Blowing Procedure For PipingDocument17 pagesPressure Test, Flushing & Air Blowing Procedure For Pipingsoumaya yahyaoui100% (8)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vevor Hbs1a Manual enDocument13 pagesVevor Hbs1a Manual enGustavs KrievkalnsNo ratings yet

- Storage Periodic Ground ChecksDocument27 pagesStorage Periodic Ground ChecksJivendra KumarNo ratings yet

- Fill Unit - Nitrogen 98F29103500000: GSE/Tool User GuideDocument18 pagesFill Unit - Nitrogen 98F29103500000: GSE/Tool User GuideJivendra KumarNo ratings yet

- (A318 - A319 - A320 - A321) : Nose Jacking Single AisleDocument7 pages(A318 - A319 - A320 - A321) : Nose Jacking Single AisleJivendra KumarNo ratings yet

- Hose Reel Calculation (Malaysia)Document5 pagesHose Reel Calculation (Malaysia)Kazehaya Ali89% (9)

- Hydrant Dispenser 1000gpmDocument2 pagesHydrant Dispenser 1000gpmJèfrì PìnémNo ratings yet

- AAGB ABAC Policy - (PagesCropped) - (Overlayed) - (Page - Transitions)Document27 pagesAAGB ABAC Policy - (PagesCropped) - (Overlayed) - (Page - Transitions)Jivendra KumarNo ratings yet

- AAGB ABAC Policy - (PagesCropped) - (Overlayed) - (Page - Transitions) - (Background) - (Split - Pages)Document108 pagesAAGB ABAC Policy - (PagesCropped) - (Overlayed) - (Page - Transitions) - (Background) - (Split - Pages)Jivendra KumarNo ratings yet

- PDL MK - Iii: ARINC 615/615A Portable Data LoaderDocument2 pagesPDL MK - Iii: ARINC 615/615A Portable Data LoaderJivendra KumarNo ratings yet

- BLEED SENSE LINES Maintenance RecommendationsDocument9 pagesBLEED SENSE LINES Maintenance RecommendationsJivendra KumarNo ratings yet

- Maths Formulas For Class 10 PDFDocument18 pagesMaths Formulas For Class 10 PDFJivendra Kumar100% (2)

- Ncert Soln Cbse Class 10 Sci CH 4Document11 pagesNcert Soln Cbse Class 10 Sci CH 4Jivendra KumarNo ratings yet

- Aai GMR ValueDocument29 pagesAai GMR ValueJivendra KumarNo ratings yet

- Dedienne Aerospace - Catalogue UTAS A320neoDocument19 pagesDedienne Aerospace - Catalogue UTAS A320neoJivendra KumarNo ratings yet

- TOOL List Used On A320Document143 pagesTOOL List Used On A320Jivendra Kumar0% (1)

- Tool / Equipment Bulletin No: TEB - 98D07103001000 - 2 - IDocument10 pagesTool / Equipment Bulletin No: TEB - 98D07103001000 - 2 - IJivendra KumarNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument9 pagesSafety Data Sheet: Section 1. IdentificationJivendra KumarNo ratings yet

- NOSE JACKING SA (TEB - Tool Equipment Bulletin)Document9 pagesNOSE JACKING SA (TEB - Tool Equipment Bulletin)Jivendra KumarNo ratings yet

- Packing and Other Electrical SparesDocument5 pagesPacking and Other Electrical SparesJivendra Kumar100% (1)

- 202 Jivendra KumarDocument2 pages202 Jivendra KumarJivendra KumarNo ratings yet

- Parts, Resources Request - Overview in AMOSDocument19 pagesParts, Resources Request - Overview in AMOSJivendra KumarNo ratings yet

- Parts, Resources Request - Overview in AMOSDocument19 pagesParts, Resources Request - Overview in AMOSJivendra KumarNo ratings yet

- 2019 Amc MMC ProgramDocument261 pages2019 Amc MMC ProgramJivendra KumarNo ratings yet

- MODULE 3 Cascade Theory, Axial Flow Turbine and Propulsion SystemDocument43 pagesMODULE 3 Cascade Theory, Axial Flow Turbine and Propulsion SystemantonNo ratings yet

- Lubricating Oil System: Instalação Propulsora Do Navio Ro-Ro Pax FerryDocument9 pagesLubricating Oil System: Instalação Propulsora Do Navio Ro-Ro Pax FerryManuel Fortes Tavares AlmeidaNo ratings yet

- Roper 2am06Document11 pagesRoper 2am06Quant ExalmarNo ratings yet

- Emitec (Groundfos) System IntroductionDocument30 pagesEmitec (Groundfos) System IntroductionЕвгений100% (2)

- Dilating Disk Valve White PaperDocument11 pagesDilating Disk Valve White PaperDeltaflyer47No ratings yet

- VALVULAS DE BRONCE COMPUERTA ItaptechDocument16 pagesVALVULAS DE BRONCE COMPUERTA ItaptechGustavo RomanNo ratings yet

- P Ice List: Comprehensive Range of Pipes and FittingsDocument33 pagesP Ice List: Comprehensive Range of Pipes and FittingsUjwal Elijah GurramNo ratings yet

- RAC Book RK RajputDocument229 pagesRAC Book RK RajputVINAYAK SHARMANo ratings yet

- Tag 0240-BH-0103-0104Document1 pageTag 0240-BH-0103-0104Alexander AcuñaNo ratings yet

- A Parametric Analysis of A Turbofan Engine With An Auxiliary BypaDocument117 pagesA Parametric Analysis of A Turbofan Engine With An Auxiliary BypaMoh16xNo ratings yet

- TSI Flow Products Frac Equipment Catalog PDFDocument17 pagesTSI Flow Products Frac Equipment Catalog PDFralphNo ratings yet

- Pumps in Series and ParallelDocument8 pagesPumps in Series and ParallelFadil Wimala33% (3)

- Catalogo de Valvulas HI-ALLOYDocument12 pagesCatalogo de Valvulas HI-ALLOYQuintin FedabNo ratings yet

- SO - Pilot Hydraulic SystemDocument8 pagesSO - Pilot Hydraulic Systemisaac989No ratings yet

- ME Engine Training BmtiDocument153 pagesME Engine Training BmtiKazi Nafiz Imtiaz Hasan100% (3)

- Borewell Compressor PumpDocument2 pagesBorewell Compressor PumpJagadish Gowda JagguNo ratings yet

- Kta VagDocument20 pagesKta VagHa HoangNo ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087100% (1)

- 09 - Ball ValvesDocument10 pages09 - Ball ValvesacildeNo ratings yet

- Manual AcumuladoresDocument12 pagesManual AcumuladoresHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- A A PSV A: Key To Oil Flow & PressureDocument1 pageA A PSV A: Key To Oil Flow & PressureRajan MullappillyNo ratings yet

- Trans Chapter6 PDFDocument106 pagesTrans Chapter6 PDFsammar_10No ratings yet

- Module 6 Discharge Energy and Head Power and Efficiency Bernoullis Energy TheoremDocument16 pagesModule 6 Discharge Energy and Head Power and Efficiency Bernoullis Energy TheoremAragones, Trisha Marie CNo ratings yet

- Steam Nozzle - 1Document39 pagesSteam Nozzle - 1Dipti PatilNo ratings yet

- 08-Plotplan FPSO FIRENZE - General Layout 2019.09Document1 page08-Plotplan FPSO FIRENZE - General Layout 2019.09SriNo ratings yet

- Teori Naca 4412Document19 pagesTeori Naca 4412Muhammad HattaNo ratings yet

Vickers: Constant Pressure Reversible Power Transfer Unit

Vickers: Constant Pressure Reversible Power Transfer Unit

Uploaded by

Jivendra KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vickers: Constant Pressure Reversible Power Transfer Unit

Vickers: Constant Pressure Reversible Power Transfer Unit

Uploaded by

Jivendra KumarCopyright:

Available Formats

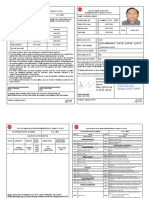

Vickers® Part Number 971600

Constant Pressure Reversible Power Transfer Unit Model MPHV3-115-1C

Model MPHV3-115-1C Power Transfer Unit

Eaton's Aerospace Group, a Similarly, when power is trans- System Function of the system. These valves can be

world leader in the design and ferred at a rate of 16 gpm Power Transfer Unit energized by the crew in flight

manufacture of advanced power (60 L/min) from the green at any time especially during

and motion control components, system to the yellow system at Eaton's model MPHV3-115-1C warning indications, or activated

is the supplier of the bi-directional a rate of 13 gpm (50 L/min), the PTU enables the green system by inhibition logic when the

Power Transfer Unit (PTU) on displacement of the inline unit to be supplied by the yellow aircraft is on the ground during

board the Airbus A319/A320/A321. is made to decrease in order to system and vice versa without engine start-up.

operate in the pumping mode fluid exchange between the

Eaton has designed and while maintaining a constant two systems. The PTU ensures

manufactured the model essential flight functions by Design Features

pressure near 3000 psi (207 bar)

MPHV3-115-1C PTU to meet in the yellow system. supplying the green system The MPHV3-115-1C PTU also

Airbus’ overall design criteria for with additional power at constant incorporates a number of

reliability, low noise, and high When the pressure is near pressure for the gear retraction design features to maximize the

maintainability. equal in both systems, the should engine number one fail reliability and maintainability of

bi-directional power transfer during take off, and similarly for the PTU. These include:

General Design Features unit does not rotate and stays the yellow system elevator servo

in a standby condition. Under control in the event of a dual • Increased fatigue strength by

The model MPHV3-115-1C PTU this condition, the variable failure of the blue and the yellow using finite element analysis

consists of a fixed displace- displacement unit is at a hydraulic system based on a methods coupled with

ment hydraulic unit serving the displacement that is nearly failure of engine number two. improved material properties

aircraft’s green system and a equal to the bent axis unit.

variable displacement hydraulic Ground maintenance functions • Improved cylinder block

unit serving the yellow system. The PTU is designed to meet are also facilitated by the designs machined from

The two units are connected via Airbus operational requirements. MPHV3-115-1C PTU while the steel for strength

a single drive shaft so that power These include: engines are shut down. The sub- • Ease of maintenance by

can be transferred between the systems associated with the designing a self-bleeding

• Compact envelope size

two systems by the driveshaft. green system can be operated unit requiring no special

Depending on the direction of • High reliability on the ground by transferring procedures or tools. The

power transfer, each unit in turn • Easy maintainability by power from the yellow system. PTU can also be removed or

works either as a motor or a pump. separable units Power to the yellow system re-installed in the aircraft with

is supplied by the on-board no additional special tools.

The fixed displacement side of • High response based on flow electric motorpump or possibly

the PTU consists of a bent-axis demands through a ground service cart. • Filtered flow to the control

hydraulic unit coupled with • High stability at all required Also, the bi-directional capability valve to increase reliability

dual impellers to operate as temperatures and flow of the unit makes possible

low as 3 psia. The variable the operation of the yellow • The design of two separable

directions

displacement side is an inline system by means of transferring units joined by a common

unit designed with a single • High efficiency in both foot allows easy maintenance

power by a ground service cart

impeller to operate as low as transfer directions at required intervals at an

attached to the green system.

3 psia. When power is transferred • Low inlet capability to approved repair facility.

at a rate of 34 gpm (130 L/min) prevent erosion and noise The only external control function

from the yellow system to the of the PTU is accomplished via

• Low vibration a switch in the cockpit, which

green system at a rate of 24 gpm

(90 L/min), the displacement • Long service life for the unit energizes valves in the PTU

of the inline unit increases to supply lines of the yellow and

• Extremely low operating

function in the motoring mode green systems. This permits

noise levels due to the

while maintaining a constant the complete isolation of the

location of the PTU on the

pressure near 3000 psi (207 bar) PTU and prevents hydraulic

pressure bulkhead in the

in the green system. power transfer to or from either

wheel well of the aircraft

2 EATON Aerospace Group TF500-1C August 2013

Flow Reversal at Constant Pressure — Flow Schematic

GREEN SYSTEM YELLOW SYSTEM

PUMP MOTOR HIGH PR ESSU RE

PORT

CONTROL FLOW

CASE DRAIN FILTER

CHECK VALVE

CYLINDER

HIGH PRESSURE BLOCK

IN- L INE

IMPELLE R PORT ADAPTER HOUS ING

ACTUATO R

COVER PISTON

PERIPHE RAL

IMPELLER CASE DRAIN PISTON

CHECK VALVE

LOW BUSHING YOKE

PRESSURE SHAF T

PORT IMPELLER CYLINDER SEAL S. A.

BLOCK

COMPENSATOR

VALVE

YOKE

POSITION

FEED BACK

LOW

PRESSURE

PORT

IMPELLER PLATE

SUB ASSEMBLIES

BLOCKING

VALVE

IMPELLER

ACTUATO R

BENT AXIS PISTON

HOUSING

COMMON COUPLI NG PISTO N

SHAF T DRIVE SHO E

FOOT SHAF T

LOW PRESSURE

IMPELLE R BOOST PRESSU RE C1 CONTROL PRESSURE

HIGH PRESSU RE C2 CONTROL P RESSURE

F ILTERED PRESSU RE CASE PRESSURE

CASE DRAIN CONNECTION

.5625-18UNJF-3A THD

PER MS24423-6

HIGH PRESSURE CONNECTION

.8750-14UNJ-3A THD

HIGH PRESSURE CONNECTION

PER MS21902J10

1.0625-12UNJF-3A THD

CASE DRAIN CONNECTION PER MS21902J12

.5625-18UNJF-3A THD 3.50

PER MS24423-6 (83.7)

1.25 2.87 LOW PRESSURE CONNECTION

(31.8) (72.8) 1.6250-12UNJ-3A THD

12.29 2.64 PER MS21902J20

.80 (312.1) (67)

(20.3) 9.16 2.35

(232.8) (59.6)

30°

(194.1)

15°00’

7.64

(163.2)

6.43

(168)

(187.6)

6.61

7.19

(132)

5.20

4 X 11.2

(72.4)

2.85

(4 X .44)

4 X 10.2

3.51 .77 2.37

(4 X .40)

(89) (13.6) (60.2)

.22 3.69 7.80

4.72 (5.6) (93.7) (198.1)

(120) CENTER OF GRAVITY 6.85

MAX SEEP DRAIN CONNECTION (174)

.4375-20UNJF-3A THD

PER MS21902D4

Ø .20

(Ø 5.2)

EATON Aerospace Group TF500-1C August 2013 3

Eaton Limited

Aerospace Group

Fuel & Motion Control Systems Divison

Larchwood Avenue

Bedhampton, Havant Hampshire P09 3QL

United Kingdom

Phone: (44) 2392 487260

Fax: (44) 2392 492400

Eaton

Aerospace Group

9650 Jeronimo Road

Irvine, California 92618 Copyright © 2013 Eaton

Ph (949) 452 9500 All Rights Reserved

Fax (949) 452 9990 Form No. TF500-1C

www.eaton.com/aerospace August 2013

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pressure Test, Flushing & Air Blowing Procedure For PipingDocument17 pagesPressure Test, Flushing & Air Blowing Procedure For Pipingsoumaya yahyaoui100% (8)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vevor Hbs1a Manual enDocument13 pagesVevor Hbs1a Manual enGustavs KrievkalnsNo ratings yet

- Storage Periodic Ground ChecksDocument27 pagesStorage Periodic Ground ChecksJivendra KumarNo ratings yet

- Fill Unit - Nitrogen 98F29103500000: GSE/Tool User GuideDocument18 pagesFill Unit - Nitrogen 98F29103500000: GSE/Tool User GuideJivendra KumarNo ratings yet

- (A318 - A319 - A320 - A321) : Nose Jacking Single AisleDocument7 pages(A318 - A319 - A320 - A321) : Nose Jacking Single AisleJivendra KumarNo ratings yet

- Hose Reel Calculation (Malaysia)Document5 pagesHose Reel Calculation (Malaysia)Kazehaya Ali89% (9)

- Hydrant Dispenser 1000gpmDocument2 pagesHydrant Dispenser 1000gpmJèfrì PìnémNo ratings yet

- AAGB ABAC Policy - (PagesCropped) - (Overlayed) - (Page - Transitions)Document27 pagesAAGB ABAC Policy - (PagesCropped) - (Overlayed) - (Page - Transitions)Jivendra KumarNo ratings yet

- AAGB ABAC Policy - (PagesCropped) - (Overlayed) - (Page - Transitions) - (Background) - (Split - Pages)Document108 pagesAAGB ABAC Policy - (PagesCropped) - (Overlayed) - (Page - Transitions) - (Background) - (Split - Pages)Jivendra KumarNo ratings yet

- PDL MK - Iii: ARINC 615/615A Portable Data LoaderDocument2 pagesPDL MK - Iii: ARINC 615/615A Portable Data LoaderJivendra KumarNo ratings yet

- BLEED SENSE LINES Maintenance RecommendationsDocument9 pagesBLEED SENSE LINES Maintenance RecommendationsJivendra KumarNo ratings yet

- Maths Formulas For Class 10 PDFDocument18 pagesMaths Formulas For Class 10 PDFJivendra Kumar100% (2)

- Ncert Soln Cbse Class 10 Sci CH 4Document11 pagesNcert Soln Cbse Class 10 Sci CH 4Jivendra KumarNo ratings yet

- Aai GMR ValueDocument29 pagesAai GMR ValueJivendra KumarNo ratings yet

- Dedienne Aerospace - Catalogue UTAS A320neoDocument19 pagesDedienne Aerospace - Catalogue UTAS A320neoJivendra KumarNo ratings yet

- TOOL List Used On A320Document143 pagesTOOL List Used On A320Jivendra Kumar0% (1)

- Tool / Equipment Bulletin No: TEB - 98D07103001000 - 2 - IDocument10 pagesTool / Equipment Bulletin No: TEB - 98D07103001000 - 2 - IJivendra KumarNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument9 pagesSafety Data Sheet: Section 1. IdentificationJivendra KumarNo ratings yet

- NOSE JACKING SA (TEB - Tool Equipment Bulletin)Document9 pagesNOSE JACKING SA (TEB - Tool Equipment Bulletin)Jivendra KumarNo ratings yet

- Packing and Other Electrical SparesDocument5 pagesPacking and Other Electrical SparesJivendra Kumar100% (1)

- 202 Jivendra KumarDocument2 pages202 Jivendra KumarJivendra KumarNo ratings yet

- Parts, Resources Request - Overview in AMOSDocument19 pagesParts, Resources Request - Overview in AMOSJivendra KumarNo ratings yet

- Parts, Resources Request - Overview in AMOSDocument19 pagesParts, Resources Request - Overview in AMOSJivendra KumarNo ratings yet

- 2019 Amc MMC ProgramDocument261 pages2019 Amc MMC ProgramJivendra KumarNo ratings yet

- MODULE 3 Cascade Theory, Axial Flow Turbine and Propulsion SystemDocument43 pagesMODULE 3 Cascade Theory, Axial Flow Turbine and Propulsion SystemantonNo ratings yet

- Lubricating Oil System: Instalação Propulsora Do Navio Ro-Ro Pax FerryDocument9 pagesLubricating Oil System: Instalação Propulsora Do Navio Ro-Ro Pax FerryManuel Fortes Tavares AlmeidaNo ratings yet

- Roper 2am06Document11 pagesRoper 2am06Quant ExalmarNo ratings yet

- Emitec (Groundfos) System IntroductionDocument30 pagesEmitec (Groundfos) System IntroductionЕвгений100% (2)

- Dilating Disk Valve White PaperDocument11 pagesDilating Disk Valve White PaperDeltaflyer47No ratings yet

- VALVULAS DE BRONCE COMPUERTA ItaptechDocument16 pagesVALVULAS DE BRONCE COMPUERTA ItaptechGustavo RomanNo ratings yet

- P Ice List: Comprehensive Range of Pipes and FittingsDocument33 pagesP Ice List: Comprehensive Range of Pipes and FittingsUjwal Elijah GurramNo ratings yet

- RAC Book RK RajputDocument229 pagesRAC Book RK RajputVINAYAK SHARMANo ratings yet

- Tag 0240-BH-0103-0104Document1 pageTag 0240-BH-0103-0104Alexander AcuñaNo ratings yet

- A Parametric Analysis of A Turbofan Engine With An Auxiliary BypaDocument117 pagesA Parametric Analysis of A Turbofan Engine With An Auxiliary BypaMoh16xNo ratings yet

- TSI Flow Products Frac Equipment Catalog PDFDocument17 pagesTSI Flow Products Frac Equipment Catalog PDFralphNo ratings yet

- Pumps in Series and ParallelDocument8 pagesPumps in Series and ParallelFadil Wimala33% (3)

- Catalogo de Valvulas HI-ALLOYDocument12 pagesCatalogo de Valvulas HI-ALLOYQuintin FedabNo ratings yet

- SO - Pilot Hydraulic SystemDocument8 pagesSO - Pilot Hydraulic Systemisaac989No ratings yet

- ME Engine Training BmtiDocument153 pagesME Engine Training BmtiKazi Nafiz Imtiaz Hasan100% (3)

- Borewell Compressor PumpDocument2 pagesBorewell Compressor PumpJagadish Gowda JagguNo ratings yet

- Kta VagDocument20 pagesKta VagHa HoangNo ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087100% (1)

- 09 - Ball ValvesDocument10 pages09 - Ball ValvesacildeNo ratings yet

- Manual AcumuladoresDocument12 pagesManual AcumuladoresHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- A A PSV A: Key To Oil Flow & PressureDocument1 pageA A PSV A: Key To Oil Flow & PressureRajan MullappillyNo ratings yet

- Trans Chapter6 PDFDocument106 pagesTrans Chapter6 PDFsammar_10No ratings yet

- Module 6 Discharge Energy and Head Power and Efficiency Bernoullis Energy TheoremDocument16 pagesModule 6 Discharge Energy and Head Power and Efficiency Bernoullis Energy TheoremAragones, Trisha Marie CNo ratings yet

- Steam Nozzle - 1Document39 pagesSteam Nozzle - 1Dipti PatilNo ratings yet

- 08-Plotplan FPSO FIRENZE - General Layout 2019.09Document1 page08-Plotplan FPSO FIRENZE - General Layout 2019.09SriNo ratings yet

- Teori Naca 4412Document19 pagesTeori Naca 4412Muhammad HattaNo ratings yet