Professional Documents

Culture Documents

VAV Box Specification

VAV Box Specification

Uploaded by

SithuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VAV Box Specification

VAV Box Specification

Uploaded by

SithuCopyright:

Available Formats

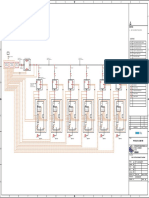

Landmark Project Yangon, Myanmar

Materials and Workmanship Specification for the Mechanical Ventilation and Air Conditioning

2.28 VARIABLE AIR VOLUME BOXES

The casing shall be constructed of minimum 22 gauge galvanized steel, internally lined by 20

mm thick, 24 kg/m3 density fiber glass with perforated metalfacing. The lining and coating

shall comply with NFPA 90A and UL181.

All performance and sound data shall be rated, tested and certified under the AHRI Standard

880-89 Certification Program.

All variable air volume boxes shall bear the AHRI-880-89 seals.

The VAV terminal unit performance including controls shall be tested at the factory by the

VAV terminal manufacturer before shipping.

The units shall be supplied together with 240/24 V 20 VA transformers and shall be pressure

independent type.

The units shall be of the pressure independent type and capable of maintaining required air flow

set points at +5% of the VAV terminal unit’s capacity at any inlet pressure up to 750 Pa. Each VAV

terminal shall include a microprocessor based controller installed and wired at the factory as an

integral part of the assembly. The terminal controller shall control each function of the terminal

using closed-loop, Direct Digital Control (DDC) and specifically designed software algorithms.

The following control components shall be provided for each unit:

Differential Pressure Transducer (Airflow Sensors)

Leaving Air Temperature Sensor (for heating option)

Space Temperature Sensor

The controller shall monitor the differential pressure signal from the air flow probe and compare

the resulting signal to a CFM (or l/s). Set point to determine the correct damper assembly position

to provide pressure independent control of the air passing through the terminal within + 5 % of set

point.

Sound power levels shall be rated and certified in accordance with the requirements of AHRI-880-

89 standard. The units shall be selected in accordance with the requirements detailed in the

equipment schedules and shall meet the design sound level in the space of NC 40.

The units shall be equipped with built-in battery back-up minimum 10 years life time without

replace the battery.

The units shall be supplied together with wall mounted thermostats and the thermostats shall be

able to monitor and adjust the room temperature. The thermostat shall send the signal to the VAV

controller to adjust the supply air flow rate to meet the room set point temperature. The thermostat

shall be the adjustable type and shall be capable of either manual adjustment or receiving a control

signal from a central controller (BMS).

The controller shall capable to communicate with the Building Management System (BMS) which

is open protocol.

The Nominated Contractor should submit certificate of the VAV terminal unit’s Performance and

Warranty including control to client representative for approval.

Z:/MY DOCUMENTS CENTER/MT/MT1862/011 (SPEC_M) FOR CONTRACT.DOC/JM/SWL Section 2-51

You might also like

- Constant Air Volume - CAV: Mode Enable Sensor OptionsDocument4 pagesConstant Air Volume - CAV: Mode Enable Sensor Optionssiva anandNo ratings yet

- Specification of Chilled Water PumpsDocument8 pagesSpecification of Chilled Water PumpsssarangNo ratings yet

- OMM-Kandis Residences (2019) PDFDocument38 pagesOMM-Kandis Residences (2019) PDFjo_eli_No ratings yet

- Measuring Team ProductivityDocument27 pagesMeasuring Team ProductivityAdhitya Setyo Pamungkas100% (1)

- 23 07 19 HVAC Piping InsulationDocument24 pages23 07 19 HVAC Piping InsulationSoumojit SamantaNo ratings yet

- Section 3.5 Fume Cupboard SpecDocument14 pagesSection 3.5 Fume Cupboard SpecBiggie ColdAngelNo ratings yet

- Installation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreDocument25 pagesInstallation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreScherraine Khrys CastillonNo ratings yet

- Fiba Guide To Basketball Facilities - Air DistributionDocument2 pagesFiba Guide To Basketball Facilities - Air DistributionMustafa Onur SarıkayaNo ratings yet

- Installing Seismic Restraints For Mechanical EquipmentDocument158 pagesInstalling Seismic Restraints For Mechanical EquipmentinitbashNo ratings yet

- Booster Brochure 4-12Document2 pagesBooster Brochure 4-12Sam Wing HongNo ratings yet

- Green Heck Fan Application GuideDocument8 pagesGreen Heck Fan Application GuideAnonymous Cxriyx9HIXNo ratings yet

- Standard Technical Requirements For Sub-Metering System: T D H B I A FDocument25 pagesStandard Technical Requirements For Sub-Metering System: T D H B I A Fshadi sabikNo ratings yet

- Nuaire Commercial Useful InfoDocument10 pagesNuaire Commercial Useful InfoYaser AkarNo ratings yet

- Cop101 V7 1Document95 pagesCop101 V7 1Kei WongNo ratings yet

- 25hp 4p 284tpa Wpi Bf37 AuDocument15 pages25hp 4p 284tpa Wpi Bf37 Aurhusseinpos4765No ratings yet

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDocument3 pagesGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarNo ratings yet

- 15940sf - Sequence of OperationDocument12 pages15940sf - Sequence of OperationRa ArNo ratings yet

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNo ratings yet

- Hvac Valves and Actuators CatalogueDocument56 pagesHvac Valves and Actuators CatalogueMokhammad Sanpradipto JaluntoroNo ratings yet

- BreatheDocument9 pagesBreatheMohammad Arshad KamarNo ratings yet

- Cold Water Plumbing DesignDocument17 pagesCold Water Plumbing DesignKHA120096 StudentNo ratings yet

- Hunter GP100 08-2003 PDFDocument1 pageHunter GP100 08-2003 PDFaymanmkNo ratings yet

- AHU CatalogueDocument16 pagesAHU CatalogueWai Ee YapNo ratings yet

- Wire Size SpecificationsDocument2 pagesWire Size Specificationsjaveeed0401No ratings yet

- Waterloo GrillesDocument48 pagesWaterloo GrillesRob QuyNo ratings yet

- TABS SiemensDocument22 pagesTABS SiemensOana MocanuNo ratings yet

- SKM Mini Ducted Split - RX DDP 052 ESMA 50Hz CatalogueDocument28 pagesSKM Mini Ducted Split - RX DDP 052 ESMA 50Hz CatalogueAntony Prashanth OliveraNo ratings yet

- Dynair Ecology UnitDocument12 pagesDynair Ecology Unitrid100% (1)

- Example FAHU ConstantDocument6 pagesExample FAHU ConstantwalsarisNo ratings yet

- AHU Vs FCU Comparison PDFDocument5 pagesAHU Vs FCU Comparison PDFamirin_kingNo ratings yet

- Tender Document HVACDocument49 pagesTender Document HVACمهيب سعيد الشميري100% (1)

- Flowtech Grilles & RegisterDocument3 pagesFlowtech Grilles & RegisterLeomark RespondeNo ratings yet

- RLT 01 GuidelineDocument24 pagesRLT 01 GuidelineBruno GuedesNo ratings yet

- Heat Load Calculation ExampleDocument5 pagesHeat Load Calculation ExampleJoshua RanjithNo ratings yet

- Casette Type 2Document7 pagesCasette Type 2Abdallah Irfaan RamjanNo ratings yet

- YORK PackageDocument28 pagesYORK PackageSreekumarNo ratings yet

- TSGDocument52 pagesTSGsirishghrceNo ratings yet

- Fuel System Schematic DiagramDocument1 pageFuel System Schematic DiagramAbhilash100% (1)

- Design Analysis VRVDocument47 pagesDesign Analysis VRVAnonymous YVUsY9JG0% (1)

- Table Z Troubleshooting Chart For Air ConditionersDocument7 pagesTable Z Troubleshooting Chart For Air Conditionersvalentinlupascu33No ratings yet

- AHU-02 Submittal Saivar Rev-02Document49 pagesAHU-02 Submittal Saivar Rev-02Hossam AttefNo ratings yet

- JT Pressure SwitchesDocument5 pagesJT Pressure SwitchesPHÁT NGUYỄN THẾNo ratings yet

- CHECKLSITDocument2 pagesCHECKLSITaboobacker siddiqueNo ratings yet

- KDK General CatalogueDocument139 pagesKDK General CatalogueIRJAN 29No ratings yet

- NABH Guidelines For Operation TheatersDocument27 pagesNABH Guidelines For Operation TheatersReal-estateNo ratings yet

- Large Floor Standing (Daikin)Document6 pagesLarge Floor Standing (Daikin)Melvin MhdsNo ratings yet

- APMRG1 Series: Packaged Air ConditionersDocument32 pagesAPMRG1 Series: Packaged Air Conditionerszaid jamaluNo ratings yet

- Boq Fans Maurer b5 b8Document6 pagesBoq Fans Maurer b5 b8georgianconstantinNo ratings yet

- Hvac Verification Checklist For Industries Buildings: Small WH OnlyDocument2 pagesHvac Verification Checklist For Industries Buildings: Small WH OnlySaahil KhaanNo ratings yet

- Swimming Pools PDFDocument75 pagesSwimming Pools PDFYazNo ratings yet

- JFDocument28 pagesJFrajarathnam.kNo ratings yet

- Tsi Panda 341 User ManualDocument37 pagesTsi Panda 341 User Manuala k bNo ratings yet

- Alarm Valve SprinklerDocument20 pagesAlarm Valve SprinklerKevin TsuiNo ratings yet

- Asy Iom MCS PDFDocument140 pagesAsy Iom MCS PDFMohammed IsmailNo ratings yet

- Project Standard Specification: Condensers) (Integral Air-Cooled Condensers)Document6 pagesProject Standard Specification: Condensers) (Integral Air-Cooled Condensers)adel rihanaNo ratings yet

- Duct Insulation SpecDocument7 pagesDuct Insulation SpecAmal SaNo ratings yet

- A Seminar Report On Water Cooled ChillerDocument15 pagesA Seminar Report On Water Cooled ChillerSudip Sharma100% (3)

- SP AV Services ManualDocument6 pagesSP AV Services Manualb7z84jb26kNo ratings yet

- Vav Terminals: Specifications - ACMV WorksDocument7 pagesVav Terminals: Specifications - ACMV WorksTalha BaigNo ratings yet

- Single Duct VAV Guide SpecificationDocument2 pagesSingle Duct VAV Guide SpecificationHarish MenonNo ratings yet

- FAN SpecificationDocument6 pagesFAN SpecificationSithuNo ratings yet

- Manufacture List - PDFDocument1 pageManufacture List - PDFSithuNo ratings yet

- Pressure Reducing Valve: 4.15.9 Manual Balancing ValvesDocument1 pagePressure Reducing Valve: 4.15.9 Manual Balancing ValvesSithuNo ratings yet

- Project Status Report - 44Document11 pagesProject Status Report - 44SithuNo ratings yet

- Project Status Report - 45Document11 pagesProject Status Report - 45SithuNo ratings yet

- Appendix 1' Manufacturers List: Equipmentdescription SpecifiedmanufacturerDocument1 pageAppendix 1' Manufacturers List: Equipmentdescription SpecifiedmanufacturerSithuNo ratings yet

- Project Status Report - 09Document6 pagesProject Status Report - 09SithuNo ratings yet

- Project Status Report - 42Document10 pagesProject Status Report - 42SithuNo ratings yet

- Copper Tubing Band Hanger: Pipe AttachmentsDocument1 pageCopper Tubing Band Hanger: Pipe AttachmentsSithuNo ratings yet

- Eurovent Ducted FCU - RS-6C002A-2017 v2Document11 pagesEurovent Ducted FCU - RS-6C002A-2017 v2SithuNo ratings yet

- Motorized Fire / Smoke DampersDocument1 pageMotorized Fire / Smoke DampersSithuNo ratings yet

- MalleableIron Pipe Fittings - MECH-Cover PDFDocument1 pageMalleableIron Pipe Fittings - MECH-Cover PDFSithuNo ratings yet

- Page 3 - AHRI Standard 440-2008 Rating of Room Chilled Water FCUDocument1 pagePage 3 - AHRI Standard 440-2008 Rating of Room Chilled Water FCUSithuNo ratings yet

- Page 6 - Eurovent Ducted FCU - RS-6C002A-2017 v2Document1 pagePage 6 - Eurovent Ducted FCU - RS-6C002A-2017 v2SithuNo ratings yet

- 1.24 Additional To Meet Acoustic Consultant Requirements: 1.24.1 Background Noise CriteriaDocument2 pages1.24 Additional To Meet Acoustic Consultant Requirements: 1.24.1 Background Noise CriteriaSithuNo ratings yet

- CertificationDiploma (Daikin AHU DM 2 Model)Document1 pageCertificationDiploma (Daikin AHU DM 2 Model)SithuNo ratings yet

- CertificationDiploma (Daikin AHU DM 2 Model)Document1 pageCertificationDiploma (Daikin AHU DM 2 Model)SithuNo ratings yet

- AHRIDocument3 pagesAHRISithuNo ratings yet

- DX VRV Fcu and Cdu Schedule FcuDocument1 pageDX VRV Fcu and Cdu Schedule FcuSithuNo ratings yet

- Carriier Int TER Rnat Tiona Al SDN N. B BHD.: PER Rfor Rman NCE E Dat TAS SheetDocument13 pagesCarriier Int TER Rnat Tiona Al SDN N. B BHD.: PER Rfor Rman NCE E Dat TAS SheetSithuNo ratings yet

- 36 CB Test Certificate For MortorDocument2 pages36 CB Test Certificate For MortorSithuNo ratings yet

- 12 Abm Bangelyns Group1Document64 pages12 Abm Bangelyns Group1G-VALDEZ, SHELAHNo ratings yet

- 4final Examination Prof Ed 10Document7 pages4final Examination Prof Ed 10Danelle EsparteroNo ratings yet

- 04-46 Analysis of Gold-Copper Braze Joint in Glidcop For UHV Components at The APS W.Toter S.SharmaDocument10 pages04-46 Analysis of Gold-Copper Braze Joint in Glidcop For UHV Components at The APS W.Toter S.SharmaKai XuNo ratings yet

- Case 4.2 Comptronic CorporationDocument2 pagesCase 4.2 Comptronic CorporationThao NguyenNo ratings yet

- Comparative Investment ReportDocument8 pagesComparative Investment ReportNelby Actub MacalaguingNo ratings yet

- Particle Filter TutorialDocument8 pagesParticle Filter TutorialTanmay NathNo ratings yet

- Shapes of NailsDocument14 pagesShapes of NailsIyannNo ratings yet

- Error Message Reference: Oracle® Hyperion Tax GovernanceDocument6 pagesError Message Reference: Oracle® Hyperion Tax GovernanceAbayneh AssefaNo ratings yet

- (Human Behavior and Environment 8) Carol M. Werner, Irwin Altman, Diana Oxley (Auth.), Irwin Altman, Carol M. Werner (Eds.) - Home Environments-Springer US (1985)Document355 pages(Human Behavior and Environment 8) Carol M. Werner, Irwin Altman, Diana Oxley (Auth.), Irwin Altman, Carol M. Werner (Eds.) - Home Environments-Springer US (1985)Carlos Roberto JúniorNo ratings yet

- English For ITDocument276 pagesEnglish For ITBao Tram100% (1)

- Plastic and Paper PDFDocument12 pagesPlastic and Paper PDFBhanu Pratap SolankiNo ratings yet

- The Strategy of Successful Total ProductDocument10 pagesThe Strategy of Successful Total ProductPham GHNo ratings yet

- Christmas Vigil MassDocument106 pagesChristmas Vigil MassMary JosephNo ratings yet

- South Oil Company (SOC) : SOC Contract No.: CSSP-ITT-04Document19 pagesSouth Oil Company (SOC) : SOC Contract No.: CSSP-ITT-04Kingsley BaptistaNo ratings yet

- SoftOne BlackBook ENG Ver.3.3 PDFDocument540 pagesSoftOne BlackBook ENG Ver.3.3 PDFLiviu BuliganNo ratings yet

- HITACHI 850, 850LC, 870H, 870LCH Components Parts Catalog (151-419) Page RecognitionDocument138 pagesHITACHI 850, 850LC, 870H, 870LCH Components Parts Catalog (151-419) Page RecognitionGeorge Zormpas100% (1)

- Statement of PurposeDocument3 pagesStatement of PurposeehsanNo ratings yet

- Kingsmill Materia MedicaDocument32 pagesKingsmill Materia Medicamax quayleNo ratings yet

- Manual C28 Plus enDocument28 pagesManual C28 Plus enSveto SlNo ratings yet

- SAILOR 6081 Power Supply Unit and Charger: Installation ManualDocument72 pagesSAILOR 6081 Power Supply Unit and Charger: Installation ManualMariosNo ratings yet

- Norton TheoremDocument18 pagesNorton TheoremZohaib NasirNo ratings yet

- Astm A 1011 2005Document8 pagesAstm A 1011 2005gao yanminNo ratings yet

- Support/downloads or Scan Above QR Code For Detailed Policy WordingDocument10 pagesSupport/downloads or Scan Above QR Code For Detailed Policy Wordingraj VenkateshNo ratings yet

- SAP Idoc Steps by Step ConfigDocument7 pagesSAP Idoc Steps by Step Configgirish85No ratings yet

- Testbank: Applying Ifrs Standards 4eDocument11 pagesTestbank: Applying Ifrs Standards 4eSyed Bilal AliNo ratings yet

- Written RequestDocument2 pagesWritten Requestcarvazro100% (1)

- Unit Iv Secondary and Auxilary Motions 12Document3 pagesUnit Iv Secondary and Auxilary Motions 129043785763No ratings yet

- Health The Basics 11th Edition Donatelle Test BankDocument19 pagesHealth The Basics 11th Edition Donatelle Test BankJosephWilliamsinaom100% (6)

- 9de13c0f0c009828f703d0103efa820b.xlsDocument70 pages9de13c0f0c009828f703d0103efa820b.xlsPreeti JaiswalNo ratings yet