Professional Documents

Culture Documents

OHS Checklist 2015

OHS Checklist 2015

Uploaded by

jerin sam kurianCopyright:

Available Formats

You might also like

- BS en 12697-27-2017 - (2018-07-07 - 01-37-13 PM) PDFDocument22 pagesBS en 12697-27-2017 - (2018-07-07 - 01-37-13 PM) PDFjerin sam kurianNo ratings yet

- ASTM A931-18 - Tension Testing of Wire Strand PDFDocument4 pagesASTM A931-18 - Tension Testing of Wire Strand PDFjerin sam kurianNo ratings yet

- ASTM C1556-11a - Determining Apparent Chloride Diffusion Coefficient by Bulk Diffusion PDFDocument7 pagesASTM C1556-11a - Determining Apparent Chloride Diffusion Coefficient by Bulk Diffusion PDFjerin sam kurianNo ratings yet

- BS EN ISO 10319 2015 - Geosynthetics - Wide Width Tensile Test PDFDocument23 pagesBS EN ISO 10319 2015 - Geosynthetics - Wide Width Tensile Test PDFjerin sam kurianNo ratings yet

- SEC Standards - 1.5 - 5-Star Safety and Health Management System - Working Environment Pollution - Air - Ground - WaterDocument7 pagesSEC Standards - 1.5 - 5-Star Safety and Health Management System - Working Environment Pollution - Air - Ground - WaterAhmad Shawky El MadhalyNo ratings yet

- ASTM C305 - 20 - Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistancy PDFDocument3 pagesASTM C305 - 20 - Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistancy PDFjerin sam kurian100% (1)

- BS en 12697-13-2017 - (2019-07-30 - 02-19-04 PM) PDFDocument10 pagesBS en 12697-13-2017 - (2019-07-30 - 02-19-04 PM) PDFjerin sam kurian100% (1)

- (Oxford Political Theory) Anne Phillips - The Politics of Presence-Oxford University Press, USA (1998)Document220 pages(Oxford Political Theory) Anne Phillips - The Politics of Presence-Oxford University Press, USA (1998)Mirna Lucaccini100% (1)

- Letter of Motivation - ICLEIDocument1 pageLetter of Motivation - ICLEIZahara ApNo ratings yet

- Legal and Other Requirements Register April 45001Document18 pagesLegal and Other Requirements Register April 45001john osullivanNo ratings yet

- Hazards and Risk Identification and ManagementDocument2 pagesHazards and Risk Identification and Managementsai ramNo ratings yet

- GNPOC List ofDocument3 pagesGNPOC List ofHSE S4No ratings yet

- ENV18 Aspects Register Procedure 2014 - UpdatedDocument5 pagesENV18 Aspects Register Procedure 2014 - UpdatedsametggtNo ratings yet

- Safety Course OutlinesDocument5 pagesSafety Course OutlinesAd ZamanNo ratings yet

- Contractor Safety InductionDocument5 pagesContractor Safety InductionBaran Shafqat100% (1)

- Risk Assessment Form - KingGroveDocument12 pagesRisk Assessment Form - KingGroveeric chenNo ratings yet

- 202221JSA (Job Safety Analysis) and HIRARC (Hazard Identification, Risk Assessment and Risk Control)Document7 pages202221JSA (Job Safety Analysis) and HIRARC (Hazard Identification, Risk Assessment and Risk Control)Khairulz AnuarNo ratings yet

- Riskman Template-FinalDocument3 pagesRiskman Template-Finalapi-238786020No ratings yet

- LUS HSE FM4 455 005.01 Audit Gap Analysis ChecklistDocument10 pagesLUS HSE FM4 455 005.01 Audit Gap Analysis ChecklistRichu PaliNo ratings yet

- Hazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisDocument7 pagesHazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisZeroRecoNo ratings yet

- FRM-OHS-002 Management Review Agenda TemplateDocument1 pageFRM-OHS-002 Management Review Agenda TemplateJoachimNo ratings yet

- HSE Inspection Report 148 AttendDocument11 pagesHSE Inspection Report 148 Attendtuan mai vanNo ratings yet

- 02-011 Training & Development PolicyDocument6 pages02-011 Training & Development PolicyJoachimNo ratings yet

- Hazard ObservationDocument8 pagesHazard ObservationMarya HasniNo ratings yet

- Binder Spine Indexing SlipsDocument4 pagesBinder Spine Indexing Slipspundir_vineetNo ratings yet

- E PAKATSDocument1 pageE PAKATSAlvee AlzhariffNo ratings yet

- 14 Driver Fatigue Management Guide 4804Document20 pages14 Driver Fatigue Management Guide 4804info kzNo ratings yet

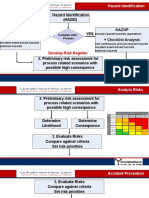

- HIRARCDocument21 pagesHIRARCAmirul Mukminin Zakaria SymantechNo ratings yet

- (Inspection Inprocess)Document15 pages(Inspection Inprocess)loserambujNo ratings yet

- Ppe ChecklistDocument1 pagePpe ChecklistIvan BaraćNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument13 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- CMPAK 2020 BIDDING Project EHS Checklist: Category No. EHS Checking Items Remark (If Not Comply) Compliance Yes/ No/ NADocument1 pageCMPAK 2020 BIDDING Project EHS Checklist: Category No. EHS Checking Items Remark (If Not Comply) Compliance Yes/ No/ NAGayas ShaikNo ratings yet

- HSE 10 Excavation PermitDocument1 pageHSE 10 Excavation PermitBa N Nhim100% (1)

- Final Scope of Work Pachmari SWMDocument10 pagesFinal Scope of Work Pachmari SWMSANJAY PARASARNo ratings yet

- Part 1 - Personal Details and Declaration IGC3 NEBOSHDocument9 pagesPart 1 - Personal Details and Declaration IGC3 NEBOSHEngi SaifNo ratings yet

- Job StudyDocument3 pagesJob StudyVictor PhiriNo ratings yet

- CRA All PDFDocument42 pagesCRA All PDFRohan PanditNo ratings yet

- Tata Safety and Health PolicyDocument1 pageTata Safety and Health PolicyFuzail AyazNo ratings yet

- Know - Workplace Health and Safety Principles (International)Document25 pagesKnow - Workplace Health and Safety Principles (International)Afroz SheikhNo ratings yet

- COVID-19 Precautionary Plan - Remal BSP 9046 - Rev00 22.04.2020 - UPDATEDDocument33 pagesCOVID-19 Precautionary Plan - Remal BSP 9046 - Rev00 22.04.2020 - UPDATEDFarhat SetharNo ratings yet

- Ra RegisterDocument2 pagesRa Registerzarni77No ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- MTC Ims Fo 14d Tool Box TalkDocument2 pagesMTC Ims Fo 14d Tool Box TalksouravrobinNo ratings yet

- Accident CausationDocument35 pagesAccident CausationAntonio Jose De JesusNo ratings yet

- Ini Dia Dokumen ISO14001Document9 pagesIni Dia Dokumen ISO14001karjayaNo ratings yet

- Hirarc: Made Up From 3 Activities That Consist of Hazard Identification, Risk Assesment and Risk ControlDocument12 pagesHirarc: Made Up From 3 Activities That Consist of Hazard Identification, Risk Assesment and Risk ControlHamizi AzizanNo ratings yet

- Compressed Fire Risk Assessment TemplateDocument9 pagesCompressed Fire Risk Assessment TemplateReaz UddinNo ratings yet

- 08PR061C - Confined Space WorkDocument11 pages08PR061C - Confined Space Workkenoly123No ratings yet

- Organizational ChartDocument3 pagesOrganizational ChartnuhaNo ratings yet

- Co-X QHS SOP13 HSE Performance Monitoring and Measurement Rev 02Document6 pagesCo-X QHS SOP13 HSE Performance Monitoring and Measurement Rev 02Abdellatef HossamNo ratings yet

- 07-F01DOCUMENT CONTROL REGISTER and INSPECTIONDocument1 page07-F01DOCUMENT CONTROL REGISTER and INSPECTIONSn AhsanNo ratings yet

- HSEQ Policy Statement - English PDFDocument1 pageHSEQ Policy Statement - English PDFTovo RafaralahyNo ratings yet

- Annex 02 - ODS 01-01 HSE Manual - Rev.1Document232 pagesAnnex 02 - ODS 01-01 HSE Manual - Rev.1Fahmi AbdullahNo ratings yet

- Job Risk Assessment and Control GIS Recovery Boilerx1Document11 pagesJob Risk Assessment and Control GIS Recovery Boilerx1FerdyCodetzNo ratings yet

- Sample of SHE ProgramDocument1 pageSample of SHE ProgramNurul Aishah AdnanNo ratings yet

- Duties & Qualities of Safety OfficersDocument21 pagesDuties & Qualities of Safety OfficersBobbit C ArninioNo ratings yet

- HSE Objectives 2 PDFDocument6 pagesHSE Objectives 2 PDFsudeesh kumarNo ratings yet

- Msc-Qhsef-04 Masterlist - Documents and RecordsDocument4 pagesMsc-Qhsef-04 Masterlist - Documents and RecordsAdil Abdulkhader100% (1)

- EHS PlanDocument37 pagesEHS PlanVishal TiwariNo ratings yet

- 2 PWT-Training Agenda Evaluation Needs For 13oct 2009Document4 pages2 PWT-Training Agenda Evaluation Needs For 13oct 2009Ahmed RaslanNo ratings yet

- Matrix TrainingDocument2 pagesMatrix TrainingcumminkNo ratings yet

- Safe Journey Management WorkshopDocument28 pagesSafe Journey Management WorkshopRamadan KareemNo ratings yet

- Unit Diploma Nebosh DniDocument32 pagesUnit Diploma Nebosh DniScribdTranslationsNo ratings yet

- HSE Observation DashboardDocument4 pagesHSE Observation Dashboardiyo_bikers4598No ratings yet

- Construction Site Safety Control Measures For Covid-19Document34 pagesConstruction Site Safety Control Measures For Covid-19Achik WahabNo ratings yet

- 6 RA - Template - BROGAN r2Document9 pages6 RA - Template - BROGAN r2Daniel100% (1)

- General Information For Hazardous MaterialsDocument8 pagesGeneral Information For Hazardous MaterialsAshraf shaikhNo ratings yet

- CML Methods - Qatar PDFDocument46 pagesCML Methods - Qatar PDFjerin sam kurian100% (1)

- BS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary BlocksDocument10 pagesBS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary Blocksjerin sam kurianNo ratings yet

- ASTM A1061 A1061M-09 - Testing Multi Wire Steel Strand PDFDocument3 pagesASTM A1061 A1061M-09 - Testing Multi Wire Steel Strand PDFjerin sam kurianNo ratings yet

- BS EN 12697 Part 36 2003 - Determination of The Thickness of A Bituminous Pavement PDFDocument13 pagesBS EN 12697 Part 36 2003 - Determination of The Thickness of A Bituminous Pavement PDFjerin sam kurianNo ratings yet

- ASTM C511 - 19 - Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and Concretes PDFDocument3 pagesASTM C511 - 19 - Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and Concretes PDFjerin sam kurianNo ratings yet

- x02 Sieve Analysis - Dry BS 812-103.1-1985rev3 6.01Document1 pagex02 Sieve Analysis - Dry BS 812-103.1-1985rev3 6.01jerin sam kurianNo ratings yet

- Plate Load Test - Equipment, Procedure, CalculationDocument5 pagesPlate Load Test - Equipment, Procedure, Calculationjerin sam kurianNo ratings yet

- Laboratory Work Sheet Test: Specific Gravity & Water Absorption of Coarse Aggregate Method: ASTM C 127-07Document1 pageLaboratory Work Sheet Test: Specific Gravity & Water Absorption of Coarse Aggregate Method: ASTM C 127-07jerin sam kurianNo ratings yet

- Laboratory Work Sheet Test: Material Passing 75 M (No. 200) Sieve Method: ASTM C117-04 Test: 8Document1 pageLaboratory Work Sheet Test: Material Passing 75 M (No. 200) Sieve Method: ASTM C117-04 Test: 8jerin sam kurian100% (1)

- Pending Review 28 Sieve Analysis - Dry Subbase BS 812-103.1-7.2 Rev1 8jun10Document1 pagePending Review 28 Sieve Analysis - Dry Subbase BS 812-103.1-7.2 Rev1 8jun10jerin sam kurianNo ratings yet

- Laboratory Work Sheet Test: Soundness of Coarse Aggregate - Mgso Method: ASTM C 88-05Document1 pageLaboratory Work Sheet Test: Soundness of Coarse Aggregate - Mgso Method: ASTM C 88-05jerin sam kurianNo ratings yet

- Pending 29 Soundness-BS812P121 For NDPP OnlyDocument1 pagePending 29 Soundness-BS812P121 For NDPP Onlyjerin sam kurianNo ratings yet

- Sieve Hyundai Q5Document1 pageSieve Hyundai Q5jerin sam kurianNo ratings yet

- Separate: Dr. Richard James Ellis Beng PH.D Ceng Fciht Fiat Miq Deputy General Manager / Laboratory ManagerDocument1 pageSeparate: Dr. Richard James Ellis Beng PH.D Ceng Fciht Fiat Miq Deputy General Manager / Laboratory Managerjerin sam kurianNo ratings yet

- Gulf Laboratories Co. W.L.L.: Project Villa at Maed Mohammed Aj Al HebabiDocument3 pagesGulf Laboratories Co. W.L.L.: Project Villa at Maed Mohammed Aj Al Hebabijerin sam kurianNo ratings yet

- Water Test Training RecordDocument2 pagesWater Test Training Recordjerin sam kurianNo ratings yet

- Concept and Definition of Sustainable Development: Nil-Nl Bird War-BRDWRDocument19 pagesConcept and Definition of Sustainable Development: Nil-Nl Bird War-BRDWRSunil PawarNo ratings yet

- Sosay Independent Regulatory Agencies in Emerging Economies MPRA Paper 380Document55 pagesSosay Independent Regulatory Agencies in Emerging Economies MPRA Paper 380FERNANDO PAEZ MENDIZABALNo ratings yet

- SCS Vijayawada-4Document124 pagesSCS Vijayawada-4Pooja VarmaNo ratings yet

- Apthorpe 1996Document17 pagesApthorpe 1996Daniela GonzalezNo ratings yet

- Project Proposal TrishaDocument6 pagesProject Proposal TrishaBALOGO TRISHA MARIENo ratings yet

- Strategic Solution (1-5)Document92 pagesStrategic Solution (1-5)Mazharul IslamNo ratings yet

- 2016 Book InformationModelsAndSustainabiDocument193 pages2016 Book InformationModelsAndSustainabiLam88rNo ratings yet

- (Report PPT) Chap 5Document41 pages(Report PPT) Chap 5Nicole Anne GatilaoNo ratings yet

- Circular 571 13.05.2024Document5 pagesCircular 571 13.05.2024vusimuzimahlangu2006No ratings yet

- NSTP 2020 ModuleDocument99 pagesNSTP 2020 ModulePaker LeeNo ratings yet

- Finance Admin Proc 648-2001Document31 pagesFinance Admin Proc 648-2001Hailu AtekaNo ratings yet

- Pil HR PDFDocument5 pagesPil HR PDFImran PathanNo ratings yet

- Separation of Powers: Legal Methods (Jurisprudence)Document16 pagesSeparation of Powers: Legal Methods (Jurisprudence)Kushagra SinghNo ratings yet

- And Not A Shot Is Fired, by Jan KozákDocument47 pagesAnd Not A Shot Is Fired, by Jan KozáktronedotnetNo ratings yet

- Business Law 1 NotesDocument74 pagesBusiness Law 1 NotesRANDAN SADIQ100% (3)

- Cyber Law PPT (Saurav)Document16 pagesCyber Law PPT (Saurav)saurav singhNo ratings yet

- An Introduction To Equality of Opportunity - Equality of Opportunity and EducationDocument4 pagesAn Introduction To Equality of Opportunity - Equality of Opportunity and Educationsujata katwalNo ratings yet

- Environment and Society 1St Ed Edition Magnus Bostrom Full ChapterDocument67 pagesEnvironment and Society 1St Ed Edition Magnus Bostrom Full Chapterbetty.barabas349100% (10)

- National and Regional Planning PrincipleDocument8 pagesNational and Regional Planning PrinciplenilueNo ratings yet

- The Genesis of International Investment Law 1 2 PDFDocument3 pagesThe Genesis of International Investment Law 1 2 PDFManuelNo ratings yet

- Theory in Action Public Health and Community.6Document6 pagesTheory in Action Public Health and Community.6praise theNo ratings yet

- Assignment Cover Sheet: Student DetailsDocument11 pagesAssignment Cover Sheet: Student DetailsHasan AhmadNo ratings yet

- PP Disec IndonesiaDocument2 pagesPP Disec IndonesiachampionNo ratings yet

- 2020 - IFMA Strategic FrameworkDocument1 page2020 - IFMA Strategic FrameworkFizz FirdausNo ratings yet

- Access To Social Work Course WalsallDocument7 pagesAccess To Social Work Course Walsallshvfihdjd100% (2)

- Respondent Memorial Respondent Memorial: Civil Law (Jiwaji University) Civil Law (Jiwaji University)Document28 pagesRespondent Memorial Respondent Memorial: Civil Law (Jiwaji University) Civil Law (Jiwaji University)Ranjan BaradurNo ratings yet

- The Failings of The Economic Freedom IndexDocument6 pagesThe Failings of The Economic Freedom IndexBav JeffNo ratings yet

- Internship Report: The Tamilnadu DR - Ambedkar Law UniversityDocument6 pagesInternship Report: The Tamilnadu DR - Ambedkar Law UniversityvarshiniNo ratings yet

OHS Checklist 2015

OHS Checklist 2015

Uploaded by

jerin sam kurianOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OHS Checklist 2015

OHS Checklist 2015

Uploaded by

jerin sam kurianCopyright:

Available Formats

OH&S INTERNAL AUDIT CHECKLIST

This checklist is prepared for the internal auditors guide in carrying out the OHSMS internal audit. The auditor shall verify all the applicable checkpoint and tick the

appropriate box in the "Classification" field. "Objective evidence/Remarks" shall be filled by verifiable objective evidences.

Abbreviations: No NCR = the process/operation conforms to the requirement; OBS = Observation, or opportunities for improvement; MIN = Minor; MAJ

- Major

Item Classification

No. Applicable

Check Points Objective Evidence /Remarks

Clause No

OBS MIN MAJ

NCR

1 Check the OH&S Policy if: 4.2 (OHSAS

18001:2007)

a) Appropriate to the nature, and scale of the organization’s

OH&S risk

b) Includes the commitment to prevent injury and ill health

and continual improvement in the OH&S management and

performance.

c) Includes a commitment to at least comply with applicable

requirements and other requirements to which the

organization subscribes relating to its OHS hazards.

d) Provides a framework for setting and reviewing OH&S

objectives.

e) Documented, implemented and maintained.

f) Reviewed for continuing suitability

2 Check the availability of OH&S Policy. 4.2 (OHSAS

18001:2007)

3 Check if the OH&S Policy is communicated and understood 4.2 (OHSAS

by all employees including sub-contractors. Check 18001:2007)

awareness.

4 Check the procedure (HSEP-50) for hazard identification, 4.3.1 (OHSAS

risk assessment and determination of necessary control if it 18001:

covers; 2007) /HSEP-

(a) routine and non-routine activities 50

(b) activities of all persons having access to the

workplace including sub-contractor and visitors

(c) human behaviour, capabilities and human factors

(d) identified hazards originating outside the workplace

capable of adversely affecting the health and safety of

persons including sub-contractors within the

workplace

(e) hazard created in the vicinity of the workplace by

work-related activities under the control of the

organization.

(f) infrastructure, equipment and materials at the

workplace whether provided by GL or others.

(g) changes or proposed changes in the organization, its

activities or materials

(h) modification to the OHSMS, including temporary

changes and their impacts on the operations,

processes and activities

(i) any applicable legal obligations relating to risk

assessment and implementation of necessary controls

(j) the design of work areas, processes, installations,

machinery/equipment, operating procedures and work

organization, including their adaptation to human

capabilities

5 Check the methodology for hazard identification and risk

assessment is

(a) defined with respect to scope, nature and timing

(b) provide for the identification, prioritization and

documentation of risks and the application of controls, as

appropriate

6 Are the significant risk identified by the company considered 4.3.1 (OHSAS

in setting the objectives? 18001:

2007) /HSEP-

7 50

Check the risk assessment and verify if the the hierarchy to 4.3.1 (OHSAS

reduce the risk considered in determining controls. 18001:

2007) /HSEP-

50

8 Is the hazard identification and risk assessment in the 4.3.1 (OHSAS

section activities complete and updated? 18001:

2007) /HSEP-

50

9 Is the risk assessment periodically reviewed? Is the risk 4.3.1 (OHSAS

assessment reviewed after an emergency/incident (if any)? 18001:

2007) /HSEP-

50

10 Is there any significant change in operations? If so, is risk 4.3.1 (OHSAS

assessment carried out? Check for records of risk 18001:

assessment. 2007) /HSEP-

50

Item Classification

No. Applicable

Check Points Objective Evidence /Remarks

Clause No

OBS MIN MAJ

NCR

11 Check the awareness and understanding of the OHS 4.3.1 (OHSAS

hazards associated to one’s tasks. Verify familiarity on 18001:

operational procedures relevant to identified significant OHS 2007) /HSEP-

hazards. 50

12 Verify the changes to legal requirements applicable to GL .

4.3.2 (OHSAS

18001: 2007) /

HSEP 200

13 Are legislation and other requirements applicable to GL

compiled and made available on a shared folder? Accessible 4.3.2 (OHSAS

to employees? 18001: 2007) /

HSEP 200

14 Check records of the evaluation of compliance with the legal

and other requirements applicable to GL. 4.5.2 (OHSAS

18001:

2007)/HSEP

200

15 Check if the documented OH&S objectives are:

(1) Established, implemented and maintained at relevant

functions and levels within the organization.

(2) Measurable and consistent with the policy

(3) includes commitment to the prevention of injury and ill

health 4.3.3 (OHSAS

(4) commitment includes compliance with applicable legal 1800: 2007)

requirements and with other requirements to which the

organization subscribes

(6) and to continual improvement

16 Are the Objectives and programmes reviewed? 4.3.3 (OHSAS

1800: 2007)

17 Check the programmes established for achieving its

objectives. It shall include;

(a) designation and responsibility and authority for

achieving objectives at relevant functions and levels

(b) the means and time-frame by which the objectives

are to be achieved. 4.3.3 (OHSAS

Monitoring of objective evidences for the implementation of 1800: 2007)

each targets and objectives should be available.

18 Top Management shall demonstrate its commitment by

ensuring availability of resources essential to establish,

implement, maintain and improve the OHSMS 4.4.1 (OHSAS

18001:2007)/H

SEMS-01

19 Top management shall ensure that roles, responsibilities and

authorities are defined, documented and communicated

within the organization 4.4.1 (OHSAS

18001:2007)/H

SEMS-01

20 The organization shall appoint a member of top

management who, irrespective of other responsibilities, shall

have responsibility and authority that includes

a) Ensuring that OHSMS is established, implemented and

4.4.1 (OHSAS

maintained in accordance with OHSAS 18001:2007

18001:2007)/H

b) Reporting to top management on the performance of the

SEMS-01

OHSMS and any need for improvement.

21 Verify employees awareness on his/her documented

responsibilities towards OHSMS. Are the employees aware

who is the Management Representative?

4.4.1 (OHSAS

18001:2007)/H

SEMS-01

22 Verify records to ensure personnel are competent on the

basis of appropriate education, training and experience.

(check competency matrix, training matrix, CV) 4.4.2 (OHSAS

18801:2007) /

HSEP-110

23 Verify training plan and system in identification of training

needs. 4.4.2 (OHSAS

18801:2007) /

HSEP-110

24 Verify if all new employees have undergone the required

induction training 4.4.2 (OHSAS

18801:2007) /

HSEP-110

25 Check the availability and accessibility of all training records

(in-house & third party) 4.4.2 (OHSAS

18801:2007) /

HSEP-110

Item Classification

No. Applicable

Check Points Objective Evidence /Remarks

Clause No

OBS MIN MAJ

NCR

26 Check system in evaluating the effectiveness of training.

4.4.2 (OHSAS

18801:2007) /

HSEP-110

27 Check is the employees are aware of the OH&S

consequences, actual or potential , of their work activities, 4.4.2 (OHSAS

THEIR BEHAVIOUR and the OH&S benefits of improved 18801:2007) /

personal performance HSEP-110

28 Verify the employees awareness on their roles and

responsibilities and importance in achieving conformity to the

OH&S policy and procedures and to the requirements of the 4.4.2 (OHSAS

OHS management system, including emergency 18801:2007) /

preparedness and response requirements HSEP-110

29 Verify the employees awareness on the potential

consequences of departure from specified procedures. 4.4.2 (OHSAS

18801:2007) /

HSEP-110

30 Top management shall ensure that appropriate

communication processes are established within the 4.4.3.1

organization and that communication takes place regarding (OHSAS

the effectiveness of the OHSMS 18001: 2007) /

HSEMS-01

31 Internal Communication

4.4.3.1

Verify the awareness on the means of communicating

(OHSAS

information on health & safety.

18001: 2007) /

HSEMS-01

32 Verify the system of communication with contractors and

4.4.3.1

other visitors to the workplace (check sample of

(OHSAS

communications)

18001: 2007) /

HSEMS-01

33 Verify the system for receiving, documenting and responding

4.4.3.1

to relevant communications from external parties (client, civil

(OHSAS

defence, etc). Check action/s taken for valid external

18001: 2007) /

concern, if any.

HSEMS-01

34 The organization shall establish, implement and maintain

procedure for

(a) participation of workers of workers by their:

- appropriate involvement in hazard identification, risk

assessments and determination of controls

- appropriate involvement in incident investigation

- involvement in the development and review of OH&S 4.4.3.2

policies and Objectives (OHSAS

- consultation where there are any changes that affect 18001: 2007) /

their OH&S HSEMS-01

- representation on OH&S matters.

(b) consultation with contractors where there are

changes that affect their OH&S

35 Are the employees aware on the participation arrangements

including who is their representative on OH&S matters? 4.4.3.1

(OHSAS

18001: 2007) /

HSEMS-01

36 Is there any recorded consultation with external parties?

37 Ensure that OHSMS documentation includes: <Management>

- statement of OH&S Policy and objectives

- description of the scope of the OHSMS

- description of the main elements of the OHSMS and

their interaction and reference to related documents

- documents including records required by OHSAS 4.4.4 (OHSAS

standard 18001:2007)/H

- documents, including records, determined by the SEMS-01

organization to be necessary to ensure the effective

planning, operation and control of processes that relate

to the management of its OH&S risks.

38 Verify approval of documents prior to issue <All Sections>

4.4.5 (OHSAS

18001:2007) /

HSEP-70

39 Check if documents had been reviewed, updated and re-

approved as necessary 4.4.5 (OHSAS

18001:2007) /

HSEP-70

40 Check if changes and the current revision status of the

documents are identified. <With vertical line for revised 4.4.5 (OHSAS

items> 18001:2007) /

HSEP-70

41 Latest revisions of applicable documents should be available

at points of use. 4.4.5 (OHSAS

18001:2007) /

HSEP-70

Item Classification

No. Applicable

Check Points Objective Evidence /Remarks

Clause No

OBS MIN MAJ

NCR

42 Documents should be legible and readily

Available. 4.4.5 (OHSAS

18001:2007) /

HSEP-70

43 Documents of external origin should be identified and their

distribution controlled

<External documents>

• Documents provided by customers i.e. customer 4.4.5 (OHSAS

correspondence (controlled by receiving section) 18001:2007) /

• Laws, national and international standards <ISO, safety HSEP-70

standards> (controlled by receiving section)

44 Verify if unintended use of obsolete documents has been

prevented and suitable identification has been applied if 4.4.5 (OHSAS

retained for any purpose. 18001:2007) /

HSEP-70

45 Noise Monitoring

46 Light Measurement

47 PPE

48 PPE

49 Equipment Maintenance

50 Third party Inspection

51 Calibration of Equipment

52 Goods and services shall be purchased from approved

suppliers. Verify supplier selection

Item Classification

No. Applicable

Check Points Objective Evidence /Remarks

Clause No

OBS MIN MAJ

NCR

53 Verify is supplier are periodically evaluated.

54 Verify the Emergency preparedness and response

procedure. Are the potential emergency situations identified?

4.4.7 (OHSAS

18001:2007)/E

PP Gulf Labs

55 Check familiarity of employees on how to respond to

relevant emergency situations:

- Accident in the workplace

4.4.7 (OHSAS

- Fire and Explosion

18001:2007)/E

- Gas leak

PP Gulf Labs

- radiation leak

56 Is the emergency procedure periodically tested? Check

records of drills. Verify if the emergency procedure is

4.4.7 (OHSAS

reviewed after the drill or occurrence of emergency

18001:2007)/E

situations.

PP Gulf Labs

57 Check the monitoring system of GL's OH&S performance.

58 Verify the monitoring of the extent to which the OH&S

objectives are met. 4.5.1 (OHSAS

18001:

2007)/HSEMS-

01

59 Verify Evaluation of Legal Compliance

4.5.1 (OHSAS

18001:

2007)/HSEMS-

01

60 Check HSE Inspections, STOP CARDS, Audit Results,

Incident Reports 4.5.1 (OHSAS

18001:

2007)/HSEMS-

01

61 Verify Non conformance, Corrective and Preventative

Actions Reporting 4.5.1 (OHSAS

18001:

2007)/HSEMS-

01

62 Verify the procedure to record, investigate and analyse

incidents in order to:

(a) determine underlying OH&S deficiencies and other

factors that might be causing or contributing to the

occurrence of incidents

4.5.3.1

(b) identify the need for corrective action

(OHSAS

(c) identify opportunities for preventive action

18001: 2007)/

(d) identify opportunities for continual improvement

HSEP -03

(e) communicate the results of such investigations

63 Check the incident reports and verify if the investigations are

4.5.3.1

performed in a timely manner, causes are identified and

(OHSAS

actions are taken to avoid recurrence

18001: 2007)/

HSEP -03

64 Are the incident investigations documented and maintained?

4.5.3.1

(OHSAS

18001: 2007)/

HSEP -03

65 Verify if causes, corrective and preventive action are

identified in the incident reports 4.5.3.1

(OHSAS

18001: 2007)/

HSEP -03

66 Verify if the corrective and preventive action in incident 4.5.3.1

investigations are effectively implemented. (OHSAS

18001: 2007)/

HSEP -03

Item Classification

No. Applicable

Check Points Objective Evidence /Remarks

Clause No

OBS MIN MAJ

NCR

67 The organization shall establish, implement and maintain

procedure for dealing with actual and potential nonconformity

and for taking corrective and preventive action. The

procedure shall define the requirements for:

(a) identifying and correcting non conformity and taking

action to mitigate their OH&S consequences

(b) investigating nonconformity, determining their causes

and taking actions in order to avoid their recurrence

(c) evaluating the need for action to prevent non 4.5.3.2

conformity and implementing appropriate action (OHSAS

designed to avoid their occurrence 18001:2007)/

(d) recording and communicating the results of corrective HSEP-140

actions and preventive action taken

(e) reviewing the effectiveness of corrective action and

preventive action taken

Item Classification

No. Applicable

Check Points Objective Evidence /Remarks

Clause No

OBS MIN MAJ

NCR

68 Is risk assessment carried out for new or changed hazard

identified during implementation of corrective and preventive 4.5.3.2

action? (OHSAS

18001:2007)/

HSEP-140

69 Any corrective and preventive action taken to eliminate the

causes of actual and potential non conformity shall be 4.5.3.2

appropriate to the magnitude of problems and (OHSAS

commensurate with the OH&S risks encountered. 18001:2007)/

HSEP-140

70 Verify if changes arising from corrective and preventive

action and reflected in the OHS relevant documentation.

4.5.3.2

(OHSAS

18001:2007)/

HSEP-140

71 Verify the availability of documented procedure to define the

controls needed for the identification, storage, protection,

4.5.4 (OHSAS

retrieval, retention time and disposition of records.

18001: 2007) /

HSEP-100

72 Check for the master list of records

4.5.4 (OHSAS

18001: 2007) /

HSEP-100

73 Verify awareness of person in-charge on proper control of

records. 4.5.4 (OHSAS

18001: 2007) /

HSEP-100

74 All records should be legible, readily identifiable and

retrievable

4.5.4 (OHSAS

18001: 2007) /

HSEP-100

75 Retention period being followed.

4.5.4 (OHSAS

18001: 2007) /

HSEP-100

76 Check for proper disposal of records

4.5.4 (OHSAS

18001: 2007) /

HSEP-100

77 Check documented procedure for internal audit if

responsibilities and requirements for planning, conducting, 4.5.5 (OHSAS

reporting results and maintaining records are defined. 18001:2007) /

HSEP- 20

78 Check if internal audits are conducted at planned intervals

(once a year). Check the audit plan and programmes. 4.5.5 (OHSAS

18001:2007) /

HSEP- 20

79 Verify the results of the previous internal audit. All findings

from the previous audit must have been closed out. 4.5.5 (OHSAS

18001:2007) /

HSEP- 20

80 Check for the implementation and effectiveness of the

corrective action for previous audit findings 4.5.5 (OHSAS

18001:2007) /

HSEP- 20

81 Top management shall review the organization’s OHSMS at

planned intervals, to ensure its continuing suitability,

adequacy and effectiveness. This review shall include 4.6 (OHSAS

assessing opportunities for improvement and the need for 18001:2007) /

changes to the OH&S, including policy and objectives. HSEP-02

Item Classification

No. Applicable

Check Points Objective Evidence /Remarks

Clause No

OBS MIN MAJ

NCR

82 Verify if the management review has been conducted at

least once a year. 4.6 (OHSAS

18001:2007) /

HSEP-02

83 Agenda for discussion during management review are

established and defined based on the standard for

management review

- HSE Policy and objectives

- Progress made towards HSE objectives, targets and

programs, and any proposed changes to targets

- Current status of HSESMS implementation

- Result of Audits (internal or external), investigation

reports, corrective and preventative actions

- Overdue remedial actions

- Setting deadlines for the completion of remedial actions

- HSE statistics

- HSE performance of the organization

- The level of HSE awareness of employees

- Results of participation and consultation and any matters 4.6 (OHSAS

raised by the HSE Committee 18001:2007) /

- Relevant communications from external interested HSEP-02

parties, including complaints

- Evaluation of compliance with Legal requirements and

other requirements to which the organization subscribes.

- Changing circumstances, including developments in legal

and other requirements related to HSE

- Planning of any new HSEMS requirements or

recommendations for improvement.

84 Records of management reviews shall be maintained

(meeting minutes & attendance sheet) 4.6 (OHSAS

18001:2007) /

HSEP-02

You might also like

- BS en 12697-27-2017 - (2018-07-07 - 01-37-13 PM) PDFDocument22 pagesBS en 12697-27-2017 - (2018-07-07 - 01-37-13 PM) PDFjerin sam kurianNo ratings yet

- ASTM A931-18 - Tension Testing of Wire Strand PDFDocument4 pagesASTM A931-18 - Tension Testing of Wire Strand PDFjerin sam kurianNo ratings yet

- ASTM C1556-11a - Determining Apparent Chloride Diffusion Coefficient by Bulk Diffusion PDFDocument7 pagesASTM C1556-11a - Determining Apparent Chloride Diffusion Coefficient by Bulk Diffusion PDFjerin sam kurianNo ratings yet

- BS EN ISO 10319 2015 - Geosynthetics - Wide Width Tensile Test PDFDocument23 pagesBS EN ISO 10319 2015 - Geosynthetics - Wide Width Tensile Test PDFjerin sam kurianNo ratings yet

- SEC Standards - 1.5 - 5-Star Safety and Health Management System - Working Environment Pollution - Air - Ground - WaterDocument7 pagesSEC Standards - 1.5 - 5-Star Safety and Health Management System - Working Environment Pollution - Air - Ground - WaterAhmad Shawky El MadhalyNo ratings yet

- ASTM C305 - 20 - Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistancy PDFDocument3 pagesASTM C305 - 20 - Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistancy PDFjerin sam kurian100% (1)

- BS en 12697-13-2017 - (2019-07-30 - 02-19-04 PM) PDFDocument10 pagesBS en 12697-13-2017 - (2019-07-30 - 02-19-04 PM) PDFjerin sam kurian100% (1)

- (Oxford Political Theory) Anne Phillips - The Politics of Presence-Oxford University Press, USA (1998)Document220 pages(Oxford Political Theory) Anne Phillips - The Politics of Presence-Oxford University Press, USA (1998)Mirna Lucaccini100% (1)

- Letter of Motivation - ICLEIDocument1 pageLetter of Motivation - ICLEIZahara ApNo ratings yet

- Legal and Other Requirements Register April 45001Document18 pagesLegal and Other Requirements Register April 45001john osullivanNo ratings yet

- Hazards and Risk Identification and ManagementDocument2 pagesHazards and Risk Identification and Managementsai ramNo ratings yet

- GNPOC List ofDocument3 pagesGNPOC List ofHSE S4No ratings yet

- ENV18 Aspects Register Procedure 2014 - UpdatedDocument5 pagesENV18 Aspects Register Procedure 2014 - UpdatedsametggtNo ratings yet

- Safety Course OutlinesDocument5 pagesSafety Course OutlinesAd ZamanNo ratings yet

- Contractor Safety InductionDocument5 pagesContractor Safety InductionBaran Shafqat100% (1)

- Risk Assessment Form - KingGroveDocument12 pagesRisk Assessment Form - KingGroveeric chenNo ratings yet

- 202221JSA (Job Safety Analysis) and HIRARC (Hazard Identification, Risk Assessment and Risk Control)Document7 pages202221JSA (Job Safety Analysis) and HIRARC (Hazard Identification, Risk Assessment and Risk Control)Khairulz AnuarNo ratings yet

- Riskman Template-FinalDocument3 pagesRiskman Template-Finalapi-238786020No ratings yet

- LUS HSE FM4 455 005.01 Audit Gap Analysis ChecklistDocument10 pagesLUS HSE FM4 455 005.01 Audit Gap Analysis ChecklistRichu PaliNo ratings yet

- Hazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisDocument7 pagesHazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisZeroRecoNo ratings yet

- FRM-OHS-002 Management Review Agenda TemplateDocument1 pageFRM-OHS-002 Management Review Agenda TemplateJoachimNo ratings yet

- HSE Inspection Report 148 AttendDocument11 pagesHSE Inspection Report 148 Attendtuan mai vanNo ratings yet

- 02-011 Training & Development PolicyDocument6 pages02-011 Training & Development PolicyJoachimNo ratings yet

- Hazard ObservationDocument8 pagesHazard ObservationMarya HasniNo ratings yet

- Binder Spine Indexing SlipsDocument4 pagesBinder Spine Indexing Slipspundir_vineetNo ratings yet

- E PAKATSDocument1 pageE PAKATSAlvee AlzhariffNo ratings yet

- 14 Driver Fatigue Management Guide 4804Document20 pages14 Driver Fatigue Management Guide 4804info kzNo ratings yet

- HIRARCDocument21 pagesHIRARCAmirul Mukminin Zakaria SymantechNo ratings yet

- (Inspection Inprocess)Document15 pages(Inspection Inprocess)loserambujNo ratings yet

- Ppe ChecklistDocument1 pagePpe ChecklistIvan BaraćNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument13 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- CMPAK 2020 BIDDING Project EHS Checklist: Category No. EHS Checking Items Remark (If Not Comply) Compliance Yes/ No/ NADocument1 pageCMPAK 2020 BIDDING Project EHS Checklist: Category No. EHS Checking Items Remark (If Not Comply) Compliance Yes/ No/ NAGayas ShaikNo ratings yet

- HSE 10 Excavation PermitDocument1 pageHSE 10 Excavation PermitBa N Nhim100% (1)

- Final Scope of Work Pachmari SWMDocument10 pagesFinal Scope of Work Pachmari SWMSANJAY PARASARNo ratings yet

- Part 1 - Personal Details and Declaration IGC3 NEBOSHDocument9 pagesPart 1 - Personal Details and Declaration IGC3 NEBOSHEngi SaifNo ratings yet

- Job StudyDocument3 pagesJob StudyVictor PhiriNo ratings yet

- CRA All PDFDocument42 pagesCRA All PDFRohan PanditNo ratings yet

- Tata Safety and Health PolicyDocument1 pageTata Safety and Health PolicyFuzail AyazNo ratings yet

- Know - Workplace Health and Safety Principles (International)Document25 pagesKnow - Workplace Health and Safety Principles (International)Afroz SheikhNo ratings yet

- COVID-19 Precautionary Plan - Remal BSP 9046 - Rev00 22.04.2020 - UPDATEDDocument33 pagesCOVID-19 Precautionary Plan - Remal BSP 9046 - Rev00 22.04.2020 - UPDATEDFarhat SetharNo ratings yet

- Ra RegisterDocument2 pagesRa Registerzarni77No ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- MTC Ims Fo 14d Tool Box TalkDocument2 pagesMTC Ims Fo 14d Tool Box TalksouravrobinNo ratings yet

- Accident CausationDocument35 pagesAccident CausationAntonio Jose De JesusNo ratings yet

- Ini Dia Dokumen ISO14001Document9 pagesIni Dia Dokumen ISO14001karjayaNo ratings yet

- Hirarc: Made Up From 3 Activities That Consist of Hazard Identification, Risk Assesment and Risk ControlDocument12 pagesHirarc: Made Up From 3 Activities That Consist of Hazard Identification, Risk Assesment and Risk ControlHamizi AzizanNo ratings yet

- Compressed Fire Risk Assessment TemplateDocument9 pagesCompressed Fire Risk Assessment TemplateReaz UddinNo ratings yet

- 08PR061C - Confined Space WorkDocument11 pages08PR061C - Confined Space Workkenoly123No ratings yet

- Organizational ChartDocument3 pagesOrganizational ChartnuhaNo ratings yet

- Co-X QHS SOP13 HSE Performance Monitoring and Measurement Rev 02Document6 pagesCo-X QHS SOP13 HSE Performance Monitoring and Measurement Rev 02Abdellatef HossamNo ratings yet

- 07-F01DOCUMENT CONTROL REGISTER and INSPECTIONDocument1 page07-F01DOCUMENT CONTROL REGISTER and INSPECTIONSn AhsanNo ratings yet

- HSEQ Policy Statement - English PDFDocument1 pageHSEQ Policy Statement - English PDFTovo RafaralahyNo ratings yet

- Annex 02 - ODS 01-01 HSE Manual - Rev.1Document232 pagesAnnex 02 - ODS 01-01 HSE Manual - Rev.1Fahmi AbdullahNo ratings yet

- Job Risk Assessment and Control GIS Recovery Boilerx1Document11 pagesJob Risk Assessment and Control GIS Recovery Boilerx1FerdyCodetzNo ratings yet

- Sample of SHE ProgramDocument1 pageSample of SHE ProgramNurul Aishah AdnanNo ratings yet

- Duties & Qualities of Safety OfficersDocument21 pagesDuties & Qualities of Safety OfficersBobbit C ArninioNo ratings yet

- HSE Objectives 2 PDFDocument6 pagesHSE Objectives 2 PDFsudeesh kumarNo ratings yet

- Msc-Qhsef-04 Masterlist - Documents and RecordsDocument4 pagesMsc-Qhsef-04 Masterlist - Documents and RecordsAdil Abdulkhader100% (1)

- EHS PlanDocument37 pagesEHS PlanVishal TiwariNo ratings yet

- 2 PWT-Training Agenda Evaluation Needs For 13oct 2009Document4 pages2 PWT-Training Agenda Evaluation Needs For 13oct 2009Ahmed RaslanNo ratings yet

- Matrix TrainingDocument2 pagesMatrix TrainingcumminkNo ratings yet

- Safe Journey Management WorkshopDocument28 pagesSafe Journey Management WorkshopRamadan KareemNo ratings yet

- Unit Diploma Nebosh DniDocument32 pagesUnit Diploma Nebosh DniScribdTranslationsNo ratings yet

- HSE Observation DashboardDocument4 pagesHSE Observation Dashboardiyo_bikers4598No ratings yet

- Construction Site Safety Control Measures For Covid-19Document34 pagesConstruction Site Safety Control Measures For Covid-19Achik WahabNo ratings yet

- 6 RA - Template - BROGAN r2Document9 pages6 RA - Template - BROGAN r2Daniel100% (1)

- General Information For Hazardous MaterialsDocument8 pagesGeneral Information For Hazardous MaterialsAshraf shaikhNo ratings yet

- CML Methods - Qatar PDFDocument46 pagesCML Methods - Qatar PDFjerin sam kurian100% (1)

- BS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary BlocksDocument10 pagesBS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary Blocksjerin sam kurianNo ratings yet

- ASTM A1061 A1061M-09 - Testing Multi Wire Steel Strand PDFDocument3 pagesASTM A1061 A1061M-09 - Testing Multi Wire Steel Strand PDFjerin sam kurianNo ratings yet

- BS EN 12697 Part 36 2003 - Determination of The Thickness of A Bituminous Pavement PDFDocument13 pagesBS EN 12697 Part 36 2003 - Determination of The Thickness of A Bituminous Pavement PDFjerin sam kurianNo ratings yet

- ASTM C511 - 19 - Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and Concretes PDFDocument3 pagesASTM C511 - 19 - Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and Concretes PDFjerin sam kurianNo ratings yet

- x02 Sieve Analysis - Dry BS 812-103.1-1985rev3 6.01Document1 pagex02 Sieve Analysis - Dry BS 812-103.1-1985rev3 6.01jerin sam kurianNo ratings yet

- Plate Load Test - Equipment, Procedure, CalculationDocument5 pagesPlate Load Test - Equipment, Procedure, Calculationjerin sam kurianNo ratings yet

- Laboratory Work Sheet Test: Specific Gravity & Water Absorption of Coarse Aggregate Method: ASTM C 127-07Document1 pageLaboratory Work Sheet Test: Specific Gravity & Water Absorption of Coarse Aggregate Method: ASTM C 127-07jerin sam kurianNo ratings yet

- Laboratory Work Sheet Test: Material Passing 75 M (No. 200) Sieve Method: ASTM C117-04 Test: 8Document1 pageLaboratory Work Sheet Test: Material Passing 75 M (No. 200) Sieve Method: ASTM C117-04 Test: 8jerin sam kurian100% (1)

- Pending Review 28 Sieve Analysis - Dry Subbase BS 812-103.1-7.2 Rev1 8jun10Document1 pagePending Review 28 Sieve Analysis - Dry Subbase BS 812-103.1-7.2 Rev1 8jun10jerin sam kurianNo ratings yet

- Laboratory Work Sheet Test: Soundness of Coarse Aggregate - Mgso Method: ASTM C 88-05Document1 pageLaboratory Work Sheet Test: Soundness of Coarse Aggregate - Mgso Method: ASTM C 88-05jerin sam kurianNo ratings yet

- Pending 29 Soundness-BS812P121 For NDPP OnlyDocument1 pagePending 29 Soundness-BS812P121 For NDPP Onlyjerin sam kurianNo ratings yet

- Sieve Hyundai Q5Document1 pageSieve Hyundai Q5jerin sam kurianNo ratings yet

- Separate: Dr. Richard James Ellis Beng PH.D Ceng Fciht Fiat Miq Deputy General Manager / Laboratory ManagerDocument1 pageSeparate: Dr. Richard James Ellis Beng PH.D Ceng Fciht Fiat Miq Deputy General Manager / Laboratory Managerjerin sam kurianNo ratings yet

- Gulf Laboratories Co. W.L.L.: Project Villa at Maed Mohammed Aj Al HebabiDocument3 pagesGulf Laboratories Co. W.L.L.: Project Villa at Maed Mohammed Aj Al Hebabijerin sam kurianNo ratings yet

- Water Test Training RecordDocument2 pagesWater Test Training Recordjerin sam kurianNo ratings yet

- Concept and Definition of Sustainable Development: Nil-Nl Bird War-BRDWRDocument19 pagesConcept and Definition of Sustainable Development: Nil-Nl Bird War-BRDWRSunil PawarNo ratings yet

- Sosay Independent Regulatory Agencies in Emerging Economies MPRA Paper 380Document55 pagesSosay Independent Regulatory Agencies in Emerging Economies MPRA Paper 380FERNANDO PAEZ MENDIZABALNo ratings yet

- SCS Vijayawada-4Document124 pagesSCS Vijayawada-4Pooja VarmaNo ratings yet

- Apthorpe 1996Document17 pagesApthorpe 1996Daniela GonzalezNo ratings yet

- Project Proposal TrishaDocument6 pagesProject Proposal TrishaBALOGO TRISHA MARIENo ratings yet

- Strategic Solution (1-5)Document92 pagesStrategic Solution (1-5)Mazharul IslamNo ratings yet

- 2016 Book InformationModelsAndSustainabiDocument193 pages2016 Book InformationModelsAndSustainabiLam88rNo ratings yet

- (Report PPT) Chap 5Document41 pages(Report PPT) Chap 5Nicole Anne GatilaoNo ratings yet

- Circular 571 13.05.2024Document5 pagesCircular 571 13.05.2024vusimuzimahlangu2006No ratings yet

- NSTP 2020 ModuleDocument99 pagesNSTP 2020 ModulePaker LeeNo ratings yet

- Finance Admin Proc 648-2001Document31 pagesFinance Admin Proc 648-2001Hailu AtekaNo ratings yet

- Pil HR PDFDocument5 pagesPil HR PDFImran PathanNo ratings yet

- Separation of Powers: Legal Methods (Jurisprudence)Document16 pagesSeparation of Powers: Legal Methods (Jurisprudence)Kushagra SinghNo ratings yet

- And Not A Shot Is Fired, by Jan KozákDocument47 pagesAnd Not A Shot Is Fired, by Jan KozáktronedotnetNo ratings yet

- Business Law 1 NotesDocument74 pagesBusiness Law 1 NotesRANDAN SADIQ100% (3)

- Cyber Law PPT (Saurav)Document16 pagesCyber Law PPT (Saurav)saurav singhNo ratings yet

- An Introduction To Equality of Opportunity - Equality of Opportunity and EducationDocument4 pagesAn Introduction To Equality of Opportunity - Equality of Opportunity and Educationsujata katwalNo ratings yet

- Environment and Society 1St Ed Edition Magnus Bostrom Full ChapterDocument67 pagesEnvironment and Society 1St Ed Edition Magnus Bostrom Full Chapterbetty.barabas349100% (10)

- National and Regional Planning PrincipleDocument8 pagesNational and Regional Planning PrinciplenilueNo ratings yet

- The Genesis of International Investment Law 1 2 PDFDocument3 pagesThe Genesis of International Investment Law 1 2 PDFManuelNo ratings yet

- Theory in Action Public Health and Community.6Document6 pagesTheory in Action Public Health and Community.6praise theNo ratings yet

- Assignment Cover Sheet: Student DetailsDocument11 pagesAssignment Cover Sheet: Student DetailsHasan AhmadNo ratings yet

- PP Disec IndonesiaDocument2 pagesPP Disec IndonesiachampionNo ratings yet

- 2020 - IFMA Strategic FrameworkDocument1 page2020 - IFMA Strategic FrameworkFizz FirdausNo ratings yet

- Access To Social Work Course WalsallDocument7 pagesAccess To Social Work Course Walsallshvfihdjd100% (2)

- Respondent Memorial Respondent Memorial: Civil Law (Jiwaji University) Civil Law (Jiwaji University)Document28 pagesRespondent Memorial Respondent Memorial: Civil Law (Jiwaji University) Civil Law (Jiwaji University)Ranjan BaradurNo ratings yet

- The Failings of The Economic Freedom IndexDocument6 pagesThe Failings of The Economic Freedom IndexBav JeffNo ratings yet

- Internship Report: The Tamilnadu DR - Ambedkar Law UniversityDocument6 pagesInternship Report: The Tamilnadu DR - Ambedkar Law UniversityvarshiniNo ratings yet