Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

36 viewsUnited States Patent (10) Patent No.: US 7,806,945 B2: The To In... T

United States Patent (10) Patent No.: US 7,806,945 B2: The To In... T

Uploaded by

esiThe document discloses a process for converting high free fatty acid grease feedstocks to biodiesel and glycerin by first performing a glycerolysis reaction to convert the free fatty acids to glycerides followed by a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin without using solvents, with both glycerin and methanol being recycled.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Freebitcoin Script 2019 Big SatoshiDocument1 pageFreebitcoin Script 2019 Big SatoshiL1N2M3G462% (26)

- Maths Socrative Quizzes BankDocument48 pagesMaths Socrative Quizzes BankJacm100% (1)

- (2012) US8231765 Process For The Purification of LactamsDocument9 pages(2012) US8231765 Process For The Purification of LactamsThitikorn WassanarpheernphongNo ratings yet

- US8178353 - Method For Determination of Polymer Concentration in Water SystemsDocument15 pagesUS8178353 - Method For Determination of Polymer Concentration in Water SystemsKhanh Nguyen TuanNo ratings yet

- US7673686Document20 pagesUS7673686Raqi IzdiharaNo ratings yet

- US Patent US6657057Document6 pagesUS Patent US6657057Vandit KhareNo ratings yet

- United States Patent (10) Patent No.: US 7,980,087 B2Document13 pagesUnited States Patent (10) Patent No.: US 7,980,087 B2viniciusschwabNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7.219.480 B2Document7 pagesUnited States Patent: (12) (10) Patent No.: US 7.219.480 B2Cảnh ĐoànNo ratings yet

- United States Patent (10) Patent No.: US 8,147,768 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,147,768 B2habbibrachmanNo ratings yet

- Sai Gó: (5) (5) (5) (Sics211Document33 pagesSai Gó: (5) (5) (5) (Sics211Dhrubajyoti BoraNo ratings yet

- Us6974107 Torque Limiter Thrust ReverserDocument12 pagesUs6974107 Torque Limiter Thrust ReverserTurk Solo100% (1)

- US7094341Document31 pagesUS7094341Diego RossoNo ratings yet

- US7596959Document48 pagesUS7596959Yu An ShihNo ratings yet

- US6351692Document12 pagesUS6351692Aram MorenoNo ratings yet

- United States Patent: Et Ai. Patent No.: Date PatentDocument15 pagesUnited States Patent: Et Ai. Patent No.: Date Patentnalin_gupta_1No ratings yet

- United States Patent (10) Patent No.: US 6,326,458 B1Document26 pagesUnited States Patent (10) Patent No.: US 6,326,458 B1Citra Adelina SitorusNo ratings yet

- United States Patent (10) Patent No.: US 9,017,983 B2Document90 pagesUnited States Patent (10) Patent No.: US 9,017,983 B2Дмитрий КоваленкоNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument7 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentHP ghnNo ratings yet

- United States Patent (10) Patent No.: US 6,908,151 B2Document20 pagesUnited States Patent (10) Patent No.: US 6,908,151 B2dylan tikoyNo ratings yet

- Patente Del Proceso Cryomax MreDocument10 pagesPatente Del Proceso Cryomax MreRuben PerezNo ratings yet

- Ojo Patente Del Proceso Cryomax MreDocument10 pagesOjo Patente Del Proceso Cryomax MrerubenpeNo ratings yet

- United States Patent: Swersey Et Al. Jan. 18, 2005Document14 pagesUnited States Patent: Swersey Et Al. Jan. 18, 2005Anonymous G1iPoNOKNo ratings yet

- Patente EGDocument19 pagesPatente EGRodrigo Thomaz TaralloNo ratings yet

- 59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Document22 pages59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Qwerty UiopNo ratings yet

- US6852957 Patend Bread CrumbDocument10 pagesUS6852957 Patend Bread CrumbMichael ChristoferNo ratings yet

- United States Patent (10) Patent No.: US 7,208,943 B2: Godoy Et Al. (45) Date of Patent: Apr. 24, 2007Document15 pagesUnited States Patent (10) Patent No.: US 7,208,943 B2: Godoy Et Al. (45) Date of Patent: Apr. 24, 2007Vansala GanesanNo ratings yet

- Capacitive Discharge Plasma Ion SourceDocument37 pagesCapacitive Discharge Plasma Ion SourceVEDANAND BELUTNo ratings yet

- United States Patent (10) Patent No.: US 6,419,788 B1: Wingerson (45) Date of Patent: Jul. 16, 2002Document11 pagesUnited States Patent (10) Patent No.: US 6,419,788 B1: Wingerson (45) Date of Patent: Jul. 16, 2002ahmetNo ratings yet

- US8658823Document16 pagesUS8658823Santiago BorgesNo ratings yet

- US7109268Document8 pagesUS7109268Kamilo ArciniegazNo ratings yet

- US7525004 New EditedDocument11 pagesUS7525004 New EditedFahreza HidayatullahNo ratings yet

- Us 7004185Document14 pagesUs 7004185My best Of bestNo ratings yet

- US7387748Document7 pagesUS7387748MaboodNo ratings yet

- United States Patent (10) Patent No.: US 7.416,645 B2: Weber Et Al. (45) Date of Patent: Aug. 26, 2008Document7 pagesUnited States Patent (10) Patent No.: US 7.416,645 B2: Weber Et Al. (45) Date of Patent: Aug. 26, 2008Maria PaulaNo ratings yet

- Backpack Suspension SystemDocument13 pagesBackpack Suspension SystemAnureet BhardwajNo ratings yet

- Us8771313 PDFDocument24 pagesUs8771313 PDFhuyenthanh1807No ratings yet

- Neste NexbtlDocument16 pagesNeste NexbtljonathanNo ratings yet

- United States Patent (10) Patent No.: US 8,584,752 B2Document17 pagesUnited States Patent (10) Patent No.: US 8,584,752 B2M FNo ratings yet

- US6337429Document14 pagesUS6337429Tasneem MNo ratings yet

- United States Patent: Nagyetal. (45) Date of Patent: Oct. 20, 2020Document11 pagesUnited States Patent: Nagyetal. (45) Date of Patent: Oct. 20, 2020Burak PalaNo ratings yet

- 12) United States Patent 10) Patent No.: US 8.841,243 B2: Tobias Et Al. 45) Date of Patent: Seb. 23, 2014Document12 pages12) United States Patent 10) Patent No.: US 8.841,243 B2: Tobias Et Al. 45) Date of Patent: Seb. 23, 2014بن زيدون المخزوميNo ratings yet

- Us8048971 PDFDocument8 pagesUs8048971 PDFSyahdillaNo ratings yet

- US9322588Document11 pagesUS9322588Uchenna BacchusNo ratings yet

- United States Patent (10) Patent No.: US 7.988,763 B2Document11 pagesUnited States Patent (10) Patent No.: US 7.988,763 B2Ernane MagalhãesNo ratings yet

- Importante Fator Q 322lecture6Document7 pagesImportante Fator Q 322lecture6AndersonNo ratings yet

- United States Patent (10) Patent No.: US 7,939.469 B2Document6 pagesUnited States Patent (10) Patent No.: US 7,939.469 B2live streamNo ratings yet

- Saturation Process For Making Lubricant Base OilsDocument27 pagesSaturation Process For Making Lubricant Base OilsBreak LimsNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument21 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentRicardo Jimenez SNo ratings yet

- US7741796Document9 pagesUS7741796ALiftsNo ratings yet

- United States Patent (10) Patent No.: US 8,381544 B2: Coyle (45) Date of Patent: Feb. 26, 2013Document43 pagesUnited States Patent (10) Patent No.: US 8,381544 B2: Coyle (45) Date of Patent: Feb. 26, 2013Erin GokNo ratings yet

- United States Patent (10) Patent No.: US 7,928,345 B2Document8 pagesUnited States Patent (10) Patent No.: US 7,928,345 B2alfarisyi27No ratings yet

- Adsorption 5ADocument9 pagesAdsorption 5ANguyễn Thị Kim PhượngNo ratings yet

- US7713387 HHHHBDocument9 pagesUS7713387 HHHHBsatria jayaNo ratings yet

- United States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Document20 pagesUnited States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Ronan RojasNo ratings yet

- United States Patent: Jaeger Et Al. (45) Date of Patent: Mar. 27, 2007Document5 pagesUnited States Patent: Jaeger Et Al. (45) Date of Patent: Mar. 27, 2007zibaNo ratings yet

- United States Patent (10) Patent No.: US 7.498,471 B2: Schultz Et Al. (45) Date of Patent: Mar. 3, 2009Document7 pagesUnited States Patent (10) Patent No.: US 7.498,471 B2: Schultz Et Al. (45) Date of Patent: Mar. 3, 2009m yusuf syafzaNo ratings yet

- US7946356Document53 pagesUS7946356Ahmad Reza FarokhiNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,344,071 B1Document20 pagesUnited States Patent: (12) (10) Patent N0.: US 6,344,071 B143No ratings yet

- United States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009Document11 pagesUnited States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009emre yıldırımNo ratings yet

- United States Patent: (10) Patent No.: US 9.234,068 B2Document21 pagesUnited States Patent: (10) Patent No.: US 9.234,068 B2Özlem YılmazNo ratings yet

- Evergreen International Aerial Delivery System - Patent US7413145 PDFDocument12 pagesEvergreen International Aerial Delivery System - Patent US7413145 PDFJeannie LorraineNo ratings yet

- Is Bad-Faith the New Wilful Blindness?: The Company Directors’ Duty of Good Faith and Wilful Blindness Doctrine Under Common Law Usa (Delaware) and Uk (England): a Comparative StudyFrom EverandIs Bad-Faith the New Wilful Blindness?: The Company Directors’ Duty of Good Faith and Wilful Blindness Doctrine Under Common Law Usa (Delaware) and Uk (England): a Comparative StudyNo ratings yet

- Novi Ken Sydney 1306621021 Review PaperDocument4 pagesNovi Ken Sydney 1306621021 Review PaperesiNo ratings yet

- United States Patent (19) : Argo Et Al. (11) 4,086,070Document16 pagesUnited States Patent (19) : Argo Et Al. (11) 4,086,070esiNo ratings yet

- United States PatentDocument4 pagesUnited States PatentesiNo ratings yet

- Process Engineering Flow Diagram Pra Rancangan Pabrik Bioetanol Dari Tandan Kosong Kelapa Sawit Kapasitas 40.000 Ton/TahunDocument1 pageProcess Engineering Flow Diagram Pra Rancangan Pabrik Bioetanol Dari Tandan Kosong Kelapa Sawit Kapasitas 40.000 Ton/TahunesiNo ratings yet

- Kualitas Minyak Blend Kelapa Kopra Dan Minyak Kelapa Sawit Ditinjau Dari Kadar Air, Kadar Asam Lemak Bebas Dan Bilangan PeroksidaDocument8 pagesKualitas Minyak Blend Kelapa Kopra Dan Minyak Kelapa Sawit Ditinjau Dari Kadar Air, Kadar Asam Lemak Bebas Dan Bilangan PeroksidaesiNo ratings yet

- Purification of Crude Glycerol From Transesterific PDFDocument11 pagesPurification of Crude Glycerol From Transesterific PDFesiNo ratings yet

- SE Comp M III Index 1Document35 pagesSE Comp M III Index 1prafullaNo ratings yet

- Educating Green Building Stakeholders About The Benefits of BIM - The Philippines ExperienceDocument19 pagesEducating Green Building Stakeholders About The Benefits of BIM - The Philippines ExperiencePeter Adrian NgoNo ratings yet

- E StatementDocument3 pagesE StatementEvin JoyNo ratings yet

- Busbar Design GuideDocument22 pagesBusbar Design Guidejohnwu_2009100% (6)

- Electric Vehicle Fire Testing: Dean D. MacneilDocument19 pagesElectric Vehicle Fire Testing: Dean D. Macneilluke hainesNo ratings yet

- FrustrationDocument13 pagesFrustrationdxtyle-1No ratings yet

- International Economics 4th Edition Feenstra Test Bank 1Document48 pagesInternational Economics 4th Edition Feenstra Test Bank 1steven100% (42)

- Fibonacci NumberDocument291 pagesFibonacci NumbersrikantsauravNo ratings yet

- Module 1 Metacognition and Multiple Intelligences Theory.Document14 pagesModule 1 Metacognition and Multiple Intelligences Theory.Danica AdobasNo ratings yet

- Accenture CRMDocument2 pagesAccenture CRMagupta@cantab.netNo ratings yet

- India - EU Free Trade AgreementDocument3 pagesIndia - EU Free Trade AgreementJay KothariNo ratings yet

- MT Educare LTD.: Sr. No. Subject PortionDocument2 pagesMT Educare LTD.: Sr. No. Subject PortionRutviNo ratings yet

- Process Industry Practices Insulation: PIP INIH1000 Hot Insulation Installation DetailsDocument25 pagesProcess Industry Practices Insulation: PIP INIH1000 Hot Insulation Installation DetailsSarwar KhanNo ratings yet

- L2.5 Using A Compound Light Microscope OptDocument8 pagesL2.5 Using A Compound Light Microscope Optochattc100% (1)

- On Site Wiring, Travelling CableDocument3 pagesOn Site Wiring, Travelling CableAli DiabNo ratings yet

- Questionnaire DesignDocument12 pagesQuestionnaire DesignYashi SinghNo ratings yet

- Interoperability Unit Running Dynamics APPLICATION OF EN 14363:2005 - Modifications and ClarificationsDocument64 pagesInteroperability Unit Running Dynamics APPLICATION OF EN 14363:2005 - Modifications and ClarificationsPratik ThakurNo ratings yet

- Soalan Assignment emDocument9 pagesSoalan Assignment emafieqafariha1904No ratings yet

- Deleting Old History Files On The As 400Document2 pagesDeleting Old History Files On The As 400rachmat99No ratings yet

- ECONOMIZERDocument17 pagesECONOMIZERTrần Văn Trọng 7350No ratings yet

- Hardness Desalination1Document18 pagesHardness Desalination1Swati U NaikNo ratings yet

- Social Media Marketing To Customer EngagementDocument27 pagesSocial Media Marketing To Customer EngagementEarly Joy BorjaNo ratings yet

- DELIBERATE Plagiarism ACCIDENTAL PlagiarismDocument1 pageDELIBERATE Plagiarism ACCIDENTAL PlagiarismJem BicolNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaSamir SabicNo ratings yet

- Yunus Et Al, 2015 - Geophysics Field Camp (GFC)Document6 pagesYunus Et Al, 2015 - Geophysics Field Camp (GFC)Muhammad YusriadyNo ratings yet

- Keynote 6,7,8Document16 pagesKeynote 6,7,8salome mumladzeNo ratings yet

- Datasheet Eaton 93 STS - Static Transfer SwitchDocument2 pagesDatasheet Eaton 93 STS - Static Transfer SwitchWilliam QuintelaNo ratings yet

- Oral Comm Q2 Module 1Document16 pagesOral Comm Q2 Module 1JESSA MAE ARADONo ratings yet

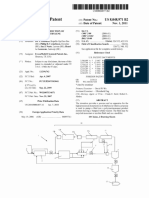

United States Patent (10) Patent No.: US 7,806,945 B2: The To In... T

United States Patent (10) Patent No.: US 7,806,945 B2: The To In... T

Uploaded by

esi0 ratings0% found this document useful (0 votes)

36 views21 pagesThe document discloses a process for converting high free fatty acid grease feedstocks to biodiesel and glycerin by first performing a glycerolysis reaction to convert the free fatty acids to glycerides followed by a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin without using solvents, with both glycerin and methanol being recycled.

Original Description:

Original Title

US7806945

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discloses a process for converting high free fatty acid grease feedstocks to biodiesel and glycerin by first performing a glycerolysis reaction to convert the free fatty acids to glycerides followed by a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin without using solvents, with both glycerin and methanol being recycled.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

36 views21 pagesUnited States Patent (10) Patent No.: US 7,806,945 B2: The To In... T

United States Patent (10) Patent No.: US 7,806,945 B2: The To In... T

Uploaded by

esiThe document discloses a process for converting high free fatty acid grease feedstocks to biodiesel and glycerin by first performing a glycerolysis reaction to convert the free fatty acids to glycerides followed by a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin without using solvents, with both glycerin and methanol being recycled.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 21

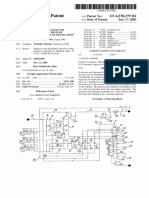

US007806945B2

(12) United States Patent (10) Patent No.: US 7,806,945 B2

Jackam et al. (45) Date of Patent: Oct. 5, 2010

(54) PRODUCTION OF BIODIESEL AND 2,383,596 A 8/1948 Dreger

GLYCERN FROM HIGH FREE FATTY ACID 2.494,366 A 1/1950 Sprules et al.

FEEDSTOCKS 2,543,421 A 2, 1951 Price et al. .................. 554,167

(75) Inventors: John P Jackam, Butte, MT (US); Joel 2,588.435 A * 3/1952 Christiaan et al. ........... 554,167

M Pierce, Butte, MT (US); Frank S 2,808.421 A 10/1957 Brokaw

Fahrenbruck, Butte, MT (US)

(73) Assignee: Seneca Landlord, LLC, Ames, IA (US)

(Continued)

(*) Notice: Subject to any disclaimer, the term of this

patent is extended or adjusted under 35 FOREIGN PATENT DOCUMENTS

U.S.C. 154(b) by 1448 days. DE 19724 O18 A 12, 1998

(21) Appl. No.: 10/766,740

22) File

(22) Filed: Jan.

an. 26,

AO 2004 (Continued)

(65) Prior Publication Data OTHER PUBLICATIONS

US 2007/0277429 A1 Dec. 6, 2007

Yuan, W. et al. (2005). Fuel, 84,943-950.*

Related U.S. Application Data (Continued)

(60) Provisional application No. 60/443,049, filed on Jan.

27, 2003, provisional application No. 60/537,251, Primary Examiner Robert J Hill, Jr.

filed on Jan. 15, 2004. Assistant Examiner—Brian McCaig

(74) Attorney, Agent, or Firm Glenn Johnson; Ryan N.

(51) Int. Cl. Carter

CIOL I/IS (2006.01)

(52) U.S. Cl. ........................... 44/308; 4.4/307:554/156; (57) ABSTRACT

554/157: 554/167:554/175

(58) Field of Classification Search ................. 554/156,

554/157,167, 175; 44/307, 308,388 A system and method for converting a high free fatty acid

See application file for complete search history. grease feedstock to biodiesel. The process comprises a glyc

(56) Ref

eerees

Cited

e

erolysis reaction to convert free fatty acids to glycerides and

a base catalyzed transesterification reaction to produce fatty

U.S. PATENT DOCUMENTS acid methyl esters and glycerin in the absence of solvents. In

preferred embodiments, both glycerin and methanol are

1659,790 A 2f1928 Starrels recycled. The process can process a feedstock containing up

2,290,609 A 7, 1942 Gosset al to 100 percent free fatty acid content to produce biodiesel and

2,383,580 A * 8, 1945 Arrowsmith et al. ........ 554,167 lvcerin with minimal waste generation

2,383,581 A * 8, 1945 Arrowsmith et al. ........ 554/168 9.

2,383,601 A 8, 1945 Kelm

2,385,599 A 8/1945 Glossop 18 Claims, 2 Drawing Sheets

Feestock th

12 8 a E. E. Metano'? 6 5.

i5 48 : r C-- w ru

Fron 35 : N For 88- shar Fin

24 revi?i- 8 42 gif S. areas

the32. to in...50 t

---,

US 7,806,945 B2

Page 2

U.S. PATENT DOCUMENTS 2003/0083514 A1 5/2003 Boocock

2003. O149289 A1 8/2003 Suppes

2,875,221 2f1959 Birnbaum 2003,0229238 A1 12/2003 Fleisher

3,102,129 8, 1963 Birnbaum et al.

3.459,736 8, 1969 Dalibor FOREIGN PATENT DOCUMENTS

4,164,506 8, 1979 Kawahara et al.

5, 1981 Torck et al. EP O591019 B1 8, 1997

4,267,393 GB 587532 A 4f1947

4,303,590 12, 1981 Tanaka et al.

12, 1982 Erner GB 612667 A 11, 1948

4,364,743 GB 2350 618 A 12/2000

4,371,470 2, 1983 Matsukura et al.

4,668.439 5, 1987 Billenstein et al. WO WO95/02661 1, 1995

9, 1987 Stern et al. WO WO9924387 * 5/1999

4,695.411 WO WOO2,288.11 A1 4/2002

4,698, 186 10, 1987 Jeromin et al.

6, 1989 Holmberg et al. WO WOO2,38529 A1 5, 2002

4,839,287

4.956,286 9, 1990 Macrae

OTHER PUBLICATIONS

5,354,878 10, 1994 Connemann et al.

5,399,731 3, 1995 Wimmer Gouw, T.H. etal. (1964). The Journal of the American Oil Chemists'

5,424,467 6, 1995 Bam et al. Society, 41, 142-145.*

5.434,279 7, 1995 Wimmer Noureddini et al., Glycerolysis of Fats and Methyl Esters, JAOCS,

5,514,820 5, 1996 ASSmann et al. 1997, pp. 419–425, vol. 74, No. 4, AOCS Press, Lincoln, Nebraska.

5,525,126 6, 1996 Basu et al. Tyson, Brown Grease Feedstocks for Biodiesel, WWW domain nrel.

5,578,090 11, 1996 Bradin gov, 2002, pp. 1-33, National Renewable Energy Laboratory, Boul

5,697,986 12, 1997 Haas der, CO.

5,713.965 2, 1998 Foglia et al. Tyson, Biodiesel Technology and Feedstocks, WWW domain nrel.

5,847,239 12, 1998 Davey et al. gov, 2003, pp. 1-37, National Renewable Energy Laboratory, Boul

5,908,946 6, 1999 Stern et al. der, CO.

6,013,817 1, 2000 Stern et al. Clements, Pretreatment of High Free Fatty Acid Feedstocks,

6,015,440 1, 2000 Noureddini Biodiesel Production Technology Workshop III, Mar. 26-28, 2003,

6,075,158 6, 2000 Hill pp. 78c-78i, Iowa State University, Lincoln, Nebraska.

6,090,959 T/2000 Hirano et al. Muniyappaetal; Improved Conversion of Plant Oils and Animal Fats

6,127,561 10, 2000 Jeromin et al. Into Biodiesel and Co-Product; Jun. 1996; Elsevier Science Limited,

6,174.501 B1 1, 2001 Noureddini 0960-8524/96 (Abstract).

6,211,390 B1 4, 2001 Peter et al. Tyson, Biodiesel Research Progress 1992-1997; pp. 1-301; National

6,262.285 B1 7, 2001 McDonald Renewable Energy Laboratory; Boulder Co.; Feb. 1997.

6,288,251 B1 9, 2001 Tsuto et al. Gerpenetal; Biodiesel Production Technology Aug. 2002-Jan. 2004;

6,398,707 B1 6, 2002 Wu et al. pp. 1-106; Jul. 2004; National Renewable Energy Laboratory; Boul

6,399,800 B1 6, 2002 Haas et al. der Co.

6,440,057 B1 8, 2002 Ergun et al. Lago, R. C. A. R. R. Szpiz, F. H. Jablonka, D. A. Pereira and L.

6,489,496 B2 12, 2002 Barnhorst et al. Hartman: “Extraction and Transesterification of Vegetable Oils and

6,500,974 B2 12, 2002 Thengumpillil et al. Ethanol': 1985; pp. 147-154; vol. 40, No. 3; Oleagineux; Paris,

6,642.399 B2 11/2003 Boocock France.

6,822, 105 11, 2004 Luxem et al. ............... 554,167 Ma, Fangrui and Milford A. Hanna; “Biodiesel Production: a

6,965,043 11/2005 Kenneally et al. ........... 554,167 review”; 1999: pp. 1-15; vol. 70, No. 1; Bioresource Technology;

7,087,771 8, 2006 Luxem et al. ... 554f157 Elsevier, GB.

2002/011 1504 8, 2002 Peter et al. .................. 554,185

2002.01563.05 A1 10, 2002 Turck * cited by examiner

US 7,806,945 B2

1. 2

PRODUCTION OF BIODIESEL AND 4,164,506, the conversion of triglycerides with base catalysis

GLYCERIN FROM HIGH FREE FATTY ACID such as the processes described in U.S. Pat. Nos. 2.383,601

FEEDSTOCKS and 2.494,366, or conversion of both free fatty acids and

triglycerides with enzyme catalysis such as the processes

CROSS-REFERENCE TO RELATED described in U.S. Pat. Nos. 4,956,286, 5,697.986 and 5,713,

APPLICATIONS 965.

The main problem with background art processes for

This application claims the benefit of U.S. Provisional biodiesel production is that none of them completely

Application Nos. 60/443,049, filed Jan. 27, 2003, and 60/537, addresses the production of biodiesel from low value high

251, filed Jan. 15, 2004, the disclosures of which applications 10 free fatty acid feedstocks. An economic analysis of any pro

are incorporated by reference as if fully set forth herein. cess for the production of biodiesel will indicate that feed

stock cost is the largest portion of the production cost for

STATEMENT REGARDING FEDERALLY biodiesel. A 15 percent free fatty acid (FFA) feedstock is the

SPONSORED RESEARCHOR DEVELOPMENT highest content that any contemporary commercial process

15 proposes to handle; whereas, the actual feedstocks many pro

Not Applicable ducers will likely use (because of cost) will have up to 100

percent FFA content. Conventional acid catalyzed esterifica

BACKGROUND OF THE INVENTION tion of fatty acids is ill equipped to handle such a high FFA

COntent.

The present invention relates generally to a process and Acid catalyzed esterification of fatty acids is not suitable

system for biodiesel production and more specifically to the for processing such high FFA concentrations. The amount of

conversion of any high free fatty acid feedstocks to fatty acid acid catalyst required to achieve high conversion rates in the

methyl esters through both esterification and transesterifica esterification process increases with FFA concentration. This

tion reactions. The process and system economically produce acid catalyst charge must be neutralized before processing the

biodiesel when compared to current technologies. 25 glycerides, and as the catalyst loading increases, the Salt

The background art is characterized by U.S. Pat. Nos. generated becomes excessive. These processes also generate

1659,790: 2,290,609; 2,383,596: 2,383,599; 2,383,601; a large volume of waste water as revealed by the disclosures

2.494,366: 2,808,421; 2,875,221; 3,102,129: 3.459,736; of U.S. Pat. Nos. 4,303,590, 5,399,731 and 6,399,800. Alter

4,164,506; 4,267,393; 4,303,590; 4,364,743; 4,371.470; natively, solid acid catalysts can be used for the fatty acid

4,668.439; 4,695,411; 4,698, 186; 4,839,287: 4,956,286: 30 esterification reaction to avoid a neutralization step before the

5,399,731; 5,424,467; 5.434.279; 5,514,820; 5,525,126; transesterification reaction. These processes have been exten

5,697,986; 5,713,965; 5,908,946; 6,013,817; 6,015,440; sively explored and documented, such as in U.S. Pat. No.

6,090,959; 6,127,561; 6,174.501; 6,211,390; 6,262,285: 3.459,736 which uses titanium oxide as a catalyst, U.S. Pat.

6,288,251; 6,398,707; 6,399,800; 6,440,057; 6,489,496; No. 4,698,186 which utilizes various solid acids as catalysts,

6,500,974 and 6,642,399 B2; and by U.S. Patent Application 35 U.S. Pat. No. 4,267,393 which uses sulfonated resins as solid

Nos. 2003/00229238 and 2003/0083514 the disclosures of acid catalysts and U.S. Pat. No. 5,908,946 which employs

which patents and patent applications are incorporated by zinc and aluminum oxide as catalysts for the esterification

reference as if fully set forth herein. reaction.

Fatty acid methyl esters (FAMEs) produced from fats and Enzymatic catalysis will readily esterify the free fatty

oils are being investigated in numerous settings as replace 40 acids, but this approach suffers reaction product inhibition

ments for petroleum-derived materials, particularly diesel from the presence of methyl esters when the fatty acids asso

fuel. There is continued and growing interest in the use of ciated with mono-, di-, and tri-glycerides in the feedstock are

renewable resources as replacements for petroleum-derived to be esterified with enzymes. Another problem with enzy

chemicals. It has long been known that diesel engines can use matic processing is the high cost of the catalyst. To avoid

the triglycerides from fats and oils as fuels. However, their use 45 two-phase operation in packed bed and other reaction set

eventually results in engine failure. The problems have been tings, some conventional processes for biodiesel production

examined and certain solutions have been proposed in the use high temperatures or volatile toxic co-solvents. Such a

methods described in U.S. Pat. Nos. 6,174.501 and 6,015. process has been investigated and claimed in U.S. Pat. No.

440. This problem is alleviated by conversion of the fatty 6,642,399 B2. Yet another problem with background art pro

acids found in lipids into their simple esters, usually methyl or 50 cesses for producing biodiesel is that water is used to wash

ethyl esters. Such a process is described in U.S. Pat. No. residual glycerin and salts from the FAMEs, generating a

6,398,707. An increasing body of evidence indicates that large volume of wastewater and potentially forming water

these esters perform well in essentially unmodified diesel and FAME emulsions as disclosed in U.S. Pat. No. 5,399,731.

engines and that they can reduce the output of particulate and Starrels in U.S. Pat. No. 1,659,790 discloses a method of

hydrocarbon pollutants relative to petroleum-diesel fuel. The 55 producing commercial stearic acid. This invention is limited

term “biodiesel' is applied to these esters, which are also in that only an esterification step is disclosed.

being explored as replacements for nonrenewable chemicals Goss et al. in U.S. Pat. No. 2.290,609 discloses a process

in other applications, including cleaning agents, fuel addi for producing fatty acid polyhydric esters. This invention is

tives, and substitutes for other organic solvents. Those appli limited in that esterification must be followed by fractionation

cations have been investigated in processes described in U.S. 60 in a solvent system.

Pat. No. 5,713,965. The invention disclosed herein can be Dreger in U.S. Pat. No. 2,383,596 discloses a method for

applied to the production of FAMEs for these applications as treating fatty acid glycerides. This invention is limited in that

well. only an esterification step is disclosed.

It can be appreciated that processes for biodiesel produc Glossop in U.S. Pat. No. 2,383,599 discloses a method for

tion have been in use for years. Typically, a process for biodie 65 treating fatty glycerides. This invention is limited in that free

sel synthesis is comprised of the conversion offatty acids with fatty acids must be separated from the fatty glycerides prior to

acid catalysis such as a process described in U.S. Pat. No. alcoholysis.

US 7,806,945 B2

3 4

Brokaw in U.S. Pat. No. 2,808,421 discloses a method for methyl ester reaction product. This invention is limited in that

preparing mixed triglyceride compositions. This invention is the starting material must be a triglyceride. Moreover, the

limited in that a titanium alcoholate catalyst is required. process is limited to mixing the alcohol and catalyst prior to

Birnbaum in U.S. Pat. No. 2,875,221 discloses a process feeding them to the transesterification operation.

for preparing monoglycerides offatty acids. This invention is 5 Ergun et al. in U.S. Pat. No. 6,440,057 disclose a method

limited in that it requires admixing a substantial proportion of for producing fatty acid methyl ester. This invention is limited

previously reacted monoglyceride product with a freshly in that crack emulsification of the contents of the transesteri

mixed stream of glycerol and fat and rapidly heating the fication reactor is required.

mixture on a hot Surface. Thengumpilliletal. in U.S. Pat. No. 6,500,974 B2 disclose

Birnbaum in U.S. Pat. No. 3,102,129 discloses a process 10 a process for preparation of a monoglyceride. This invention

for producing monoglycerides offatty acids. This invention is is limited in that the presence of a food grade polar solvent is

limited in that monoglycerides are produced, not methyl required in the glycerolysis reactor.

esterS. Boocock in U.S. Patent Application No. 2003/0083514A1

Erner in U.S. Pat. No. 4.364,743 discloses a synthetic discloses a single-phase process for production of fatty acid

liquid fuel and fuel mixtures. This invention is limited in that 15 methyl esters from mixtures of triglycerides and fatty acids.

a process for the production and purification of alkyl esters of This invention is limited in that it requires acid catalyzed

fatty acids is not disclosed. esterification offatty acids prior to the transesterification step.

Matsukura et al. in U.S. Pat. No. 4,371,470 disclose a Fleisher in U.S. Patent Application No. 2003/0229238A1

method for manufacturing high quality fatty acid esters. This discloses a continuous transesterification process. This inven

invention is limited in that a method for processing high free tion is limited in that use of a plug-flow reactor is required for

fatty acid feedstocks is not disclosed. the transesterification reaction.

Billenstein et al. in U.S. Pat. No. 4,668,439 disclose a The background art is also characterized by a number of

process for the preparation of fatty acid esters of short-chain non-patent publications. The limitations of the processes dis

alcohols. This invention is limited in that a process for use on closed by these publications are described below.

high free fatty acid feedstocks is not disclosed. 25 Noureddini et al. in Glycerolysis of Fats and Methyl Esters,

Sternet al. in U.S. Pat. No. 4,695,411 disclose a process for JAOCS, 1997, pp. 419–425, vol. 74, no. 4, AOCS Press, Lin

manufacturing a fatty acid ester composition. This invention coln, Nebr., discloses the glycerolysis of methyl esters and

is limited in that an acid transesterification step must be triglycerides with crude glycerin (glycerin). Glycerolysis of

followed by a basic transesterification step. free fatty acids is not disclosed.

Holmberg et al. in U.S. Pat. No. 4,839.287 disclose a pro 30 Tyson in Brown Grease Feedstocks for Biodiesel, WWW

cess for transesterification of triglycerides. This invention is domain nrel.gov, 2002, pp. 1-33, National Renewable Energy

limited in that the presence of a lipase enzyme is required. Laboratory, Boulder, Colo., discloses techniques for convert

Bametal. in U.S. Pat. No. 5,424,467 disclose a method for ing greases to biodiesel. The techniques disclosed in this

purifying alcohol esters. This invention is limited in that the reference are limited in that washing of crude biodiesel with

starting material must be a triglyceride. Moreover, while 35 mildly acidic water is required. Moreover, the conditions

glycerin is recycled in the process, it is recycled downstream taught for glycerolysis of free fatty acids (temperature in the

of the transesterification reactor. range of 250° C. to 260°C. in the absence of a catalyst or 220

Assmann et al. in U.S. Pat. No. 5,514,820 disclose a con C. with a catalyst) would cause degradation of a major

tinuous process for the production of lower alkyl esters. This amount of the feedstock and loss of yield. The reference

invention is limited in that the transesterification process must 40 teaches that there is “no proven technology for 50+% FFA

be carried out in at least two stages in a tube reactor. More mixes” and that “combined processes for ASTM quality

over, the reference teaches that “it is particularly important to biodiesel not well developed, technical and economic ques

the transesterification reaction that no glycerol (reaction tions exist.”

product) come into contact with starting oil (col. 3, lines Tyson in Biodiesel Technology and Feedstocks, WWW

4-7). 45 domain nrel.gov, 2003, pp. 1-37, National Renewable Energy

Wimmer in U.S. Pat. No. 5,434.279 discloses a process for Laboratory, Boulder, Colo., includes much of the same infor

preparing fatty acid esters of short-chain monohydric alco mation as contained in her 2002 presentation. The reference

hols. This invention is limited in that glycerin produced by the notes that using “glycerolysis to treat FFA to “convert FFA

transesterification process and previously separated off is to monoglycerides, then transesterify is "commercial, not

added back to produced fatty acid ester. 50 currently used in biodiesel.”

Basu et al. in U.S. Pat. No. 5,525,126 disclose a process for Davis Clements in Pretreatment of High Free Fatty Acid

the production of esters for use as a diesel fuel substitute. This Feedstocks, Biodiesel Production Technology Workshop III,

invention is limited in that a catalyst comprising calcium Mar. 26-28, 2003, pp. 78c-78i, Iowa State University, Lin

acetate and barium acetate is required. coln, Nebr. discloses a number of methods for pretreatment of

Sternet al. in U.S. Pat. No. 6,013,817 disclose a process for 55 high free fatty acid feedstocks prior to transesterification.

the production of ethyl esters. This invention is limited in that This invention is limited in that glycerolysis is carried out at

a process for the production of ethyl esters of fatty acids is 200° C. under an 11 pounds per square inch vacuum, usually

disclosed. Moreover, this process uses water as an extractant with a catalyst Such as Zinc chloride, with venting of water.

for purification of the esters. This invention is limited in that in the absence of a catalyst, a

Jeromin et al. in U.S. Pat. No. 6,127.561 discloses a pro 60 residence time of over 5 hours is required to achieve an

cess for the production of monoglycerides. This invention is effluent containing less than 1 percent free fatty acids.

limited in that methyl esters are subjected to glycerolysis. In Summary, the applicants are aware of no reports of using

Peter et al. in U.S. Pat. No. 6,211,390 disclose a method for inexpensive feedstocks and effective technologies to produce

producing fatty acid esters. This invention is limited in that fatty acid esters (biodiesel) economically and without envi

use of a near-critical extractant is required. 65 ronmental concerns. The current processes have the follow

McDonald in U.S. Pat. No. 6,262.285 B1 discloses a pro ing drawbacks, which have been addressed in the process

cess for dry synthesis and continuous separation of fatty acid disclosed herein:

US 7,806,945 B2

5 6

1. High temperatures and pressures, catalyst for rapid salt-free conversion of FFA to glycerides,

2. Acid catalyzed esterification offatty acids present in the and the rapid conversion of glycerides to methyl esters by

starting material, caustic methoxide catalysis.

3. Use of toxic co-solvents, Another object of preferred embodiments of the invention

4. Long processing times, is the optimization of a process for the separation and purifi

5. Low quality glycerin production, and cation of the major by-product of biodiesel production, glyc

6. Using water to extract impurities from biodiesel. erin, to ensure it will be greater than 95 or 99.7 percent purity,

In these respects, the conversion of high free fatty acid with non-detectable levels of methanol and less than 0.5

feedstocks to biodiesel according to the present invention percent weight/weight (w/w) salts.

Substantially departs from the conventional concepts and 10 Another object of preferred embodiments of the invention

designs of the background art, and in so doing provides a is to recover the alkali catalyst and convert it to a marketable

process and apparatus primarily developed for the purpose of phosphorous and potassium fertilizer or potassium Sulfate

producing fatty acid methyl esters and high quality glycerol fertilizer. Another object of preferred embodiments of the

from any low-value high free fatty acid feedstock. present invention is the use of distillation rather than water

15 washing as a means to purify FAMEs.

BRIEF SUMMARY OF THE INVENTION Yet another object of preferred embodiments of the inven

tion is to minimize waste streams during normal operations,

The applicants have invented a novel process for the pro use lower operating temperatures and pressures than other

duction offatty acid methyl esters (FAMEs) and high quality commercial biodiesel processes, use no toxic co-solvents and

glycerin from high free fatty acid grease feedstocks. In accor produce a high quality glycerin byproduct.

dance with this development, it is an object of the invention to A further object of preferred embodiments of the invention

provide a method for the preparation of biodiesel by non is to enable production of biodiesel from low-value high free

catalytic glycerolysis and base catalyzed transesterification fatty acid feedstocks at a market price comparable to that of

using high free fatty acid waste grease as the feedstock. petroleum derived diesel fuels.

Through this novel combination of process steps, these low 25 Another object of preferred embodiments of the invention

grade lipid materials that previously could not be utilized by is to provide a process wherein the impure methanol recov

existing processes are easily converted to biodiesel by means ered from the process is purified such that water is removed.

of the invention disclosed herein. Preferably, this purification comprises adsorption onto

In a preferred embodiment, the process disclosed herein molecular sieves that can then be dried and reused or distill

converts high Free Fatty Acid (FFA) feedstock into biodiesel. 30 lation resulting in a bottoms product consisting mainly of

The disclosed process is an efficient, cost-effective method Water.

for the conversion of animal fats and recycled vegetable oils In a preferred embodiment, the invention is a process for

into biodiesel fuel. Moreover, the disclosed process is a low the production of biodiesel from a lipid feedstock comprising

cost method to synthesize biodiesel from animal fats and a plurality of free fatty acids, said process comprising: intro

yellow greases. These feedstocks are very complex and dif 35 ducing the lipid feedstock to a conditioning vessel; condition

ficult to economically process because of their high FFA ing the lipid feedstock in the conditioning vessel, wherein the

levels (ranging from a few percent to 50 percent, and higher), lipid feedstock is heated to a temperature in the range of about

and because they contain unprocessable material and con 55° C. to about 65° C., mixed by an agitator with a power

taminates that must be removed prior to processing, or during input per unit volume of about 0.5 watts per gallon (W/gal) to

refinement of the products. To be economically profitable, the 40 about 1.5 W/gal and filtered using a rotary screen to remove

biodiesel industry must take advantage of lower cost feed solids having a dimension over about 1 micron to about 200

stocks. Yield is a very important criterion as feedstock costs microns to produce a conditioned lipid feedstock; reacting the

approach two thirds of the total cost of production of biodie plurality of free fatty acids in the conditioned lipid feedstock

sel. To gain market share in the fuels industry, biodiesel must with a purified glycerin product in a glycerolysis reactor,

be competitively priced with conventional hydrocarbon die 45 wherein the plurality of free fatty acids in the feedstock is

sel. To accomplish this pricing objective and provide glycerin mixed with the purified glycerin product by an agitator with a

for the glycerolysis reaction, glycerin is economically pro power input per unit volume of about 5.5 W/gal to about 60

duced in preferred embodiments of the disclosed process. In W/gal and continuously reacted with the purified glycerin

preferred embodiments, the process described in this disclo product in the absence of a catalyst at a temperature of about

Sure has been developed to accommodate these features. 50 180° C. to about 250° C. and at a pressure of about 0.1 pounds

In a preferred embodiment, the invention disclosed herein per square inch absolute to about 7 pounds per square inch

combines several unit operations into an economical and absolute in a glycerolysis reaction to produce a glycerolysis

unique process for the conversion of free fatty acids to glyc reactor effluent stream that contains less than 0.5 percent by

erides and the Subsequent conversion of glycerides to glyc weight of free fatty acids and a plurality of glycerides, the

erin and FAMEs. Another object of preferred embodiments of 55 purified glycerin product being continuously added to the

the present invention is to provide a biodiesel and glycerin glycerolysis reactorata rate in the range of about 110 percent

production process using high free fatty acid feedstocks that to about 400 percent of the stoichiometric amount of glycerin

overcomes the shortcomings of the background art processes. required for the glycerolysis reaction, water being continu

A preferred aspect of preferred embodiments of the dis ously removed from the glycerolysis reactor as a vapor

closed process is the use of glycerin as a reactant to convert 60 through a fractionation column that returns condensed glyc

the free fatty acid in the feedstock to glycerides (mono-, di-, erinto the glycerolysis reactor, said glycerolysis reactor.com

and tri-) through glycerolysis and then transesterifying the prising at least two continuous stirred tank reactors that are

glycerides into fatty acid alkyl esters and glycerin with a operated in series; said reactors having a combined residence

lower alcohol with 1-5 carbons, in the preferred embodiment, time of not more than about 500 minutes; reacting the plural

methanol, through an alkali catalyzed process. 65 ity of glycerides contained in the glycerolysis effluent stream

Another object of preferred embodiments of the invention with a purified methanol product comprising methanol in a

is the optimization of the process, which uses no co-solventor transesterification reactor, wherein the plurality of glycerides

US 7,806,945 B2

7 8

are mixed with said purified methanol product and potassium temperature and pressure in a glycerolysis reaction to pro

hydroxide by an agitator with a power input per unit volume duce a glycerolysis reactor effluent stream that contains a

of about 3.0 W/gal to about 50 W/gal and continuously glyceride, the purified glycerin product being continuously

reacted with the methanol at a temperature in the range of added to the glycerolysis reactor at a rate that is greater than

about 25°C. to about 65° C. and at a pressure of about 1 bar 5 the Stoichiometric amount of glycerin required for the glyc

in an alkali catalyzed reaction to produce a transesterification erolysis reaction, water being continuously removed from the

reactor effluent stream that contains a plurality of fatty acid glycerolysis reactor as a vapor, reacting the glyceride con

methyl esters and glycerin, the purified methanol product tained in the glycerolysis effluent stream with a purified alco

being added to the transesterification reactorata rate equal to hol product comprising an alcohol in a transesterification

about 200 percent of the stoichiometric amount of methanol 10 reactor, wherein the glyceride is mixed with said purified

required for the catalyzed reaction, the potassium hydroxide alcohol product and continuously reacted with the alcohol at

being added to the transesterification reactor at a rate of about an appropriate temperature and pressure in analkalicatalyzed

0.5 percent by weight to 2.0 percent by weight of glycerides transesterification reaction to produce a transesterification

present in the glycerolysis effluent stream, said transesterifi reactor effluent stream that contains a fatty acid alkyl ester

cation reactor comprising at least two continuous stirred tank 15 and glycerin, the purified alcohol product being added to the

reactors that are operated in series, said reactors having a transesterification reactor at a rate that is greater than the

combined residence time of about 15 minutes to about 90 Stoichiometric amount of alcohol required for the alkali cata

minutes; separating the plurality of fatty acid methyl esters lyzed transesterification reaction; separating the plurality of

from the glycerin in the transesterification effluent stream in fatty acid alkyl esters from the glycerin in the transesterifica

continuous clarifier, wherein a first liquid phase in which the tion effluent stream in a continuous operation, wherein a first

plurality of fatty acid methyl esters are concentrated and a liquid phase in which the plurality of fatty acid methyl esters

second liquid phase in which glycerin is concentrated are are concentrated and a second liquid phase in which glycerin

continuously separated at a temperature of about 25°C. to is concentrated are continuously separated to produce a fatty

about 65° C. to produce a fatty acid methyl ester rich stream acid methyl ester rich stream and a glycerin rich stream;

and a glycerin rich stream; purifying the fatty acid methyl 25 purifying the fatty acid alkyl ester rich stream in a fatty acid

ester rich stream in a distillation column and recovering alkyl ester distillation column or a fatty acid alkyl ester frac

methanol from it to produce a purified biodiesel product and tionation column and recovering the alcohol from it to pro

a wet methanol stream, wherein the distillation column is duce a purified biodiesel product and a first wet alcohol

operated at a temperature in the range of about 180° C. to stream; purifying the glycerin rich stream and recovering the

about 230° C. and at a pressure in the range of about 0.1 30 alcohol from it to produce the purified glycerin product and a

pounds per square inch absolute to about 2 pounds per square second wet alcohol stream, wherein the alkali in the glycerin

inch absolute; purifying the glycerin rich stream and recov rich stream is reacted with an acid to produce an insoluble salt

ering methanol from it to produce the purified glycerin prod that is removed from the glycerin rich stream and thereafter

uct and a wet methanol stream, wherein the potassium filtered and rinsed with the alcohol, the pH of the glycerinrich

hydroxide in the glycerinrich stream is reacted with a mineral 35 stream being adjusted to neutral and the glycerin rich stream

acid to produce an insoluble salt having fertilizer value that is being further purified in a glycerin distillation column or a

removed from the glycerin rich stream in a solids separation glycerin fractionation column and in a decolorization col

operation and thereafter filtered and rinsed with methanol, the umn; and purifying the wet alcohol streams by removing

pH of the glycerin rich stream being adjusted to neutral by excess water to produce a purified alcohol product, wherein

adding an alkali solution and then further purified in a glyc 40 the wet alcohol streams are purified in an alcohol distillation

erin distillation column that is operated at a temperature in the column or an alcohol fractionation column. Preferably, the

range of about 180°C. to about 230°C. and at a pressure in the process further comprises: recycling at least a portion of the

range of about 0.1 pounds per square inch absolute to about 2 purified glycerin product into the glycerolysis reactor for

pounds per square inch absolute and in a decolorization col reaction with the free fatty acid. Preferably, the process fur

umn comprising a packed bed of activated carbon operated at 45 ther comprises: recycling at least a portion of the purified

a temperature in the range of about 40°C. to about 200°C.; alcohol product into the transesterification reactor for reac

purifying the wet methanol stream by removing water from it tion with the glyceride.

to produce a purified methanol product, wherein the wet In yet another preferred embodiment, the invention is a

methanol stream is purified in a methanol distillation column process for the production of biodiesel from a lipid feedstock

that is operated at a temperature in the range of about 60° C. 50 comprising a free fatty acid, said process comprising: a step

to about 110° C. and at a pressure in the range of about 14 for continuously conditioning the lipid feedstock to produce

pounds per square inch absolute to about 20 pounds per a conditioned lipid feedstock; a step for continuously mea

square inch absolute; recycling at least a portion of the puri Suring the concentration of the free fatty acid in the condi

fied glycerin product into the glycerolysis reactor for reaction tioned lipid feedstock by means of an in-line free fatty acid

with the plurality of free fatty acids; and recycling at least a 55 titration device that produces a signal; a step for continuously

portion of the purified methanol product into the transesteri reacting the free fatty acid in the conditioned lipid feedstock

fication reactor for reaction with the plurality of glycerides. in a glycerolysis reaction, wherein the free fatty acid in the

In another preferred embodiment, the invention is a process feedstock is reacted with glycerin to produce a glyceride in

for the production of biodiesel from a lipid feedstock com response to the signal from the in-line free fatty acid titration

prising a free fatty acid, said process comprising: condition 60 device; a step for continuously reacting the glyceride in a

ing the lipid feedstock in a conditioning reactor, wherein the transesterification reaction, wherein the glyceride is con

lipid feedstock is heated, mixed and filtered to produce a Verted to a fatty acid methyl ester and glycerin via an alkali

conditioned lipid feedstock; reacting the free fatty acid in the catalyzed reaction; a step for continuously separating the

conditioned lipid feedstock with a purified glycerin product fatty acid methyl ester from the glycerin to produce a fatty

in a glycerolysis reactor, wherein the free fatty acid in the 65 acid methyl ester rich stream and a glycerinrich stream; a step

feedstock is mixed and continuously reacted with the purified for continuously purifying the fatty acid methyl ester rich

glycerin product in the absence of a catalyst at an appropriate stream and recovering the methanol from the fatty acid

US 7,806,945 B2

10

methyl ester rich stream to produce a purified biodiesel prod acid step further comprises: performing the glycerolysis reac

uct and a first wet methanol stream; a step for continuously tion at a temperature in the range of about 150° C. to about

purifying the glycerin rich stream and recovering the metha 250° C.; and removing water from the glycerolysis reactor.

nol from the glycerin rich stream to produce a purified glyc Preferably, the water is removed as vapor through a fraction

erin product and a second wet methanol stream; a step for ation column or a distillation column that returns condensed

continuously purifying the wet methanol streams to produce glycerin to the glycerolysis reactor.

a purified methanol product; and a step for recycling at least In a preferred embodiment, the reacting the glyceride step

a portion of the purified glycerin product into the glycerolysis further comprises: contacting the glyceride with an effective

reactor for reaction with the free fatty acid. Preferably, the amount of methanol and an effective amount of alkali catalyst

process further comprises: a step for recycling at least a 10 under conditions wherein the glyceride, the effective amount

portion of the purified methanol product into the transesteri of methanol and the effective amount of alkali catalyst come

fication reactor for reaction with the glyceride. into substantially intimate contact; and wherein the effective

In a further preferred embodiment, the invention is a pro amount of the alkali catalyst is selected from the group con

cess for the production of biodiesel from a lipid feedstock sisting of an effective amount of Sodium hydroxide, and an

comprising a free fatty acid, said process comprising: intro 15 effective amount of potassium hydroxide. Preferably the

ducing a lipid feedstock to a conditioning reactor, condition reacting the glyceride step further comprises: performing the

ing the lipid feedstock, wherein the lipid feedstock is heated, transesterification reaction at a temperature in the range of

mixed and filtered to produce a conditioned lipid feedstock; about 20° C. to about 250° C. More preferably, the reacting

reacting the free fatty acid in the conditioned lipid feedstock the glyceride step further comprises: performing the transes

in a glycerolysis reactor, wherein the free fatty acid in the terification reactionata temperature in the range of about 55°

feedstock is continuously reacted with a stoichiometric C. to about 65° C. Preferably, the reacting the glyceride step

excess of glycerin to produce a glyceride via a glycerolysis further comprises: performing the transesterification reaction

reaction; reacting the glyceride in a transesterification reac at an absolute pressure in the range of about 1 bar to about 250

tor, wherein the glyceride is continuously converted to a fatty bar. More preferably, the reacting the glyceride step further

acid methyl ester and glycerin via an alkali catalyzed trans 25 comprises: performing the transesterification reaction at an

esterification reaction; separating the fatty acid methyl ester absolute pressure of about 1 bar. Preferably, a low frequency

from the glycerin, wherein a first liquid phase in which the acoustic transducer is used to mix the glyceride, the effective

fatty acid methyl ester is concentrated and a second liquid amount of methanol and the effective amount of alkali cata

phase in which glycerin is concentrated are continuously lyst.

separated to produce a fatty acid methyl ester rich stream and 30 In a preferred embodiment, the separating the fatty acid

a glycerin rich stream; purifying the fatty acid methyl ester methyl ester from the glycerin step involves using the density

rich stream and recovering the methanol from the fatty acid difference between the first liquid phase and the second liquid

methyl ester rich stream to produce a purified biodiesel prod phase to separate them in a continuous operation. Preferably,

uct and a first wet methanol stream; purifying the glycerin the purifying the fatty acid methyl ester rich stream step

rich stream and recovering the methanol from the glycerin 35 further comprises: using a fatty acid methyl ester distillation

rich stream to produce a purified glycerin product and a column or a fractionation column to separate the fatty acid

second wet methanol stream; purifying the wet methanol methyl ester rich stream into a bottoms fraction, an overhead

streams by removing water from them to produce a purified fraction comprising primarily methanol, and a side stream

methanol product; recycling at least a portion of the purified fraction comprising a fatty acid methyl ester product. Prefer

glycerin product into the glycerolysis reactor for reaction 40 ably the bottoms fraction produced by the fatty acid methyl

with the free fatty acid; and recycling at least a portion of the ester distillation column or fractionation column comprises

purified methanol product into the transesterification reactor impurities, and unsaponafiable materials, unreacted

for reaction with the glyceride. Preferably, the introducing the monoglycerides, unreacted diglycerides, unreacted triglycer

lipid feedstock step further comprises: introducing a feed ides and fatty acids. Preferably, the fatty acid methyl ester

stock that includes at least one free fatty acid at a concentra 45 product produced by the fatty acid methyl ester distillation

tion in the range of about 3 percent to about 97 percent by column meets ASTM specification D 6751-02. Preferably,

weight; moisture, impurities and unsaponafiable matter at a the overhead fraction produced by the fatty acid methyl ester

concentration up to about 5 percent by weight; and a remain distillation column or fractionation column comprises essen

der that includes monoglycerides, diglycerides and/or trig tially methanol. Preferably, the fatty acid methyl ester distil

lycerides. 50 lation column or fractionation column is operated at a pres

In a preferred embodiment, the conditioning the lipid feed sure below about 2 pounds per square inch absolute. More

stock step produces a conditioned feedstock that is a Substan preferably, the fatty acid methyl ester distillation column or

tially uniform mixture of liquid lipids having a temperature in fractionation column is operated at a pressure in the range of

the range of about 35° C. to about 250° C. More preferably, about 0.1 pounds per square inch absolute to about 2 pounds

the conditioning the lipid feedstock step produces a condi 55 per square inch absolute. Preferably, the fatty acid methyl

tioned feedstock having a temperature in the range of about ester distillation column or fractionation column is operated

45° C. to about 65° C. Preferably, the conditioning the lipid at a temperature in the range of about 180°C. to about 280°C.

feedstock step produces a conditioned feedstock that is a More preferably, the fatty acid methyl ester distillation col

substantially free of insoluble solids. umn or fractionation column is operated at a temperature in

In another preferred embodiment, the reacting the free fatty 60 the range of about 180° C. to about 230° C. Preferably, the

acid step further comprises: combining the free fatty acid with fatty acid methyl ester distillation column or fractionation

an effective amount of glycerin for an effective amount of column contains a packing material.

time to facilitate the glycerolysis reaction under conditions In a preferred embodiment, the purifying the glycerin rich

wherein the free fatty acid and the glycerin come into sub stream and recovering methanol step further comprises: per

stantially intimate contact. Preferably, a low frequency acous 65 forming glycerin fractionation, wherein the fractions within

tic transducer is used to mix the free fatty acid and the effec the glycerin rich stream are separated by distillation; per

tive amount of glycerin. Preferably, the reacting the free fatty forming phase separation, wherein the impurities that co

US 7,806,945 B2

11 12

fractionate with glycerin are removed by immiscibility and In another preferred embodiment, the invention is a process

differences in density; and glycerin polishing, wherein other for production of biodiesel and glycerin comprising: input

impurities are removed from glycerin. Preferably, the purify ting to a glycerolysis reactor an effective amount of glycerin

ing the glycerin rich stream and recovering methanol step and a feedstock comprising 3 to 100 percent free fatty acids

further comprises: performing alkali catalyst precipitation, and, optionally, a fat and/oran oil; reacting in the glycerolysis

wherein the glycerinrich stream is reacted with a mineral acid reactor the glycerin and at least a portion of the feedstock in

suitable to forman insoluble salt with the alkali catalyst used an esterification reaction, with removal of water, to continu

in the transesterification reaction, wherein the mineral acid is ously produce a first intermediate product comprising glyc

selected from the group consisting of sulfuric acid, and phos erides (including monoglycerides, diglycerides and/or trig

phoric acid; performing solids separation, wherein the 10 lycerides) and essentially no water; performing in a

insoluble salt is removed from the liquid permeate; perform transesterification reactor continuous base-catalyzed transes

ing phase separation, wherein a fatty acid methyl ester rich terification of the intermediate product to produce a second

liquid phase and a glycerin rich liquid phase are separated; intermediate product comprising fatty acid methyl esters and

performing pH adjustment, wherein the pH of the glycerin glycerin; continuously treating the second intermediate prod

rich stream is adjusted by adding an alkali solution; perform 15 uct to separate the fatty acid methyl esters from the glycerinto

ing glycerinfractionation, wherein the glycerinrich stream is produce a fatty acid methyl ester rich stream and a glycerin

purified by means of a glycerin distillation column and rich stream; continuously purifying the fatty acid methyl ester

methanol is collected for further purification and reuse in the rich stream and recovering methanol from it to produce a

process; and performing glycerin polishing, wherein colored purified biodiesel product and a first wet methanol stream;

impurities are removed from the glycerin. Preferably the per continuously purifying the glycerin rich stream to produce a

forming glycerin phase pH adjustment step is performed purified glycerin product and a second wet methanol stream;

using ion exchange media. Preferably, the insoluble salt is continuously purifying the wet methanol streams to produce

separated using a rotary vacuum drum filter, a plate and frame a purified methanol product; and recycling at least a portion of

press or a belt press. Preferably, the alkalicatalyst and mineral the purified glycerin product into the glycerolysis reactor for

acid used for alkali catalyst precipitation are chosen so that 25 reaction with the free fatty acids; and recycling at least a

their reaction will produce a byproduct salt having fertilizer portion of the purified methanol product into the transesteri

value; said byproduct salts are washed free of organic mate fication reactor for reaction with the glycerides. Preferably,

rials with a solvent to produce a purified salt and the purified the feedstock comprises an animal fat and/or a vegetable oil.

salt is then dried and the solvent is recovered for reuse in the Preferably, the effective amount of glycerin is about two

process. Preferably, the insoluble salt is washed free of 30 times the stoichiometric amount of fatty acids in the feed

organic impurities with a solvent prior to the performing stock. Preferably, the reacting step is carried out at a tempera

solids separation step or during the performing solids sepa ture in the range of about 200° C. to about 250° C., under

ration step using filtration equipment. Preferably, the process agitation and to the extent that the first intermediate product

further comprises drying the insoluble salt in a drier under contains no more than 0.5 percent w/w of free fatty acids.

conditions wherein temperature of the drier exceeds the boil 35 Preferably, the performing step comprises adding potassium

ing point of the solvent at the operating pressure of the dryer, methoxide to the intermediate product to facilitate base

the dryer is optionally operated under a vacuum to improve catalysis and wherein the performing step is carried out at a

the drying; and the drier includes a condenser to recover the temperature in the range of about 40°C. to about 60° C.

solvent for reuse. Preferably, the solvent is methanol. Prefer In yet another preferred embodiment, the invention is a

ably, the insoluble salt is further processed for use as a fertil 40 system for the production of biodiesel from a lipid feedstock

izer by dissolving it in water. comprising a plurality of free fatty acids, said system com

In a preferred embodiment, the performing glycerin frac prising: means for introducing the lipid feedstock to a condi

tionation step further comprises: distilling the neutralized tioning reactor; means for conditioning the lipid feedstock in

crude glycerin stream to produce a bottoms material, a side the conditioning reactor, said means for conditioning com

stream and an overhead stream. Preferably, the bottoms mate 45 prising means for heating the lipid feedstock, an acoustic

rial contains essentially waste materials; the side stream con transducer or an impellor system (or mixing the lipid feed

tains essentially glycerin and trace impurities; and the over stock), and means for filtering the lipid feedstock comprising

head stream contains essentially water and methanol that is a traveling screen, said means for conditioning being opera

recovered and recycled. Preferably, the glycerin distillation tive to produce a conditioned lipid feedstock; means for mea

column is operated under a reduced pressure of below about 50 Suring the concentration of free fatty acids in the conditioned

2 pounds per square inch absolute. More preferably, the glyc lipid feedstock; first means for reacting the plurality of free

erin distillation column contains packing material and is fatty acids in the conditioned lipid feedstock with a purified

operated under a reduced pressure of between about 0.1 and glycerin product in a glycerolysis reactor, said first means for

about 2 pounds per square inch absolute. Preferably, the glyc reacting comprising first means for mixing the plurality of

erin distillation column is operated at an elevated temperature 55 free fatty acids in the feedstock with the purified glycerin

between about 180° C. and about 280° C. More preferably, product, said first means for mixing comprising an acoustic

the glycerin distillation column contains packing material transducer oran impellor system, and means for continuously

and is operated at an elevated temperature between about reacting the plurality of fatty acids with the purified glycerin

180° C. and about 230°C. Preferably, the glycerin polishing product in the absence of a catalyst in a glycerolysis reaction,

step comprises contacting the glycerin with activated carbon 60 means for continuously adding the purified glycerin product

at a temperature that is between about 35° C. and 200° C. to the glycerolysis reactor, and means for removing water

Preferably, the glycerin polishing step comprises contacting continuously from the glycerolysis reactor as a vapor, said

the glycerin with a packed bed of activated carbon for a means for removing water comprising a fractionation column

contact time of less than four hours at a temperature that is that is operative to return condensed glycerin to the glycer

between about 40° C. and 100° C. and wherein activated 65 olysis reactor, said glycerolysis reactor comprising at least

carbon fines carried through the packed bed are removed by two continuous stirred tank reactors that are operated in

filtration through a hydrophilic filter material. series, said at least two continuous stirred tank reactors hav

US 7,806,945 B2

13 14

ing a combined residence time of about 200 minutes, said first glycerolysis reaction, means for continuously adding the

means for reacting being operative to produce a glycerolysis purified glycerin product to the glycerolysis reactor at a rate

reactor effluent stream; second means for reacting the plural that is greater than the Stoichiometric amount of glycerin

ity of glycerides contained in the glycerolysis effluent stream required for the glycerolysis reaction, and means for continu

with a purified methanol product in a transesterification reac ously removing water from the glycerolysis reactor as a

tor, said second means for reacting comprising second means vapor, said first means for reacting being operative to produce

for mixing the plurality of glycerides with said purified a glycerolysis reactor effluent stream that contains a glycer

methanol product and potassium hydroxide, said second ide; second means for reacting the glyceride contained in the

means for mixing comprising an acoustic transducer or an glycerolysis effluent stream with a purified alcohol product in

impellor system, means for continuously reacting the glycer 10 a transesterification reactor, said second means for reacting

ides with the methanol in an alkali catalyzed transesterifica comprising second means for mixing the glyceride with said

tion reaction, means for adding the purified methanol product purified alcohol product, means for continuously reacting the

to the transesterification reactor, means for adding the potas glyceride with the alcohol in an alkali catalyzed transesteri

sium hydroxide to the transesterification reactor, said trans fication reaction, means for adding the purified alcohol prod

esterification reactor comprising at least two continuous 15 uct to the transesterification reactor at a rate that is greater

stirred tank reactors that are operated in series, said reactors than the stoichiometric amount of alcohol required for the

having a combined residence time of about 60 minutes, said alkali catalyzed transesterification reaction, said second

second means for reacting being operative to produce a trans means for reacting being operative to produce a transesteri

esterification reactor effluent stream that contains a plurality fication reactor effluent stream that contains a fatty acid

offatty acid methyl esters and glycerin; means for separating methyl ester and glycerin; means for separating the plurality

the plurality of fatty acid methyl esters from the glycerin in of fatty acid methyl esters from the glycerin in the transes

the transesterification effluent stream, said means for separat terification effluent stream, said means for separating com

ing comprising means for concentrating a first liquid phase in prising a continuous operation, and said means for separating

which the plurality of fatty acid methyl esters are concen being operative to produce a first liquid phase in which the

trated and a second liquid phase in which glycerin is concen 25 plurality of fatty acid methyl esters are concentrated and a

trated, said means for concentrating comprising a continuous second liquid phase in which glycerin is concentrated to

clarifier, said means for separating being operative to produce produce a fatty acid methyl ester rich stream and a glycerin

a fatty acid methyl ester rich stream and a glycerin rich rich stream; first means for purifying the fatty acid methyl

stream; first means for purifying the fatty acid methyl ester ester rich stream comprising a fatty acid methyl ester distil

rich stream comprising a fatty acid methyl ester distillation 30 lation column or a fatty acid methyl ester fractionation col

column and means for recovering methanol from it to produce umn and first means for recovering alcohol from the fatty acid

a purified biodiesel product and a first wet methanol stream: methyl ester rich stream that are operative to produce a puri

second means for purifying the glycerin rich stream and fied biodiesel product and a first wet alcohol stream; second

recovering methanol from it to produce the purified glycerin means for purifying the glycerin rich stream and second

product and a second wet methanol stream, said second 35 means for recovering alcohol from the glycerin rich stream

means for purifying comprising means for reacting the potas that are operative to produce the purified glycerin product and

sium hydroxide in the glycerin rich stream with phosphoric a second wet alcohol stream, said second means for purifying

acid to produce an insoluble salt having fertilizer value, a comprising means for reacting the alkali in the glycerin rich

Solids separation operation for removing the insoluble salt stream with an acid to produce an insoluble salt, means for

from the glycerinrich stream, means for rinsing the insoluble 40 removing the insoluble salt from the glycerin rich stream,

salt with methanol and filtering the insoluble salt, means for means for filtering the insoluble salt and rinsing the insoluble

adjusting the pH of the glycerin rich stream to about neutral salt with the alcohol, means for adjusting the pH of the glyc

by adding an alkali solution and a glycerin distillation column erin rich stream to about neutral, a glycerin distillation col

for further purifying the glycerin rich stream and a decolori umn or a glycerin fractionation column, and a decolorization

Zation column comprising a packed bed of activated carbon 45 column; and third means for purifying the wet alcohol

column; third means for purifying the wet methanol streams streams by removing water that is operative to produce a

by removing water to produce a purified methanol product, purified alcohol product, said third means for purifying com

said third means for purifying comprising a methanol distil prising an alcohol distillation column or an alcohol fraction

lation column wherein the wet methanol streams are purified; ation column. Preferably, the system further comprises: first

first means for recycling at least a portion of the purified 50 means for recycling at least a portion of the purified glycerin

glycerin product into the glycerolysis reactor for reaction product into the glycerolysis reactor for reaction with the free

with the plurality of free fatty acids; and second means for fatty acid. Preferably, the system further comprises: second

recycling at least a portion of the purified methanol product means for recycling at least a portion of the purified alcohol

into the transesterification reactor for reaction with the plu product into the transesterification reactor for reaction with

rality of glycerides. 55 the glyceride. Preferably, the system further comprises means

In a further preferred embodiment, the invention is a sys for delivering at least a portion of the purified biodiesel prod

tem for the production of biodiesel from a lipid feedstock uct and at least a portion of the purified glycerin product to

comprising a free fatty acid, said system comprising: means their markets.

for conditioning the lipid feedstock in a conditioning reactor, In another preferred embodiment, the invention is a system

said means for conditioning being operative to heat, mix and 60 for the production of biodiesel from a lipid feedstock com

filter the lipid feedstock to produce a conditioned lipid feed prising a free fatty acid, said system comprising: means for