Professional Documents

Culture Documents

16-88 05 30 Alternator and Batteries

16-88 05 30 Alternator and Batteries

Uploaded by

p_janko100%(1)100% found this document useful (1 vote)

163 views44 pagesOriginal Title

16-88 05 30 ALTERNATOR AND BATTERIES

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

163 views44 pages16-88 05 30 Alternator and Batteries

16-88 05 30 Alternator and Batteries

Uploaded by

p_jankoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 44

ALTERNATOR AND BATTERIES

Function description

Charge balance ...

Sulphation . r

Cycling... 5

Battery charging inwinter

Batteries, general ......

Battery charging

Alternator, general :

Alternator amperage with exch. ratio 3.5:1

Calculation of alternator size...

Alternator design Paris-Rhone 35,55 and 75A

Charge testing on truck or in test cell

Output test

Regulated voltage test

Contents

2 Work description :

2 Dismantling Paris-RhOne 354/55)

2 Assembling Paris-Rhone 35A/SSA

3 Dismantling Paris-Rhone 754,

3 Assembling Paris-Rhone 758

4 Check measuring

5 brushes i

6 diode bridge 35, 554

7 diode bridges 75.

8 rotor :

9 stator

13 Specifications

13

B

© Saab-Scania AB Seana Yvon, service (834) 1988

14

16

20

25

29

33

33

34

37

40

4

42

Function description SCAN

service

Function description

Charge balance

Some trucks have very extensive electric equipment

that consumes a lot of power. It is important that

the alternator output is adapted to such

consumption. An alternator that is too small

shortens battery life and leads to starting problems

because of flat batteries.

Satisfactory charge balance

Analternator should manage the constant power

requirement and also provide a satisfactory charge

surplus (at least 10 A). Basically, the batteries are

Used for starting the engine

Poor charge balance

Poor charge balance implies that maximum.

consumption to an excessive degree is taken from

the batteries. As a consequence, battery life is

shortened and starting is made difficult because of

flat batteries.

There are, above all, two malfunctions that are

harmful to the batteriesi.e, sulphation and cycling.

Sulphation

if there is no time for the batteries to be recharged

between discharges there will be gradual

sulphation leading to capacity reduction. When this

takes place the metal in the plus and minus plates is

converted to PbSO,, i.e. lead sulphate. Thereby the

density of the acid is reduced. Lead sulphate is

formed as minute crystals. f such a discharged

battery is allowed to stand for some time, these

minute crystals grow together. This mainly applies

to the minus plate. Crystals that have grown

together are difficult to convert when charging

This is known as a sulphated battery. If the

sulphation has been allowed to carry on for some

time the lead sulphate can no longer be converted

when charging. The battery emits gas which means

that the current just divides the water content into

hydrogen and oxygen. If gas development takes

place at the beginning of charging a flat battery,

thisis a sign that the battery is sulphated

2 © Saab-Scania AB, Scania Diusion, Service (834) 1988, 16-88 05 30GT EN

SCANIA

service

Cycling:

Atevery discharge, even if followed by recharging,

some of the battery life is spent. A battery will only

withstand a limited number of cycles. Depending

on how the battery is made, a life of between 100-

200 cycles can be expected. If discharging and

recharging take place very frequently the lead will

separate from the plates which after some time

results ina capacity decrease and may cause short-

Circuit in one of the cells.

Cycling occurs when, for instance, using extra

heaters.

BATTERY CHARGING IN WINTER

Batteries are difficult to charge at low

temperatures. Furthermore, the useful capacity of

the battery is reduced. If, for instance, an extra

heater is used on the vehicle during the night and

the truck, furthermore, uses a lot of power in

loading operation during the day, there may be

battery problems because of the alternator not

having the ability to recharge the batteries before

next discharge. This has nothing to do with the

alternator or the battery size but just because of

batteries being difficult to charge in cold weather.

Itis no good to the battery to just carry half a

charge for long periods as this after some time

results in sulphating which in turn means that the

chargeability is heavily reduced. In some cases the

batteries have to be changed

140

120

100

80 Ah

ieee eee an

Charge diagram

16-88 05 30 GT EN

© Saab-Scania AB, Scania Division, Service (824) 1988

Function description

With a battery heater this problem is solved. The

batteries are heated to approx. 15°C. The charging

problem disappears.

Thanks to the insulation, the battery can be kept

warm. This makes it easier to start the vehicle. A

warm battery has approximately twice the capacity

of one that is cold

The following example illustrates how a battery is

affected by temperature and driving time

The vehicle has 160 Ah batteries. The batteries are

discharged at 80 Ah. The charge diagram illustrates

how much of the 80 Ah is recharged at various

temperatures during driving for 8 hours. As can be

seen, at-20°C the batteries only have time to

recover approx. 40 Ah, without battery heater.

With heater 80 Ah is recovered.

+ 20°C

100% charge

—

With battery heater

at -20°C 100 % charge

orc

85% charge

-20°C

75% charge

7 8 _ Driving time/hours

Function description SCANIA

BATTERIES, GENERAL

‘The trucks are equipped with two series connected

12V batteries.

Removal

= Loosen earth cable first

= Donot loosen battery cables with the engine

running. This is harmful to the alternator

Cleaning

= Clean batteries, cables and battery box. Oxide

and dirt may cause voltage drop.

- Lubricate poles with vaseline.

Mounting

- Always connect the plus cable first.

= Connect negative (-) to earth

= Tighten cable terminals

Acid level

~ Check that the acid level is correct, ie. level

with the upper part of the white plastic ring

(which is part of the cell fixture) visible in the

battery when plugs have been removed

Top up with destilled water.

Note. Sulphuric acid or so called electrolyte

improver must not be used

Charge condition

Check acid gravity with an acid tester. Ina fully

charged battery it should be

at +20°C 1.280

at orc 1.298

at =20°C 1.308

= Ifacid gravity is lower than 1.24 the battery

must be charged. A flat battery freezes at -5°C

= Avoid crash charging. This damages the battery

in the long run.

Note. If the charge differs between the batteries

they MUST be charged separately. (See charging of

batteries)

service

4 © Saab-Scania AB, Scania Oiision Service (834) 1988 16-88 05 30GTEN

SCANIA

service

‘START BOOST

Booth trucks must have 24 V electrics. Follow below

sequence to avoid battery explosion. Use thick

booster cables with at least 25 mm2.cross-cut area,

Connect + on flat batteries.

to + on charged batteries.

Connect ~ on charged batteries.

to the frame a distance away from the battery

on the truck with the flat batteries

Start engine on truck with charged batteries.

Start engine on the other truck. DO NOT STAND

NEAR THE BATTERIES.

7. First loosen cable from frame and thereafter

the other cables.

Beno

an

BATTERY CHARGING

Warning!

Explosive gas is formed when

charging battery (oxyhydrogen gas)

Important!

= The premises must be well ventilated.

= Nosmoking

= There must be no equipment that may cause

sparks in the vicinity.

When charging the cell voltage rapidly increases to

approx. 2.15 \V to slowly drop to 2.3-2.4V when gas,

starts to form. Towards end of charging the voltage

increases faster and reaches 2.5-2.7 V after which it

does not increase any more, even if the charging

continues. The charging period for different

batteries varies depending on size and charge

amperage

If distilled water is needed this should be added at

the beginning of charging. Otherwise, the water

remains uppermost in the cells and this can crack

the battery ifit freezes.

Long-term charging

Amperage must not exceed 10 % of the battery

capacity. Example: Maximum charge for a 160 Ah

battery is 16 A.

Batteries that have been slowly discharged

(sulphated) should be charged with maximum half

the amperage (see also "Sulphating").

16-88 05 30GT EN

Function description

Crash charging

Crash charging implies charging batteries over a

short period at a higher amperage tha normal.

Note. Crash charging reduces battery life and

should only be resorted to in emergency

Stop charging when gas starts to form.

Crash charging of old batteries may result in that

active lead loosens from the plates and drops to the

bottom. in adverse cases this can cause short-circuit

inacell.

Sulphated batteries must not be subjected to crash

charging (see "Sulphating”)

© Saab-Scania AB, Scania Devision, Service (834) 1988, 5

Function description

ALTERNATOR, GENERAL

For wiring, see booklet Circuit diagrams.

Connection point markings.

Paris-RhOne (Valeo): 35A,55Aand 75A

Bosch: 35A.and 554

B+ (+)

D+ (+A,61+)

B- (D-,M)

Ww AR)

Old markings in brackets

CHARGE WARNING LIGHT

The charge warning light is on when the alternator

isnot turning. It obtains power from the battery via

relay A and earth through alternator D + further

through a brush, through the rotor winding,

through the other brush and to earth via the charge

regulator. See circuit diagram

When the alternator is turning excitation voltage is

generated by the stator winding and the D +

connection is powered on whereby the light goes

out,

Trouble-shooting

A The warning light is on, system voltage too low

(engine running)

1. Drive belts off or poorly tensioned

2. Short-circuit between wire 61 and earth

3. Faulty charge regulator

4. Faulty alternator

B Warning light out, system voltage too high

(engine running)

1. Faulty charge regulator

C Warning light out, system voltage too low

(engine running)

1. Drive belts off or poorly tensioned

2. Faulty alternator

D Warning light does not come on with starter lock

in drive position (stopped engine)

1. Faulty warning light

2. Faulty charge regulator

3. Worn carbon brushes

4. Broken rotor winding

E Warning light flashes (engine running)

Drive belts off or poorly tensioned

2. Poor contact in wire 61 to warning light,

3. Faulty charge regulator

4. Faulty alternator

6 © Saab-Scania AB Scania Div.siun Service (834) 1988,

SCANA

service

VOLTMETER

Glance at the voltmeter at regular intervals when

driving. Ifit indicates too low or too high voltage or

if the charge warning light comes on, stop the truck

and find the fault.

Normal function

charge warning light out

voltage 27 to 28.5 V

Special rules ©

~ Ensure that batteries are connected with

correct polarity. Changing poles will destroy the

alternator diodes.

~ Never loosen battery or alternator cables when

the engine is running @

= When arc welding there is no need to

disconnect the alternator cables. Always

connect the welding unit as near the welding

point as possible,

Note. The rectifiers in the alternator and the charge

regulator may become damaged if above rules are

not observed.

ALTERNATOR TYPE BOSCH

As regards repair instructions for Bosch alternators

we refer to Bosch service organisation

16-87 1030GT EN

SCAN'A Function description

service

ALTERNATOR AMPERAGE WITH EXCHANGE RATIO 3.5:1

The table lists minimum charge amperage for the alternator at various engine speeds.

The table applies with effect from chassis number:

Scania Sodertalje 1069694

Scania Nederland 4231589

Engine speed | Alternator speed Alternator/Amperage

Fimin min 55A Bosch 75A Wabco

500 1750 20 24

600 2100 30 36

2450 36 44

2800 40 50

3150 a4 3a

3500 46 57

3850 48 59)

4200 50 61

4550 51 63

"4900 52 65

5250 53 66

5600 54 67

5950 55. 69

6300 55. 70

6650 56 7

7000 37 2

7350 57, 3B

700 58 B

8050 58 7B

8400 59 73

16-88-05-30 GT EN/Page 7

16-87 1030 GTEN © Saab-Scania A8, Scania Division, Service (834) 1988 7

Function description SCANLA

service

CALCULATION OF ALTERNATOR SIZE Alternator Consumption Alternator

1. Use the diagram to decide which type of driving ae WO ee

applies. — 1750

750 oe

2. Add all power consumers of the vehicle that

may be on at the same time when driving. See L- 1500 750

table. (62a)

3. See where in the diagram you end up when the 1250

consumption is known, (52a)

55A

Example: Long-distance 1000

You arrive ata consumption of 50A. Asa (a2a) 554

surplus charge of at least 10 Ais needed the

choice is simple 750

SOA +10A=60A Gia)

~The truck needs a 75 A alternator. 350

500

The diagram applies to trucks in long-distance as (31a) 35A

well as trucksin forestry and distribution operation.

As along-distance truck runs for longer periods 250

between breaks such a truck can have slightly larger Z (aoa)

consumption with a small alternator than the +

forestry and distribution trucks. ong tidiance tees

Distribution

Alternator

Consumer Ampere/each Qty Total

Truck, standard ek Sf 3

Headiights (Extra) ae =

Side marker lights 05 x

Roof light ey

Loading lights 32k (stationary)

Electrically heated seat ot

Electricallyheated mirror «2x

Air dryer wok

Retridgerator tek

Cabheater 45% (stationary)

Battery heater Pek

Radio is x

Box body lighting 1

Tail lift 2a (stationary)

Trailer

Rearlights 0s x

Side marker lights 05 x

th marker lights 025 x

Box body lighting 1h x

Total consumption = A

Surplus charge A. (should be 10-25 A)

Suitable alternator =

8 © Saab-Scania AB, Scania Cnvision Service (834) 1988 16-88 05 30 GTEN

SCAN Function descrip'

service Nig Gee Sa a

Alternator design Paris-Rhone 35, 55 and

5A

The rotor in an alternator consists of two claw

shaped metal pieces that encase a coil (exitation

winding), all carried by one shaft. The coil is

supplied with direct current via slip rings to

magnetize the claw shaped pieces, The rotor has six

north poles and six south poles.

The rotor has magnetic force lines between the

north and south poles, Supply to the slip rings for

building up the magnetic field takes place via

connections DF and D-

When the rotor turns at the same time as current

flows through the exitation winding via + DF,

charge amperage is generated in the stator phase

windings. The three-phase alternating current that

is then generated has to be rectified to be able to

charge batteries. This is done with diodes.

16-88 05 30 GT EN © Saab-Scania AB Scarva D wisn Service (834) 1988 9

Function descrip

SCAN

service

A diode only permits current to flow in one

direction, the conducting direction. In this way the

alternating current is turned into direct current

The 35/55A alternators have three plus and three

minus diodes as well as three exitizing diodes.

‘The 7SA alternator has seven plus and seven minus = ‘ >

diodes. Of these six plus and six minus diodes are Conductive direction

used for the three phases and two for the star

point. There are also three exitation diodes to

supply the alternator with exitation current after

sian =k

Techingdretton @

The charge regulator monitors the charge voltage

so that the alternator delivers correct output

voltage. It isa transistorized regulator without

moving parts, made as one unit and it is not

adjustable

10 © Saab-Scania AB, Scania Diusion, Service (834) 1988 16-88 05 30 GT EN

SCAN Function description

service

Stator phase windings

The 35A alternator is of type three-phase, star

connected. See figure for stator windings.

F = phase winding

The 55A alternator is of type three-phase, delta

connected. See figure for stator windings.

F = phase winding

The 75A alternator is of type three-phase, star

connected with double windings. The star point (0)

@ of the phase windings are connected together.

O= middle winding

16-88 05 30 GT EN © Saab Scania AB Scania Ovi, Service (834) 1988 n

Function description

235A alternator internal wiring

55A alternator internal wiring

75A alternator internal wiring

12

SCANIA

service

1.Rotorwinding 4. Condenser

(interference protection)

2.Statorwinding _§. Exitation diodes

3.Rectifier diodes 6. Charge regulator e

| ae

1.Rotorwinding 4. Condenser

(interference protection)

2.Statorwinding _5. Exitation diodes

3.Rectifierdiodes 6. Charge regulator e

|

1.Rotorwinding 4. Condenser

(interference protection)

2 Stator winding _5. Exitation diodes

.Rectifierdiodes 6. Charge regulator

© Saab-Scania AB, Scama Dwsion, Service (834) 1968 16-88 05 30 GT EN

SCANIA

service

CHARGE TESTING ON TRUCK OR IN TEST

CELL

Alternators should not be run with disconnected

batteries, since the rectifiers will be overloaded and

damaged

Output test

Connect the load resistance as illustrated.

1. Calibrate the instrument before the test is

started with the engine stopped. Remove

amperage meter and turnit to zero.

2. Start engine and let it run for a minute before

making the test.

3. Increase engine speed to 1140 r/min or 4000

min on the alternator and apply a load with

the resistance as per below.

The voltmeter should indicate 27 V.

A digital amperage meter can be connected to

8+ on thealternator for a more accurate

setting value,

4, The alternator must produce the following max

values

For 35A alternator - 288

55A alternator - 46 A

75A alternator - 66 A

Regulated voltage test

This test demands fully charged batteries to obtain

correct results.

1. Calibrate the instrument before making the test,

with the engine stopped. Turn amperage meter

and voltmeter to zero.

2. Start engine and let itrun until alternator

delivers max 5A.

3. Increase engine speed to 1140 r/min or 4000

r/min on the alternator. The regulated voltage

at + on the alternator should now be 28.1-28.9,

Vat +20°C

16-88 05 30GTEN

Function description

Test instrument (with volt- 124. Alternator

‘meter, amperagemeter 125. Starter

and load resistance) for ‘motor

alternator. 126. Batteries

Connection for load resistance.

Pliers for amperage metering.

Connection for voltmeter.

© Saab Scamia AB, Scama Division, Service (834) 1988. 13

Work description SCANA

service

Work description

Alternator type Paris-Rhéne 35A

1. Rotor 9. Stator

2. Rearbearing 10. Front bearing shield

3. Rear bearing shield 11. Front bearing

4. Plasticring 12. Cover washer with screw

5. Screwset 13, Screwset

6. Diode bridge 14. Spacing washer

7. Regulator with screw 15, Assembly kit

8 — Brush holder 16. Plastic cover

4 © Saab-Scania AB, Seana Diwsian Service (834) 1988 16-88 05 30GTEN

Alternator type Paris-Rhéne 55A

Rotor

Rear bearing

Rear bearing shield

Plastic ring

Screw set

Diode bridge

Regulator with screw

Brush holder

PNOVAWNS

service

10.

12.

13.

14,

15.

16.

Work description

Stator

Front bearing shield

Front bearing

Cover washer with screw

Screw set

Spacing washer

Assembly kit

Plastic cover

16-88 05 30 GTEN © Saab-Scania A8 Scania 0 vision Serwce (834) 1988 15

Work description SCANA

service

Dismantling of Paris-Rhéne 35A/55A

alternator.

1. Remove plastic cover and two screws in

regulator and cable connection (arrow).

Remove regulator.

2. Solder off phase wires from diode bridge. Use a

pair of pliers for heat dissipation

3. Remove nuts and lift off diode bridge.

16 © Saab-Scania AB, Scama Division, Service (834) 1988

16-88 05 30 GT EN

SCAN Work description

service

4. Mark off stator position in relation to bearing

shields

5. Set up pulley in vice with soft jaws. Remove nut,

pulley, spacing washer and cooling fan.

© g semore nus trom four trough-botsn

bearing shields

16-88 05 30 GTEN © Saab-Scama AB, Scania Division, Service (834) 1988 7

Work description SCANIA

service

7. Remove screws by front bearing. Remove

bearing shield.

8. Remove stator.

9. Loosen rotor from rear bearing shield with

puller 98 609.

10. Pull off both bearings from rotor with suitable

puller.

Check rotor shaft for wear.

18 ® Saab-Scania AB, Scania Division, Service (834) 1988 16-88 05 30 GT EN

SCANIA Work description

service

11. Turn and polish worn slip rings with fine emery

cloth. The slip rings can be turned down to a

diameter of 28.5. Use commutator chuck for

accurate centring.

Note. Normally the slip rings do not have to be

turned. Turning should only be resorted to if the

rings have become grooved.

12. Checkin V-block that slip ring and rotor frame

radial run-out does not exceed 0,05 mm.

16-88 05 30 GTEN © Saab-Scania AB, Scania Divison, Service (834) 1988. 19

Work description

SCANIA

Assembling Paris-Rhéne 35A/55A

alternator

1. Press rear bearing on rotor shaft.

Note. Place drift on inner race.

2. Place washer for front bearing in position. Turn

it with wane edge of holes facing the bearing.

Press on front bearing on rotor shaft.

3. Fitrotorin rear bearing shield

20

© Saab-Scania AB Scania Division, Service (834) 1988

ervice ee ee

16-88 05 30GTEN

SCANIA Work description

service

4, Fitstator and front bearing shield as previously

marked. Push out phase wires through rear

bearing shield, Press together alternator and

thereafter tighten through-bolts alternatingly.

@ 5. Tighten washer that holds bearing in front

bearing shield

6. Fitinsulation washers next to bearing shield on

pole screws.

16-88 05 30GTEN © Saab-Scania AB Scania Oision, Service (834) 1988 21

Work description SCANA

service

7. fit diode bridge. Tighten with plain washers

and thick nuts on pole screws M61 and + for

35A alternator and B-,D + and B + for 55.

alternator.

8. Check that there is no voltage loss between

bearing shield and pole screws +, W and 61 for

JTAgen. and 8 +, Wand D + for 55A alternator.

9. Solder phase wires to diode bridge. Use a pair

of pliers for heat dissipation.

22 © Saab-Scania AB, Scania Ouon, Service (834) 1988 16-88 05 30 GTEN

SCANIA

service

10. Press down regulator carefully with brush

holders in position and tighten it. Connect

cable.

11. Fit plastic cover over diode bridge.

@ 12. Fit spacing washer, pulley and plain washer.

Tighten nut with 50 Nm.

Test alternator as per instructions under

@ “Charge testing”.

16-88 05 30 GT EN © Saab-Scania AB Scania Owision Service (834) 1988

Work description

23

Work description

service

Alternator type Paris-Rhéne 75A

24

OM AwNs

Rotor

7. Regulator with screw

Stator 8 Diode bridge

Front bearing shield 9. Assembly kit

Cover washer 10. Rear bearing shield

Front bearing 11. Extra attachment plate

Brush holder 12. Plastic cover

© Saab-Scania AB, Scania Orwsion, Service (824) 1988

©

Teer ete ee se eae

\

16:47

16-8805 30 GTEN

SCANIA

service

Dismantling of Paris-Rhdne 75A clternator

1. Remove plastic cover and two screws in

regulator and cable connection inside,

Remove regulator carefully.

e@ 2. Screw off phase wires.

3. Remove diode bridges and condenser B +

16-88 05 30GTEN © Saab Scama AB, Scan: Onision, Service (834) 1988

Work description

25

Work description SCAN

service

4, Mark off stator position in relation to bearing

shields.

5. Set up pulley in vice with soft jaws. Remove nut,

pulley, spacing washer and cooling fan.

6. Remove nuts from four through-bolts in

bearing shields. Remove extra attachment

plate.

26 © Saab-Scania AB, Scama Dison, Service (834) 1988 16-88 05 30 GT EN

SCANIA

service

7. Remove screws by front bearing. Remove

bearing shield.

8. Removestator.

9. Loosen rotor from rear bearing shield with

puller 98 609.

10. Pull off both bearings from rotor with suitable

puller.

Check rotor shaft for wear

16-88 05 30 GTEN © Saab-Scania AB. Scania Division, Service (834) 1988

Work description

27

Work description SCANIA

service

11, Turn and polish worn slip rings with fine emery

cloth. The slip rings can be turned down toa

diameter of 28.5. Use commutator chuck for

accurate centring.

Note. Normally the slip rings do not have to be

turned. Turning should only be resorted toif the

rings have become grooved.

12. Check in V-block that slip ring and rotor frame

radial run-out does not exceed 0.05 mm.

28 © Saab-Scania AB Scania Owision, Service (834) 1988 16-88 05 30 GT EN

SCANIA Work description

service

Assembling Paris-Rhdne 75A alternator

1. Press rear bearing on rotor shaft.

Note. Place drift on inner race.

2. Place washer for front bearing in position. Turn

it with wane edge of holes facing the bearing,

Press on front bearing on rotor shaft

3. Fitrotorin rear bearing shield

16-88 05 30GTEN © Saab:Scania AB, Scania Owision, Service (834) 1988 29

Work description SCAN

eT Se service

4, Fitstator and front bearing shield as previously

marked. Push out phase wires through rear

bearing shield, Press together alternator and

thereafter tighten through-bolts alternatingly.

5. Tighten washer that holds bearing in front

bearing shield

6. Fitinsulation washers next to bearing shield on

pole screws.

30 © Saab-Scania AB, Scania Division, Service (834) 1988, 16-88 05 30GTEN

@ &. creccinatinere isn vottagetos between

bearing shield and pole screws B +, Wand D +

7. Fit condenser and diode bridges. Tighten with

plain washers and thick nuts on pole screws D-,

D+ ande+

9. Tighten phase wires thick nut on pole screw W.

16-88 05 30 GT EN

SCANIA

service

© Saab-Scania AB, Scania Division. Service (834) 1988

Work description

31

ption SCANIA

service

10. Press down regulator carefully with brush,

holder in position and tighten it. Connect cable.

11. Fit plastic cover.

12. Fit spacing washer, pulley and piain washer.

Tighten nut with 50 Nm. Test alternator as per

instructions under "Charge testing”

32 © Saab-Scania AB Scania Dwision Service (834) 1988 16-88 05 30GT EN

SCAN Work description

service

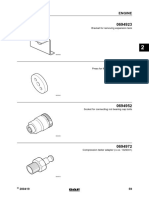

CHECK MEASURING

Checking of brushes, Paris-Rhéne 35, 55,

750

1. The brush holderis soldered to the regulator.

For checking the brushes the regulator thus has

to be removed.

Remove plastic cover and both screws in

regulator as well as the wire connection inside

it. Liftregulator carefully not to damage the

brush holder.

2. Check brush holder for damage and also the

length of the brushes. They should move easily

in the holder and the brush length must not be

less than 5 mm.

Changing brush holder

1. Asolder sucker or strap should be used when,

soldering off the brush holder from the

tegulator. When soldering the brush holder it

should be screwed in the regulator for the

purpose of centring the screw holes.

AMR

16-88 05 30 GT EN ® Saab-Scania AB, Scania Division, Service (834) 1988 33

Work description

Checking of diode bridge 35, 55A

1. Remove plastic cover and solder off phase wires

from diode bridge. Protect the diodes from heat,

by using a pair of pliers for heat dissipation

Loosen nuts on diode bridge and lift it off.

Diode bridge design

- Regulator connection

Excitation diodes

Condenser (interference protection)

Phase connection

Plus diodes

Minus diodes

3. Diodes can be checked by using:

-Ohmmeter, suitable for diode testing.

~24V power source and test light in series

34

© Saab-Scania AB,

SCANIA

service

ae

Scania Division, Service (834) 1988

16-88 05 30 GT EN

16-88 05 30 GT EN

4, Checking with ohmmeter. The resistance must

be low in the forward direction of the diode

and high in the reverse direction

5. Checking with light in series. The light must be

‘nin the forward direction of the diode and off

in the reverse direction

SCANIA

service

© Saab-Scania AB, Scama Division, Service (824) 1988,

Work description

Diode in forward direction (Jow resistance )

Diode in reverse direction ( high resistance )

Diode in reverse direction ( light off )

35

16:479

Work description SCAN

service

6. Check plus and minus diodes by touching the

metal plate with one test probe and the solder

point of each diode with the other. Thereafter,

let the probes change places and repeat the

check. The diodes should only allow current to

flow in one direction.

7. Check the excitation diodes by touching the

regulator connection with one test probe and

each of the three phase connections with the

other. Thereafter, let the probes change places

and repeat the check. The diodes should only

allow current to flow in one direction. Change

faulty diodes.

36 © Saab-Scania AB, Scania Division, Service (834) 1988

16-88 05 30 GT EN

SCANIA

service

Checking of diode bridges

Paris-RhOne 75 A

1. Removeplastic coverand loosen phase wires

from diode bridges. Loosen nuts from diode

bridges and lift them off.

2. Design of diode bridges:

61. (D+) Regulator connection

M. Excitation diodes

B+. Condenser (interference protection)

F. Phase connection

©. Phase winding star point connection

e@ K1,K4. Plus diodes

K2,K3. Minus diodes

3. Diodes can be checked by using:

2S -Ohmmeter, suitable for diode testing.

=24V power source and test light in series.

~

16-88 05 30GTEN © Saab-Scania AB, Scania Vinson. Service (834) 1988

Work description

37

38

Work description SCANA

service

4. Checking with ohmmeter. The resistance must

bbe low in the forward direction of the diode

and high in the reverse direction.

Checking with light in series. The light must be

‘nin the forward direction of the diode and off

Diode in forward direction (low resistance )

A

Diode in reverse direction ( high resistance )

inthe reverse direction

&

X

Diode in reverse direction (light off)

© Saab-Scania AB, Scanve Division, Service (834) 1988. 16-88 05 30GT EN

SCAN Work description

service

6. Check minus diodes by touching the metal plate

with one test probe and the solder point of

each diode with the other. Thereafter, let the

probes change places and repeat the check. The

diodes should only allow current to flow in one

direction

7. Check plus diodes by touching the negative

heat dissipation body with one test probe and

each plus diode with the other. Thereafter, let

the probes change places and repeat the check.

The diodes should only allow current to flow in

one direction

8. Check the excitation diodes by touching the

regulator connection with one test probe and

each of the three phase connections with the

other. Thereafter, let the probes change places

and repeat the check. The diodes should only

allow current to flow in one direction. In case of

a faulty diode, change diode bridge

16-88 05 30 GTEN © Saab-Scania Aa, Scania Dwision, Service (834) 1988 39

Work description SCANIA

service

Checking of rotor Paris-RhOne 35, 55, 75A

1. Ifthe regulator is removed it is possible to

measure the resistance between the rotor slip

rings. The following values apply:

35A/10.9-120

55A/9.7-10.72

T5AI9-110

Use an ohmmeter when checking. if resistance

deviates from these values the rotor has to be

changed.

2. Check for voltage loss across the slip rings and

to the rotor frame with an ohmmeter. When

measuring with ohmeter the instrument should

indicate infinite value (min 10M 2)

40 © Saab-Scania AB, Scania Division, Service (834) 1988 16-88 05 30GTEN

SCANIA

service

Checking of stator Paris-RhGne 35, 55, 75A.

1. Measure resistance in stator by measuring

voltage. The resistance should be

He

Wu

aA

35A/0.34.0.3900F-F Between phase

55A/0.12-0.140F-F — windings F

75A/0.20-0.25 0 F-F

75A/0.10-0.150M-F Measure between star

point connection O and

each phase F.

35 and SSA have 3 phases. 754 has 3 + 3 phases

and a star point connection.

oO 2. Check for voltage loss to the stator frame with

‘an ohmmeter. Touch the stator frame with one

test probe and one of the phase wires with the

other.

When measuring with ohmmeter, instrument

should indicate infinite value (min 10M 2)

16-88 05 30GTEN © Saab-Scania AB, Scania Dwision, Service (834) 1988

Work description

reso

4

Specifications

Batteries

Type

Quantity

Earth connection

System voltage

Battery capacity

Electrolyte specific gravity at +20

with fully charged battery

Battery re-charging point

Charge amperage

Acid level

Special tool

Part name

Puller for rotor bearing shield

Alternator, Paris-Rhone

Designation

Output

Exchange ratio crankshaft/alternator

Resistance in rotor

Resistance in stator between phases

Brushes, min length outside holder

Slip rings, rotor min diameter

Slip rings, max radial run-out

Output test

Alternator speed

Engine speed

Min amperage

Min voltage

Regulator voltage test.

Regulator voltage at + on alternator

Alternator speed

Engine speed

Alternator load

Ambient temperature

Tightening torque, pulley nut

Alternator, Bosch

Refer to Bosch service organization

Starter motor, Bosch

Refer to Bosch service organization.

SCANIA

service

Specifications

Cold-start

Two 12 V series connected

Minus

2av

88 Ah, 118 Ah or 160Ah

1.28

1.24

10% of capacity

Correct when level with upper edge of plastic ring

Part No.

98609

35A

A13N11

980

1:35

109-120

0.34-0.39.9

5mm

28.5

0.05

4000 r/m

1140 fm,

28A

27

28.540.4V

4000 r/m

1140 r/m

max 5A

+20°C

50Nm

lustrated on page

a

55A

A14N39

1600

4:35

9.7-10.79

0.12-0.140

5mm

28.5

0.05

4000 rim

1140 r/m

464

27V

28540.4V

4000 r/m

1140 r/m

max 5A

+20°C

50Nm

42 © Saab-Scania 98, Scania Drvon, Service (834) 1988

75A

A1AN104.

2100W

1:35

9120

0.20-0.25 2 F-F

0.10-0520-F

5mm

285

0.05

4000 r/m

1140 r/m

66A

27

28540.4V

4000 r/m

1140 r/m

max SA

+20°C

50.Nm

16-88 05 30GTEN

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 01 Service Data 3-Series EngineDocument128 pages01 Service Data 3-Series Enginep_janko100% (3)

- Engine: Bracket For Removing Expansion TankDocument20 pagesEngine: Bracket For Removing Expansion Tankp_jankoNo ratings yet

- Special Tools 3Document20 pagesSpecial Tools 3p_jankoNo ratings yet

- Special Tools 1Document20 pagesSpecial Tools 1p_janko100% (1)

- 00-84 06 29 Measuring of Road GradientsDocument4 pages00-84 06 29 Measuring of Road Gradientsp_jankoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printerp_jankoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printerp_jankoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument5 pagesYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printerp_jankoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printerp_jankoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument5 pagesYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printerp_jankoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printerp_jankoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printerp_jankoNo ratings yet

- 16 Electronic InstrumentsDocument32 pages16 Electronic Instrumentsp_jankoNo ratings yet

- 16-88 12 27 Alternator BracketsDocument8 pages16-88 12 27 Alternator Bracketsp_jankoNo ratings yet