Professional Documents

Culture Documents

Service Manual Inspeccion Interior Flaps 200h

Service Manual Inspeccion Interior Flaps 200h

Uploaded by

Andres Santiago Restrepo0 ratings0% found this document useful (0 votes)

18 views1 pageThis document provides special inspection requirements for a Piper Cherokee Arrow III aircraft in addition to the standard inspections listed in Table III-I. Inspections include changing the engine oil and cleaning screens every 25 hours of engine operation for aircraft with pressure screen oil filtration systems. It also requires inspecting the interior of wing flaps for corrosion every 200 hours for aircraft over 10 years old, and cleaning fuel nozzles every 300 hours or annually. For PA-28R-201 aircraft, the document requires inspecting valve rockers and related components for wear or damage every 400 hours of engine operation.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides special inspection requirements for a Piper Cherokee Arrow III aircraft in addition to the standard inspections listed in Table III-I. Inspections include changing the engine oil and cleaning screens every 25 hours of engine operation for aircraft with pressure screen oil filtration systems. It also requires inspecting the interior of wing flaps for corrosion every 200 hours for aircraft over 10 years old, and cleaning fuel nozzles every 300 hours or annually. For PA-28R-201 aircraft, the document requires inspecting valve rockers and related components for wear or damage every 400 hours of engine operation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views1 pageService Manual Inspeccion Interior Flaps 200h

Service Manual Inspeccion Interior Flaps 200h

Uploaded by

Andres Santiago RestrepoThis document provides special inspection requirements for a Piper Cherokee Arrow III aircraft in addition to the standard inspections listed in Table III-I. Inspections include changing the engine oil and cleaning screens every 25 hours of engine operation for aircraft with pressure screen oil filtration systems. It also requires inspecting the interior of wing flaps for corrosion every 200 hours for aircraft over 10 years old, and cleaning fuel nozzles every 300 hours or annually. For PA-28R-201 aircraft, the document requires inspecting valve rockers and related components for wear or damage every 400 hours of engine operation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

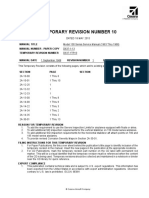

PIPER CHEROKEE ARROW III SERVICE MANUAL

3-8. Special Inspections

WARNING: FAILURE TO CONSULT APPLICABLE VENDOR PUBLICATION(S), WHEN

SERVICING OR INSPECTING VENDOR EQUIPMENT INSTALLED IN PIPER

AIRCRAFT, MAY RENDER THE AIRCRAFT UNAIRWORTHY. (SEE INTRODUCTION

- SUPPLEMENTARY PUBLICATIONS.)

A. Requirements

The following inspections are in addition to those listed in Table III-I. These inspections are performed

at intervals of:

Q Flight hours;

Q Calendar Year; or

Q the specific operation being conducted or the environment being operated in.

Unless otherwise indicated, these inspections are to be repeated at each occurrence of the specified

interval. Note that the items listed herein are guidelines based on past operating experience. Each

operator should closely monitor his own unique operating conditions/environment and react

accordingly to keep his aircraft airworthy.

NOTE: A log book entry should be made upon completion of any inspections.

(1) Per Flight Hour

(a) Each 25 Hours

[ ] For engines using only a pressure screen oil filtration system (i.e., not equipped

with any full flow cartridge filter), change the engine oil and clean the screens

each 25 hours of engine operation.

(b) (Each 200 Hours

[ ] 1) For airplanes with wing flap(s) which have accumulated ten (10) years time-

in-service, conduct the following special inspection each 200 hours: Inspect

the interior of the wing flap for evidence of dissimilar metal corrosion where

aluminum sheet metal is in contact with steel flap brackets. Use a bore scope or

other suitable tool. Installation of a new wing flap will relieve this inspection

requirement until such time as the replacement wing flap reaches ten (10) years

time-in-service.

[ ] 2) Clean fuel nozzles every 300 hours or at the annual inspection. Clean nozzles by

soaking in lacquer thinner, acetone or methyl ethylketone (MEK).

(c) Each 400 Hours

[ ] In PA-28R-201 airplanes, at every 400 hours of engine operation, remove the

rocker box covers and check for freedom of valve rockers when valves are closed.

Look for evidence of abnormal wear or broken parts in the area of the valve tips,

valve keepers, springs, and spring seats. If any indications are found, the cylinder

and all of its components must be removed (including the piston and connecting

rod assembly) and inspected for further damage. Replace any parts that do not

conform with limits shown in the latest revision for Lycoming Service Table of

Limits SSP1776.

01/15/16 III - INSPECTION

1D16C

You might also like

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Beginners Guide To Blackwork by Lesley Wilkins2 PDFDocument63 pagesBeginners Guide To Blackwork by Lesley Wilkins2 PDFSCP100% (4)

- Maharaja Sayajirao University of Baroda B.com SyllabusDocument105 pagesMaharaja Sayajirao University of Baroda B.com SyllabusKartik ChaturvediNo ratings yet

- PiperSeneca PA34 220T MaintenanceManual 100hrinspectionDocument18 pagesPiperSeneca PA34 220T MaintenanceManual 100hrinspectionR. Demmin100% (2)

- Pre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListDocument5 pagesPre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListLandy FebriansyahNo ratings yet

- A320-200 WEEKLY CHECK (Daily) : Airworthiness ManagementDocument7 pagesA320-200 WEEKLY CHECK (Daily) : Airworthiness ManagementOmair Aziz Rabbani100% (3)

- Temporary Revision 8Document38 pagesTemporary Revision 8Daniel Vásquez CabreraNo ratings yet

- Service Manual CE-172 - 1969 - 1976Document13 pagesService Manual CE-172 - 1969 - 1976Kyle BrandonNo ratings yet

- AAA079 APEX R2000 SM SN 001 To 378 Iss 5, 2017Document21 pagesAAA079 APEX R2000 SM SN 001 To 378 Iss 5, 2017jerome chaussonNo ratings yet

- Service Bulletin: TitleDocument12 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- MccauleyDocument14 pagesMccauleyjose luis rocha marquezNo ratings yet

- 72.00.00 Engine - Inspection - CheckDocument83 pages72.00.00 Engine - Inspection - CheckTimoteo Molina RomeroNo ratings yet

- Service Bulletin: TitleDocument13 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- 05-11-00 - Overhaul and Replacement ScheduleDocument4 pages05-11-00 - Overhaul and Replacement ScheduleFabricio ValenteNo ratings yet

- Service Bulletin 239CDocument14 pagesService Bulletin 239CoscarNo ratings yet

- 6 Ovh and Replacement ScheduleDocument4 pages6 Ovh and Replacement ScheduleWilly GrNo ratings yet

- (Beechcraft) Annual Inspection - 100-Hour Inspection ChecklistDocument19 pages(Beechcraft) Annual Inspection - 100-Hour Inspection ChecklistRobertNo ratings yet

- 5 Hard Time and Maintenance ChecksDocument3 pages5 Hard Time and Maintenance ChecksWilly Gr100% (1)

- Silo - Tips - Added Additional Inspection RequirementsDocument5 pagesSilo - Tips - Added Additional Inspection RequirementsJ DaugNo ratings yet

- 02insp 2weekDocument5 pages02insp 2weekfaisal jawadNo ratings yet

- AMM 5-20 Scheduled Maintenance ChecksDocument16 pagesAMM 5-20 Scheduled Maintenance ChecksLeandro CalientoNo ratings yet

- Operaciones de Mantenimiento c172Document5 pagesOperaciones de Mantenimiento c172Juan G Correa100% (1)

- 05 00 00 inDocument4 pages05 00 00 inMarco Antonio PrietoNo ratings yet

- Service Bulletin 234BDocument17 pagesService Bulletin 234BoscarNo ratings yet

- 1245ADocument3 pages1245AdzakubNo ratings yet

- Agem 2nd UnitDocument18 pagesAgem 2nd UnitJanani .SNo ratings yet

- N-Series High Speed Gear Long-Term Maintenance PlanDocument8 pagesN-Series High Speed Gear Long-Term Maintenance PlanErnani MesquitaNo ratings yet

- Blanik l13 - Gfa Ad-369Document11 pagesBlanik l13 - Gfa Ad-369mersoigNo ratings yet

- Prop TboDocument1 pageProp TbommNo ratings yet

- 4-10-00 - Inspection Time Limits 500Document1 page4-10-00 - Inspection Time Limits 500AdilsonNo ratings yet

- Exec 90 Maintenance Manual 3 03Document95 pagesExec 90 Maintenance Manual 3 03najmul100% (1)

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 5Document32 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 5anony8103100% (1)

- Time Limits / Maintenance Checks A. GeneralDocument6 pagesTime Limits / Maintenance Checks A. GeneralAlexis CabreraNo ratings yet

- M250 - C20R Series Operation and MaintenanceDocument8 pagesM250 - C20R Series Operation and MaintenanceturboshaftNo ratings yet

- Agem 2nd Unit NotesDocument18 pagesAgem 2nd Unit Notesmurjass85No ratings yet

- MotorDocument4 pagesMotorjoaofelippejsaNo ratings yet

- 35-590096 - Section 8Document8 pages35-590096 - Section 8Fábio FariaNo ratings yet

- Civil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: ForthwithDocument6 pagesCivil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: ForthwithManish MishraNo ratings yet

- Amm 05-10-00 Time Limits and Maintenance ChecksDocument21 pagesAmm 05-10-00 Time Limits and Maintenance ChecksLUCIENE ORECCHIO VIEIRANo ratings yet

- Cirrus: Airworthiness LimitationsDocument4 pagesCirrus: Airworthiness LimitationsBiblioteca TecnicaNo ratings yet

- TSF 6000 Preflight Night Halt Transit Inspn. - Iss. 5 Rev 4 DT 21 - Sep - 2021Document8 pagesTSF 6000 Preflight Night Halt Transit Inspn. - Iss. 5 Rev 4 DT 21 - Sep - 2021Sonu kumarNo ratings yet

- Ssid Doc For 180Document60 pagesSsid Doc For 180Pankaj SharmaNo ratings yet

- CPCP, Sid S Cessna Model 188 SeriesDocument155 pagesCPCP, Sid S Cessna Model 188 Seriesvilladazafabian713100% (1)

- 05 20 00 inDocument24 pages05 20 00 inWalter AsanzaNo ratings yet

- Pre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListDocument5 pagesPre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListrameshneupaneNo ratings yet

- Standard 625 Appendix CDocument7 pagesStandard 625 Appendix CBakerviewNo ratings yet

- ML B 1900d b19dmm9 1Document8 pagesML B 1900d b19dmm9 1ramzi30No ratings yet

- SB 482 Crankshaft Flange Area Cracking PDFDocument2 pagesSB 482 Crankshaft Flange Area Cracking PDFElzo FreitasNo ratings yet

- MODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Document1 pageMODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Gabriel vieiraNo ratings yet

- Weekly Check A320Document7 pagesWeekly Check A320TDHNo ratings yet

- Weekly Check A320 PDFDocument7 pagesWeekly Check A320 PDFTDHNo ratings yet

- 05-00-00time Limits Maintenance ChecksDocument3 pages05-00-00time Limits Maintenance ChecksShaurya AeronauticsNo ratings yet

- Critical Service Bulletin: Teledyne Continental Aircraft Engine Category 2Document3 pagesCritical Service Bulletin: Teledyne Continental Aircraft Engine Category 2FlavioRodolfoSeveroNo ratings yet

- MM TPE-331-5-xxx table 601 InspeçõesDocument12 pagesMM TPE-331-5-xxx table 601 InspeçõesthallesNo ratings yet

- TM-175 Ms-Uni PDFDocument29 pagesTM-175 Ms-Uni PDFsanjayisdonNo ratings yet

- TM-175 Ms-UniDocument29 pagesTM-175 Ms-UniSivaneswaran SabaratnamNo ratings yet

- 13 Biennial Scheduled Inspection ProgramDocument4 pages13 Biennial Scheduled Inspection ProgramWilly GrNo ratings yet

- Piper Aircraft Corporation: Haven, Pennsylvania, U.S.ADocument2 pagesPiper Aircraft Corporation: Haven, Pennsylvania, U.S.AmaximeNo ratings yet

- Temporary Revision Number Chapter/ Section Date: 250 - B17F Series Operation and Maintenance ManualDocument7 pagesTemporary Revision Number Chapter/ Section Date: 250 - B17F Series Operation and Maintenance ManualAnonymous 298xlo3uUNo ratings yet

- Insp. Time Limit - StrucDocument5 pagesInsp. Time Limit - Strucjesus francoNo ratings yet

- RR250 - C30 OmmDocument16 pagesRR250 - C30 OmmturboshaftNo ratings yet

- RotorWay Exec 90 Helicopter Maintenance ManualDocument95 pagesRotorWay Exec 90 Helicopter Maintenance Manualtahir sadikovicNo ratings yet

- Garmin GTN 650xiDocument52 pagesGarmin GTN 650xiAndres Santiago Restrepo100% (1)

- 761-639 - Arrow Iii - Turbo Arrow Iii Service Manual - Pa-28r-201 - 201TDocument9 pages761-639 - Arrow Iii - Turbo Arrow Iii Service Manual - Pa-28r-201 - 201TAndres Santiago RestrepoNo ratings yet

- Catalogo de Partes GeneralDocument290 pagesCatalogo de Partes GeneralAndres Santiago RestrepoNo ratings yet

- Piper SB 1161B - Rib Assy Inspection and ModificationDocument6 pagesPiper SB 1161B - Rib Assy Inspection and ModificationAndres Santiago RestrepoNo ratings yet

- Indian Income Tax Return Acknowledgement: Name of Premises/Building/VillageDocument1 pageIndian Income Tax Return Acknowledgement: Name of Premises/Building/Villagehealth with wealthNo ratings yet

- Diploma in Creative Writing in English Project DCE-06 in IGNOUDocument7 pagesDiploma in Creative Writing in English Project DCE-06 in IGNOUTelika RamuNo ratings yet

- People vs. ObiasDocument2 pagesPeople vs. ObiasRobNo ratings yet

- Office of The Punong Barangay Barangay Certification of AcceptanceDocument1 pageOffice of The Punong Barangay Barangay Certification of AcceptanceMah Jane DivinaNo ratings yet

- A Preliminary Geo Seismological Report On Kashmir Earthquake of 8th Oct 2005Document13 pagesA Preliminary Geo Seismological Report On Kashmir Earthquake of 8th Oct 2005Abdul HafeezNo ratings yet

- Adjustment LetterDocument14 pagesAdjustment LetterQadr IftikharNo ratings yet

- 6-9 Summer Happy LearningDocument8 pages6-9 Summer Happy Learningjairohith9711No ratings yet

- Succession Cause 846 of 2011Document6 pagesSuccession Cause 846 of 2011kbaisa7No ratings yet

- Ch-8 Challeges To DemocracyDocument2 pagesCh-8 Challeges To DemocracySujitnkbpsNo ratings yet

- Project Management A Systems Approach To Planning Scheduling and Controlling 10Th Edition Kerzner Test Bank Full Chapter PDFDocument24 pagesProject Management A Systems Approach To Planning Scheduling and Controlling 10Th Edition Kerzner Test Bank Full Chapter PDFGeorgeAndersonkqmr100% (13)

- Technical Data: Protective Grease For Overhead Line ConductorsDocument3 pagesTechnical Data: Protective Grease For Overhead Line ConductorssreedharNo ratings yet

- Worksheet 8 Gread Number1Document3 pagesWorksheet 8 Gread Number1nknbjjqh5gNo ratings yet

- The Hyperbolic-Paraboloidal Shell and Its Mechanical PropertiesDocument9 pagesThe Hyperbolic-Paraboloidal Shell and Its Mechanical PropertiesmateovarelaortizNo ratings yet

- Powerful Computing and Dynamic Scheduling: Digital EngineDocument2 pagesPowerful Computing and Dynamic Scheduling: Digital EngineLeomark RespondeNo ratings yet

- 10/03/2020 Asbestosis: Dr. A. Sau MBBS, MD (Gold Medalist) DD (Medical) 1Document20 pages10/03/2020 Asbestosis: Dr. A. Sau MBBS, MD (Gold Medalist) DD (Medical) 1puneet100% (1)

- Inorganic Chemistry 1 - Alkali Metals RevisioDocument7 pagesInorganic Chemistry 1 - Alkali Metals RevisioAshleyn Mary SandersNo ratings yet

- Drug StudyDocument2 pagesDrug StudySORENI SORENINo ratings yet

- Criminal ProfilingDocument13 pagesCriminal ProfilingAiseba Lezba RemleNo ratings yet

- Qualitative ResearchDocument27 pagesQualitative ResearchElizabeth PalasanNo ratings yet

- Neonatal Intubation: Past, Present, and Future: Practice GapsDocument9 pagesNeonatal Intubation: Past, Present, and Future: Practice GapskiloNo ratings yet

- Sapiens A Brief History of HumankindDocument8 pagesSapiens A Brief History of HumankindAli GoharNo ratings yet

- Knowledge Management & Specialized Information SystemsDocument21 pagesKnowledge Management & Specialized Information SystemsAntonyNo ratings yet

- Anth 133 - HUNTERS AND GATHERERS PDFDocument15 pagesAnth 133 - HUNTERS AND GATHERERS PDFAnjelica Pearl NazarenoNo ratings yet

- Schools in Ghaz. & NoidaDocument58 pagesSchools in Ghaz. & Noidanitinthukral10No ratings yet

- Blog Profile: Activity A. " ". Complete El Perfil Con Su Información Personal en Los Espacios Indicados "Document5 pagesBlog Profile: Activity A. " ". Complete El Perfil Con Su Información Personal en Los Espacios Indicados "El dominadorNo ratings yet

- Microbial Alkaline ProteasesDocument34 pagesMicrobial Alkaline Proteasessalin MajumdarNo ratings yet

- Upotte Last Episode ThreadDocument48 pagesUpotte Last Episode Threaddeclinar260No ratings yet

- "©HAND Rapids" Grinders .: & Livomsstron CODocument42 pages"©HAND Rapids" Grinders .: & Livomsstron CONew100% (1)