Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

16 viewsAssignment: Course Name:Civil and Environmental Technology 1 Course No:CEE 4361 Dept:Btm Sec:B

Assignment: Course Name:Civil and Environmental Technology 1 Course No:CEE 4361 Dept:Btm Sec:B

Uploaded by

Maisha MalihaThe document summarizes the results of a tensile strength test on a rod. It provides the load and dial gauge readings recorded during the test. It then lists calculation questions to determine properties like yield strength, ultimate strength, and the ratio between the two from the experimental data. The solution section provides calculations to convert some of the given dimensions to metric units needed for the analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Chapter 10 Fin Man SolutionDocument48 pagesChapter 10 Fin Man SolutionMaisha Maliha100% (7)

- Engineering Materials Dr. TarekDocument118 pagesEngineering Materials Dr. TareksheshirNo ratings yet

- Methodology of Control BlastingDocument4 pagesMethodology of Control BlastingB&R HSE BALCO SEP SiteNo ratings yet

- 1Document9 pages1Hammad AhmadNo ratings yet

- Section 1 Threaded Fasteners: STUDS # 835Document1 pageSection 1 Threaded Fasteners: STUDS # 835박준용No ratings yet

- Dynamics Lab Report: Geneva MechanismDocument17 pagesDynamics Lab Report: Geneva MechanismBhargav PurimetlaNo ratings yet

- Sas Micropile Manual With Grade 97Document16 pagesSas Micropile Manual With Grade 97JR GEOCONSULTORES INGENIEROSNo ratings yet

- National University: Department of Civil Engineering Fgetec2 Seatwork NO. 2 Shear Strength of SoilDocument2 pagesNational University: Department of Civil Engineering Fgetec2 Seatwork NO. 2 Shear Strength of SoilArciel Leynes AdornadoNo ratings yet

- National University: Department of Civil EngineeringDocument2 pagesNational University: Department of Civil EngineeringArciel Leynes AdornadoNo ratings yet

- Technical Datas Voltage Drop For Low Voltage CablesDocument14 pagesTechnical Datas Voltage Drop For Low Voltage CablesFelipe GustavoNo ratings yet

- Cam and Follower GuntDocument20 pagesCam and Follower GuntAurangzebNo ratings yet

- Gende R Favored Hand Total Right Left Male Female TotalDocument6 pagesGende R Favored Hand Total Right Left Male Female TotalPrincess SalvadorNo ratings yet

- Federal NYMHY 300 500 VDocument1 pageFederal NYMHY 300 500 VilabuloNo ratings yet

- CNG-1 Natural Gas Cylinders For Vehicles - Zhejiang Tianen Pressure Vessel Co - CILINDROS ESPESSURA ZHEJIANGDocument4 pagesCNG-1 Natural Gas Cylinders For Vehicles - Zhejiang Tianen Pressure Vessel Co - CILINDROS ESPESSURA ZHEJIANGDouglas SilvaNo ratings yet

- Cube Strength & Cylinder StrengthDocument5 pagesCube Strength & Cylinder StrengthRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 100 3 CM Electrode Immersion Height 6 CM Electrode Immersion Height 9 CM Electrode Immersion HeightDocument6 pages100 3 CM Electrode Immersion Height 6 CM Electrode Immersion Height 9 CM Electrode Immersion HeightvahidNo ratings yet

- BukuDocument3 pagesBukuNisyaNo ratings yet

- 03 Poprecni Ramovi 1100 - 1200Document2 pages03 Poprecni Ramovi 1100 - 1200M PNo ratings yet

- 03 Poprecni Ramovi 1100 - 1200Document2 pages03 Poprecni Ramovi 1100 - 1200M PNo ratings yet

- Physics AtwoodsDocument3 pagesPhysics AtwoodsSebastian SmytheNo ratings yet

- Determination of CBR From DCP Test ResultDocument4 pagesDetermination of CBR From DCP Test ResultSaya NamaNo ratings yet

- Luminaire PropertyDocument7 pagesLuminaire PropertyGonzalo LunaNo ratings yet

- Chapter 6Document5 pagesChapter 6mcm.mmltransformerNo ratings yet

- Data Trial Cheme CarDocument2 pagesData Trial Cheme CarWidyAdityaNo ratings yet

- Zone 1 Zone 2: Ukuran Ayakan Ukuran AyakanDocument20 pagesZone 1 Zone 2: Ukuran Ayakan Ukuran AyakanAgus AwwaNo ratings yet

- Luminaire PropertyDocument7 pagesLuminaire PropertyLucas NunesNo ratings yet

- Huff Calculation MBRDocument345 pagesHuff Calculation MBRMuhammad Ashiqur Rahman BhuiyanNo ratings yet

- Pipe CulvertDocument5 pagesPipe CulvertfazsNo ratings yet

- Frequency Distribution - Quantitative: Diámetro de PelletsDocument4 pagesFrequency Distribution - Quantitative: Diámetro de PelletsRonald Martín Paisig CotrinaNo ratings yet

- Effect of Organosolv PretreatmentDocument13 pagesEffect of Organosolv PretreatmentBadruzamanIbadNo ratings yet

- Table 1a - Rated Insulation Levels For Rated Voltages of Range I, Series IDocument1 pageTable 1a - Rated Insulation Levels For Rated Voltages of Range I, Series IavinashuklaNo ratings yet

- New MTRP: Plug-In Motor Starting RelayDocument5 pagesNew MTRP: Plug-In Motor Starting RelayMaricel Villafuerte100% (1)

- Minimum Clearance As Per IEC 61936-1-2014Document2 pagesMinimum Clearance As Per IEC 61936-1-2014Saroj0% (1)

- 3Document14 pages3Ziad GamalNo ratings yet

- Dhaka University of & Technology: EngineeringDocument17 pagesDhaka University of & Technology: EngineeringSujon AhmmedNo ratings yet

- Tugas Pendahuluan Mt2205 Laboratorium Teknik Material 1 Modul F Uji Impak (Impact Test)Document7 pagesTugas Pendahuluan Mt2205 Laboratorium Teknik Material 1 Modul F Uji Impak (Impact Test)Muhammad SiddiqNo ratings yet

- Table 10-Segregated and Nonsegregated-Phase Bus - Preferred Rated Withstand CurrentDocument1 pageTable 10-Segregated and Nonsegregated-Phase Bus - Preferred Rated Withstand CurrentAhmed AbozahrahNo ratings yet

- EE5 Soln Study of EMI AnalysisPlots 1652207439083Document6 pagesEE5 Soln Study of EMI AnalysisPlots 1652207439083The RevolutionNo ratings yet

- Alphard OK!Document70 pagesAlphard OK!Devi LusianaNo ratings yet

- Ac10cfiip.c18158 002Document2 pagesAc10cfiip.c18158 002anon_116727886No ratings yet

- Book 1Document8 pagesBook 1aaaNo ratings yet

- Milling Mixing SievingDocument12 pagesMilling Mixing SievingHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Sieve AnalysisDocument6 pagesSieve Analysisahm531No ratings yet

- Tugas Pengolahan Nilai Menggunakan Pap (Penilaian Acuan Patokan)Document5 pagesTugas Pengolahan Nilai Menggunakan Pap (Penilaian Acuan Patokan)riskha lestariNo ratings yet

- Tugas Pengolahan Nilai Menggunakan Pap (Penilaian Acuan Patokan)Document5 pagesTugas Pengolahan Nilai Menggunakan Pap (Penilaian Acuan Patokan)riskha lestariNo ratings yet

- Productivity - Dia Wise-Zone Wise Pipeline LengthDocument5 pagesProductivity - Dia Wise-Zone Wise Pipeline LengthDilip KumarNo ratings yet

- Problem A 14Document7 pagesProblem A 14Juan Valdez EscalanteNo ratings yet

- Laboratorium Pengendalian Proses: Semester Genap Tahun Ajaran 2017/2018Document12 pagesLaboratorium Pengendalian Proses: Semester Genap Tahun Ajaran 2017/2018AntiiSukmaNo ratings yet

- TensileDocument1 pageTensileGokhan KayaNo ratings yet

- Overhauling Instructions: Pusher LegsDocument12 pagesOverhauling Instructions: Pusher LegsNgười Chiến Sĩ ẤyNo ratings yet

- Book 1Document6 pagesBook 1Jocker GreickNo ratings yet

- DCP On TP 3Document3 pagesDCP On TP 3Demsew AdelahuNo ratings yet

- Minimal Spanning Tree ProblemDocument25 pagesMinimal Spanning Tree Problemerfan_nugroho9063No ratings yet

- Jwb_ANTabc Model 1 ANTIabDocument10 pagesJwb_ANTabc Model 1 ANTIabIvani Marine BiotaNo ratings yet

- Bahan No T (°C) P (MM) L (MM) T (MM) H (MM) Luas (MM )Document4 pagesBahan No T (°C) P (MM) L (MM) T (MM) H (MM) Luas (MM )Boni PrakasaNo ratings yet

- MR 1Document19 pagesMR 1Santosh ChowdaryNo ratings yet

- ADocument3 pagesAMonica GrecuNo ratings yet

- Chart Title: 90 F (X) 1.05896739130435 X + 0.817934782608688 R 0.905833426382423Document20 pagesChart Title: 90 F (X) 1.05896739130435 X + 0.817934782608688 R 0.905833426382423ESMERALDA PERALTA OJEDANo ratings yet

- Graph Showing... : Voice-Onset Time (Miliseconds)Document5 pagesGraph Showing... : Voice-Onset Time (Miliseconds)jhkjhkNo ratings yet

- Group 12 MIS Assignment 2Document8 pagesGroup 12 MIS Assignment 2Maisha MalihaNo ratings yet

- Industrial Visit Report On Amber DenimDocument3 pagesIndustrial Visit Report On Amber DenimMaisha MalihaNo ratings yet

- Mim Bus ComDocument18 pagesMim Bus ComMaisha MalihaNo ratings yet

- Movie Review: PsychologyDocument4 pagesMovie Review: PsychologyMaisha MalihaNo ratings yet

- Assignment For B-ComDocument11 pagesAssignment For B-ComMaisha MalihaNo ratings yet

- Accounting Case Study ReportDocument5 pagesAccounting Case Study ReportMaisha MalihaNo ratings yet

Assignment: Course Name:Civil and Environmental Technology 1 Course No:CEE 4361 Dept:Btm Sec:B

Assignment: Course Name:Civil and Environmental Technology 1 Course No:CEE 4361 Dept:Btm Sec:B

Uploaded by

Maisha Maliha0 ratings0% found this document useful (0 votes)

16 views3 pagesThe document summarizes the results of a tensile strength test on a rod. It provides the load and dial gauge readings recorded during the test. It then lists calculation questions to determine properties like yield strength, ultimate strength, and the ratio between the two from the experimental data. The solution section provides calculations to convert some of the given dimensions to metric units needed for the analysis.

Original Description:

Original Title

civil Assignment.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the results of a tensile strength test on a rod. It provides the load and dial gauge readings recorded during the test. It then lists calculation questions to determine properties like yield strength, ultimate strength, and the ratio between the two from the experimental data. The solution section provides calculations to convert some of the given dimensions to metric units needed for the analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

16 views3 pagesAssignment: Course Name:Civil and Environmental Technology 1 Course No:CEE 4361 Dept:Btm Sec:B

Assignment: Course Name:Civil and Environmental Technology 1 Course No:CEE 4361 Dept:Btm Sec:B

Uploaded by

Maisha MalihaThe document summarizes the results of a tensile strength test on a rod. It provides the load and dial gauge readings recorded during the test. It then lists calculation questions to determine properties like yield strength, ultimate strength, and the ratio between the two from the experimental data. The solution section provides calculations to convert some of the given dimensions to metric units needed for the analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

Assignment

Course Name:Civil and

Environmental Technology

1

Course No:CEE 4361

Dept:BTM Sec:B

Student Name:Maisha Maliha

Student ID:170061001

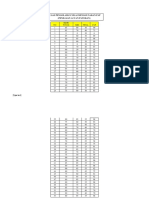

The load and dial gauge reading of a rod tested for tensile strength is summarized below:

Gauge Length = 1 inch

1 Div of Dial Gauge = 0.001 mm

Bar Diameter = 0.5 inch

Load(kN) Dial Gauge Reading

0 0

5 7

10 20

15 27

20 39

25 49

30 63

35 76

40 83

45 90

50 104

55 117

60 129

65 225

70 465

75 5080

70 10160

(i) Draw the “stress-strain curve” (strain axis – from 0 to 0.2)

(ii) Draw the “stress-strain curve” (strain axis – 0 to 0.02)

(iii) Determine the “yield strength”

(iv) Determine the “ultimate strength”

(v) Determine the ratio between “yield strength” and “ultimate strength”

(vi) Make Comments on the results

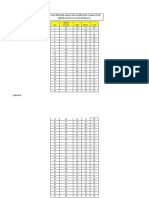

Solution:

Calculation:

Gauge Length = 1 inch = 1 × 25.4 = 25.4 mm

Bar diameter = 0.5 inch = 0.5 × 25.4 = 12.7 mm

Area of bar = (π/4) × (12.7)2= 126.73 mm2

Stress = 5000/126.73 = 39.45462436 N/mm 2

Elongation = 7 × 0.01 = 0.07 mm

Strain = 0.07/50.8 = 0.000137795

You might also like

- Chapter 10 Fin Man SolutionDocument48 pagesChapter 10 Fin Man SolutionMaisha Maliha100% (7)

- Engineering Materials Dr. TarekDocument118 pagesEngineering Materials Dr. TareksheshirNo ratings yet

- Methodology of Control BlastingDocument4 pagesMethodology of Control BlastingB&R HSE BALCO SEP SiteNo ratings yet

- 1Document9 pages1Hammad AhmadNo ratings yet

- Section 1 Threaded Fasteners: STUDS # 835Document1 pageSection 1 Threaded Fasteners: STUDS # 835박준용No ratings yet

- Dynamics Lab Report: Geneva MechanismDocument17 pagesDynamics Lab Report: Geneva MechanismBhargav PurimetlaNo ratings yet

- Sas Micropile Manual With Grade 97Document16 pagesSas Micropile Manual With Grade 97JR GEOCONSULTORES INGENIEROSNo ratings yet

- National University: Department of Civil Engineering Fgetec2 Seatwork NO. 2 Shear Strength of SoilDocument2 pagesNational University: Department of Civil Engineering Fgetec2 Seatwork NO. 2 Shear Strength of SoilArciel Leynes AdornadoNo ratings yet

- National University: Department of Civil EngineeringDocument2 pagesNational University: Department of Civil EngineeringArciel Leynes AdornadoNo ratings yet

- Technical Datas Voltage Drop For Low Voltage CablesDocument14 pagesTechnical Datas Voltage Drop For Low Voltage CablesFelipe GustavoNo ratings yet

- Cam and Follower GuntDocument20 pagesCam and Follower GuntAurangzebNo ratings yet

- Gende R Favored Hand Total Right Left Male Female TotalDocument6 pagesGende R Favored Hand Total Right Left Male Female TotalPrincess SalvadorNo ratings yet

- Federal NYMHY 300 500 VDocument1 pageFederal NYMHY 300 500 VilabuloNo ratings yet

- CNG-1 Natural Gas Cylinders For Vehicles - Zhejiang Tianen Pressure Vessel Co - CILINDROS ESPESSURA ZHEJIANGDocument4 pagesCNG-1 Natural Gas Cylinders For Vehicles - Zhejiang Tianen Pressure Vessel Co - CILINDROS ESPESSURA ZHEJIANGDouglas SilvaNo ratings yet

- Cube Strength & Cylinder StrengthDocument5 pagesCube Strength & Cylinder StrengthRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 100 3 CM Electrode Immersion Height 6 CM Electrode Immersion Height 9 CM Electrode Immersion HeightDocument6 pages100 3 CM Electrode Immersion Height 6 CM Electrode Immersion Height 9 CM Electrode Immersion HeightvahidNo ratings yet

- BukuDocument3 pagesBukuNisyaNo ratings yet

- 03 Poprecni Ramovi 1100 - 1200Document2 pages03 Poprecni Ramovi 1100 - 1200M PNo ratings yet

- 03 Poprecni Ramovi 1100 - 1200Document2 pages03 Poprecni Ramovi 1100 - 1200M PNo ratings yet

- Physics AtwoodsDocument3 pagesPhysics AtwoodsSebastian SmytheNo ratings yet

- Determination of CBR From DCP Test ResultDocument4 pagesDetermination of CBR From DCP Test ResultSaya NamaNo ratings yet

- Luminaire PropertyDocument7 pagesLuminaire PropertyGonzalo LunaNo ratings yet

- Chapter 6Document5 pagesChapter 6mcm.mmltransformerNo ratings yet

- Data Trial Cheme CarDocument2 pagesData Trial Cheme CarWidyAdityaNo ratings yet

- Zone 1 Zone 2: Ukuran Ayakan Ukuran AyakanDocument20 pagesZone 1 Zone 2: Ukuran Ayakan Ukuran AyakanAgus AwwaNo ratings yet

- Luminaire PropertyDocument7 pagesLuminaire PropertyLucas NunesNo ratings yet

- Huff Calculation MBRDocument345 pagesHuff Calculation MBRMuhammad Ashiqur Rahman BhuiyanNo ratings yet

- Pipe CulvertDocument5 pagesPipe CulvertfazsNo ratings yet

- Frequency Distribution - Quantitative: Diámetro de PelletsDocument4 pagesFrequency Distribution - Quantitative: Diámetro de PelletsRonald Martín Paisig CotrinaNo ratings yet

- Effect of Organosolv PretreatmentDocument13 pagesEffect of Organosolv PretreatmentBadruzamanIbadNo ratings yet

- Table 1a - Rated Insulation Levels For Rated Voltages of Range I, Series IDocument1 pageTable 1a - Rated Insulation Levels For Rated Voltages of Range I, Series IavinashuklaNo ratings yet

- New MTRP: Plug-In Motor Starting RelayDocument5 pagesNew MTRP: Plug-In Motor Starting RelayMaricel Villafuerte100% (1)

- Minimum Clearance As Per IEC 61936-1-2014Document2 pagesMinimum Clearance As Per IEC 61936-1-2014Saroj0% (1)

- 3Document14 pages3Ziad GamalNo ratings yet

- Dhaka University of & Technology: EngineeringDocument17 pagesDhaka University of & Technology: EngineeringSujon AhmmedNo ratings yet

- Tugas Pendahuluan Mt2205 Laboratorium Teknik Material 1 Modul F Uji Impak (Impact Test)Document7 pagesTugas Pendahuluan Mt2205 Laboratorium Teknik Material 1 Modul F Uji Impak (Impact Test)Muhammad SiddiqNo ratings yet

- Table 10-Segregated and Nonsegregated-Phase Bus - Preferred Rated Withstand CurrentDocument1 pageTable 10-Segregated and Nonsegregated-Phase Bus - Preferred Rated Withstand CurrentAhmed AbozahrahNo ratings yet

- EE5 Soln Study of EMI AnalysisPlots 1652207439083Document6 pagesEE5 Soln Study of EMI AnalysisPlots 1652207439083The RevolutionNo ratings yet

- Alphard OK!Document70 pagesAlphard OK!Devi LusianaNo ratings yet

- Ac10cfiip.c18158 002Document2 pagesAc10cfiip.c18158 002anon_116727886No ratings yet

- Book 1Document8 pagesBook 1aaaNo ratings yet

- Milling Mixing SievingDocument12 pagesMilling Mixing SievingHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Sieve AnalysisDocument6 pagesSieve Analysisahm531No ratings yet

- Tugas Pengolahan Nilai Menggunakan Pap (Penilaian Acuan Patokan)Document5 pagesTugas Pengolahan Nilai Menggunakan Pap (Penilaian Acuan Patokan)riskha lestariNo ratings yet

- Tugas Pengolahan Nilai Menggunakan Pap (Penilaian Acuan Patokan)Document5 pagesTugas Pengolahan Nilai Menggunakan Pap (Penilaian Acuan Patokan)riskha lestariNo ratings yet

- Productivity - Dia Wise-Zone Wise Pipeline LengthDocument5 pagesProductivity - Dia Wise-Zone Wise Pipeline LengthDilip KumarNo ratings yet

- Problem A 14Document7 pagesProblem A 14Juan Valdez EscalanteNo ratings yet

- Laboratorium Pengendalian Proses: Semester Genap Tahun Ajaran 2017/2018Document12 pagesLaboratorium Pengendalian Proses: Semester Genap Tahun Ajaran 2017/2018AntiiSukmaNo ratings yet

- TensileDocument1 pageTensileGokhan KayaNo ratings yet

- Overhauling Instructions: Pusher LegsDocument12 pagesOverhauling Instructions: Pusher LegsNgười Chiến Sĩ ẤyNo ratings yet

- Book 1Document6 pagesBook 1Jocker GreickNo ratings yet

- DCP On TP 3Document3 pagesDCP On TP 3Demsew AdelahuNo ratings yet

- Minimal Spanning Tree ProblemDocument25 pagesMinimal Spanning Tree Problemerfan_nugroho9063No ratings yet

- Jwb_ANTabc Model 1 ANTIabDocument10 pagesJwb_ANTabc Model 1 ANTIabIvani Marine BiotaNo ratings yet

- Bahan No T (°C) P (MM) L (MM) T (MM) H (MM) Luas (MM )Document4 pagesBahan No T (°C) P (MM) L (MM) T (MM) H (MM) Luas (MM )Boni PrakasaNo ratings yet

- MR 1Document19 pagesMR 1Santosh ChowdaryNo ratings yet

- ADocument3 pagesAMonica GrecuNo ratings yet

- Chart Title: 90 F (X) 1.05896739130435 X + 0.817934782608688 R 0.905833426382423Document20 pagesChart Title: 90 F (X) 1.05896739130435 X + 0.817934782608688 R 0.905833426382423ESMERALDA PERALTA OJEDANo ratings yet

- Graph Showing... : Voice-Onset Time (Miliseconds)Document5 pagesGraph Showing... : Voice-Onset Time (Miliseconds)jhkjhkNo ratings yet

- Group 12 MIS Assignment 2Document8 pagesGroup 12 MIS Assignment 2Maisha MalihaNo ratings yet

- Industrial Visit Report On Amber DenimDocument3 pagesIndustrial Visit Report On Amber DenimMaisha MalihaNo ratings yet

- Mim Bus ComDocument18 pagesMim Bus ComMaisha MalihaNo ratings yet

- Movie Review: PsychologyDocument4 pagesMovie Review: PsychologyMaisha MalihaNo ratings yet

- Assignment For B-ComDocument11 pagesAssignment For B-ComMaisha MalihaNo ratings yet

- Accounting Case Study ReportDocument5 pagesAccounting Case Study ReportMaisha MalihaNo ratings yet