Professional Documents

Culture Documents

U R T Foraw R L F: Ser Equirements Emplate Ide Ange Iquid Iller

U R T Foraw R L F: Ser Equirements Emplate Ide Ange Iquid Iller

Uploaded by

BREWSKICopyright:

Available Formats

You might also like

- DNV-RU-SHIP Pt.2 Ch.4. (2022.07) - Ship Hull WeldsDocument144 pagesDNV-RU-SHIP Pt.2 Ch.4. (2022.07) - Ship Hull Weldsnanotech123No ratings yet

- RFCC PDFDocument324 pagesRFCC PDFMohamed AdelNo ratings yet

- Label Er UrsDocument42 pagesLabel Er UrsMr Thanh100% (1)

- DNV RU SHIP Pt2Ch4Document144 pagesDNV RU SHIP Pt2Ch4Rahul KamillaNo ratings yet

- ITAP3012 Developing Web Applications Tutorial - 12: Prabhjot Singh Grewal-47294Document7 pagesITAP3012 Developing Web Applications Tutorial - 12: Prabhjot Singh Grewal-47294FarhanAshrafNo ratings yet

- BP Guide To Valve SelectionDocument156 pagesBP Guide To Valve Selectionjemorpe100% (4)

- Production Riser Life Extension: Guidance Notes OnDocument24 pagesProduction Riser Life Extension: Guidance Notes OnGopalakrishnanNo ratings yet

- SER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperDocument26 pagesSER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperBREWSKINo ratings yet

- SER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperDocument26 pagesSER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperBREWSKINo ratings yet

- Sap Basis Syllabus PDFDocument4 pagesSap Basis Syllabus PDFmpsing11330% (1)

- SER Equirements Emplate IAL Asher: Vial WasherDocument22 pagesSER Equirements Emplate IAL Asher: Vial Washermehdi ershadiNo ratings yet

- URS Saya Isi Halaman 1-16Document33 pagesURS Saya Isi Halaman 1-16Yonas SinsengNo ratings yet

- Rp62-1 - Guide To Valve SelectionDocument145 pagesRp62-1 - Guide To Valve Selectionkamal arab100% (1)

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAINo ratings yet

- Water Source Injection and Disposal Service Wells Summary November Release 2014Document20 pagesWater Source Injection and Disposal Service Wells Summary November Release 2014Satria 'igin' Girindra NugrahaNo ratings yet

- 28 Hail Te010 0002 R3Document50 pages28 Hail Te010 0002 R3Parthasarathy TNo ratings yet

- Specification - Hvac Central Station Air Handling UnitsDocument21 pagesSpecification - Hvac Central Station Air Handling UnitsJaseelKanhirathinkalNo ratings yet

- The Water Transmission CodeDocument62 pagesThe Water Transmission CodeSantosh Kumar PandeyNo ratings yet

- MQ SP H 4702 PDFDocument20 pagesMQ SP H 4702 PDFShamimNo ratings yet

- Specification - Hvac Design CriteriaDocument34 pagesSpecification - Hvac Design CriteriaShamimNo ratings yet

- BP RP62-1 ValvesDocument155 pagesBP RP62-1 ValvesMohd Khairul100% (1)

- NHT UnitDocument197 pagesNHT Unitsathya perumal100% (3)

- Autoclave URSDocument28 pagesAutoclave URSShejil BalakrishnanNo ratings yet

- DNV RU UWT Pt7Document29 pagesDNV RU UWT Pt7lijinNo ratings yet

- Minibooster Hc6d2w Operations and MaintenanceDocument70 pagesMinibooster Hc6d2w Operations and MaintenanceAlessandro Carneiro de AraujoNo ratings yet

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAI100% (1)

- Specification - Hvac Air Cooled Condensing UnitsDocument15 pagesSpecification - Hvac Air Cooled Condensing UnitsJaseelKanhirathinkalNo ratings yet

- DIO 01.5a. Pregledi Postojećih Brodova July 2020Document217 pagesDIO 01.5a. Pregledi Postojećih Brodova July 2020Samo SpontanostNo ratings yet

- DNV Ru Ship Pt1ch1Document48 pagesDNV Ru Ship Pt1ch1programmer dhruv KumarNo ratings yet

- 4251-RA-00379913 - D - 01 - Regulatory Compliance PlanDocument42 pages4251-RA-00379913 - D - 01 - Regulatory Compliance Plansivaguruswamy thangaraj100% (1)

- DG Pse 0104 PDFDocument24 pagesDG Pse 0104 PDFErika Caicedo100% (1)

- English 12 / 2012: SpecificationDocument40 pagesEnglish 12 / 2012: SpecificationmarceloNo ratings yet

- Qra Version FDocument60 pagesQra Version Fbukaro85No ratings yet

- Guide To Valve Selection1 (BP) PDFDocument152 pagesGuide To Valve Selection1 (BP) PDFmadihanaz84No ratings yet

- MQ SP I 7020Document74 pagesMQ SP I 7020jaseel kNo ratings yet

- Pdo SP 1211Document71 pagesPdo SP 1211MuddasarNo ratings yet

- 8384-2602-SQ-0720 B1 Spec Welding and NDTDocument100 pages8384-2602-SQ-0720 B1 Spec Welding and NDTHướng PhạmNo ratings yet

- Disposal and Injection Well Requirements: Directive PNG008Document24 pagesDisposal and Injection Well Requirements: Directive PNG008arispriyatmonoNo ratings yet

- Disposal Requirements Volume1Document9 pagesDisposal Requirements Volume1mcemce100% (1)

- MQ SP I 7027 PDFDocument19 pagesMQ SP I 7027 PDFJaseelKanhirathinkalNo ratings yet

- Gis 46 020 - ADocument71 pagesGis 46 020 - Amulldoctor1No ratings yet

- Validation Plan TemplateDocument22 pagesValidation Plan TemplateBlank BacktobasicNo ratings yet

- HT-400 Fluid End Onshore, Facility and Offshore InspectionDocument21 pagesHT-400 Fluid End Onshore, Facility and Offshore InspectionFrancisco javierNo ratings yet

- Construction Monitoring CM Procedure November 2022Document33 pagesConstruction Monitoring CM Procedure November 2022leonghenry84No ratings yet

- DNV Ru Ship Pt4ch2Document56 pagesDNV Ru Ship Pt4ch2Ken VikstromNo ratings yet

- SP-1246 Part-1Document31 pagesSP-1246 Part-1Rajkumar ANo ratings yet

- 10 Survey Method StatementDocument44 pages10 Survey Method Statementali mehmetNo ratings yet

- Nitp 5.1 Fuel Dispensers Other Than LPG DispensersDocument19 pagesNitp 5.1 Fuel Dispensers Other Than LPG DispensersDinh Bac PhamNo ratings yet

- Guide For VesselDocument72 pagesGuide For VesselFlorin Daniel AnghelNo ratings yet

- MOU Part 8 July20Document56 pagesMOU Part 8 July20martin.rochardNo ratings yet

- Guide For VesselDocument41 pagesGuide For Vesseltutuionut100% (1)

- DatasheetDocument28 pagesDatasheetGastonNo ratings yet

- Supplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment S 561v2022 11Document46 pagesSupplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment S 561v2022 11maximusala83No ratings yet

- Aker BP Preservation-Procedure-4Document32 pagesAker BP Preservation-Procedure-4M SidinaNo ratings yet

- G1280-Z-MA-005 (Auto Generated From .Doc File) - G1280-Z-MA-005 - Rev 0 - Bulk SystemDocument27 pagesG1280-Z-MA-005 (Auto Generated From .Doc File) - G1280-Z-MA-005 - Rev 0 - Bulk Systemhumberto NascimentoNo ratings yet

- Jiskoot Hydraulic Power Pack UKDocument26 pagesJiskoot Hydraulic Power Pack UKsatishkumarkarri.skkNo ratings yet

- Wash Water Injection System in Hydropocessing Units For Mitigation of Fouling & CorrosionDocument27 pagesWash Water Injection System in Hydropocessing Units For Mitigation of Fouling & Corrosionjk.jackycheokNo ratings yet

- Nfxp4 TWJV SH PRC 00057 BDocument41 pagesNfxp4 TWJV SH PRC 00057 BAbdulhamit KAYYALINo ratings yet

- ES 403 - Portable Electrical Equipment Version 5Document24 pagesES 403 - Portable Electrical Equipment Version 5muhammad nomanNo ratings yet

- MOU Part 8 Jan22Document62 pagesMOU Part 8 Jan22Sujith Madatt ParambuNo ratings yet

- Separation and Purification Technologies in BiorefineriesFrom EverandSeparation and Purification Technologies in BiorefineriesShri RamaswamyNo ratings yet

- Operating Instructions Coding and Inspection Unit TQS-LM (Line Manager)Document94 pagesOperating Instructions Coding and Inspection Unit TQS-LM (Line Manager)BREWSKINo ratings yet

- OQ & PQ Medical DeviceDocument13 pagesOQ & PQ Medical DeviceBREWSKI100% (1)

- Process Validation and Revalidation in Medical Device ProductionDocument7 pagesProcess Validation and Revalidation in Medical Device ProductionBREWSKINo ratings yet

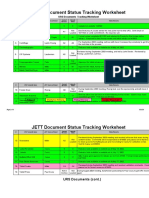

- JETT Document Status Tracking WorksheetDocument6 pagesJETT Document Status Tracking WorksheetBREWSKINo ratings yet

- URS Contents: Blank TemplateDocument11 pagesURS Contents: Blank TemplateBREWSKI100% (1)

- Jett Urs P P: Reparation RocessDocument7 pagesJett Urs P P: Reparation RocessBREWSKINo ratings yet

- NT - Akivision A CFRDocument60 pagesNT - Akivision A CFRBREWSKINo ratings yet

- Cleaning Validation StandardDocument14 pagesCleaning Validation StandardBREWSKINo ratings yet

- Whitepaper Serialisation 150127Document3 pagesWhitepaper Serialisation 150127BREWSKINo ratings yet

- Texwipe PDA Cleaning and Cleaning Validation Chapter19Document26 pagesTexwipe PDA Cleaning and Cleaning Validation Chapter19davincicode888100% (1)

- Change Control Risk AssessmentDocument1 pageChange Control Risk AssessmentBREWSKINo ratings yet

- fr2006 130409 BW PDFDocument94 pagesfr2006 130409 BW PDFBREWSKINo ratings yet

- Installation Qualification For Compressed Air SystemDocument15 pagesInstallation Qualification For Compressed Air SystemBREWSKI100% (2)

- Cleaning Validation Master Plan PDFDocument9 pagesCleaning Validation Master Plan PDFBREWSKINo ratings yet

- 14 Werum BR PAS-X TrackTrace enDocument2 pages14 Werum BR PAS-X TrackTrace enBREWSKINo ratings yet

- Operational Qualification For Compressed Air System.Document11 pagesOperational Qualification For Compressed Air System.BREWSKI50% (2)

- Chapter 5: Project Invoicing: ObjectivesDocument26 pagesChapter 5: Project Invoicing: ObjectivesKarthik ShriramneniNo ratings yet

- THE ROLE OF THE PROJECT MANAGER Assignment ID 242111Document9 pagesTHE ROLE OF THE PROJECT MANAGER Assignment ID 242111imesha pereraNo ratings yet

- AME Service Contract Approval 1456324.1Document10 pagesAME Service Contract Approval 1456324.1sreenivasNo ratings yet

- Quote Everything': Burning - Shearing - Sawing - DrillingDocument6 pagesQuote Everything': Burning - Shearing - Sawing - DrillingJimmy MyNo ratings yet

- ZDLRA - Optimized Backups-V10Document16 pagesZDLRA - Optimized Backups-V10Tran Quoc DungNo ratings yet

- Mohamed Sedik El-Sayed CVDocument3 pagesMohamed Sedik El-Sayed CVharshNo ratings yet

- MBA Syllabus 2022Document160 pagesMBA Syllabus 2022Trichy MaheshNo ratings yet

- Strategic Planning For Competitive AdvantageDocument45 pagesStrategic Planning For Competitive AdvantageSeema MohammedNo ratings yet

- CV Pablo Goldmann IDocument10 pagesCV Pablo Goldmann IPablo GoldmannNo ratings yet

- Shubham Resume FaureciaDocument2 pagesShubham Resume FaureciaShubham YadavNo ratings yet

- UNit-IV Business EnvironmentDocument19 pagesUNit-IV Business EnvironmentSOUMYA DEEP CHATTERJEENo ratings yet

- FY22 Activate Digital Selling - Partner Opportunity DeckDocument37 pagesFY22 Activate Digital Selling - Partner Opportunity DeckMaria Paula Cruz100% (1)

- Assignment Webpivot TableDocument4 pagesAssignment Webpivot TableAleeza AnjumNo ratings yet

- CRM Mba ProjectDocument93 pagesCRM Mba Projectravi singhNo ratings yet

- AUE2602 Lesson 2 2023Document22 pagesAUE2602 Lesson 2 2023Alestaire BrownNo ratings yet

- Matecconf Jcmme2018 02022Document7 pagesMatecconf Jcmme2018 02022amirhossein hosseiniNo ratings yet

- Employee Offboarding Checklist 1679881966Document4 pagesEmployee Offboarding Checklist 1679881966Novianti Alit RahayuNo ratings yet

- PayPal APIsDocument124 pagesPayPal APIsthiawNo ratings yet

- Brand IdentityDocument23 pagesBrand IdentityTanujaa HemakumarNo ratings yet

- Group 4 - M1 Assignment 1 Group (International Trade and Business) Sample CompanyDocument9 pagesGroup 4 - M1 Assignment 1 Group (International Trade and Business) Sample Companyxo xoNo ratings yet

- Hosek P 2015 PHD ThesisDocument122 pagesHosek P 2015 PHD ThesisRyan CookNo ratings yet

- International Journal of Information ManagementDocument16 pagesInternational Journal of Information ManagementdinaNo ratings yet

- Project Manager Cover Letter Template - Corporate ModernDocument2 pagesProject Manager Cover Letter Template - Corporate ModernCed Aimé Simo DzudieNo ratings yet

- QAharbor Limited - Engineer Augmentation - HishabeeDocument3 pagesQAharbor Limited - Engineer Augmentation - Hishabeeafarzam.lsdNo ratings yet

- SERVICE ORDER - SapDocument42 pagesSERVICE ORDER - Saprksapfc_61823862100% (1)

- CT026-3-2 Human Computer Interaction Incourse QuestionDocument7 pagesCT026-3-2 Human Computer Interaction Incourse Questionjames smithNo ratings yet

- Tvet Programme Title Autonotive Servicing Opration Management Level 4Document61 pagesTvet Programme Title Autonotive Servicing Opration Management Level 4enale endrisNo ratings yet

- The Fastest Growing in Bangladesh: Software CompanyDocument11 pagesThe Fastest Growing in Bangladesh: Software CompanyKowshik Shikder FNo ratings yet

U R T Foraw R L F: Ser Equirements Emplate Ide Ange Iquid Iller

U R T Foraw R L F: Ser Equirements Emplate Ide Ange Iquid Iller

Uploaded by

BREWSKIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U R T Foraw R L F: Ser Equirements Emplate Ide Ange Iquid Iller

U R T Foraw R L F: Ser Equirements Emplate Ide Ange Iquid Iller

Uploaded by

BREWSKICopyright:

Available Formats

USER REQUIREMENTS TEMPLATE

for a WIDE RANGE LIQUID FILLER

Page 1 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

TABLE OF CONTENTS

1 INTRODUCTION..................................................................................................................................4

2 OVERVIEW.........................................................................................................................................5

3 OPERATIONAL REQUIREMENTS................................................................................................5

3.1 FUNCTIONS................................................................................................................................. 5

3.1.1 Operation...................................................................................................................................5

VIAL SIZE....................................................................................................................................................6

NECK FINISH.............................................................................................................................................6

HEIGHT........................................................................................................................................................6

WIDTH..........................................................................................................................................................6

VIAL ID........................................................................................................................................................6

STOPPER ID................................................................................................................................................6

PLUG/ LYO..................................................................................................................................................6

RATE (V/MIN).............................................................................................................................................6

COMMENTS................................................................................................................................................6

3.1.2 Product Output..........................................................................................................................7

3.1.3 Product Contact Parts...............................................................................................................7

3.1.4 Power Failure and Recovery.....................................................................................................8

3.1.5 Emergency Stop.........................................................................................................................8

3.1.6 Alarms and Warnings................................................................................................................9

3.2 DATA & SECURITY................................................................................................................... 10

3.2.1 Interfaces.................................................................................................................................10

3.2.2 Interface with Supervisors.......................................................................................................11

3.2.3 Interface with Other Systems...................................................................................................11

3.2.4 Interface with Equipment.........................................................................................................12

3.2.5 Data Collection........................................................................................................................12

3.3 ENVIRONMENT.......................................................................................................................... 13

3.3.1 Layout......................................................................................................................................13

3.3.2 Physical Conditions.................................................................................................................13

4 CONSTRAINTS.................................................................................................................................14

4.1 MILESTONES AND TIMELINES.................................................................................................... 14

4.2 COMPATIBILITY........................................................................................................................ 15

4.2.1 PLC Controllers.......................................................................................................................15

4.2.2 Utilities....................................................................................................................................15

JOINT EQUIPMENT TRANSITION TEAM

Page 2 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

4.3 AVAILABILITY.......................................................................................................................... 16

4.4 PROCEDURAL CONSTRAINTS..................................................................................................... 16

4.5 MAINTENANCE.......................................................................................................................... 17

5 LIFE-CYCLE.....................................................................................................................................17

5.1 DEVELOPMENT.......................................................................................................................... 17

5.2 TESTING.................................................................................................................................... 18

5.3 DELIVERY................................................................................................................................. 18

5.3.1 Documentation.........................................................................................................................18

5.4 SUPPORT................................................................................................................................... 19

5.4.1 Start-up Support.......................................................................................................................19

5.4.2 Post Start-up Support..............................................................................................................19

6 GLOSSARY........................................................................................................................................20

7 REFERENCES...................................................................................................................................20

8 APPROVAL........................................................................................................................................20

JOINT EQUIPMENT TRANSITION TEAM

Page 3 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

REVISION HISTORY

Rev. Date Approval Revision Summary

A1 12/21/00 TGP Initial Draft

A2 1/16/01 TGP Incorporated comments from JETT Group and Gary Pardekooper

A2 2/5/01 TGP Incorporated comments from JETT meeting of 1/24/01

A3 3/13/01 TGP Moved notes to second page, modified procedural constraints as

requested from JETT meeting on 2/15/01

B1 7/16/02 TGP Changes from validation review of 1/17/02

C1 04/17/03 MRR Format Review

JOINT EQUIPMENT TRANSITION TEAM

Page 4 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

Project No.: Wide Range Filler #1234

Document No.: 8111234567

Document Description: Wide Range Filler User Requirements Specification

1 INTRODUCTION

This document was generated under the authority of the ___________________ Company for the

purpose of specifying the user requirement for a wide range filler that will fill, sample checkweigh

and stopper a wide range of vial sizes in a pharmaceutical environment. The User Requirements

Specification (URS) is provided to aid the user through the important components, variables and

options necessary to procure a functional filling stoppering system that meets the users needs in the

most cost-effective method possible. The URS is then provided to the Supplier to provide a price

quote for the wide range filler supply including the design and manufacture of the equipment.

This URS will be recognized as an integral part of the procurement agreement with the selected

equipment vendor. The equipment supplier or vendor will abide by the information and conditions

set forth by this document as well as the standard purchasing term and conditions of the

____________________ Company.

The wide range filler will be interfaced to the output of a depyrogenation tunnel, and will be located

in a designated operating area within a cGMP packaging operation.

An equipment validation plan has been developed to outline the planned tasks and expectations for

validation of the wide range filler. This plan has been included as Attachment _____. The

equipment supplier or vendor has specific responsibilities as outlined by the Validation Plan and this

document.

JOINT EQUIPMENT TRANSITION TEAM

Page 5 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

2 OVERVIEW

The wide range liquid filler shall process pharmaceutical vials under sanitary conditions with the

following functions:

Vial Filling

Vial Stoppering

Oxygen Reduction

Sample Checkweighing

Vial Eject

Other (specify):

3 OPERATIONAL REQUIREMENTS

3.1 Functions

3.1.1 Operation

The wide range filler is expected to satisfactorily fill and stopper vials at

production speeds up to and including ______________ vials per minute.

Satisfactory performance is defined by the following criteria:

3.1.1.1 Sterilized vials are to be run through the wide range filler without

becoming contaminated, disoriented, marred, scratched, broken or

otherwise damaged in the process. Properly filled vials are defined as

those possessing the desired dose (+/- _____% by weight) with a

properly seated stopper. Specifically, the rejection rate caused by the

wide range filler must not exceed ______ % during any given

production run.

3.1.1.2 The machine shall not experience more than _____ % downtime at

production speeds up to and including the ______ vials per rate

specified, during an eight hour production run.

3.1.1.3 The vial eject system must be 100% reliable. It must eject all rejected

vials, and not eject acceptable vials.

JOINT EQUIPMENT TRANSITION TEAM

Page 6 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

3.1.1.4 The machine changeover between vial sizes by a single operator is

expected to take no longer than ____ minutes from the last vial out of

the prior run to the first vial out of the next run.

3.1.1.5 Commodity Table

Vial Neck Vial Stopper Plug/ Rate

Height Width Comments

Size Finish ID ID Lyo (V/Min)

3.1.1.6 Vial Handling

The wide range filler shall transfer, fill, checkweigh and stopper

pharmaceutical grade glass or plastic vials at the rates defined in the

commodity table:

The wide range filler shall be operable by one person, with safety

related faults stopping the machine immediately. The machine shall not

be allowed to restart without operator intervention.

3.1.1.7 Vial filling

The wide range filler shall fill vials with

__________________________product that has a specific gravity of

_________________ to an accuracy of +/- __________%. The product

has _______________________________________ foaming

tendencies.

JOINT EQUIPMENT TRANSITION TEAM

Page 7 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

3.1.1.8 Oxygen Reduction

The wide range filler will reduce the levels of oxygen in the headspace

of the vial to __________%, as measured using sparged WFI for a

product. The Oxygen Reduction System must be selectable to allow

flow of nitrogen to the vial only for products that are oxygen sensitive.

3.1.1.9 Stoppering

The wide range filler shall stopper vials with stoppers listed, and at the

rate defined in the commodity table. Silicone treatment of stoppers

being placed is defined as_______________

__________________________________________________________

______________________

3.1.1.10 Checkweighing

The wide range filler shall sample checkweigh vials prior to filling

(tare) and after filling (gross). The weight accuracy shall be +/-

__________% of fill weight. The sampling frequency shall be

__________ weighs/minute.

3.1.1.11 Vial Eject

The wide range filler shall eject all vials that are faulty due to

__________________________________________________________

__________________________________________________________

Vials shall be removable from the filler for manual sampling.

3.1.2 Product Output

The wide range filler shall have a machine efficiency rate of ________ %, as

measured by the actual number of good vials filled and stoppered during a one

hour test run, divided by the calculated number at the rate defined in the vial

commodity table. Machine efficiency rate excludes downtime due to faulty

commodities or supply issues.

3.1.3 Product Contact Parts

All product contact parts shall be constructed from materials acceptable to the

product and sterility assurance methods. Certificates for material, weld and finish

shall be provided.

JOINT EQUIPMENT TRANSITION TEAM

Page 8 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

3.1.4 Power Failure and Recovery

On power failure, the system shall fail into a “safe state.” On power restoration,

the system shall not restart without operator or communication-link input.

All equipment shall be designed to retain the PLC program in case of power loss,

and be able to recover with minimal operator actions.

A “safe state” shall be defined as:

All motion stopped on the machine

Reset required before machine can be restarted

No damage to machine will occur as a result of going to the safe state.

3.1.5 Emergency Stop

Emergency-stop buttons shall be supplied within the reach of the operator at

normal operator stations. When activated, the emergency stop shall shut the

system down immediately in accordance with the following requirements:

No damage to the machine will occur as a result of an emergency stop.

Emergency stop will seal product path or take actions to prevent product

contamination if so equipped.

The machine shall not be allowed to restart without operator intervention. It shall

be necessary to restore the emergency stop button to the original state, and reset the

system before restarting.

JOINT EQUIPMENT TRANSITION TEAM

Page 9 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

3.1.6 Alarms and Warnings

The wide range filler shall be equipped with the following alarms and warnings:

Cycle Operate

Alarm Or Warning Immediate*

Stop** Alert***

PLC Battery Low X

Emergency Stop X

Machine Overtorque X

No Vials X

Stopper Hopper Low X

No Stoppers X

Missing Stoppers X

Low Air Pressure X

High Stoppers X

Output Full X

Checkweigh Low Alarm X

Checkweigh Low Alert X

Checkweigh High Alert X

Checkweigh High Alarm X

* “Immediate alarms” shall take action immediately to stop the wide range filler. The operator

shall be required to acknowledge the alarm before the alarm can be reset and the machine

restarted.

** “Cycle-Stop alarms” shall take action at the end of a fill cycle to stop the wide range filler. The

operator shall be required to acknowledge the alarm before the alarm can be reset and the machine

restarted.

JOINT EQUIPMENT TRANSITION TEAM

Page 10 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

*** “Operator Alert” allows the machine to continue to run, but provides an “alert” message to be

displayed on the operator screen. The operator shall be required to acknowledge the alert in order

to remove the warning message form the operator screen.

3.2 Data & Security

3.2.1 Controls provided with a data collection systems intended for use in the

manufacture of pharmaceutical products shall comply with 21 CFR, Part 11 of the

FDA cGMP regulations or _______________ Company policy and procedure.

The supplier shall stipulate the methods by which this criterion is met.

3.2.2 Interfaces

The Programmable Logic Controller / Operator-Interface Panel system (hereafter

referred to as the “PLC/OIP system”) shall include interfaces with the Operator,

Supervisors, external equipment, and the User’s control system to ensure safe,

reliable, continuous, and automatic operation and easy, safe, and reliable

configuration.

3.2.2.1 Interface with Operators

The PLC/OIP system shall include interfaces with the Operator that ensures

easy, safe, and reliable operation.

An operator-interface panel shall be provided and mounted on the machine.

This panel shall provide the necessary switches, indicators, and devices to

operate the wide range filler. The following shall be displayed:

Machine Drive Controls

Vial Transfer Controls

Filling Controls

Checkweigh Controls

Stoppering Controls

Eject Controls

Utility Controls

Alarms and Warnings.

System Status (e.g., “ready,” “running,” etc.).

Other (specify).

JOINT EQUIPMENT TRANSITION TEAM

Page 11 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

3.2.3 Interface with Supervisors

The PLC/OIP system shall provide supervisory access to specific functions to

ensure easy, safe, and reliable configuration of the wide range filler. The following

shall be accessible only to Supervisors:

Fill Volume Adjustment

Checkweigh Alarm and Alert Settings

Vial Counter Reset

Alarm Settings.

Other (specify).

3.2.4 Interface with Other Systems

Access to all Input/Output values and system status bits by an external computer

system(s) shall be provided through a data-communication link to the PLC and/or

PLC/OIP. Security for data and operator access is provided by ______________.

List the application that provides security functions to the system, either internal

via the local OIP or external via a SCADA system, etc.

The PLC/OIP system shall include interfaces with the User’s control system to

facilitate recipe download and configuration.

The port shall be configured to communicate the following data to a supervisory

control and data acquisition (SCADA) node (Note: the SCADA system shall be

supplied and installed by the User):

Machine Rate

Vial Count

Checkweigh Data

Alarms and Warnings.

System Status (e.g. “off,” “ on,” “standby” states, etc.).

Other (specify).

3.2.5 Interface with Equipment

The PLC/OIP system may include interfaces with external equipment to ensure

safe, continuous transfer of vials without operator intervention.

JOINT EQUIPMENT TRANSITION TEAM

Page 12 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

3.2.6 Data Collection

3.2.6.1 Data required for collection

Machine Rate

Vial Count

Checkweigh Data

Alarms and Warnings.

System Status (e.g. “off,” “ on,” “standby” states, etc.).

Other (specify).

3.2.6.2 Data Collection and Storage Requirements

None

3.3 Environment

3.3.1 Layout

Allocated floor space for the wide range filler is _______ inches wide by ________

inches deep with a 24 inch corridor around the periphery of the machine.

Vertical clearance is _________ inches.

See attached drawing #________________________ (if applicable).

3.3.2 Physical Conditions

The wide range filler shall be mounted in an environment with a temperature range

of ______ to ______ °Fahrenheit and non-condensing humidity.

JOINT EQUIPMENT TRANSITION TEAM

Page 13 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

Vibration levels are:

Negligible.

Other (specify).

Electromagnetic interference levels are:

Negligible.

Other (specify).

This area is intended for the following use:

Class 100 Cleanroom.

Other (specify).

4 CONSTRAINTS

4.1 Milestones and Timelines

The Supplier shall provide a written proposal within _______ weeks of receipt of this

document at the Supplier’s local office.

The Supplier shall provide a Functional and Design Specifications within ________ weeks

of receipt of the purchase order.

The User shall review, comment and/or approve, and return the Functional and Design

Specification to the Supplier within _______ weeks of receipt from the Supplier.

The Supplier shall provide the Factory Acceptance Test Specification within _______

weeks of receipt of approved the Functional and Design Specification. The User shall

review, comment and/or approve, and return the test specifications to the Supplier within

_______ weeks of receipt from the Supplier.

The wide range filler shall be delivered to the User’s receiving dock on or before

_________________.

The Preferred Format Is:

Date written proposal/quote required:

Date purchase order will be placed by:

Functional and Design Specification delivery date:

Factory Acceptance Test Plan due for review:

Factory Acceptance Test Plan due for approval:

JOINT EQUIPMENT TRANSITION TEAM

Page 14 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

Date equipment is required on-site:

4.2 Compatibility

4.2.1 PLC Controllers

The Supplier shall utilize manufactured programmable logic

controllers that shall include a ___________________ communications port. The

Supplier shall provide documentation that the program (embedded software) was

developed and coded utilizing _______ program development and

documentation software.

The Supplier shall identify the impact of adhering to the attached Preferred

Manufacturers List.

4.2.2 Product Contact Parts

All product contact parts shall be constructed from materials acceptable to the

product and sterility assurance methods. Certificates for material, weld and finish

shall be provided.

4.2.3 Utilities

The User shall ensure that the following utilities are available and that the utility

supply lines and piping are terminated with fittings or connections, which are

compatible with those described on the Customer Connection Drawing.

The Supplier shall specify utility data, which is marked with an asterisk (“*”).

Utility requirements, which are not specified or marked with an asterisk, shall be

brought to the attention of the User. These requirements shall be approved by both

the User and the Supplier before system design begins.

4.2.3.1 “Primary” Conditions

Primary Electrical Service: _______ VAC, _______ amps, _______ ph, ______ Hz

Secondary Electrical Service: _______ VAC, _______ amps, _______ ph, ______ Hz

Instrument Air: _______ cfm @ _______ ± _____ psig (minimum: 2 cfm @ 80 psig).

Clean, Filtered Air: _______ cfm @ _______ ± _____ psig (minimum: .5 cfm @ 80 psig).

Nitrogen: _______ cfm @ _______ ± _____ psig (Minimum: 3 cfm @ 25 psig).

JOINT EQUIPMENT TRANSITION TEAM

Page 15 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

SIP Steam: _______ C @ ________ ± _____ psig (Minimum: 135C @ 30

psig).

4.3 Availability

The Wide Range Filler is intended to be operated:

Continuously

Regularly

_________ hours per day.

_________ hours per week.

Other (specify).

_________________________________________________________________________

_________________________________________________________________________

Operation of the wide range filler shall be shut down, and the machine shall be available

for maintenance or service:

_______ hours per week.

_______ continuous hours per week.

_______ days per month.

_______ weeks per year.

4.4 Procedural Constraints

The wide range shall be designed to meet the appropriate GMP regulations. e.g.: cGMP 21 CFR

part 210 and 211 as published at the time of order.

Controls for the wide range filler shall meet the appropriate electrical requirements. e.g.:

NFPA/NEC 70 and 79 for industrial machinery.

Control panels for the wide range filler shall meet the appropriate certifications. e.g.: Underwriters

Laboratories UL-508A certification for industrial equipment.

The wide range filler shall meet the appropriate safety regulations. e.g.: OSHA regulations for the

safety of operators of equipment with regards to safety, guarding and noise.

The wide range filler shall meet CE requirements if delivered to the European Community.

JOINT EQUIPMENT TRANSITION TEAM

Page 16 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

All piping welds shall meet the appropriate piping regulations. e.g.: ASME and 3A specification

requirements.

Other standards are attached. The Supplier shall adhere to the indicated sections only.

Installation, operation, and maintenance instruction documentation for the system shall be

developed to a level that is comprehensible by a high school graduate.

JOINT EQUIPMENT TRANSITION TEAM

Page 17 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

4.5 Maintenance

4.5.1 The vial washer shall be maintained on a schedule as indicated by the supplier. Supplier is to

provide (at minimum) the following maintenance instructions.

4.5.1.1 Maintenance activities for all sub-systems (maintenance and operation manuals of vendor

equipment).

4.5.1.2 A comprehensive lubrication list and recommended lubrication schedule.

4.5.1.3 A comprehensive recommended maintenance (regular recommended inspection intervals, wear

points, recommended spare parts list)

4.5.1.4 Supplier shall supply ________ copies of operation, installation, maintenance and de-

commissioning manuals.

5 LIFE-CYCLE

5.1 Development

The Supplier shall provide a Quality and Project Plan as part of its proposal. The Supplier shall

have a quality system in place. Internal quality procedures shall be available for the User’s review.

The Supplier shall provide a Project Manager for the project to provide a single communication

point with the User.

The project shall utilize the GAMP methodology when developing the system and documentation.

5.2 Testing

In order to verify machine performance, the User shall witness the execution of the approved

Factory Acceptance Test procedures. The Supplier shall notify the User _______ weeks in advance

of the start of this test.

5.3 Delivery

The wide range filler, with all options, equipment, and the documentation listed below, shall be

delivered to the User’s receiving dock.

5.3.1 Documentation

JOINT EQUIPMENT TRANSITION TEAM

Page 18 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

The Supplier shall use the formats described in the current version of the GAMP Supplier Guide to

produce the documentation. The Supplier shall provide the documentation for preliminary review.

The Supplier shall provide documentation reflecting “as-built” condition with final delivery.

All final documents shall be shipped with transmittals that identify them as contractually required

documents. All final documents and drawings shall reflect “as-built” condition.

All documents shall be in the language of the destination country, and supplied with hard copies

and electronic versions supplied in the format identified for each document:

Project Plan

User Requirements Specification

Functional Specification

Design Specification

Software Module Test

Software Integration Test

Controls Test

Hardware Installation Test

Operational Test

Factory Acceptance Test

Operator, Maintenance and Service Manuals

Process and Instrumentation Diagram (P&ID)

Instrument Listing

Control Schematics

Control Panel Assembly Drawings

Machine Assembly Drawings

Bill of Materials

Spare Parts List

Component Cut Sheets

PLC Program Printout and Disk File

JOINT EQUIPMENT TRANSITION TEAM

Page 19 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

OIP Configuration Printout and Disk File

5.4 Support

5.4.1 Start-up Support

5.4.1.1 Start-up support shall consist of ______ weeks of full time assistance on the User’s site for

rigging, installation, start-up and commissioning.

5.4.2 Training

5.4.2.1 User training shall consist of ______ hours of Operator training and _______ hours of

Maintenance training.

5.4.3 Post Start-up Support

5.4.3.1 Post start-up support shall consist of monthly User site visits for a period of _____ years after the

completion of commissioning activities.

5.4.4 Technical Support

5.4.4.1 Technical support shall be provided via telephone for a period of _____ years following the

completion of commissioning.

5.4.4.2 A recommended replacement parts list including normal lead times shall be provided for the

machine and all sub-assemblies.

5.4.5 User Site Support

5.4.5.1 The Supplier shall notify the User of preventative maintenance system improvement availability.

6 GLOSSARY

Table 6.0 Glossary

Acronym Definition

C Degrees Celsius

JOINT EQUIPMENT TRANSITION TEAM

Page 20 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

BL Biohazard Level

CFR Code of Federal Regulations

DB Decibels

EMI Electro-Magnetic Interference

M Meter

GUI Graphic User Interface

HMI Human – Machine Interface

HVAC Heating, Ventilation, and Air Conditioning

ISO International Organization for Standardization

JETT Joint Equipment Transition Team

LEL Lower Explosion Limit

OIP Operator Interface Panel

RFI Radio Frequency Interference

URS User Requirement Specification

JOINT EQUIPMENT TRANSITION TEAM

Page 21 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

7 REFERENCES

Table 7.0 References

Document Attached to URS (Yes / No)

Equipment Validation Plan

Current revision of GAMP Guidelines

Vendor Piping Certification (if applicable)

Customer Connection Diagram

Approved Instrumentation List

Process Flow Diagram

21 CFR Part 11

National Electric Code

JOINT EQUIPMENT TRANSITION TEAM

Page 22 of 24

USER REQUIREMENTS SPECIFICATION Doc ID: Wide Range Liquid Filler

JETT Wide Range Liquid Filler Rev. 0

August 2005

8 APPROVAL

This document has been reviewed by the User Project Manager and approved for

use by the Supplier.

Printed/Typed Name Signature Date

This document has been reviewed by the User Quality Assurance Group and

approved for use by the Supplier.

Printed/Typed Name Signature Date

This document has been reviewed by the Supplier Project Manager and approved

for use by the Supplier Project Team.

Printed/Typed Name Signature Date

JOINT EQUIPMENT TRANSITION TEAM

You might also like

- DNV-RU-SHIP Pt.2 Ch.4. (2022.07) - Ship Hull WeldsDocument144 pagesDNV-RU-SHIP Pt.2 Ch.4. (2022.07) - Ship Hull Weldsnanotech123No ratings yet

- RFCC PDFDocument324 pagesRFCC PDFMohamed AdelNo ratings yet

- Label Er UrsDocument42 pagesLabel Er UrsMr Thanh100% (1)

- DNV RU SHIP Pt2Ch4Document144 pagesDNV RU SHIP Pt2Ch4Rahul KamillaNo ratings yet

- ITAP3012 Developing Web Applications Tutorial - 12: Prabhjot Singh Grewal-47294Document7 pagesITAP3012 Developing Web Applications Tutorial - 12: Prabhjot Singh Grewal-47294FarhanAshrafNo ratings yet

- BP Guide To Valve SelectionDocument156 pagesBP Guide To Valve Selectionjemorpe100% (4)

- Production Riser Life Extension: Guidance Notes OnDocument24 pagesProduction Riser Life Extension: Guidance Notes OnGopalakrishnanNo ratings yet

- SER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperDocument26 pagesSER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperBREWSKINo ratings yet

- SER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperDocument26 pagesSER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperBREWSKINo ratings yet

- Sap Basis Syllabus PDFDocument4 pagesSap Basis Syllabus PDFmpsing11330% (1)

- SER Equirements Emplate IAL Asher: Vial WasherDocument22 pagesSER Equirements Emplate IAL Asher: Vial Washermehdi ershadiNo ratings yet

- URS Saya Isi Halaman 1-16Document33 pagesURS Saya Isi Halaman 1-16Yonas SinsengNo ratings yet

- Rp62-1 - Guide To Valve SelectionDocument145 pagesRp62-1 - Guide To Valve Selectionkamal arab100% (1)

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAINo ratings yet

- Water Source Injection and Disposal Service Wells Summary November Release 2014Document20 pagesWater Source Injection and Disposal Service Wells Summary November Release 2014Satria 'igin' Girindra NugrahaNo ratings yet

- 28 Hail Te010 0002 R3Document50 pages28 Hail Te010 0002 R3Parthasarathy TNo ratings yet

- Specification - Hvac Central Station Air Handling UnitsDocument21 pagesSpecification - Hvac Central Station Air Handling UnitsJaseelKanhirathinkalNo ratings yet

- The Water Transmission CodeDocument62 pagesThe Water Transmission CodeSantosh Kumar PandeyNo ratings yet

- MQ SP H 4702 PDFDocument20 pagesMQ SP H 4702 PDFShamimNo ratings yet

- Specification - Hvac Design CriteriaDocument34 pagesSpecification - Hvac Design CriteriaShamimNo ratings yet

- BP RP62-1 ValvesDocument155 pagesBP RP62-1 ValvesMohd Khairul100% (1)

- NHT UnitDocument197 pagesNHT Unitsathya perumal100% (3)

- Autoclave URSDocument28 pagesAutoclave URSShejil BalakrishnanNo ratings yet

- DNV RU UWT Pt7Document29 pagesDNV RU UWT Pt7lijinNo ratings yet

- Minibooster Hc6d2w Operations and MaintenanceDocument70 pagesMinibooster Hc6d2w Operations and MaintenanceAlessandro Carneiro de AraujoNo ratings yet

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAI100% (1)

- Specification - Hvac Air Cooled Condensing UnitsDocument15 pagesSpecification - Hvac Air Cooled Condensing UnitsJaseelKanhirathinkalNo ratings yet

- DIO 01.5a. Pregledi Postojećih Brodova July 2020Document217 pagesDIO 01.5a. Pregledi Postojećih Brodova July 2020Samo SpontanostNo ratings yet

- DNV Ru Ship Pt1ch1Document48 pagesDNV Ru Ship Pt1ch1programmer dhruv KumarNo ratings yet

- 4251-RA-00379913 - D - 01 - Regulatory Compliance PlanDocument42 pages4251-RA-00379913 - D - 01 - Regulatory Compliance Plansivaguruswamy thangaraj100% (1)

- DG Pse 0104 PDFDocument24 pagesDG Pse 0104 PDFErika Caicedo100% (1)

- English 12 / 2012: SpecificationDocument40 pagesEnglish 12 / 2012: SpecificationmarceloNo ratings yet

- Qra Version FDocument60 pagesQra Version Fbukaro85No ratings yet

- Guide To Valve Selection1 (BP) PDFDocument152 pagesGuide To Valve Selection1 (BP) PDFmadihanaz84No ratings yet

- MQ SP I 7020Document74 pagesMQ SP I 7020jaseel kNo ratings yet

- Pdo SP 1211Document71 pagesPdo SP 1211MuddasarNo ratings yet

- 8384-2602-SQ-0720 B1 Spec Welding and NDTDocument100 pages8384-2602-SQ-0720 B1 Spec Welding and NDTHướng PhạmNo ratings yet

- Disposal and Injection Well Requirements: Directive PNG008Document24 pagesDisposal and Injection Well Requirements: Directive PNG008arispriyatmonoNo ratings yet

- Disposal Requirements Volume1Document9 pagesDisposal Requirements Volume1mcemce100% (1)

- MQ SP I 7027 PDFDocument19 pagesMQ SP I 7027 PDFJaseelKanhirathinkalNo ratings yet

- Gis 46 020 - ADocument71 pagesGis 46 020 - Amulldoctor1No ratings yet

- Validation Plan TemplateDocument22 pagesValidation Plan TemplateBlank BacktobasicNo ratings yet

- HT-400 Fluid End Onshore, Facility and Offshore InspectionDocument21 pagesHT-400 Fluid End Onshore, Facility and Offshore InspectionFrancisco javierNo ratings yet

- Construction Monitoring CM Procedure November 2022Document33 pagesConstruction Monitoring CM Procedure November 2022leonghenry84No ratings yet

- DNV Ru Ship Pt4ch2Document56 pagesDNV Ru Ship Pt4ch2Ken VikstromNo ratings yet

- SP-1246 Part-1Document31 pagesSP-1246 Part-1Rajkumar ANo ratings yet

- 10 Survey Method StatementDocument44 pages10 Survey Method Statementali mehmetNo ratings yet

- Nitp 5.1 Fuel Dispensers Other Than LPG DispensersDocument19 pagesNitp 5.1 Fuel Dispensers Other Than LPG DispensersDinh Bac PhamNo ratings yet

- Guide For VesselDocument72 pagesGuide For VesselFlorin Daniel AnghelNo ratings yet

- MOU Part 8 July20Document56 pagesMOU Part 8 July20martin.rochardNo ratings yet

- Guide For VesselDocument41 pagesGuide For Vesseltutuionut100% (1)

- DatasheetDocument28 pagesDatasheetGastonNo ratings yet

- Supplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment S 561v2022 11Document46 pagesSupplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment S 561v2022 11maximusala83No ratings yet

- Aker BP Preservation-Procedure-4Document32 pagesAker BP Preservation-Procedure-4M SidinaNo ratings yet

- G1280-Z-MA-005 (Auto Generated From .Doc File) - G1280-Z-MA-005 - Rev 0 - Bulk SystemDocument27 pagesG1280-Z-MA-005 (Auto Generated From .Doc File) - G1280-Z-MA-005 - Rev 0 - Bulk Systemhumberto NascimentoNo ratings yet

- Jiskoot Hydraulic Power Pack UKDocument26 pagesJiskoot Hydraulic Power Pack UKsatishkumarkarri.skkNo ratings yet

- Wash Water Injection System in Hydropocessing Units For Mitigation of Fouling & CorrosionDocument27 pagesWash Water Injection System in Hydropocessing Units For Mitigation of Fouling & Corrosionjk.jackycheokNo ratings yet

- Nfxp4 TWJV SH PRC 00057 BDocument41 pagesNfxp4 TWJV SH PRC 00057 BAbdulhamit KAYYALINo ratings yet

- ES 403 - Portable Electrical Equipment Version 5Document24 pagesES 403 - Portable Electrical Equipment Version 5muhammad nomanNo ratings yet

- MOU Part 8 Jan22Document62 pagesMOU Part 8 Jan22Sujith Madatt ParambuNo ratings yet

- Separation and Purification Technologies in BiorefineriesFrom EverandSeparation and Purification Technologies in BiorefineriesShri RamaswamyNo ratings yet

- Operating Instructions Coding and Inspection Unit TQS-LM (Line Manager)Document94 pagesOperating Instructions Coding and Inspection Unit TQS-LM (Line Manager)BREWSKINo ratings yet

- OQ & PQ Medical DeviceDocument13 pagesOQ & PQ Medical DeviceBREWSKI100% (1)

- Process Validation and Revalidation in Medical Device ProductionDocument7 pagesProcess Validation and Revalidation in Medical Device ProductionBREWSKINo ratings yet

- JETT Document Status Tracking WorksheetDocument6 pagesJETT Document Status Tracking WorksheetBREWSKINo ratings yet

- URS Contents: Blank TemplateDocument11 pagesURS Contents: Blank TemplateBREWSKI100% (1)

- Jett Urs P P: Reparation RocessDocument7 pagesJett Urs P P: Reparation RocessBREWSKINo ratings yet

- NT - Akivision A CFRDocument60 pagesNT - Akivision A CFRBREWSKINo ratings yet

- Cleaning Validation StandardDocument14 pagesCleaning Validation StandardBREWSKINo ratings yet

- Whitepaper Serialisation 150127Document3 pagesWhitepaper Serialisation 150127BREWSKINo ratings yet

- Texwipe PDA Cleaning and Cleaning Validation Chapter19Document26 pagesTexwipe PDA Cleaning and Cleaning Validation Chapter19davincicode888100% (1)

- Change Control Risk AssessmentDocument1 pageChange Control Risk AssessmentBREWSKINo ratings yet

- fr2006 130409 BW PDFDocument94 pagesfr2006 130409 BW PDFBREWSKINo ratings yet

- Installation Qualification For Compressed Air SystemDocument15 pagesInstallation Qualification For Compressed Air SystemBREWSKI100% (2)

- Cleaning Validation Master Plan PDFDocument9 pagesCleaning Validation Master Plan PDFBREWSKINo ratings yet

- 14 Werum BR PAS-X TrackTrace enDocument2 pages14 Werum BR PAS-X TrackTrace enBREWSKINo ratings yet

- Operational Qualification For Compressed Air System.Document11 pagesOperational Qualification For Compressed Air System.BREWSKI50% (2)

- Chapter 5: Project Invoicing: ObjectivesDocument26 pagesChapter 5: Project Invoicing: ObjectivesKarthik ShriramneniNo ratings yet

- THE ROLE OF THE PROJECT MANAGER Assignment ID 242111Document9 pagesTHE ROLE OF THE PROJECT MANAGER Assignment ID 242111imesha pereraNo ratings yet

- AME Service Contract Approval 1456324.1Document10 pagesAME Service Contract Approval 1456324.1sreenivasNo ratings yet

- Quote Everything': Burning - Shearing - Sawing - DrillingDocument6 pagesQuote Everything': Burning - Shearing - Sawing - DrillingJimmy MyNo ratings yet

- ZDLRA - Optimized Backups-V10Document16 pagesZDLRA - Optimized Backups-V10Tran Quoc DungNo ratings yet

- Mohamed Sedik El-Sayed CVDocument3 pagesMohamed Sedik El-Sayed CVharshNo ratings yet

- MBA Syllabus 2022Document160 pagesMBA Syllabus 2022Trichy MaheshNo ratings yet

- Strategic Planning For Competitive AdvantageDocument45 pagesStrategic Planning For Competitive AdvantageSeema MohammedNo ratings yet

- CV Pablo Goldmann IDocument10 pagesCV Pablo Goldmann IPablo GoldmannNo ratings yet

- Shubham Resume FaureciaDocument2 pagesShubham Resume FaureciaShubham YadavNo ratings yet

- UNit-IV Business EnvironmentDocument19 pagesUNit-IV Business EnvironmentSOUMYA DEEP CHATTERJEENo ratings yet

- FY22 Activate Digital Selling - Partner Opportunity DeckDocument37 pagesFY22 Activate Digital Selling - Partner Opportunity DeckMaria Paula Cruz100% (1)

- Assignment Webpivot TableDocument4 pagesAssignment Webpivot TableAleeza AnjumNo ratings yet

- CRM Mba ProjectDocument93 pagesCRM Mba Projectravi singhNo ratings yet

- AUE2602 Lesson 2 2023Document22 pagesAUE2602 Lesson 2 2023Alestaire BrownNo ratings yet

- Matecconf Jcmme2018 02022Document7 pagesMatecconf Jcmme2018 02022amirhossein hosseiniNo ratings yet

- Employee Offboarding Checklist 1679881966Document4 pagesEmployee Offboarding Checklist 1679881966Novianti Alit RahayuNo ratings yet

- PayPal APIsDocument124 pagesPayPal APIsthiawNo ratings yet

- Brand IdentityDocument23 pagesBrand IdentityTanujaa HemakumarNo ratings yet

- Group 4 - M1 Assignment 1 Group (International Trade and Business) Sample CompanyDocument9 pagesGroup 4 - M1 Assignment 1 Group (International Trade and Business) Sample Companyxo xoNo ratings yet

- Hosek P 2015 PHD ThesisDocument122 pagesHosek P 2015 PHD ThesisRyan CookNo ratings yet

- International Journal of Information ManagementDocument16 pagesInternational Journal of Information ManagementdinaNo ratings yet

- Project Manager Cover Letter Template - Corporate ModernDocument2 pagesProject Manager Cover Letter Template - Corporate ModernCed Aimé Simo DzudieNo ratings yet

- QAharbor Limited - Engineer Augmentation - HishabeeDocument3 pagesQAharbor Limited - Engineer Augmentation - Hishabeeafarzam.lsdNo ratings yet

- SERVICE ORDER - SapDocument42 pagesSERVICE ORDER - Saprksapfc_61823862100% (1)

- CT026-3-2 Human Computer Interaction Incourse QuestionDocument7 pagesCT026-3-2 Human Computer Interaction Incourse Questionjames smithNo ratings yet

- Tvet Programme Title Autonotive Servicing Opration Management Level 4Document61 pagesTvet Programme Title Autonotive Servicing Opration Management Level 4enale endrisNo ratings yet

- The Fastest Growing in Bangladesh: Software CompanyDocument11 pagesThe Fastest Growing in Bangladesh: Software CompanyKowshik Shikder FNo ratings yet