Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

karthi51289Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

karthi51289Copyright:

Available Formats

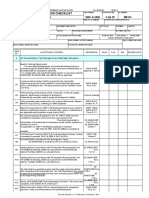

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure - Hot Tap & Stopple Connection Installation

SAIC-L-2090 30-Apr-17 MECH-

(Per SAEP-311, 13 September 2009)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIM

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIR

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DA

No.

A General Requirements (See Notes 1, 2, 3)

Each Hot Tap & Stopple Connection Installation is Controlled from the design

phase through Completion utilizing the following requirements:

A) Latest Edition of SAEP-311 (Install. of Hot Tapped & Stopple Conns)

SAEP-311

A1 B) Materials are per latest approved edition of 02-SAMSS-006.

(Procedure)

Procedure details design package content

per SAEP-311. Procedure shall be approved prior to the

start of work by SA.

Procedure follows the sequence of operations outlined in SAEP-311 for HOT TAP

SAEP-311

A2 INSTALLATION for welded connections to pipe, pressure vessels and tanks while

(Procedure)

in service. See Attachment 1.

Procedure follows sequence of operations outlined in SAEP-311 for PLUGGING

SAEP-311

A3 PIPELINES THROUGH HOT TAPPED CONNECTIONS (ALSO KNOWN AS

(Procedure)

STOPPLING). See Attachment 1.

Procedure States*: Hot tapping & stoppling are complex operations to be

performed by trained techs with support of experienced engineers. SAEP-311,

A4

Only skilled welders and fitters Section 1

with experience in Hot Tap Activities shall be utilized for Hot Tap work.

Procedure States: Personnel responsible for work are fully trained in use of

SAEP-311,

A5 procedure & shall be carefully supervised by experienced Engineers &

Section 1

Construction Supervisors during execution of HOT Work

Procedure references & has Attached the following Forms:

SAEP-311,

A6 See Attachment 1 for a complete list of Latest

Appendix A

Forms Req'd

Procedure Definitions Include the following per SAEP-311:

Stopple: A stopple is an articulated pipe

plugging device, normally inserted through a stopple split tee with a full line size

hot tapped opening, while the line is pressurized. Saudi Aramco has stoppling

equipment for pipe sizes from 1" to 60". Stopple Split Tee:

A stopple split tee is a fitting designed with dimensional requirements to suit the SAEP-311,

A7 stopple plugging head. These fittings shall be purchased in accordance with 02- Section 4

SAMSS-006. Sandwich Valve: This is a gate valve (Definitions)

designed to have a short face to face dimension used as a temporary valve for

stoppling. They are also used for hot tapping when the connection will only be used

temporarily or when the reach of the hot tap machine is insufficient to complete a

hot tap through a conventional valve. These valves cannot be operated unless the

pressure is equalized across the gate..

Saudi Aramco: Company General Use

Hot Tap: Hot tapping is technique, performed using specialized equipment for

cutting a hole in a pipe or tank through a welded or bolted branch connection while

they are under pressure.. Lock-o-Ring Flange and Plug:

This is a special flange and plug assembly designed to allow the recovery of the

SAEP-311,

hot tap valve while the pipeline is under pressure. The L-o-R plug has an o-ring

A8 Section 4

seal on its circumference and can be lowered into the bore of the L-o-R flange,

(Definitions)

using a hot tap machine. The L-o-R flange has retractable segments that can be

advanced into a groove in the circumference of the plug above the o-ring. These

segments retain the plug in position so that the valve can be depressurized and

removed and replaced with a blind flange or permanent valve.

Saudi Aramco: Company General Use

R NUMBER

NTRACTOR

PLANT NO.

MCC / MCC NO.

TRAVEL TIME

MCO USE ONLY

WORK PERMIT REQUIRED?

RE-INSP DATE

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure - Hot Tap & Stopple Connection Installation

SAIC-L-2090 30-Apr-17 MECH-

(Per SAEP-311, 13 September 2009)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DA

No.

B FIELD ENGINEERING & INSPECTION RESPONSIBILITIES (DESIGN, DOCUMENTATION & DRAWINGS)

Procedure details FIELD ENGINEER & INSPECTION RESPONSIBILITIES:

SAEP-311,

B1 A) Field Verification of Data for Calcs

Section 5

B) Inspection & Evaluation of Results

Procedure ensures Documentation of Design Pkgs & Work Activities includes docs SAEP-311,

B2

& drawings listed in Section 12. Section 12

Procedure ensures Pressure Testing & Inspection Section includes all the checks SAEP-311,

B3

and requirements listed in Section 14. Section 14

C STOPPLE SPECIFIC SAFETY MEASURES (SECTION 15)

SAEP-311,

C1

Para. 15.1.1

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure - Hot Tap & Stopple Connection Installation

SAIC-L-2090 30-Apr-17 MECH-

(Per SAEP-311, 13 September 2009)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DA

No.

SAEP-311,

C2

Para. 15.1.2

SAEP-311,

C3

Para. 15.1.3

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure - Hot Tap & Stopple Connection Installation

SAIC-L-2090 30-Apr-17 MECH-

(Per SAEP-311, 13 September 2009)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DA

No.

SAEP-311,

C4

Para. 15.1.4

SAEP-311,

C5

Para. 15.1.5

Stopples cannot be guaranteed to seal 100%. A small amount of

leakage should be expected and a secondary barrier with a bleed

SAEP-311,

C6 connection between the stopple and the secondary barrier should be

Para. 15.1.6

planned for. The secondary barrier could be a balloon and mud pack,

sealing scraper, mechanical plug or similar device.

D MATERIAL RECEIVING & MATERIAL REQMTS (PROCEDURE SPECIFIC) ... Utilize Checklist SAIC-L-2092 with this Section

Procedure ensures Materials Received meet 02-SAMSS-006 Requirements as SAEP-311,

D1

detailed in Attachment 4. See Also SAIC-L-2092. Section 13

Procedure has these elements & they are strictly followed.

1) Mat'ls are uniquely identified by Hot Tap/Tie-In number

2) Matl's are segregated after such ID (mark & organize)

3) Markings are low stress stamp (coating applications) 4) Sch. Q, Att

Matl's are stored & preserved after receipt. Valves that require Field Testing VI,Para-3-5

D2

are so tested and properly preserved. Coating of materials shall ensure no Tables & SAEP-

loss of traceability. 5) Matl's that 311 (Procedure)

require cutting & distribution into segments have id (by low stress stamp)

transferred before cutting. 6) Mixing of any

mat'ls is prevented by Quality Controls.

E DESIGN PACKAGE & DESIGN SPECIFICS (From Item A1) ... Note: Design Package "Content" is listed in Procedure.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure - Hot Tap & Stopple Connection Installation

SAIC-L-2090 30-Apr-17 MECH-

(Per SAEP-311, 13 September 2009)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DA

No.

Design Package: The initiating organization* shall prepare a design package for

each hot tap that will include fully dimensioned drawings, a materials list, Direct

SAEP-311,

E1 Charge Requisitions and welding procedures.

Para. 5.1

The design package shall be approved by Hot Tap Group.

SAPMT is the initiating Organization

Hot tap connections shall be designed for the Maximum Allowable Operating SAEP-311,

E2

Pressure for tapped equipment per applicable ASME code. Para. 9.1

The dimensions of the connection, the hot tap valve, and clearances shall be within

the limits specified for the hot tapping equipment to be used. Hot-Tap and Stopple SAEP-311,

E3

Unit should be contacted to provide this data prior to purchase of any fitting with an Para. 9.2

extended branch nipple.

The minimum valve bore shall be large enough to pass the cutter. The valve seat SAEP-311,

E4

lugs shall not restrict the opening. Para. 9.3

A tap equal to the nominal size of the header (such as required for stoppling of a

SAEP-311,

E5 pipeline) shall be made only when accurate positioning of the cutter can be

Para. 9.4

guaranteed.

In hot tap cases other than those for stoppling purposes, the cutter should be at SAEP-311,

E6

least one pipe size smaller than the pipe to be tapped. Para. 9.5

If the hot tap is to be used for stoppling the pipe, the hot tap crew shall take

measurements and mark the tapping location prior to welding of split tee to ensure

that the pipe out of roundness meets the tolerances in the following table:

SAEP-311,

E7

Para. 9.6

Adequate support of the hot tap machine shall be provided to prevent

SAEP-311,

E8 overstressing of the pipe and/or fitting, particularly in cases where the hot tap

Para. 9.7

sticker is not installed in a vertical position. Staging often req'd.

Storage Tanks: For atmospheric or low pressure hydrocarbon storage tanks, hot

tap connections shall be located at least 1 m (39 inches) below the liquid level

while welding or hot tapping is in progress.

SAEP-311,

E9 A) If the tank or vessel is in service during the welding or hot tapping

Para. 9.8

process, the operating organization must ensure that the liquid level

above the level of the weld or cut shall not be less than 1 meter.

B) Connections on tanks shall meet the requirements SAES-D-108.

F INSTALLATION & WELDING (HOT TAP & STOPPLE SAFEGUARDS & LIMITATIONS, ADDITIONAL DESIGN CHECKS)

Procedure ensures Restrictions are listed & steps are taken to assure that Work is SAEP-311,

F1

strictly controlled. Section 6

Procedure ensures Installation & Welding Section includes all the checks and SAEP-311,

F2

requirements per Section 13. Section 13

G Safety Requirements

SAEP-311,

G1 Procedure ensures Safety Requirements are identified and met.

Section 7

REMARKS: UPON AGREEMENT, THIS CHECKLIST & SAEP-311 in entirety may be used in lieu of a Procedure.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure - Hot Tap & Stopple Connection Installation

SAIC-L-2090 30-Apr-17 MECH-

(Per SAEP-311, 13 September 2009)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DA

No.

NOTES: 1. Copy and paste as much of checklist into finished procedure as possible. SAEP-311 = Procedure = This Checklist

2. June 3 2008 Version of SAEP-311 has been utilized & referenced here (Pipeline Safety). Utilize latest edition regardless of date (Safety).

3. Quality Managers shall ensure the correct and thorough development of procedures & Design Packages using this checklist.

4. SAES-L-052 is no longer utilized for Hot Taps. SAEP-311 is MANDATORY. SAEP-310 requirements may also be mandatory in the event

that damage assessment & Pressure Piping Considerations come into the picture due to Inspection Findings (HIC Damage, etc).

5. Utilize SATR-NDE-2007 for HOT TAP UT REPORT (Appendix A4). UT Results shall be *current. *Utilize 30-day rule in Procedure.

ATTACHMENT 1: SAEP-311, Appendix A (Applicable Forms)

Appendix A1 - UT Thickness Measurements

Appendix A2 - Hot Tap Reinforcement Data & Calculation Sheet (Form 7827-ENG) PG 1, 2 & 3

Appendix A3 - Hot Tap Data & Checklist (Form 7235)

Appendix A4 - Hot Tap & Stopple Measurements Form PG 1 & 2

REFERENCE DOCUMENTS:

1- SAEP-311 -- Installation of Hot Tapped & Stopple Connections, (01March 2013)

2- SAEP-310 -- Pipeline Repair and Maintenance (10 March 2012)

3- SAES-A-004 -- General requirements for Pressure Testing (30 Jan 2011)

4- SAES-D-008 -- Repairs, Alterations, and Re-rating of Pressured Equipment 30 June 2014.

5-SAES-W-010 -- Welding Requirements for Pressure Vessels 08 September 2012.

6-SAES-W-011 -- Welding Requirements for On-Plot Piping (16 December 2013)

7-SAES-W-012 -- Welding Requirements for Pipelines 08 September 2012.

8. SASD AB-036719- Sht-001-Rev-11--Reinforcement of Welded Branch Connections

9- 02-SAMSS-006 -- Hot Tap and Stopple Fittings, (6 September 2011)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FA

Saudi Aramco: Company General Use

R NUMBER

NTRACTOR

RE-INSP DATE

Saudi Aramco: Company General Use

R NUMBER

NTRACTOR

RE-INSP DATE

Saudi Aramco: Company General Use

R NUMBER

NTRACTOR

RE-INSP DATE

tion

Saudi Aramco: Company General Use

R NUMBER

NTRACTOR

RE-INSP DATE

Saudi Aramco: Company General Use

R NUMBER

NTRACTOR

RE-INSP DATE

ty).

vent

Work Verified

Work Verified

Work Verified

Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure - Hot Tap & Stopple Connection Installation

SAIC-L-2090 30-Apr-17 MECH-

(Per SAEP-311, 13 September 2009)

SAEP-311 Appendix A - APPLICABLE FORMS for HOT TAP & STOPPLE INSTALLATION

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

QR NUMBER

BLE FORMS for HOT TAP & STOPPLE INSTALLATION

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- Catalogo FMC - Link Belt - Belt Conveyors IdlersDocument124 pagesCatalogo FMC - Link Belt - Belt Conveyors IdlersErich Thomas100% (1)

- Astm D 2665 PDFDocument7 pagesAstm D 2665 PDFfayaz khan100% (2)

- The FAT Test ProcedureDocument1 pageThe FAT Test Procedurenisha_khanNo ratings yet

- Shutdown Tie in Procedure 1075 Well 22 Nov 2017Document12 pagesShutdown Tie in Procedure 1075 Well 22 Nov 2017Sumanth Reddy100% (2)

- Difference ASME B31.1 AND B31.3Document2 pagesDifference ASME B31.1 AND B31.3ShreyasGadkari100% (1)

- SULZER Water MixerDocument12 pagesSULZER Water MixerAlfonso José García LagunaNo ratings yet

- Manual Omega (ENG)Document46 pagesManual Omega (ENG)Eduardo Pereira0% (1)

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Saudi Aramco Inspection Checklist: Review of Hot Tap/Stopple & Reinforcement Calc Sheet SAIC-L-2091 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Review of Hot Tap/Stopple & Reinforcement Calc Sheet SAIC-L-2091 30-Apr-17 Mechkarthi51289No ratings yet

- Satr A 2007Document2 pagesSatr A 2007usmanNo ratings yet

- SAIC-W-2031 In-Process Welding Inspection of Hot TapDocument2 pagesSAIC-W-2031 In-Process Welding Inspection of Hot TapAnonymous S9qBDVkyNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007Shahzad HussainNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- SAIC-L-2094 Rev 7Document18 pagesSAIC-L-2094 Rev 7Jaseel KanhirathingalNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007razzak.me.enggNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Saic A 2025Document3 pagesSaic A 2025usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 PipeDocument10 pagesSaudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 Pipesuresh100% (1)

- SATR-L-2001 Rev. 5Document10 pagesSATR-L-2001 Rev. 5Neelam AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-L-2095 Rev 7Document6 pagesSAIC-L-2095 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-A-2011 Rev 6 Pressure TestDocument8 pagesSAIC-A-2011 Rev 6 Pressure Testpookkoya thangalNo ratings yet

- SAIC-A-2026 Rev 6 Pre Test API TankDocument6 pagesSAIC-A-2026 Rev 6 Pre Test API Tankpookkoya thangalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- SATIP-L-052-01Document12 pagesSATIP-L-052-01zoopladoNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SATR-L-2001 Flange Joint Tightening Test ReportDocument6 pagesSATR-L-2001 Flange Joint Tightening Test ReportAnonymous S9qBDVkyNo ratings yet

- Saic-A-2006 Rev 62Document5 pagesSaic-A-2006 Rev 62pradeepthalava97No ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- Saic Co 3008Document12 pagesSaic Co 3008zhangNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : Fadhili Gas Sulfur Recovery Unit (Package 3)Document4 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : Fadhili Gas Sulfur Recovery Unit (Package 3)Nivash KrishnabalaNo ratings yet

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Document3 pagesSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- On A/C All: Reference DesignationDocument10 pagesOn A/C All: Reference DesignationOsama MagedNo ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Leak Test Procedure - FinalDocument29 pagesLeak Test Procedure - FinalUbong P. EffiongNo ratings yet

- On A/C All: Reference DesignationDocument10 pagesOn A/C All: Reference DesignationOsama MagedNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saic L 2115Document4 pagesSaic L 2115khuram shahzadNo ratings yet

- SAIC-L-2002 Rev 6Document13 pagesSAIC-L-2002 Rev 6biplabpal2009No ratings yet

- SAIC-A-2015 Rev 2Document9 pagesSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 PipingDocument15 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument7 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurepookkoya thangalNo ratings yet

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocument5 pagesSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709Document3 pagesNPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709afareenkhanNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Hot Tap Form Proposed SignatoriesDocument43 pagesHot Tap Form Proposed SignatoriesSongAn BuiNo ratings yet

- Ammonia Trap SpecDocument7 pagesAmmonia Trap SpecDaniel FernándezNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- SAIC-L-2106 Rev 7Document8 pagesSAIC-L-2106 Rev 7Jaseel KanhirathingalNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- TWAD - Hdpe Certificate - 75231 Sudhakar 90mmDocument2 pagesTWAD - Hdpe Certificate - 75231 Sudhakar 90mmkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18Document5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18karthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- SECTION 23 23 00 Refrigerant PipingDocument11 pagesSECTION 23 23 00 Refrigerant PipingCamio HormazabalNo ratings yet

- RF Return Line FilterDocument8 pagesRF Return Line Filterboobalan_shriNo ratings yet

- Pdam DentsDocument9 pagesPdam DentsnankingNo ratings yet

- Grundfosliterature 5269322Document20 pagesGrundfosliterature 5269322Norbert MeyerNo ratings yet

- 5032-6 Fixed Inductors PDFDocument2 pages5032-6 Fixed Inductors PDFRobert NixonNo ratings yet

- Annex B - TOR of 6 Water Projects in NinvehDocument7 pagesAnnex B - TOR of 6 Water Projects in Ninvehwafiullah sayedNo ratings yet

- Hydac Rvs SeriesDocument15 pagesHydac Rvs SeriesMauricio De'LeónNo ratings yet

- SPE114486Document10 pagesSPE114486Vikas ANo ratings yet

- Part 2 Checklist - Boat Safety SchemeDocument5 pagesPart 2 Checklist - Boat Safety Schemeibrafeeu100% (1)

- Demco Butterfly ValveDocument35 pagesDemco Butterfly ValveJairo PuentesNo ratings yet

- B13R-7, B15R-7, B16R-7: Fba37-1340-000001 Up Fba38-1340-000001 Up Fba39-1340-000001 UpDocument445 pagesB13R-7, B15R-7, B16R-7: Fba37-1340-000001 Up Fba38-1340-000001 Up Fba39-1340-000001 UpGORDNo ratings yet

- Ibr 1925Document11 pagesIbr 1925sartrNo ratings yet

- 1 - Rig ComponentsDocument8 pages1 - Rig ComponentsBatish HakimNo ratings yet

- 0-10V AHU DX Coil Interface (LC / VRF) Installation Manual: EnglishDocument36 pages0-10V AHU DX Coil Interface (LC / VRF) Installation Manual: EnglishAhmed Salah Abd EL-WahedNo ratings yet

- Gas CalorimeterDocument4 pagesGas CalorimeterIndra Kusuma Aditya HermantoNo ratings yet

- Collarwings: The New Passive Fire Protection SystemDocument12 pagesCollarwings: The New Passive Fire Protection SystemRoger ChetcutiNo ratings yet

- Qdoc - Tips - Identification and TraceabilityDocument6 pagesQdoc - Tips - Identification and TraceabilityMohamed Reda Hussein SengarNo ratings yet

- 1079-Finnøy Instruction ManualDocument99 pages1079-Finnøy Instruction ManualRaul Ramos TudelaNo ratings yet

- BellowsDocument38 pagesBellowsanon_830101620No ratings yet

- Manual VendorRegistrationDocument37 pagesManual VendorRegistrationAshwet JadhavNo ratings yet

- Wellhead Fittings & Valve Components - PGI-WFDocument28 pagesWellhead Fittings & Valve Components - PGI-WFIan Kevin100% (1)

- Talim Resume Jan2013Document4 pagesTalim Resume Jan2013spydaman4uNo ratings yet

- Introductory To Well HeadDocument20 pagesIntroductory To Well HeadAhmad Reza Atef100% (1)

- Aeroquip AdaptersDocument98 pagesAeroquip AdaptersSetyohdWNo ratings yet

- Pfi Es-3 2004Document2 pagesPfi Es-3 2004bayu212No ratings yet