Professional Documents

Culture Documents

Mueller - Mixing Basics

Mueller - Mixing Basics

Uploaded by

Vasilis PolykarpidisCopyright:

Available Formats

You might also like

- Training Manual Consepts of Steam Turbine MaintenanceDocument102 pagesTraining Manual Consepts of Steam Turbine Maintenancemen100% (2)

- Steam Turbines: Dr. Hitendra ShahDocument161 pagesSteam Turbines: Dr. Hitendra ShahNitish Tole100% (1)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- A To Z of Steam Turbine Maintenance PDFDocument157 pagesA To Z of Steam Turbine Maintenance PDFivaturi100% (3)

- STEAM TURBINE Project Training ReportDocument25 pagesSTEAM TURBINE Project Training ReportShams Tabrez100% (1)

- Borescope TrainingDocument40 pagesBorescope Traininggantuya battulga100% (2)

- CE 111 - 02a Hydraulic Machinery-Turbines PDFDocument18 pagesCE 111 - 02a Hydraulic Machinery-Turbines PDFAyeeSerranoNo ratings yet

- Axial Flow TurbinesDocument145 pagesAxial Flow TurbinesRaj Narayan100% (1)

- Vertical Turbine PumpsDocument22 pagesVertical Turbine PumpsRahul100% (2)

- Chapter 4 Axial-Flow PumpsDocument26 pagesChapter 4 Axial-Flow PumpsMartha BelayNo ratings yet

- FD, Lect-Pumps-IIDocument24 pagesFD, Lect-Pumps-IISalam AlaikumNo ratings yet

- Notes-2 (TurboMachines)Document21 pagesNotes-2 (TurboMachines)VIRAJ HADKARNo ratings yet

- Fluid Machines: Chapter 3: Water TurbineDocument22 pagesFluid Machines: Chapter 3: Water TurbineSneha SahNo ratings yet

- L2 Specific EnergyDocument30 pagesL2 Specific EnergySahil AcharyaNo ratings yet

- Steam Turbine IIDocument11 pagesSteam Turbine IIg9958306No ratings yet

- Steam Turbines: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESDocument85 pagesSteam Turbines: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESRaj NarayanNo ratings yet

- CentrifugeDocument4 pagesCentrifugeagsan.algabh2718No ratings yet

- Voith Gear Pump RecommendationDocument28 pagesVoith Gear Pump RecommendationcotteNo ratings yet

- Turbomechinery 7Document11 pagesTurbomechinery 7Hussein SaeedNo ratings yet

- Scavenging & TurbochargingDocument25 pagesScavenging & TurbochargingSayem kaifNo ratings yet

- Chap6 7 PPT 171128132742 - 2 PDFDocument58 pagesChap6 7 PPT 171128132742 - 2 PDFHabtamu Tkubet Ebuy100% (1)

- Presentation Centrifugal 02.ppsxDocument97 pagesPresentation Centrifugal 02.ppsxEslam Elmadboly100% (2)

- Axial and Radial Flow TurbinesDocument138 pagesAxial and Radial Flow TurbinesPRAVEEN100% (1)

- Automotive - Motorsport Powertrain Lecture 7 Exhaust Turbine and Charge CoolingDocument43 pagesAutomotive - Motorsport Powertrain Lecture 7 Exhaust Turbine and Charge CoolingWaleedNo ratings yet

- L3-PPD - Turbine Selection - Unit 1Document25 pagesL3-PPD - Turbine Selection - Unit 1Amrit PandeyNo ratings yet

- Family Tree: Positive Displacement PumpDocument20 pagesFamily Tree: Positive Displacement PumpMuhammad Qasim SajidNo ratings yet

- Series T90: Transit Mixer Drive SystemDocument22 pagesSeries T90: Transit Mixer Drive SystemEngkus KuswayaNo ratings yet

- Training Module On Turbine, Lub Oil, Gland Steam SystemDocument228 pagesTraining Module On Turbine, Lub Oil, Gland Steam Systemdinesh7136100% (4)

- Hydropoer II PDFDocument78 pagesHydropoer II PDFyared sitotawNo ratings yet

- Operation and Maintenance of Hydro TurbineDocument133 pagesOperation and Maintenance of Hydro TurbineDSTPS ANDALNo ratings yet

- Centrifugal Pump Centrifugal PumpDocument29 pagesCentrifugal Pump Centrifugal PumpChirag Bhagat100% (1)

- Centrifugal Pumps TRGDocument35 pagesCentrifugal Pumps TRGsudhakarrajam2002No ratings yet

- TurbineDocument14 pagesTurbineArjit GoswamiNo ratings yet

- Ydraulic Achine: Compiled by RabinDocument56 pagesYdraulic Achine: Compiled by RabinRabinNo ratings yet

- Axial Thrust Dummy PistonDocument12 pagesAxial Thrust Dummy Pistondeevan rajNo ratings yet

- FALLSEM2023-24 BCHE301L TH VL2023240101571 2023-11-08 Reference-Material-IDocument31 pagesFALLSEM2023-24 BCHE301L TH VL2023240101571 2023-11-08 Reference-Material-IkalepallinarenNo ratings yet

- Hydraulic TurbinesDocument39 pagesHydraulic TurbinesAd Man GeTigNo ratings yet

- Renold Rev2015Document12 pagesRenold Rev2015anandparasu5459No ratings yet

- PCE-Training Manual-HandoutsDocument63 pagesPCE-Training Manual-Handoutswoldemariam workuNo ratings yet

- Mastering Mixing FundamentalsDocument82 pagesMastering Mixing FundamentalsArturo K. Cabras Jr.100% (1)

- Turbine FundamentalsDocument102 pagesTurbine FundamentalsAkshayNo ratings yet

- Steamturbineintroductionmaintenanceppt 170211165058Document101 pagesSteamturbineintroductionmaintenanceppt 170211165058praditya100% (1)

- '' Turbine - Nozzle - Diffuser - Compressor ''Document15 pages'' Turbine - Nozzle - Diffuser - Compressor ''Eng-Ahmed Salama100% (1)

- V001t01a071 91 GT 194Document10 pagesV001t01a071 91 GT 194Uzair BukhariNo ratings yet

- Design of Agitation SystemsDocument24 pagesDesign of Agitation SystemsMurong MedinaNo ratings yet

- Hydraulic TurbinesDocument43 pagesHydraulic TurbinesKarim SayedNo ratings yet

- Axial Flow CompressorDocument50 pagesAxial Flow CompressorSunil Panwar100% (1)

- MCE 403-Francis Türbini Deney FöyüDocument6 pagesMCE 403-Francis Türbini Deney FöyüAnonymous tE5Xw9rA5No ratings yet

- Steam TurbineDocument77 pagesSteam TurbineAmit Khadka100% (2)

- Steam TurbineDocument17 pagesSteam Turbineakshay takNo ratings yet

- Agitator DesignDocument6 pagesAgitator Designप्रमोद रणपिसेNo ratings yet

- Pumps StudentsDocument62 pagesPumps StudentsAKHIL JOSEPH100% (1)

- Steam TurbinesDocument6 pagesSteam Turbinesmhawan104No ratings yet

- Agitator DesignDocument6 pagesAgitator DesignGLENDA CASINONo ratings yet

- Rotodynamic Machines: Engine or Motor Is UsedDocument25 pagesRotodynamic Machines: Engine or Motor Is UsedWika ElmasryNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- ΧΑΤΖΗΦΩΤΗΣ ΑΓΙΟΝ ΟΡΟΣ ΛΟΓΟΤΕΧΝΙΚΑ ΚΕΙΜΕΝΑDocument156 pagesΧΑΤΖΗΦΩΤΗΣ ΑΓΙΟΝ ΟΡΟΣ ΛΟΓΟΤΕΧΝΙΚΑ ΚΕΙΜΕΝΑVasilis PolykarpidisNo ratings yet

- Management Operating System Auckland CityDocument20 pagesManagement Operating System Auckland CityVasilis PolykarpidisNo ratings yet

- 90 Degrees Bend Angle: Previous Post I Talked About K-Factor, Bend Allowance and Bend DeductionDocument8 pages90 Degrees Bend Angle: Previous Post I Talked About K-Factor, Bend Allowance and Bend DeductionVasilis PolykarpidisNo ratings yet

- Bend Allowance Bend Deduction K-FactorDocument5 pagesBend Allowance Bend Deduction K-FactorVasilis PolykarpidisNo ratings yet

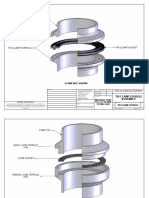

- Tube O.D.: Assembly Tri-Clamp FerruleDocument12 pagesTube O.D.: Assembly Tri-Clamp FerruleVasilis PolykarpidisNo ratings yet

- Practical Examples On Database Management SystemsDocument9 pagesPractical Examples On Database Management SystemsReem Essam MohamedNo ratings yet

- Dwnload Full Strategic Management Text and Cases 7th Edition Dess Solutions Manual PDFDocument35 pagesDwnload Full Strategic Management Text and Cases 7th Edition Dess Solutions Manual PDFsaucerbield61wpyn100% (13)

- AirBreather Spec SheetDocument2 pagesAirBreather Spec SheetDanny LuowintoNo ratings yet

- Full Answers For Level 2 Accounting Learning Work BookDocument80 pagesFull Answers For Level 2 Accounting Learning Work BookSerki Love Setki LiveNo ratings yet

- Installation Of: Athena Solomon 9-PhilippiansDocument21 pagesInstallation Of: Athena Solomon 9-PhilippiansArthur R. LopezNo ratings yet

- The Dilemma For Team MembersDocument2 pagesThe Dilemma For Team Membersheinhtetsan425No ratings yet

- Springfield Golf Course AuditDocument40 pagesSpringfield Golf Course AuditGreg SaulmonNo ratings yet

- IddqDocument66 pagesIddqRajasekharVenkataNo ratings yet

- Gavin A. Ruotolo v. Jay Gould, 489 F.2d 1324, 1st Cir. (1974)Document3 pagesGavin A. Ruotolo v. Jay Gould, 489 F.2d 1324, 1st Cir. (1974)Scribd Government DocsNo ratings yet

- Iso 3613 2000 FR PDFDocument6 pagesIso 3613 2000 FR PDFJeannie VargasNo ratings yet

- Chemseal - 109 SDocument3 pagesChemseal - 109 SghazanfarNo ratings yet

- ShockLog Essentials v10 4Document79 pagesShockLog Essentials v10 4William Rubio AvilaNo ratings yet

- Railway FAQDocument9 pagesRailway FAQvempadareddyNo ratings yet

- Travclan - Business Development Associate: About UsDocument3 pagesTravclan - Business Development Associate: About Uscharu bishtNo ratings yet

- EURME 303 (Applied Termo Dynamics 1)Document2 pagesEURME 303 (Applied Termo Dynamics 1)Sri KayNo ratings yet

- Admixtures 2Document34 pagesAdmixtures 2MudduKrishna shettyNo ratings yet

- Online Booking As A Marketing Strategy: A Survey On Hotels in AntalyaDocument9 pagesOnline Booking As A Marketing Strategy: A Survey On Hotels in AntalyaMuhammed UsmanNo ratings yet

- Merican Stainless Steel Product RangeDocument15 pagesMerican Stainless Steel Product RangegangrukaNo ratings yet

- Final 2Document72 pagesFinal 2VM MittalNo ratings yet

- (Chapter 1) TboxDocument122 pages(Chapter 1) TboxhhmiziNo ratings yet

- CFIN 300 Practice QuestionsDocument17 pagesCFIN 300 Practice QuestionsJennNo ratings yet

- MM 10 EngDocument4 pagesMM 10 EngdaniaufaNo ratings yet

- Distillation Sequencing PDFDocument39 pagesDistillation Sequencing PDFshan0214No ratings yet

- Chapter 1 - Fundamental To Microlectronic FabricationDocument26 pagesChapter 1 - Fundamental To Microlectronic FabricationAmriNo ratings yet

- A Level Math Paper 1 Quadratic EquationsDocument7 pagesA Level Math Paper 1 Quadratic EquationsisifumwiduNo ratings yet

- CPAT Reviewer - Key Audit MattersDocument3 pagesCPAT Reviewer - Key Audit MattersZaaavnn VannnnnNo ratings yet

- ALI BAUG (Gardens of Ali)Document38 pagesALI BAUG (Gardens of Ali)Manal KhatibNo ratings yet

- Rulloda Vs ComelecDocument4 pagesRulloda Vs ComelecZarah MaglinesNo ratings yet

Mueller - Mixing Basics

Mueller - Mixing Basics

Uploaded by

Vasilis PolykarpidisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mueller - Mixing Basics

Mueller - Mixing Basics

Uploaded by

Vasilis PolykarpidisCopyright:

Available Formats

MUELLER® TURBINE MIXERS

The Perfect Mix

B Bc

Z = Liquid Product Height

N

T = Inside Tank Diameter

B = Baffle Width

CV Bc = Baffle Wall Clearance

O

C = Impeller Bottom Clearance

S = Spacing Between Impellers

CV = Impeller Liquid Coverage

D = Impeller Diameter

Z

S W = Projected Blade Height

O = Shaft Diameter

W N = Shaft Speed

PROCESSING SYSTEMS AND EQUIPMENT

Mueller Turbine Mixers…

AXIAL TURBINE application must be based on tank geometry, product

An axial flow impeller is used to promote a downward characteristics, and cost considerations.

velocity profile important for:

TURBINE MIXER

■ Blending of miscible liquids

The top-entering turbine mixer is the most common

■ Solid suspension form of agitation equipment used in the process

■ Promotion of heat transfer industry. The turbine agitator is an open impeller that

may be thought of as a centrifugal pump without a

■ Incorporating dry powders into liquids housing. The impeller is characterized by 4, 6, or 8 flat

Figure A shows the flow pattern induced by an axial blades either pitched at a 45° angle (axial turbine) or in

turbine. A predominant axial velocity component line with the axis of the shaft (radial turbine). Mueller

results as the fluid is drawn in from above the impeller incorporates these two common configurations, or any

and forced down to the bottom of the tank. From there special variation that may be required, into a system to

the baffles assist in redirecting the fluid back up the meet your particular process needs.

tank walls, resulting in an efficient top-to-bottom

turnover of the product with high flow rates and The flow pattern induced by a turbine contains three

minimum shearing action. The interaction between distinct velocity components: axial, radial, and

upward and downward streams inherent in this rolling tangential. The axial and radial components act parallel

action is used to blend fluids with viscosities of up to and normal to the shaft, respectively. They provide the

100,000 centipoise. Solid suspension is achieved when flow and turbulence necessary for effective mixing. The

the rising velocity of the fluid is greater than the tangential component produces a circular pattern or

settling rate of the solids. By knowing the particulars of swirling effect, and must be broken through the use of

your product and process needs, Mueller can provide baffles or off-center mounting of the shaft in order to

an efficient, economical solution. provide a desirable flow pattern in the tank. The

relative magnitude of each component is determined

AXIAL TURBINE AGITATION LEVELS by the impeller type.

The table on the following page is based on a single

axial flow turbine in a cylindrical tank with the product The type, number, and rotational speed of the

height equal to the tank diameter (Z=T) and a final turbine(s) is selected for your particular application and

product specific gravity of 1.0. Presented are possible is readily adaptable to a wide variety of products,

combinations of horsepower and shaft speed required processes, and tank geometries. Mueller will provide

to achieve mild, medium, and vigorous levels of the engineering and the complete agitation package

agitation for a range of tank volumes and final product and then install the system in your tank or ours—with

viscosities. Heavier or more viscous products and a 100% guarantee of process results.

different tank volumes and geometries are easily

accommodated. RADIAL TURBINE

A radial or flat blade turbine is used to promote a

■ Mild Agitation—Establishes complete batch

velocity profile for:

motion with a flat fluid surface sufficient for

maintaining product temperature or blending ■ Blending of immiscible liquids

liquids with similar viscosities and specific gravities. ■ Gas dispersion

■ Medium Agitation—The most common, it ■ Promotion of heat transfer

produces surface rippling at lower viscosities,

decreases blend time, blends fluids with large Figure B illustrates the flow pattern of a radial turbine.

differences in viscosity, and aids in heating or The fluid is drawn into the impeller area from both the

cooling. top and bottom in an axial direction and then

discharged radially to the tank wall. At the wall the

■ Vigorous Agitation—Produces surface surging at fluid is directed down to the tank bottom and up to the

lower viscosities and is required when mixing time fluid surface. The high shearing action which results as

is critical or viscosity differences are great. the flow is changed from axial to radial in the impeller

Often several combinations of impeller diameter and zones is required for effective mass transfer in the

shaft speed, which in turn determine the required processes listed above. Because more torque is needed

horsepower, will produce the same level of agitation in to deliver this shear, the radial turbine consumes more

the same tank. The correct choice for a particular power than an axial turbine.

…The Perfect Mix

TYPICAL HORSEPOWER/SPEED COMBINATIONS FOR AGITATION LEVELS TABLE

Viscosity Agitation Volume (Gallons)

(Centipoise) Level* 250 500 1,000 2,500 5,000 10,000

A / hp-115 rpm

1 2 / hp-115 rpm

1 2 / hp-115 rpm

1 2 / hp-69 rpm

1 2 1 hp-43 rpm 1 hp-43 rpm

100 B / hp-115 rpm

1 2 / hp-43 rpm

1 2 1 hp-69 rpm 1 / hp-43 rpm

1 2 3 hp-43 rpm 5 hp-43 rpm

C 1 hp-69 rpm 11/2 hp-69 rpm 3 hp-69 rpm 5 hp-43 rpm 15 hp-69 rpm 25 hp-69 rpm

A / hp-115 rpm

1 2 / hp-115 rpm

1 2 / hp-115 rpm

1 2 / hp-43 rpm

1 2 1 hp-43 rpm 11/2 hp-69 rpm

500 B / hp-69 rpm

1 2 / hp-43 rpm

1 2 1 hp-43 rpm 3 hp-69 rpm 3 hp-43 rpm 71/2 hp-43 rpm

C 1 / hp-115 rpm

1 2 2 hp-69 rpm 3 hp-69 rpm 7 / hp-69 rpm

1 2 15 hp-69 rpm 40 hp-115 rpm

A / hp-115 rpm

1 2 / hp-115 rpm

1 2 / hp-69 rpm

1 2 1 hp-69 rpm 11/2 hp-69 rpm 11/2 hp-43 rpm

1,000 B / hp-69 rpm

1 2 1 hp-43 rpm 1 hp-43 rpm 3 hp-69 rpm 5 hp-69 rpm 10 hp-69 rpm

C 2 hp-115 rpm 2 hp-69 rpm 3 hp-69 rpm 10 hp-69 rpm 20 hp-69 rpm 50 hp-115 rpm

A / hp-115 rpm

1 2 / hp-69 rpm

1 2 / hp-69 rpm

1 2 1 hp-43 rpm 11/2 hp-43 rpm 2 hp-43 rpm

2,500 B 1 hp-115 rpm 11/2 hp-115 rpm 11/2 hp-43 rpm 3 hp-43 rpm 71/2 hp-69 rpm 15 hp-115 rpm

C 3 hp-115 rpm 3 hp-69 rpm 5 hp-69 rpm 10 hp-69 rpm 20 hp-69 rpm 50 hp-115 rpm

A / hp-69 rpm

1 2 / hp-69 rpm

1 2 1 hp-115 rpm 11/2 hp-69 rpm 2 hp-43 rpm 3 hp-43 rpm

5,000 B 1 / hp-115 rpm 1 / hp-69 rpm

1 2 1 2 3 hp-69 rpm 5 hp-69 rpm 10 hp-69 rpm 15 hp-69 rpm

C 5 hp-115 rpm 71/2 hp-115 rpm 71/2 hp-69 rpm 15 hp-69 rpm 25 hp-69 rpm 60 hp-115 rpm

*Agitation Levels: A = Mild, B = Medium, and C = Vigorous

Axial Turbine: Figure A Mueller turbine agitation systems offer a

broad range of possibilities in providing a

package that is right for you.

■ Constructed of 304, 316, or special alloys;

welded, ground, and polished to meet your

specifications for cleanliness and sterility.

Also available in bolted construction where

allowed.

■ Wide range of shaft speeds available with

high quality, reliable gear reduction units

sized to assure long life.

■ Prime movers include AC and DC motors

with a full range of enclosures including

special wash down and explosion-proof

units. Variable speed drives of mechanical or

Radial Turbine: Figure B frequency control. Air and hydraulic motors

also available.

■ Vapor seals, high- and low-pressure stuffing

boxes, and single- and double-mechanical

seals.

■ Pedestal mounting for standard ANSI flanges

or truss mounting.

■ Bottom steady guides and impeller stabilizers

to reduce shaft whip and end play.

■ Other agitation systems including scrapers,

side and bottom sweeps, side-entering, dual

motion, and custom designs. Contact your

Mueller representative.

MUELLER SPECIALIZES IN SOLVING YOUR AGITATION PROBLEMS

Paul Mueller Company fabricates a broad range of agitation systems, all designed with performance in mind.

Whether it be heavy-duty or lighter agitation systems, or for use in a sanitary application, the quality that made

Mueller a major producer of stainless steel processing equipment is evident in every system.

Side and Bottom Scrape Ribbon Blender

Designed to ensure complete scraping of Triple-action agitation ensures thorough

sidewall and bottom with Polysulfone blending and mixing with capacities from

scraper blades eliminating product burn- 13 to 106 cubic feet. Product is moved

on or freeze-on. Increases heat transfer simultaneously in opposite directions while

efficiency by moving product across the the mixing action of the ribbons moves the

heat transfer surface sidewall and bottom. product across the heat transfer surface

completing the blending or heat transfer process.

Side and Bottom Sweep

An anchor-type agitator consisting of Dual Motion

bottom and side blades providing close Provides fast, efficient blending

clearance to the sidewall while promoting and heat transfer through the

rapid heat transfer and reducing localized combination of a slow speed scraper

burn-on or freeze-on. This low speed and a higher speed turbine assembly,

agitator is also useful for processing shear rotating opposite each other. Designed

sensitive product. to ensure complete movement of

viscous product in the tank, not just in

Bottom Sweep the area of the impeller.

Consisting of a large-diameter paddle sweeping

across the tank bottom, lifting the product and Portable Mixer

pushing it ahead with a horizontal and vertical Utilizing single or dual, high-flow propellers driven directly or

mixing action. Ensures thorough mixing and through a 5:1 gear box, these mixers are applicable to a wide

aids in unloading product. range of products and tank volumes. The universal clamp

mounting makes them ideal for most simple open tank

Side Scrape and Bottom Sweep mixing problems.

This agitation system combines a low-level sweep

paddle with a circumferential scraper. Vertical Offset

The cupped bottom blade ensures a These agitation systems incorporate

homogenous product mix and an even multiple paddles or turbines in an

temperature distribution while off-center tank mounting. This

Polysulfone scrapers continually expose configuration eliminates the need

new product to the sidewall, providing for baffles and guarantees thorough

rapid heat transfer and eliminating film top-to-bottom pumping of product,

buildups which might burn or freeze on the producing complete movement of

sidewall surface. the entire body of product in your

tank. This agitation system is ideal

Side-Entering Agitator for applications in a tank with a

Consists of a direct-drive height-to-diameter ratio greater

horizontal propeller which than one to one.

provides thorough bottom to top

pumping of product. This provides

a gentle mixing of light- and

medium-bodied products, assures CUSTOM AGITATION SYSTEMS

good heat transfer, and ensures an

Along with our “standard” agitation system, our

adequate blending of liquids.

expertise in solving agitation problems can

result in solutions for your company. Whatever

the need, our staff will work with you to isolate

®

and solve the problem.

P.O. Box 828 • Springfield, Missouri 65801-0828, U.S.A.

Phone: (417) 831-3000 •1-800-MUELLER • Fax: (417) 831-3528

www.muel.com • E-mail: processing@muel.com

International Inquiries • Fax: (417) 831-6906 • E-mail: international@muel.com

©1989-2002 Paul Mueller Company AG-1903-4

You might also like

- Training Manual Consepts of Steam Turbine MaintenanceDocument102 pagesTraining Manual Consepts of Steam Turbine Maintenancemen100% (2)

- Steam Turbines: Dr. Hitendra ShahDocument161 pagesSteam Turbines: Dr. Hitendra ShahNitish Tole100% (1)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- A To Z of Steam Turbine Maintenance PDFDocument157 pagesA To Z of Steam Turbine Maintenance PDFivaturi100% (3)

- STEAM TURBINE Project Training ReportDocument25 pagesSTEAM TURBINE Project Training ReportShams Tabrez100% (1)

- Borescope TrainingDocument40 pagesBorescope Traininggantuya battulga100% (2)

- CE 111 - 02a Hydraulic Machinery-Turbines PDFDocument18 pagesCE 111 - 02a Hydraulic Machinery-Turbines PDFAyeeSerranoNo ratings yet

- Axial Flow TurbinesDocument145 pagesAxial Flow TurbinesRaj Narayan100% (1)

- Vertical Turbine PumpsDocument22 pagesVertical Turbine PumpsRahul100% (2)

- Chapter 4 Axial-Flow PumpsDocument26 pagesChapter 4 Axial-Flow PumpsMartha BelayNo ratings yet

- FD, Lect-Pumps-IIDocument24 pagesFD, Lect-Pumps-IISalam AlaikumNo ratings yet

- Notes-2 (TurboMachines)Document21 pagesNotes-2 (TurboMachines)VIRAJ HADKARNo ratings yet

- Fluid Machines: Chapter 3: Water TurbineDocument22 pagesFluid Machines: Chapter 3: Water TurbineSneha SahNo ratings yet

- L2 Specific EnergyDocument30 pagesL2 Specific EnergySahil AcharyaNo ratings yet

- Steam Turbine IIDocument11 pagesSteam Turbine IIg9958306No ratings yet

- Steam Turbines: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESDocument85 pagesSteam Turbines: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESRaj NarayanNo ratings yet

- CentrifugeDocument4 pagesCentrifugeagsan.algabh2718No ratings yet

- Voith Gear Pump RecommendationDocument28 pagesVoith Gear Pump RecommendationcotteNo ratings yet

- Turbomechinery 7Document11 pagesTurbomechinery 7Hussein SaeedNo ratings yet

- Scavenging & TurbochargingDocument25 pagesScavenging & TurbochargingSayem kaifNo ratings yet

- Chap6 7 PPT 171128132742 - 2 PDFDocument58 pagesChap6 7 PPT 171128132742 - 2 PDFHabtamu Tkubet Ebuy100% (1)

- Presentation Centrifugal 02.ppsxDocument97 pagesPresentation Centrifugal 02.ppsxEslam Elmadboly100% (2)

- Axial and Radial Flow TurbinesDocument138 pagesAxial and Radial Flow TurbinesPRAVEEN100% (1)

- Automotive - Motorsport Powertrain Lecture 7 Exhaust Turbine and Charge CoolingDocument43 pagesAutomotive - Motorsport Powertrain Lecture 7 Exhaust Turbine and Charge CoolingWaleedNo ratings yet

- L3-PPD - Turbine Selection - Unit 1Document25 pagesL3-PPD - Turbine Selection - Unit 1Amrit PandeyNo ratings yet

- Family Tree: Positive Displacement PumpDocument20 pagesFamily Tree: Positive Displacement PumpMuhammad Qasim SajidNo ratings yet

- Series T90: Transit Mixer Drive SystemDocument22 pagesSeries T90: Transit Mixer Drive SystemEngkus KuswayaNo ratings yet

- Training Module On Turbine, Lub Oil, Gland Steam SystemDocument228 pagesTraining Module On Turbine, Lub Oil, Gland Steam Systemdinesh7136100% (4)

- Hydropoer II PDFDocument78 pagesHydropoer II PDFyared sitotawNo ratings yet

- Operation and Maintenance of Hydro TurbineDocument133 pagesOperation and Maintenance of Hydro TurbineDSTPS ANDALNo ratings yet

- Centrifugal Pump Centrifugal PumpDocument29 pagesCentrifugal Pump Centrifugal PumpChirag Bhagat100% (1)

- Centrifugal Pumps TRGDocument35 pagesCentrifugal Pumps TRGsudhakarrajam2002No ratings yet

- TurbineDocument14 pagesTurbineArjit GoswamiNo ratings yet

- Ydraulic Achine: Compiled by RabinDocument56 pagesYdraulic Achine: Compiled by RabinRabinNo ratings yet

- Axial Thrust Dummy PistonDocument12 pagesAxial Thrust Dummy Pistondeevan rajNo ratings yet

- FALLSEM2023-24 BCHE301L TH VL2023240101571 2023-11-08 Reference-Material-IDocument31 pagesFALLSEM2023-24 BCHE301L TH VL2023240101571 2023-11-08 Reference-Material-IkalepallinarenNo ratings yet

- Hydraulic TurbinesDocument39 pagesHydraulic TurbinesAd Man GeTigNo ratings yet

- Renold Rev2015Document12 pagesRenold Rev2015anandparasu5459No ratings yet

- PCE-Training Manual-HandoutsDocument63 pagesPCE-Training Manual-Handoutswoldemariam workuNo ratings yet

- Mastering Mixing FundamentalsDocument82 pagesMastering Mixing FundamentalsArturo K. Cabras Jr.100% (1)

- Turbine FundamentalsDocument102 pagesTurbine FundamentalsAkshayNo ratings yet

- Steamturbineintroductionmaintenanceppt 170211165058Document101 pagesSteamturbineintroductionmaintenanceppt 170211165058praditya100% (1)

- '' Turbine - Nozzle - Diffuser - Compressor ''Document15 pages'' Turbine - Nozzle - Diffuser - Compressor ''Eng-Ahmed Salama100% (1)

- V001t01a071 91 GT 194Document10 pagesV001t01a071 91 GT 194Uzair BukhariNo ratings yet

- Design of Agitation SystemsDocument24 pagesDesign of Agitation SystemsMurong MedinaNo ratings yet

- Hydraulic TurbinesDocument43 pagesHydraulic TurbinesKarim SayedNo ratings yet

- Axial Flow CompressorDocument50 pagesAxial Flow CompressorSunil Panwar100% (1)

- MCE 403-Francis Türbini Deney FöyüDocument6 pagesMCE 403-Francis Türbini Deney FöyüAnonymous tE5Xw9rA5No ratings yet

- Steam TurbineDocument77 pagesSteam TurbineAmit Khadka100% (2)

- Steam TurbineDocument17 pagesSteam Turbineakshay takNo ratings yet

- Agitator DesignDocument6 pagesAgitator Designप्रमोद रणपिसेNo ratings yet

- Pumps StudentsDocument62 pagesPumps StudentsAKHIL JOSEPH100% (1)

- Steam TurbinesDocument6 pagesSteam Turbinesmhawan104No ratings yet

- Agitator DesignDocument6 pagesAgitator DesignGLENDA CASINONo ratings yet

- Rotodynamic Machines: Engine or Motor Is UsedDocument25 pagesRotodynamic Machines: Engine or Motor Is UsedWika ElmasryNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- ΧΑΤΖΗΦΩΤΗΣ ΑΓΙΟΝ ΟΡΟΣ ΛΟΓΟΤΕΧΝΙΚΑ ΚΕΙΜΕΝΑDocument156 pagesΧΑΤΖΗΦΩΤΗΣ ΑΓΙΟΝ ΟΡΟΣ ΛΟΓΟΤΕΧΝΙΚΑ ΚΕΙΜΕΝΑVasilis PolykarpidisNo ratings yet

- Management Operating System Auckland CityDocument20 pagesManagement Operating System Auckland CityVasilis PolykarpidisNo ratings yet

- 90 Degrees Bend Angle: Previous Post I Talked About K-Factor, Bend Allowance and Bend DeductionDocument8 pages90 Degrees Bend Angle: Previous Post I Talked About K-Factor, Bend Allowance and Bend DeductionVasilis PolykarpidisNo ratings yet

- Bend Allowance Bend Deduction K-FactorDocument5 pagesBend Allowance Bend Deduction K-FactorVasilis PolykarpidisNo ratings yet

- Tube O.D.: Assembly Tri-Clamp FerruleDocument12 pagesTube O.D.: Assembly Tri-Clamp FerruleVasilis PolykarpidisNo ratings yet

- Practical Examples On Database Management SystemsDocument9 pagesPractical Examples On Database Management SystemsReem Essam MohamedNo ratings yet

- Dwnload Full Strategic Management Text and Cases 7th Edition Dess Solutions Manual PDFDocument35 pagesDwnload Full Strategic Management Text and Cases 7th Edition Dess Solutions Manual PDFsaucerbield61wpyn100% (13)

- AirBreather Spec SheetDocument2 pagesAirBreather Spec SheetDanny LuowintoNo ratings yet

- Full Answers For Level 2 Accounting Learning Work BookDocument80 pagesFull Answers For Level 2 Accounting Learning Work BookSerki Love Setki LiveNo ratings yet

- Installation Of: Athena Solomon 9-PhilippiansDocument21 pagesInstallation Of: Athena Solomon 9-PhilippiansArthur R. LopezNo ratings yet

- The Dilemma For Team MembersDocument2 pagesThe Dilemma For Team Membersheinhtetsan425No ratings yet

- Springfield Golf Course AuditDocument40 pagesSpringfield Golf Course AuditGreg SaulmonNo ratings yet

- IddqDocument66 pagesIddqRajasekharVenkataNo ratings yet

- Gavin A. Ruotolo v. Jay Gould, 489 F.2d 1324, 1st Cir. (1974)Document3 pagesGavin A. Ruotolo v. Jay Gould, 489 F.2d 1324, 1st Cir. (1974)Scribd Government DocsNo ratings yet

- Iso 3613 2000 FR PDFDocument6 pagesIso 3613 2000 FR PDFJeannie VargasNo ratings yet

- Chemseal - 109 SDocument3 pagesChemseal - 109 SghazanfarNo ratings yet

- ShockLog Essentials v10 4Document79 pagesShockLog Essentials v10 4William Rubio AvilaNo ratings yet

- Railway FAQDocument9 pagesRailway FAQvempadareddyNo ratings yet

- Travclan - Business Development Associate: About UsDocument3 pagesTravclan - Business Development Associate: About Uscharu bishtNo ratings yet

- EURME 303 (Applied Termo Dynamics 1)Document2 pagesEURME 303 (Applied Termo Dynamics 1)Sri KayNo ratings yet

- Admixtures 2Document34 pagesAdmixtures 2MudduKrishna shettyNo ratings yet

- Online Booking As A Marketing Strategy: A Survey On Hotels in AntalyaDocument9 pagesOnline Booking As A Marketing Strategy: A Survey On Hotels in AntalyaMuhammed UsmanNo ratings yet

- Merican Stainless Steel Product RangeDocument15 pagesMerican Stainless Steel Product RangegangrukaNo ratings yet

- Final 2Document72 pagesFinal 2VM MittalNo ratings yet

- (Chapter 1) TboxDocument122 pages(Chapter 1) TboxhhmiziNo ratings yet

- CFIN 300 Practice QuestionsDocument17 pagesCFIN 300 Practice QuestionsJennNo ratings yet

- MM 10 EngDocument4 pagesMM 10 EngdaniaufaNo ratings yet

- Distillation Sequencing PDFDocument39 pagesDistillation Sequencing PDFshan0214No ratings yet

- Chapter 1 - Fundamental To Microlectronic FabricationDocument26 pagesChapter 1 - Fundamental To Microlectronic FabricationAmriNo ratings yet

- A Level Math Paper 1 Quadratic EquationsDocument7 pagesA Level Math Paper 1 Quadratic EquationsisifumwiduNo ratings yet

- CPAT Reviewer - Key Audit MattersDocument3 pagesCPAT Reviewer - Key Audit MattersZaaavnn VannnnnNo ratings yet

- ALI BAUG (Gardens of Ali)Document38 pagesALI BAUG (Gardens of Ali)Manal KhatibNo ratings yet

- Rulloda Vs ComelecDocument4 pagesRulloda Vs ComelecZarah MaglinesNo ratings yet