Professional Documents

Culture Documents

Embankment PDF

Embankment PDF

Uploaded by

Tin Win HtutOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Embankment PDF

Embankment PDF

Uploaded by

Tin Win HtutCopyright:

Available Formats

EMBANKMENT PROCEDURE MANUAL

2.0 EMBANKMENT (Specification 2.6)

Key Points

• All fill materials must be free from vegetable matter and the

material must be approved as suitable.

• The material should be of an appropriate nature and at a

moisture content that it can be compacted to form a stable

layer.

• Generally embankments should be constructed in 150 mm

compacted layers parallel to the finished grade of the road.

• For each completed layer the density should be checked (One

test for each 1,000 square metres) by laboratory personnel. If

test results show the required density is not achieved further

compaction is necessary

• Any soft areas must be rectified before further material is

placed. Each earthworks layer requires to be approved before

the next layer can be started.

2.1 Embankment Construction Methods

Before placing any material, clearing and grubbing and the

removal of any unsuitable materials needs to have been

completed. Also any necessary information to determine

earthwork quantities should have been collected (normally

cross sections of the original ground).

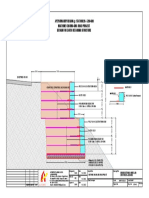

Where an existing embankment is widened, the new fill

material must be fully keyed into the old embankment by

means of benching. Steps not less than 300 mm high and 600

mm wide should be cut into the old embankment prior to any

filling, see Figure 3. Material cut from these benches may be

used as fill, if it is suitable.

May 2001 Page 6 of 52

EMBANKMENT PROCEDURE MANUAL

Proposed

widening

and raising of

embankment

Peg to mark extent

of new embankment

Existing

Embankment

a) Widening of existing embankment Remove vegetable matter

below widened embankment

Cut back old embankment

in steps

Maximum

slope

0.6 m 2

Embankment

1

compacted

to 95% standard

compaction

0.3 m

Old Embankment

b) Widening procedure Compacted in steps.

Minimum two layers

of 0.15 m

Figure 3. Embankment widening procedure

May 2001 Page 7 of 52

EMBANKMENT PROCEDURE MANUAL

Normally embankments should be constructed in layers

approximately parallel to the finished grade of the road. The

grade and crossfall should be maintained during construction,

as this will enable water to run off the embankment allowing

construction work to start as soon as possible after rainfall and

avoid soft spots forming.

All fill material used must be free from roots, or any vegetable

matter. Each layer of fill should be less than 150 mm on

completion of the compaction. Compaction must be

undertaken using appropriate equipment. If large rollers (very

heavy vibrating compaction) are used it may be possible to

increase the depth of the layers but this should only occur

after checking that adequate compaction is being achieved.

Generally the compaction should begin at the outer

embankment edges and gradually progress toward the centre

rolling in a longitudinal direction so that the full width is

uniformly compacted. In order to ensure proper compaction of

the embankment slope it is good practice to overfill by 150 –

300 mm and then trim the embankment to the specified

shape. The arisings can be re-used as fill material.

The fill material needs to be of a type and moisture content so

that it can be compacted to form stable layers. The water

content of each layer, before being compacted, must be

assessed. The material may require water to be added or be

allowed to dry to bring the moisture content close to the

optimum in order to make it possible to achieve the required

dry density and hence degree of compaction.

Normally one density test for each 1,000 square metres of

every layer should be carried out by laboratory personnel.

These tests should be carried out at random and be across

the full width of the embankment. If the test results show that

the density is less than that required, then further compaction

to obtain at least the required density is necessary. Results of

all the compaction tests undertaken should be kept on file.

May 2001 Page 8 of 52

EMBANKMENT PROCEDURE MANUAL

If it is not possible to arrange for compaction testing at the

appropriate time (e.g. where this would delay the contractor) a

visual check of the earthworks should be made. If the layer

appears to be satisfactorily compacted, approval maybe given.

In this case tests must be carried out on the subsequent layer.

This procedure is not acceptable for any layer within 300 mm

of the subgrade level.

As an alternative the Dynamic Cone Penetrometer (DCP) can

be used to test earthworks. The DCP is a rapid in-situ method

which after correlation can be utilised to obtain CBR's and

density results.

If the embankment contains any -

- soft areas this generally means insufficient compaction has

been used. Further rolling required.

- spongy areas, (which move under the wheel of the roller)

this generally means the materials have been placed too

wet. In this case the material needs to dry out, and to

enable this to occur scarification of the surface is often

necessary.

Each compacted layer requires to be approved before the

Contractor can commence on a new layer. If the Contractor

does not obtain approval before starting a new layer, or does

not follow acceptable procedures, the contractor must be

advised of the non-compliance and the Engineer informed

immediately.

Adequate compaction for embankments (refer to Appendix ‘B’)

is to ensure that only limited settlement will occur with time. If

the embankment settles unevenly this will give an uneven

surface to the road. Figure 4 provides a comparison between

placing material in a single thick layer and placing thinner

layers in an approved manner. It is particularly important to

adequately compact fill material adjacent to bridges and

culverts to prevent noticeable transverse level differences

occurring.

May 2001 Page 9 of 52

EMBANKMENT PROCEDURE MANUAL

May 2001 Page 10 of 52

You might also like

- Construction MethodologyDocument7 pagesConstruction MethodologyAllehsiad Zenitram100% (4)

- Quantitative Information On Dutch Greenhouse Horticulture 2019Document288 pagesQuantitative Information On Dutch Greenhouse Horticulture 2019Don GivsyitNo ratings yet

- Stabilised Base MethodologyDocument6 pagesStabilised Base MethodologyPanashe Chikomwe100% (1)

- Construction of Embankment and Sub-GradeDocument63 pagesConstruction of Embankment and Sub-Gradeਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ100% (1)

- Potato Production Systems 2020Document633 pagesPotato Production Systems 2020Luis Mateo Tufiño Gudiño100% (1)

- 12-02-15 Z250 Users GuideDocument63 pages12-02-15 Z250 Users GuideTin Win HtutNo ratings yet

- Explain Briefly About Preloading. A. Preloading of Soil Is Merely Applying An External Loading For A Long Duration ToDocument10 pagesExplain Briefly About Preloading. A. Preloading of Soil Is Merely Applying An External Loading For A Long Duration Tohimabindugvsd71No ratings yet

- CIDB - Construction - of - Peat - Guidelines - Method Statement (P) PDFDocument16 pagesCIDB - Construction - of - Peat - Guidelines - Method Statement (P) PDFChen Fook YewNo ratings yet

- Bonsai Focus MayJune 2017 English Ed PDFDocument84 pagesBonsai Focus MayJune 2017 English Ed PDFGiampaolo PastorinoNo ratings yet

- Clearing, Grubbing and ExcavationDocument25 pagesClearing, Grubbing and ExcavationArah Louise ApostolNo ratings yet

- Highway Engineering ReportDocument17 pagesHighway Engineering ReportJerick Magalang GallanoNo ratings yet

- Lab SandDocument4 pagesLab Sandshamsulaliff94No ratings yet

- Clearing, Grubbing and ExcavationDocument11 pagesClearing, Grubbing and ExcavationArah Louise ApostolNo ratings yet

- Project SpecificationsDocument23 pagesProject SpecificationsMydeen ThangalNo ratings yet

- Tech Spec 2 ConstructionDocument8 pagesTech Spec 2 ConstructionHuascar Medrano LazarteNo ratings yet

- Microsoft Word - FAQ-For Supervision ProjectsDocument16 pagesMicrosoft Word - FAQ-For Supervision ProjectsAman LawaniaNo ratings yet

- Road ConstructionDocument23 pagesRoad ConstructionPiyum Nimmana SamarawickramaNo ratings yet

- Tagupa, Mara Erna-ResearchworkDocument14 pagesTagupa, Mara Erna-ResearchworkMara Erna TagupaNo ratings yet

- Design of Surfaces & Guide Ways: PavementDocument20 pagesDesign of Surfaces & Guide Ways: PavementSam BarotillaNo ratings yet

- Construction Steps of Flexible PavermentDocument6 pagesConstruction Steps of Flexible PavermentE5 Sec - DW & CE [Army]No ratings yet

- Methodology For Soil ShoulderDocument7 pagesMethodology For Soil ShoulderAkash SarkarNo ratings yet

- Paving: ConcreteDocument19 pagesPaving: ConcreteAle HurtadoNo ratings yet

- Flexible Pavement ConstructionDocument18 pagesFlexible Pavement ConstructionThopuri Maruthi Chowdary100% (1)

- Embankment PDFDocument3 pagesEmbankment PDFahmed tahameemNo ratings yet

- Embankment PDFDocument3 pagesEmbankment PDFSugumarRaviNo ratings yet

- 2 - Deep Compaction of Cohesionless SoilsDocument24 pages2 - Deep Compaction of Cohesionless SoilsMuhammad AfrasiyabNo ratings yet

- Class Notes RailwaysDocument25 pagesClass Notes Railwaysvenkat123457No ratings yet

- Highway Drainage1Document27 pagesHighway Drainage1FLUXO ENGENHARIANo ratings yet

- Unit2 - Lecture1 CIV241Document64 pagesUnit2 - Lecture1 CIV241Soumya MishraNo ratings yet

- Pavement Design & Highway ConstructionDocument50 pagesPavement Design & Highway ConstructionAjay PatelNo ratings yet

- Waterwise Paver Installation GuidelinesDocument5 pagesWaterwise Paver Installation GuidelinesComaNo ratings yet

- RD Segm PavingDocument4 pagesRD Segm PavingAurelius GoraNo ratings yet

- Data Draikot 2Document8 pagesData Draikot 2Fani Septiana Nilam SariNo ratings yet

- Abstract For Cement Treated Sub-BaseDocument4 pagesAbstract For Cement Treated Sub-Basep.v.n. lakshmanNo ratings yet

- Preparation of Existing Pavement For Patching, Profile CorrectionDocument8 pagesPreparation of Existing Pavement For Patching, Profile CorrectionRISHABHNo ratings yet

- As 1012.5-1999 PDFDocument9 pagesAs 1012.5-1999 PDFPham Duc QuangNo ratings yet

- Ground Improvement TechniquesDocument30 pagesGround Improvement TechniquesNaveen Natarajan100% (1)

- Flexible PavementsDocument13 pagesFlexible PavementsAhmad NajiNo ratings yet

- Handout 3 Earthwork OperationsDocument25 pagesHandout 3 Earthwork OperationsthuraiyaNo ratings yet

- Permeable Bases Help Solve Pavement Drainage ProblemsDocument2 pagesPermeable Bases Help Solve Pavement Drainage ProblemsShivani LodhaNo ratings yet

- Roads 04 Earthworks TDO 10mar2022Document14 pagesRoads 04 Earthworks TDO 10mar2022FehkalNo ratings yet

- Pavement Design SeminarDocument12 pagesPavement Design SeminarWayaya2009100% (3)

- Pavement DesignDocument92 pagesPavement Designpankaj_mbm100% (1)

- Subgrade: Subgrade Preparation For New PavementsDocument5 pagesSubgrade: Subgrade Preparation For New PavementsmuhanadNo ratings yet

- ConcreteDocument2 pagesConcreteAle HurtadoNo ratings yet

- Noote Book BekeleDocument108 pagesNoote Book Bekelebekelemokonen544No ratings yet

- Git Unit IiiDocument21 pagesGit Unit IiiRameshNo ratings yet

- Earthworks1 (1) .PDF - Adobe Acrobat ProDocument6 pagesEarthworks1 (1) .PDF - Adobe Acrobat ProPeolebleNo ratings yet

- Caisson Constr PDFDocument10 pagesCaisson Constr PDFwijendra48No ratings yet

- Research Work 1Document14 pagesResearch Work 1Mara Erna TagupaNo ratings yet

- 3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementDocument56 pages3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementFATIN NABILA100% (1)

- Chapter8 Landfilling ProcessesDocument69 pagesChapter8 Landfilling Processeskrekre sungahid100% (1)

- Ground Improvement Oct2014 PDFDocument24 pagesGround Improvement Oct2014 PDFPatrick AscañoNo ratings yet

- GROUND IMPROVEMENT TECHNIQUES ReportDocument14 pagesGROUND IMPROVEMENT TECHNIQUES ReportFareena FatimaNo ratings yet

- Rhta - 18cv645 - Module 2Document24 pagesRhta - 18cv645 - Module 2Avinash AviiNo ratings yet

- Concrete Construction: A. Types of Materials. C. Mass ConcreteDocument9 pagesConcrete Construction: A. Types of Materials. C. Mass ConcreteماقوريNo ratings yet

- 7-Highway Drainage Maintenance DR KhairilDocument111 pages7-Highway Drainage Maintenance DR Khairildanielhaikhal1No ratings yet

- Execution & Engineering Principles of Control Modulus Column (CMC)Document6 pagesExecution & Engineering Principles of Control Modulus Column (CMC)faisaltmNo ratings yet

- Surface Preparation: ContructionDocument33 pagesSurface Preparation: ContructionAmbar SundariniNo ratings yet

- Worktips16 Reinstatement PDFDocument2 pagesWorktips16 Reinstatement PDFjoebriffaNo ratings yet

- Civil - Iv Ground Improvement Techniques: Department: Semester:Vii Sub - Code/ Name: Ce 2033Document22 pagesCivil - Iv Ground Improvement Techniques: Department: Semester:Vii Sub - Code/ Name: Ce 2033Industry Standard Structural DesignNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Ayeyarwaddy Region at Station 28+520-600 Ngathine Chaung-Gwa Road Project Design For Earth Retaining StructureDocument1 pageAyeyarwaddy Region at Station 28+520-600 Ngathine Chaung-Gwa Road Project Design For Earth Retaining StructureTin Win HtutNo ratings yet

- The Military hi-WPS OfficeDocument9 pagesThe Military hi-WPS OfficeTin Win HtutNo ratings yet

- True - False, BlankDocument8 pagesTrue - False, BlankTin Win HtutNo ratings yet

- Federalism ExamDocument11 pagesFederalism ExamTin Win HtutNo ratings yet

- NgaThaingChaung-Gwa RoadDocument26 pagesNgaThaingChaung-Gwa RoadTin Win HtutNo ratings yet

- Nitrogen Fixers For Temperate Climate Permaculture Forest GardensDocument9 pagesNitrogen Fixers For Temperate Climate Permaculture Forest GardensformlessFlowerNo ratings yet

- Growing Orchids On Guam: James Mcconnell Frank CruzDocument27 pagesGrowing Orchids On Guam: James Mcconnell Frank CruzLonCin123No ratings yet

- April May Wvu Extension Service Garden CalendarDocument2 pagesApril May Wvu Extension Service Garden Calendarapi-660325689No ratings yet

- Gardening Thesis StatementDocument6 pagesGardening Thesis Statementdianamarquezalbuquerque100% (2)

- April Meeting in Winfield: "Panama: Finca Dracula, Orchids, Etc"Document5 pagesApril Meeting in Winfield: "Panama: Finca Dracula, Orchids, Etc"don baileyNo ratings yet

- Naturcomplet - G: Soil ImproverDocument1 pageNaturcomplet - G: Soil Improverchichu09No ratings yet

- KSEEB Solutions: 2nd PUC Biology Question Bank Chapter 2 Sexual Reproduction in Flowering PlantsDocument23 pagesKSEEB Solutions: 2nd PUC Biology Question Bank Chapter 2 Sexual Reproduction in Flowering Plantsjäšħwâñtħ rNo ratings yet

- Pearson Pearson Pearson 2010 Urban AgricultureDocument15 pagesPearson Pearson Pearson 2010 Urban AgricultureYusi PramandariNo ratings yet

- STC FittingDocument32 pagesSTC Fittingdj22500No ratings yet

- Menheniot NDP Green Space Assessment v2Document41 pagesMenheniot NDP Green Space Assessment v2Wanna MsAbstractNo ratings yet

- English Scrapbook Project Based Learning (Aqua Terrarium)Document9 pagesEnglish Scrapbook Project Based Learning (Aqua Terrarium)Helna InaNo ratings yet

- Soal UTS Bahasa Inggris Kelas 4 Semester 2Document2 pagesSoal UTS Bahasa Inggris Kelas 4 Semester 2ddsconan100% (1)

- 10 The Edible City Katrin Bohn and Andre ViljoenDocument13 pages10 The Edible City Katrin Bohn and Andre ViljoenChristian RahardjaNo ratings yet

- NSTP2 Environmental Awareness GuidelinesDocument12 pagesNSTP2 Environmental Awareness GuidelinesAbegail CatindigNo ratings yet

- Grade 7 Kingdom Classification NotesDocument3 pagesGrade 7 Kingdom Classification NotespriyagvspvNo ratings yet

- 463-Article Text-2467-1-10-20200317Document14 pages463-Article Text-2467-1-10-20200317AOBO2OO32 Fadhila RamadhaniNo ratings yet

- TrichomesDocument19 pagesTrichomesHezekiah Eujhan BuendiaNo ratings yet

- Change of Payment Modality For The Remaining WorkDocument4 pagesChange of Payment Modality For The Remaining WorkEDEN2203No ratings yet

- Babi and Waga DocDocument23 pagesBabi and Waga DocYomif NiguseNo ratings yet

- Entris PlantationDocument28 pagesEntris PlantationWui Kiong HoNo ratings yet

- From Architecture To LandscapeDocument14 pagesFrom Architecture To Landscapevan abinoNo ratings yet

- Solved Salem Supply Co Sells New and Used Gardening Equipment BenDocument1 pageSolved Salem Supply Co Sells New and Used Gardening Equipment BenAnbu jaromiaNo ratings yet

- CRPSCI 1100-Module6Document18 pagesCRPSCI 1100-Module6carbonel.carlaNo ratings yet

- Leach Garden News Spring 2020Document8 pagesLeach Garden News Spring 2020Jo ShintaniNo ratings yet

- Steven Grist - Nuffield Report - FINALDocument39 pagesSteven Grist - Nuffield Report - FINALAlexi WiedemannNo ratings yet

- Action Plan Tle Sy 2022 2023Document2 pagesAction Plan Tle Sy 2022 2023CHRISTOPHER TIZONNo ratings yet

- Preliminary Substrate Mixtures Including Peat Moss (SphagnumDocument10 pagesPreliminary Substrate Mixtures Including Peat Moss (SphagnumManda ManuelaNo ratings yet