Professional Documents

Culture Documents

Steel Construction: Today & Tomorrow

Steel Construction: Today & Tomorrow

Uploaded by

Joel Solis VelasqueCopyright:

Available Formats

You might also like

- Structural Steel and Timber Design Projectr EportDocument48 pagesStructural Steel and Timber Design Projectr EportDiogo Lima Guimarães100% (1)

- Ladle Nozzle Filling CompoundDocument2 pagesLadle Nozzle Filling CompoundRam Deo Awasthi75% (4)

- Design and Construction of Factory Architecture in The Dawn of Domestic Steel StructuresDocument12 pagesDesign and Construction of Factory Architecture in The Dawn of Domestic Steel StructuresPriatna suheriNo ratings yet

- Steel Structure Corrosion Protection Technology For Port & HarbourDocument18 pagesSteel Structure Corrosion Protection Technology For Port & HarbourMochamad Aji PamungkasNo ratings yet

- Kanno Sei-2016 IabseDocument13 pagesKanno Sei-2016 IabseYana KholodovaNo ratings yet

- 28 - HitakaDocument11 pages28 - HitakaKha PhucNo ratings yet

- Steel As A Structural SystemDocument13 pagesSteel As A Structural SystemRawan AlsamairiNo ratings yet

- Steel Structures FOR Architecture IN Japan AND Asia: T. TakeuchiDocument7 pagesSteel Structures FOR Architecture IN Japan AND Asia: T. TakeuchiVasil Georgiev GeorgievNo ratings yet

- Chapter 1Document17 pagesChapter 1Anket Pandey92No ratings yet

- Secure QualityDocument15 pagesSecure QualityAnonymous e2wolbeFsNo ratings yet

- Research Steel Tokyo SkytreeDocument1 pageResearch Steel Tokyo SkytreeJezza Faith GomezNo ratings yet

- Historical and Technological Developments of Steel Bridges in Japan - A ReviewDocument25 pagesHistorical and Technological Developments of Steel Bridges in Japan - A ReviewBridge&StructureNo ratings yet

- Structural Design and Construction of The Foundation of Tokyo Sky TreeDocument12 pagesStructural Design and Construction of The Foundation of Tokyo Sky TreeKaung Htet100% (1)

- November: Advanced Large-Span ConstructionDocument20 pagesNovember: Advanced Large-Span ConstructionTrần KhươngNo ratings yet

- Considerations On Recent Trends In, and Future Prospects Of, Steel Bridge Construction in JapanDocument7 pagesConsiderations On Recent Trends In, and Future Prospects Of, Steel Bridge Construction in JapanZou BillyNo ratings yet

- Steels, Steel Products and Steel Structures Sustaining Growth of Society (Infrastructure Field)Document12 pagesSteels, Steel Products and Steel Structures Sustaining Growth of Society (Infrastructure Field)Ronak GorNo ratings yet

- Outline of Earthquake Provisions in The Japanese Building CodesDocument39 pagesOutline of Earthquake Provisions in The Japanese Building CodesBrian TaylorNo ratings yet

- Design and Construction of Steel-Structured Houses and Future EffortsDocument11 pagesDesign and Construction of Steel-Structured Houses and Future EffortsMIDHUN BABUNo ratings yet

- Steelinarchitecturecontemporaryarchitecture 150317125824 Conversion Gate01Document22 pagesSteelinarchitecturecontemporaryarchitecture 150317125824 Conversion Gate01Arsamatha KandukuriNo ratings yet

- Chapter 1 Introduction To Steel DesignDocument33 pagesChapter 1 Introduction To Steel DesignRami Demachki100% (1)

- NSTR101 10 Tech Review 1 4Document11 pagesNSTR101 10 Tech Review 1 4palak shuklaNo ratings yet

- Ho KawazuDocument17 pagesHo KawazuThomas DupontNo ratings yet

- Wa0000.Document5 pagesWa0000.umeshlahoti632No ratings yet

- Recent Development of The Seismic Resistant Steel Structures in JapanDocument10 pagesRecent Development of The Seismic Resistant Steel Structures in JapanFabio IannoneNo ratings yet

- Steel FrameDocument5 pagesSteel FrameDanielle Ann Joyce ValenciaNo ratings yet

- Steel Arch BridgesDocument14 pagesSteel Arch BridgesMarekNo ratings yet

- Nipponsteel Brochure enDocument6 pagesNipponsteel Brochure enNadimNo ratings yet

- Steel Construction: Today & TomorrowDocument20 pagesSteel Construction: Today & TomorrowPvp PvpNo ratings yet

- Japanese Seismic Design of High-Rise Reinforced Concrete Buildings - An Example of Performance-Based Design Code and State of PracticesDocument28 pagesJapanese Seismic Design of High-Rise Reinforced Concrete Buildings - An Example of Performance-Based Design Code and State of Practicesx-kapoNo ratings yet

- Steel Design: Introduction: OutlineDocument13 pagesSteel Design: Introduction: Outlinejudy ann vidalNo ratings yet

- Durability of Light Steel Framing in Residential ApplicationDocument13 pagesDurability of Light Steel Framing in Residential ApplicationAmira RamleeNo ratings yet

- Earthquake and Tsunami Damage To Steel StructuresDocument12 pagesEarthquake and Tsunami Damage To Steel StructuresZainab FarooqNo ratings yet

- Steel DesignDocument131 pagesSteel DesignAndrea RamirezNo ratings yet

- Corrosion Protection For Steel Pipe Piles and Sheet Piles: Special FeatureDocument20 pagesCorrosion Protection For Steel Pipe Piles and Sheet Piles: Special FeatureviralisursNo ratings yet

- Engineering Structures: Shreya Thusoo, Susumu Kono, Junji Hamada, Yoichi Asai TDocument15 pagesEngineering Structures: Shreya Thusoo, Susumu Kono, Junji Hamada, Yoichi Asai TPLABAN DEBNo ratings yet

- Design of Steel Elements As Per Is 800Document28 pagesDesign of Steel Elements As Per Is 800Shatrughna BargeNo ratings yet

- Comparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsDocument7 pagesComparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsEphrata MussieNo ratings yet

- Non-Ferrous Structural Materials (Titanium, Aluminum) : Technical ReviewDocument9 pagesNon-Ferrous Structural Materials (Titanium, Aluminum) : Technical ReviewZaky GhufronNo ratings yet

- Avani and RitijaDocument17 pagesAvani and RitijaDevyaniAgrawalNo ratings yet

- Dss PDFDocument141 pagesDss PDFBoxer BharathNo ratings yet

- Design of Cold Formed Steel StructuresDocument94 pagesDesign of Cold Formed Steel Structuresrobersasmita80% (5)

- Steel Design Module 1Document19 pagesSteel Design Module 1MAGNI FICATNo ratings yet

- 2004 Experimental Assessment of Floor Vibration Using Itech Composite BeamDocument9 pages2004 Experimental Assessment of Floor Vibration Using Itech Composite BeamOmar CaballeroNo ratings yet

- 011.chapter 1Document2 pages011.chapter 1zwepyae914No ratings yet

- Lecture 1Document72 pagesLecture 1feysalNo ratings yet

- TOS III Chapter V Design of Steel Structures. A.PropertiesDocument4 pagesTOS III Chapter V Design of Steel Structures. A.PropertiesShyam WanaskarNo ratings yet

- Summary Iintroction To Structural Steel DesgnDocument5 pagesSummary Iintroction To Structural Steel Desgnbrayan guevaraNo ratings yet

- Treatment of Western Wooden Roof Trusses in Early 20th Century KoreaDocument9 pagesTreatment of Western Wooden Roof Trusses in Early 20th Century KoreaHELLMINo ratings yet

- Steel and Composite StructuresDocument372 pagesSteel and Composite StructuresTATATAHER100% (1)

- Chapter 1Document43 pagesChapter 1Suleiman AldbeisNo ratings yet

- AStateofArtReviewofLight Weight FormattedPaperDocument10 pagesAStateofArtReviewofLight Weight FormattedPaperAmira RamleeNo ratings yet

- Steel ConstructionDocument3 pagesSteel ConstructionLen-Len CobsilenNo ratings yet

- 3800 Review of Buckling Restrained Brace Design and Application To Tall BuildingsDocument10 pages3800 Review of Buckling Restrained Brace Design and Application To Tall Buildingst3487810interzetruNo ratings yet

- Castings SchoberDocument23 pagesCastings SchoberLLNo ratings yet

- Seismic Retrofit Design With The Steel Frames Integrated Structural Element and Facade DesignDocument8 pagesSeismic Retrofit Design With The Steel Frames Integrated Structural Element and Facade DesigndimisorNo ratings yet

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- High-Speed Steel - The Development, Nature, Treatment, and use of High-Speed Steels, Together with Some Suggestions as to the Problems Involved in their UseFrom EverandHigh-Speed Steel - The Development, Nature, Treatment, and use of High-Speed Steels, Together with Some Suggestions as to the Problems Involved in their UseNo ratings yet

- Home Instruction for Sheet Metal Workers - Based on a Series of Articles Originally Published in 'Metal Worker, Plumber and Steam Fitter'From EverandHome Instruction for Sheet Metal Workers - Based on a Series of Articles Originally Published in 'Metal Worker, Plumber and Steam Fitter'No ratings yet

- SG-30 Safety Guideline For Blast Furnace PDFDocument10 pagesSG-30 Safety Guideline For Blast Furnace PDFgautamcoolNo ratings yet

- Permanent Mold CastingDocument9 pagesPermanent Mold CastingBrown MeshNo ratings yet

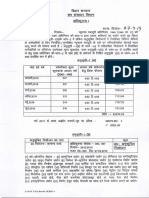

- Minimum Wages 1-10-2019Document6 pagesMinimum Wages 1-10-2019TariqueNo ratings yet

- A9-1&2 SL03,04-Street Lighting Feeder Pillar Detail-A9-1Document1 pageA9-1&2 SL03,04-Street Lighting Feeder Pillar Detail-A9-1amirul aizadNo ratings yet

- Unit 1.6 Homogeneous and Heterogeneous MixturesDocument8 pagesUnit 1.6 Homogeneous and Heterogeneous MixturesJhinrie BarceloNo ratings yet

- Construction Drawings@DillibazaarDocument15 pagesConstruction Drawings@DillibazaarSaurav ShresthaNo ratings yet

- Technical Information Schoeck Isokorb For Steel Structures (8404)Document104 pagesTechnical Information Schoeck Isokorb For Steel Structures (8404)damindaNo ratings yet

- Art Cloth A Guide To Surface Design For Fabric PDFDocument8 pagesArt Cloth A Guide To Surface Design For Fabric PDFNidhi TimesgroupNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- Hydrothermally Stable Metal Oxide Zeolite Composite Catalys - 2023 - Chinese CheDocument12 pagesHydrothermally Stable Metal Oxide Zeolite Composite Catalys - 2023 - Chinese CheDana MateiNo ratings yet

- 3 ReportDocument23 pages3 ReportClassic PrintersNo ratings yet

- Fosroc Nitomortar FC (B) : Constructive SolutionsDocument2 pagesFosroc Nitomortar FC (B) : Constructive SolutionsVincent JavateNo ratings yet

- 2 SORB R8 R16 - CompressedDocument489 pages2 SORB R8 R16 - Compressedbibo92221No ratings yet

- NotesDocument36 pagesNotesULTRA College of Engineering & Technology for WomenNo ratings yet

- Compressed Gas Association CGA V-1 Cylinder Valve ConnectionsDocument4 pagesCompressed Gas Association CGA V-1 Cylinder Valve ConnectionsmauroNo ratings yet

- Flowsheet Dan Block Diagram Pulp and Tissue: Nama: 1. Bayu Wisnu Buana Putra (M1B116001) 2. MUHAMMAD ASWARI (M1B116019)Document4 pagesFlowsheet Dan Block Diagram Pulp and Tissue: Nama: 1. Bayu Wisnu Buana Putra (M1B116001) 2. MUHAMMAD ASWARI (M1B116019)Bayu Wisnu Buana PutraNo ratings yet

- Current Trends in Building MaterialsDocument6 pagesCurrent Trends in Building MaterialsCatherine ChengNo ratings yet

- A 304 - 11 Aceros Tipo HDocument48 pagesA 304 - 11 Aceros Tipo Halucard375No ratings yet

- NCR-017-final - ClosedDocument46 pagesNCR-017-final - ClosedANIL PLAMOOTTILNo ratings yet

- B9 Exp5 ME222Document19 pagesB9 Exp5 ME222Yash Varun100% (1)

- Chapter 2Document15 pagesChapter 2LesClauMarHarHan LCMHHNo ratings yet

- LN194 1 - 10215200 005 LST enDocument8 pagesLN194 1 - 10215200 005 LST enaakash bhardwajNo ratings yet

- Checklist For Civil Works: Engr. Jerome V. KatigbakDocument35 pagesChecklist For Civil Works: Engr. Jerome V. KatigbakKian InductivoNo ratings yet

- Different Refrigeration CyclesDocument11 pagesDifferent Refrigeration CyclesLester AngelesNo ratings yet

- Interseal 670HS: Surface Tolerant EpoxyDocument2 pagesInterseal 670HS: Surface Tolerant EpoxyAndri AjaNo ratings yet

- Ecosol: Water Soluble Packaging SolutionDocument2 pagesEcosol: Water Soluble Packaging SolutionBharat GargNo ratings yet

- In-Situ Infrared Study of Methanol Synthesis From H2-CO2 Over Cu-SiO2 and Cu-ZrO2-SiO2 PDFDocument21 pagesIn-Situ Infrared Study of Methanol Synthesis From H2-CO2 Over Cu-SiO2 and Cu-ZrO2-SiO2 PDFtunganh1110No ratings yet

- Chloride Removal From Industrial Cooling Water Using A Two-Stage UHLADocument6 pagesChloride Removal From Industrial Cooling Water Using A Two-Stage UHLAHamed TorabyNo ratings yet

- Technical Data Sheet: Ptfe + 20% PeekDocument1 pageTechnical Data Sheet: Ptfe + 20% PeekRohan KulkarniNo ratings yet

Steel Construction: Today & Tomorrow

Steel Construction: Today & Tomorrow

Uploaded by

Joel Solis VelasqueOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Construction: Today & Tomorrow

Steel Construction: Today & Tomorrow

Uploaded by

Joel Solis VelasqueCopyright:

Available Formats

No.

37 December 2012

STEEL CONSTRUCTION

TODAY & TOMORROW http://www.jisf.or.jp/en/activity/sctt/index.html

【 s u - m u 】

“住む (su-mu)” in Japanese, or “live” in English

After choosing a house and its location, people live there; Living

Steel structures are increasingly being used as houses,

station buildings and other structures common to our daily life.

In this issue.....

Advanced Construction Project

1 Conservation and Restoration of Tokyo Station Building

Special Feature: Prefabricated Steel-frame Housing

2 Development of Prefabricated Steel-frame Housing in Japan

4 Prefabricated Steel-frame Housing in Japan

• Development of Prefabricated Steel-frame House Technologies

• Overseas Operations of Japanese Prefabricated Homebuilders

Published Jointly by 14 Steel-frame House Employing

Light-gauge Steel Shape

The Japan Iron and Steel Federation Steel Application Technology

16 Basic Details about Welding and

Welding Control

Japanese Society of Steel Construction 19 Steel Construction in Thailand

Advanced Construction Project

Conservation and Restoration of

Tokyo Station Building

by Atsushi Hayashi, Manager, Structural Engineering Center, Construction Dept.,

East Japan Railway Company; and Katsuhiko Osako, Deputy Director, Design Div.,

JR East Design Corporation

Located in Marunouchi at the center of Frodingham Iron & Steel of

Tokyo, the Tokyo Station Building is famil- the U.K.

iarly known as the “Red-brick Station Manufacture and assembly

Building” in Japan. Designed by Kingo Tat- of the steel frames started in

suno, the father of modern architecture in September 1909, and installa-

Japan, the building opened in 1914. While tion of all the steel-frame

damage to its roof and exterior walls caused members was finished in

by air raids during the Second World War September 1911 (Photo 3).

led to the building being lowered from its On-site surveys of the

original three-story construction to two sto- Tokyo Station Building con-

ries, the station has long served as Tokyo’s ducted in 1988 found local-

main railway station and is representative of ized structural deterioration

Japanese buildings erected in the Taisho and and various structural con-

Showa Eras (together spanning most of the cerns, but indicated that the

20th century). (Photos 1 and 2) building had been kept in

With this background, the Tokyo Station good condition as a steel-

Building was designated as an Important frame/masonry structure even

Cultural Property of Japan in 2003. In 2007, Photo 2 Damage by air raids 75 years after construction.

a project was begun to conserve as much of

the existing station building as possible ● Steel-frame Building Structure

while restoring it to its original appearance. The framing structure, shown in Fig. 1, was Fig. 1 Wall Framing1)

The project was successfully completed in adopted for construction of the station build-

October 2012. ing. Ten-inch I-beams were adopted for

most of the columns.

History and Structure of The steel frames used for each structural

Tokyo Station Building section weighed a total of 3,135 tons. The 3rd floor

● Appearance of Original Building adopted building plan called for the use of

Facing the Imperial Palace, the Tokyo Sta- as many domestically produced steel prod-

tion Building is a long structure with a total ucts as possible. The steel products supplied

length of 335 m. As it originally stood, the by overseas producers were used for the col-

building had three stories above ground and umns and joining members that would get

one that was partially underground; it also much usage, and those produced at the gov-

had a one-story annex building at its rear ernment-run Yawata Steel Works in Japan 2nd floor

(station platform side). The total floor area were used for all the other structural mem-

was 10,500 m2. bers. Domestic steel products accounted for

56% of all the steel products used, and the

foreign steel products for 44%. The major

suppliers of foreign steel products were

Carnegie Steel Company of the U.S. and

1st floor

Underground

floor

Photo 1 Appearance of Tokyo Station Building in the days of initial construction (1914)

1 Steel Construction Today & Tomorrow December 2012

Restoration of the Historical Station

Building

The primary objective of the restoration work

was to provide sufficient seismic resistance.

The restoration design was made so that, even

in the event of the largest predictable class of

earthquake, cracking in the brick walls would

be allowed but the building itself would be

used without the need of any large-scale repair

work.

Extensive examination of seismic resis- Photo 3 Installation of steel frames2)

tance showed the following results: with adop-

tion of the base-isolation method, almost no

seismic reinforcement would be required. On

the other hand, if conventional seismic rein-

forcing methods were employed, about half of

the interior walls would need reinforcement.

Consequently, it was decided to adopt the

base-isolation method in view of the projected

improvements to structural safety, application

freedom and conservation accuracy. (Photo 4)

Renewed Historical Building

Conservation and restoration of the historical

Tokyo Station Building was successfully fin-

ished by adding a base-isolation structure, an

example of contemporary technology, to the

original steel-frame/masonry structure that Photo 4 Advanced base-isolation systems (base-isolation laminated rubber and

was an example of one of the most advanced oil damper) were adopted for securing sufficient seismic resistance of

the renewed Tokyo Station Building.

architectural technologies available in Japan at

the earliest stage of the Japanese adoption of

European-style modern architecture. The References 2) Tokyo Station Improvement Office, Jap-

Tokyo Station Building (Marunouchi side) 1) H. Kanai: Report on Construction of anese Government Railways: Commem-

saw its grand opening on October 1, 2012, re- Tokyo Railway Station, Journal of Japan oration Photo Album, 1914

producing its 1914 appearance at the initial Society of Civil Engineers, Vol. 1, No. 1, 3) Photos 1, 2 and 4: Owned by East Japan

stage of construction (Photo 5). ■ 1915 Railway Company

Photo 5 Image of appearance upon completion (2012)

December 2012 Steel Construction Today & Tomorrow 2

Special Feature: Prefabricated Steel-frame House

Development of Prefabricated

Steel-frame Housing in Japan

by Shuichi Matsumura

Professor, School of Engineering, The University of Tokyo

Studies of the total floor space of new build- directed at the building construction market, giants of the steel industry as ready-to-use

ing construction starts in Japan show that al- which was expected to show rapid growth. structural members for building construc-

though wooden structures have long account- In order to effectively establish a new steel tion.

ed for the largest share, in the recent economic market in building construction, it was nec- While the home structural methods em-

bubble period, steel-frame structures have essary to develop the technology to produce ploying light-gauge shapes differed from

suddenly captured the top spot. I believe that light-gauge shapes such as channels etc. by one prefabricated steel-frame homebuilder

amidst the worldwide construction market, it cold-forming steel sheets with thicknesses to another, the framing method was nearly

is only in Japan that steel-frame structures of 2~6 mm. the same for every builder-channels and

comprise the largest share of total national As soon as the domestic production of square tubes were used as column members

building construction, outstripping both RC light-gauge shapes by means of cold form- while channels and light-gauge H-shapes

and wooden structures. It can be said that ing became available, the Japanese steel in- were used as lateral framing and truss mem-

Japan is uniquely a “great country for steel- dustry quickly started developing applica- bers. Compared to the precast concrete wall

frame structures.” tions for these shapes. The Light-gauge method, this method of steel framing gained

When considering structures that are rep- Steel-frame Association was inaugurated by popularity because of the flexibility in ar-

resentative of steel buildings in Japan, some the Kozai Club (an association for develop- ranging rooms that was permitted by con-

people call to mind high-rise office buildings ing new steel markets, which then merged ventional wood framing methods. As a

such as the Kasumigaseki Building, Japan’s with the Japan Iron and Steel Federation). result, pref a b r i c a t e d steel-frame

first full-scale high-rise building completed in The leading figures of the time and prom- homebuilders directed their marketing ef-

1967. Still others suggest the ubiquitous, me- ising young researchers in the field of ar- forts not only towards expanding sales

dium-rise buildings that are constructed by at- chitecture as well as many scholars in a volume but also towards steadily expanding

taching ALC panels to framing composed of wide range of fields, from structural and

square steel tube columns and H-shape beams. planning engineering to architectural design,

However, these two types of steel structures participated in the Association’s work. Their

alone cannot command the largest share of goal was to design guidelines for houses,

steel building construction. There is another school buildings and other low-rise build-

type of steel-structure building that also ac- ings employing light-gauge shapes and to

counts for a considerable share of the floor develop structuring methods including join-

space in new building construction starts. This ing details. Further, trial designs and con-

type consists of low-rise prefabricated steel- struction formats were accumulated at a

frame buildings such as steel-frame detached rapid pace.

homes and apartment buildings.

Prefabricated Houses Employing Photo 1 A prefabricated steel-frame house in

Light-gauge Steel Shapes for Light-gauge Steel Shapes the initial day and marketed in 1960.

Structural Use From around 1960 when these efforts start- Brilliant aluminum wall, new steel sash,

The history of prefabricated steel-frame ed to yield results, the housing market start- and plastic-made eaves and buttress

housing in Japan dates back to 1955 when ed to show signs of rapid growth, and many were impressive.

light-gauge steel shapes were domestically companies that had been engaged in non-

produced by means of cold forming. Fol- building operations started moving into this

lowing the Meiji Era (1968~1912), develop- promising market. The companies that ad-

ment of the Japanese steel industry was con- vanced from the steel, chemical and home

sidered a national priority and was steadily appliance industries focused on the produc-

realized with support provided mainly tion and supply of highly industrialized

through public demand. However, with the (prefabricated) houses, in contrast to

end of the Second World War and the ne- wood-framed houses that depended on tra-

gotiated cease-fire of the Korean War, there ditional carpentry skills. Consequently,

was strong sentiment for the steel industry these companies, or homebuilders, directed

to cultivate new sources of steel demand, their attention to the application potential

i.e. for private demand to replace military of the light-gauge shapes that had just Photo 2 A prefabricated house in the first part of

demand. come to market. In those days, light-gauge the 1960s, which is remained in a

Given this situation, broad attention was shapes were already being marketed by the homebuilder’s research institute.

3 Steel Construction Today & Tomorrow December 2012

floor plan flexibility, which has allowed quests to be incorporated in “custom-made” opment of the prefabricated steel-frame

these homebuilders to gain their current plans. New importance was placed on how housing industry as a whole. ■

leadership position in the Japanese housing to realize the dreams of each homebuyer in

market. the construction of their own homes, rather

At the infancy of prefabricated steel- than on the preparation of future home de-

frame housing around 1960, some houses signs drawn by architects, structural engi-

demonstrated a “novel feature” that was re- neers and other professionals. As a result,

garded somewhat strangely by people ac- prefabricated steel-frame housing was ac-

customed to conventional wooden housing. cepted in the Japanese housing market, and

Whereas it had been common for the joints prefabricated homes were established in so-

between wall panels to be clearly visible ciety as a new type of housing different

from outside the home, the new approach from conventional wooden homes.

of covering the exterior walls with alumi-

num and other materials took people by sur- The Prefabricated House as

prise. (See Photos 1~4) Further, because a Mass-produced Product

mass production was almost unheard of at In 1970, just 10 years after a number of

prefabricated homebuilding plants at this companies entered the prefabricated steel- Photo 5 Example of 3-story house employing

time and the kinds of structural members frame housing market, some emerged that heavyweight rigid steel frame system

produced were few, only a limited variety annually sold more than 10,000 houses. In

of outer wall configurations were available the 1980s, in spite of the severe operating

in the structural plans. For example, the cat- environment caused by the oil shock and

alogs of that time showed only one or two other events, the number of homebuilders

floor plans. that annually produced and sold more than

In the latter part of the 1960s, prefabri- 10,000 homes increased further, and sys-

cated home design adopted methods used tems were developed for building homes

for wooden houses. The selection of with three or more stories employing heavy-

“ready-made plans” from a restricted cata- weight steel frames (Photo 5).

log of designs was replaced by flexible Based on the concept of using enhanced

design systems that allowed homebuyer re- shop-production ratios to achieve a level of

cost performance appropriate for prefabri-

cated housing, a succession of new structur-

al methods were developed: one was a

method to design large panels, and another

was the unit method whereby individual Photo 6 From around 1970, extensive efforts

rooms are shop-assembled (Photo 6). As a were directed toward developing the

result, housing supplied by prefabricated structural method that enhances the

homebuilders has taken on the character of prefabrication ratio (photo: an example

of unit system housing production line).

being mass-produced and mass-marketed.

◆ ◆ ◆ Acknowledgment

Lastly, I wish to comment on a task con- The author wishes to thank the following

fronting all prefabricated steel-frame home- companies for their generous cooperation in

Photo 3 Midget house, one of prefabricated

houses in the initial days, which was builders. In an operating environment of providing the photos and figures used in this

marketed as a study room installed in moribund housing starts, the problem of how article: Sekisui House, Ltd., Daiwa House

the garden. It is exhibited in a to effectively use the “closed” structural sys- Industry Co., Ltd., PanaHome Corp., Asahi

homebuilder’s research institute. tems unique to each homebuilder demands Kasei Homes Corp. and Sekisui Chemical

our attention. Such systems in the current Co., Ltd.

environment are no longer rational or viable;

in fact, there are cases in which they consti-

tute an operating burden for the individual

builder.

However, because these companies have

accumulated considerable specific knowhow

over the last 50 years regarding the details

of their respective closed structural sys-

tems, it is my conclusion that now is the

time for them to consider terminating the use

Photo 4 One of prefabrica t e d s t e e l - f r a m e

homes, developed in 1961 of their closed proprietary systems and to

collaborate in bringing to market an open

system that will promote sustainable devel-

December 2012 Steel Construction Today & Tomorrow 4

Prefabricated Steel-frame House

Prefabricated Steel-frame Housing

in Japan

by Japan Prefabricated Construction Suppliers & Manufacturers Association

Development of Prefabricated Steel-frame House Technologies

Progress of Prefabricated Steel-frame tion of small-scale buildings. While light- ing light-gauge steel shapes resembles the

Housing gauge steel shapes were first used mainly for wood framing methods conventionally used

In Japan, the production of light-gauge steel purlins, furring strips and other secondary in Japan, many companies initiated their own

shapes started in the late 1950s. These shapes structural members, the Association’s ex- development of prefabricated steel-frame

drew attention as new steel products for use tensive R&D efforts steadily expanded their houses. As a result, prefabricated steel-frame

in building construction. use to include core structural members such homes account for about 80% of all prefabri-

The Light-gauge Steel-frame Association as beams, columns and trusses. The design cated housing starts in Japan, even today.

was established in 1955 under the auspice of and construction technologies yielded by The exterior and interior members of pre-

the Kozai Club (an association of steelmak- these R&D efforts served as a starting point fabricated steel-frame houses are manufac-

ers and traders in Japan) with a focus on the in the structural design of prefabricated tured at plants offering high-level quality

research and development on applications steel-frame houses. control systems. As a result, high-quality

for light-gauge steel shapes in the construc- Because the framing of structures employ- members are supplied on a stable, constant

Rigid frame system (Asahi Kasei Homes) Framing brace system (Sanyo Homes) Box rigid-frame unit system (Sekisui Chemical)

Panel frame system (Sekisui House) Framing brace system (CEL Corp.) Framing-panel combined system (Daiwa House)

Framing system (Toyota Home) Framing system (PanaHome) Unit system (Misawa Homes)

Photo 1 Representative prefabricated steel-frame homes marketed in Japan

5 Steel Construction Today & Tomorrow December 2012

basis by manufacturing lines at these plants Fig. 1 Outline of Panel-frame System

that in addition to roll forming, cutting, drill-

ing and welding also provide highly corro- Roof finish

sion-resistant coatings.

Welding, cutting and drilling operations

are no longer needed at home construction

Waterproofing

sites because shop-manufactured members (modified asphalt roofing)

Truss

with high dimensional accuracy are deliv- Roof backing (sheathing board)

ered for assembly, which allows building of

Roof backing (purline)

high-quality homes.

Among the main structural methods for

prefabricated steel-frame houses are the

panel framing system, framing system, fram- Partition wall backing

Interior backing

ing-panel combined system, the rigid frame

Floor backing

system using heavy-weight steel frames, and Stair

the unit system. Homebuilders offering mul-

tiple structural systems are promoting the de- Beam

Pass core

velopment of houses and housing projects

that meet specified building applications and Floor backing (plywood)

regional needs. (See Photo 1)

These structural systems were originally Floor backing (joist)

developed by various prefabricated home-

builders. Even within the same framing Exterior wall panel

Floor backing (sleeper)

system, the structural system differs by Window sash

homebuilder. Wall framing

Foundation

The main structural systems adopted for

building prefabricated steel-frame houses by rated into the new design. Specifically, the In the newly-developed system, the bear-

respective prefabricated homebuilders in metric module (1,000 mm) was adopted, ing walls contain steel braces (pivotal to se-

Japan are introduced below: and, in order to increase vertical expanse, curing seismic resistance) assembled in an

the ceiling height was increased to 2,400 X-shape and are arranged independently on

Framing System mm, 300 mm higher than the minimum stan- the 1st and 2nd floors in order to secure

● Panel-Frame System dard height prescribed in the Building Stan- compatibility between design freedom and

A typical framing system in this category is dard Law. Sandwich panels composed of structural strength.

the panel-frame system developed in 1960 styrene foam and aluminum were adopted

by Sekisui House, Ltd. The system mainly for the exterior walls to improve thermal in-

employs C-shaped light-gauge steel. At a sulation. While a simple gable roof was ad-

time when houses were most commonly opted, the girders were lengthened to extend

built of wood, the homes built using the the eaves by about 1 m; this was to provide

system employing steel, aluminum and plas- devices to prevent the influx of rainwater

tics as the main structural materials were during the rainy season and to block off sun-

highly innovative. light during the summer.

In 1961, the company improved on its ini- The windows incorporated newly market-

tial homes with the development of new ed aluminum sashes to improve installation

structures with high performance and a new precision. The interiors were finished by re-

structural design (Photo 2). Many epoch- placing the plastic members used widely in Photo 3 Original panel-frame system

making improvements, that were well ahead the initial-stage homes with wooden mem-

of competing homebuilders, were incorpo- bers, which led to more appealing to the

tastes of the Japanese people. (Fig. 1)

In 1962, two-story houses adopting the

new system in an overlapped form were de-

veloped, and in 1964, split-level 2-story

houses with improved design performance

were developed that employs an original

steel framing system (Photo 3). The new

system allowed for effective structural de-

signs that met not only the need of home-

buyers for flexibility in locating the 2nd

story and arranging rooms but also to meet Photo 4 Shop production line of panel-frame

Photo 2 Panel frame system originally marketed legal specifications. (Photo 4) system

December 2012 Steel Construction Today & Tomorrow 6

In 2003, a base-isolated house was devel-

oped that has attracted attention for offering

the highest level of seismic resistance. Fur-

ther, research efforts were promoted to de-

velop response-control technology with ex-

cellent cost performance, and in 2007 its

own seismic motion energy-absorbing

system was introduced in housing design.

This system absorbs seismic vibrations by

replacing some of the bearing walls used as

seismic-resistant structures with seismic

motion energy-absorbing frames containing

special dampers (Photos 5 and 6). Develop-

ment of this new seismic energy-absorbing

system allows the panel-frame housing Photo 5 Framing system into which damper is Photo 6 Seismic energy-absorbing system

system to offer a full lineup of quakeproof assembled

performances: seismic resistance, response

control and base isolation.

● Framing-Panel Combined System Fig. 2 Framing-Panel Combined Method

Another typical system in this category is

the framing-panel combined system devel- Tie strap

oped by Daiwa House Industry Co., Ltd. Roof truss

Prefabricated steel-frame housing that em-

ploys this combined system reduces on-site

execution processes and the construction

term by completing the wall panels (exterior

member, thermal insulation material and in- Purlin

Joist

terior substrate) and attaching them to the Floor Roof brace

Girder beam

steel frame at the shop and then assembling

them at the construction site. This basic con-

cept has shown no change since the system

was developed. (Figs. 2~4) Horizontal

Because of the need to join each of the brace

Outer

panels with a closed structure by use of an wall

exterior member and an interior substrate, entrance

panel Eaves

channel-shaped connectors (columns) are girder

required between the panels. And, when Angle

brace

joining the panels to a reinforced-concrete Floor

foundation and an upper girder, it is neces- strut Joist

Continuous footing

sary to embed nuts in the panels and to pre-

Floor beam

pare the joining material in advance. The Connector

Outer wall panel

housing frame can be structured with typi-

cal, module-allotted panels even in the plans Foundation

Partition panel

with external and internal angles, by con-

forming the width of connectors with the

thickness of panel frames as well as by situ-

ating a datum line at the center of external Fig. 3 Panel Assembly of Framing-panel comes 1,880 mm, and half of 1,880 mm is

wall panels. Combined System 940 mm.)

This approach constitutes the basis of the However, in order to improve the dimen-

panel-framing combined system. The size of sional efficiency of the interior structural

the module was set at 940 mm, which is members of the floor and ceiling panels, not

close to 945 mm, half the size of Japan’s tra- the dimensional efficiency of the exterior

ditional tatami mat. Further, the 940-mm Outer

Outer Outer wall structural members, the 940 mm

wall wall

module size was derived from the view that wall panel panel module size was modified to about 910 mm,

the 1,820 mm size, twice that of the exterior panel

Connector Connector which is the average size of currently avail-

walls then available, be usable without any able structural members. Further, the datum

loss. (When the 60 mm gap between connec- line, which originally was located at the

tors is added to 1,820 mm, the total size be- Foundation center of the structural core, was put on the

7 Steel Construction Today & Tomorrow December 2012

Fig. 4 Plan of Framing-panel Combined System Rigid Frame System

● Rigid Frame System Structure

Characteristic of rigid frame systems are the

rigid frame structures of Asahi Kasei Homes

Corporation. In this system, H-shape beams

are touch-joined directly to square steel tube

columns in an end-brace form, and rigid

joining is realized by the use of special

high-strength bolts. It is this housing system

that allowed the prefabrication of rigid-

frame structures capitalizing on mass-pro-

duced parts and simple framing, while the

prefabrication of rigid-frame housing struc-

Semi-partition panel Partition ture continued to be difficult when using

wall panel

N=Datum line conventional methods.

Interior wall finish line P=Module dimension (940 mm) In 1985, the new rigid-frame housing

T=Depth of frame (structure)

Outer wall finish line t =Thickness of interior wall panel

system was completed by means of the orig-

g=Thickness of exterior member inal method using beam-column joints and

column bases. For the latter, the exposed-

type column base method was adopted by

which the column bases are fixed by pouring

Fig. 5 Plan of Framing-panel Combined System (Improved System) grout mortar from a special washer; for col-

umn-to-column joining, weld-free bolt join-

ing (column coupler method) was adopted.

This system features an on-site weld-free

Interior backing housing system. (Fig. 6)

crosspiece Compared to brace structures, the rigid

Interior member frame system offers greater freedom in plan

Internal angle

accessory panel design, and in 1986, a 3-story house employ-

Exterior wall

plate member

ing this system was marketed, which led to a

rapid expansion of the 3-story housing

market (Photo 7). Further, because fire-

Semi-partition panel Partition

wall panel

proofing can easily be secured for 3-story

rigid frame structures compared to brace

Interior wall finish line N=Datum line structures, the rigid-frame 3-story housing

P=Module dimension (910 mm)

Outer wall finish line T=Depth of frame (structure) system gained market acceptance as a

t =Thickness of interior wall panel method of medium-rise apartment house

g=Thickness of exterior member framing, thereby leading to the expansion of

inner side of the structural members to the medium-rise apartment housing market.

reduce the use of unique panels especially The range of applicable member sizes was

for ceiling edges etc. As a result, the plan expanded in order to develop a rigid frame

and the plan detail were changed to those Fig. 6 Rigid Frame System Structure

Column coupler

shown in Fig. 5 (improved type).

Corner clipper

The initial plans for 2-story prefabricated

Torshear-type

housing with many room numbers has been high-strength bolt

improved to allow for large spaces and Column coupler

openings and to provide a partial stiffening

system for the structural members (lateral ALC rigid floor

framing and high-strength bearing panels). Column coupling method

Cast steel

In 3-story housing construction, while joining fitting ロ-150×150

the panel-framing combined system has cer-

tain difficulties in meeting every

Tapping screw

homebuyer’s request, the system does have H-250×125

the advantage of allowing housing construc- End plate

tion on narrow sites in urban areas.

Column-beam connection 1st-floor

column base

AS bolt

December 2012 Steel Construction Today & Tomorrow 8

system employing 250-mm square steel tube

columns. Three to five story structures that

employ this system are not used solely for

apartment housing but also for composite

structures zoned for combined shop and

apartment use.

Currently, the rigid-framing system uses

150-mm steel tube columns and supplies di-

verse kinds of houses to the 3~4-story hous-

ing market, thereby meeting today’s exten-

sive need from medium-rise urban housing

(Photos 8~10).

Photo 7 3-story house employing rigid frame system

Unit System

● Steel Unit System

Among unit systems is the steel unit system

developed by Sekisui Chemical Co., Ltd. In

Photo 8 Urban-type 3-story house employing this system, a housing structure is divided

rigid frame system into multiple structural units, which are

shop-manufactured to a nearly finished state.

These units are then transported to the con-

struction site and assembled to complete the

house. At a time when great numbers of

houses were needed, the steel unit system

with its high shop productivity was able to

produce high-performance and high-quality

housing.

The first steel unit system house was mar-

keted in 1971. This system featured a high

degree of shop prefabrication of unit box

rigid frame structures. Assembly of each unit

structure was easy, which made it possible to Photo 12 Installation of unit structure

Photo 9 Exhibition model house employing rigid meet the need for detached houses with com-

frame system plex plans and specifications. (Photos

11~13)

Photo 10 4-story house of composite use type Photo 11 House employing unit system Photo 13 Production line for unit system

employing rigid frame system housing

9 Steel Construction Today & Tomorrow December 2012

The first houses of this type adopted a Fig. 7 Unit System Structure ● Sub-units: These units have half the width

standard dimension of 800 mm (currently of a standard unit. This greatly improves

900 mm) – a simple system in which structur- freedom of design with regard to floor area

al units measuring 2,400 mm in width, 5,600 and building site.

mm in length (external dimension: 5,000 ● Roofing method: This method is used to

mm) and 2,700 mm in height were regularly build triangle-shaped roofs. Diverse roof

arranged in terms of both plan and elevation. shapes can be completed in one day by di-

The difference in loading conditions at the viding the roof structural members into

1st and 2nd stories was met by changing the roof units and panels.

section size and wall thickness of the adopted ● High beam method: This method allows

column and beam members. A notable fea- the central column section, consisting of

ture of these homes were gabled exterior wall four 1st-story units, to be removed by on-

sections that projected from the unit’s gabled site reinforcement of the 2nd-story floor

side, which facilitated the smooth joining of beam section. This approach allows for the

each unit and their use as storage spaces. Fig. 8 Module of Initial-stage Unit System provision of large spaces (equal to a maxi-

(Figs. 7 and 8) mum of 33 tatami mats) that are free of

In order to meet ever more divergent de- walls and columns, a feature that is un-

mands for plan, price and design, the kind of available in conventional housing (Photo

incorporating

units available has multiplied and the assem- 14).

Space for

bly method for these units has evolved. The

cabinet

following three types are cited as particularly

characteristic:

Fig. 9 Production Process for Outer Walls Employing Multi-function ALC Panels

Welded mesh Silica sand

Cement

Air Foaming

Admixture Hardening Photo 14 High beam method

machine

accelerator

agent

Water ● Unit System

Form mesh frame Pump Water Another unit-type housing system is the one

developed by Misawa Homes Co., Ltd. The

Reinforcing material

development of the system started with the

Mixer company’s entry in the “House 55 Proposal

Competition” sponsored by the then Minis-

Mold try of Construction and Ministry of Interna-

Corrosion-

Mold removal tional Trade and Industry in 1976. The

protection Misawa’s housing system is a rigid steel-

Loading

treatment

on bogie frame structure with “multifunctional” new

bearing walls (ALC walls) featuring excel-

lent performance in structural strength, fire

Dimensional resistance, and thermal and sound insulation

checking (Photo 15, Fig. 9).

Strength

drying

Coating

Autoclave

curing

Advance curing Photo 15 House employing steel rigid frame

unit system (combination bearing

wall/rigid steel-frame housing structure)

December 2012 Steel Construction Today & Tomorrow 10

In 1989, Misawa Homes enhanced the winds, allowing easier housing planning in less on-site construction work for shorter

unit-type housing system to develop a cap- which bearing elements can be arranged in a construction periods (Photo 16).

sule (box) unit rigid steel-frame system, in balanced way and dispensing bearing walls At the housing construction site, the de-

which each capsule unit is finished as a com- to allow much more freedom to provide velopment of new joining methods and other

plete single-shell box structure. Each cap- large floor-to-ceiling openings. erection systems now allows for the joining

sule unit adopts 125-mm square steel tubes The main objectives in the development of upper and lower capsule units, as well as

for the columns and 175 mm light-gauge of the capsule method were to further en- neighboring capsule units, using only one

steel channels for the beams: these members hance industrialization of housing and to in- high-strength bolt per column. As a result, a

are weld-joined to form a single rigid frame crease the speed of house construction. The process has been established by which ev-

box structure per span and layer; and these new capsule unit system has allowed ad- erything from erection to waterproofing of

box structures are then joined vertically and vance at-factory installation of not only ex- the joined capsule units can be completed in

horizontally, using bolts and anchor bolts to terior walls and exterior members but also one day (Photo 17).

complete the whole housing structure (Fig. interior partition walls and fittings, thereby

10). dramatically enhancing the “industrializa-

Each capsule frame bears vertical load tion” rate. A higher level of industrialization

and horizontal forces from earthquakes and has also allowed for quality stabilization and

Fig. 10 Assembly Outline in Unit System

Photo 16 Structural image of double-layer wall

in unit system

①Completion of foundation placement ②1st-story unit installation

Photo 17 Installation of unit structure

The Future Direction of Prefabricated

③2nd-story unit installation ④Completion of unit installation Steel-frame Housing

Prefabricated steel-frame homebuilders, in

order to realize a low-carbon society, are

promoting technological development that

will further improve energy-saving perfor-

mance and expand the use of energy-cre-

ation and energy-storage systems.

In addition, homebuilders are directing

their efforts toward the development of a

stock-utilization society. Specifically, they

are promoting technological development

for more effective utilization and regenera-

tion of the prefabricated steel-frame houses

already supplied and they are pushing for the

⑤Installation of roof frame and panel ⑥Completion of house positive application of legal systems to en-

large and remodel these houses.

11 Steel Construction Today & Tomorrow December 2012

Overseas Operations of Japanese Prefabricated Homebuilders

In recent years, Japanese prefabricated steel-

frame homebuilders have actively promoted

overseas operations. They are extending

house-building and town-building projects in

the world market, fully capitalizing on the high

quality and performance features acquired

through the development of prefabricated

steel-frame houses in Japan. Typical overseas

operations being promoted in China (Sekisui

House), Thailand (Sekisui Chemical), and

China and Taiwan (Misawa Homes) are intro-

duced below:

Construction of a Housing Plant

in China

Sekisui House promotes housing projects in

Australia, Singapore, the United States and

China.

In April 2012, the company completed in

China the construction of a prefabricated

steel-frame housing plant and started its op-

erations (Photos 18, 19). This was the first

entry of a full-scale prefabricated steel-frame

homebuilding plant owned by a Japanese

firm into the Chinese market. The plant was

built to meet the need for next-generation,

energy-efficient, high-performance houses in

China. It produces structural members, exte-

rior walls and interior equipment used for de-

tached prefabricated steel-frame houses built

in China by the company (Photo 20). The

annual production capacity is 72,000 m2.

Capitalizing on knowhow acquired from

the construction of two million houses in Photo 19 Steel-frame home production line in China

Japan and as the top-ranking producer of

eco-friendly homes, the company intends to

rely on the newly completed production

plant as its base of operations in supplying

high-quality houses employing a prefabricat-

ed steel-frame system to the major cities of

China.

Photo 18 Steel-frame home production plant in Photo 20 Detached house constructed in China

China

December 2012 Steel Construction Today & Tomorrow 12

Production and Marketing in Thailand

Eyeing a completion date in December 2012,

Sekisui Chemical is constructing a plant in

Thailand for the mass production of detached

houses (Photo 21). The company intends to

start full-scale housing operations there in

2013.

A major feature of the company’s over-

seas operations is the implementation of its

approach to the housing business as estab-

lished in Japan jointly with joint ventures

with local companies: namely, local procure-

ment and production, and carrying out of a

wide range of operations from plant con-

struction to marketing, housing construction

and after-sales service.

In order to promote housing operations in

Thailand, two joint-venture companies

(marketing and production) were established

jointly with Thailand’s largest conglomerate.

The two-year verification of the production

system, marketing method and cost perfor- Photo 21 Example of houses constructed in the plots of land for sale by developer

mance was carried out by these two ventures.

The production plant was constructed in

Saraburi Industrial Park (Photo 22, Fig. 11),

about 80 km north of Bangkok. Plans call for

annual production and sales of 1,000 houses

in 2014.

Fig. 11 Location of Thai Production Plant

Saraburi Industrial Park

Local production plant

About 50 km apart from main sale area

Photo 22 Housing production plant in Thailand

Bangkok prefabricated steel-frame houses, Japanese

homebuilders are expected to further acceler-

ate their overseas operations. ■

Acknowledgment

We wish to thank the following companies

for their generous cooperation in providing

the photos and figures used in this article:

● Asahi Kasei Homes Corporation

● Daiwa House Industry Co., Ltd.

● Sekisui Chemical Co., Ltd.

Photo 23 House for sale in lots exhibited in Taiwan

Successful Operations ● Sekisui House, Ltd.

in China and Taiwan ● Misawa Homes Co., Ltd.

Misawa Homes has promoted overseas hous- home in Taipei (Photo 23). Visitors to the site

ing operations for nearly 30 years. exceeded 300 during the first month after

In 1986, the company built 134 single-fam- opening, an indication of high user interest.

ily homes in Beijing and in the following year ◆◆◆

14 homes in Tianjin. The company has also On the strength of advanced knowhow accu-

built homes in Taiwan, including a model mulated in the design and construction of

13 Steel Construction Today & Tomorrow December 2012

Residential Steel Framing

Steel-framed House Employing

Light-gauge Steel Shape

by The Japan Iron and Steel Federation and Steel-Framed House Association

What Is a Steel-framed House? Subsequently, in order to assure a uni-

Steel-framed houses are built with a new form level of quality and to promote the

construction method that utilizes a non- wider use of KC-Type Steel-framed Houses,

welding system to connect cold-formed three major steelmakers−Nippon Steel, JFE

steel shapes made of galvanized steel Steel (corporate merger of NKK and Kawa-

sheets with a thickness of about 1.0 mm saki Steel in April 2003) and Kobe Steel−

(Photo 1).This new house framing tech- established the Steel-Framed House Associ-

nique is based on the traditional 2×4 stud ation, whose general membership consists of

wall framing method used in the United builders, structural design offices and manu-

States. In steel-framed house construction, factures. The association conducts the fol-

Photo 1 Light-gauge steel shapes

the lumber frames are replaced by steel lowing activities:

frames. ● Training courses for structural designers

Once the wall and floor panels are pre- Development and Diffusion by and construction supervisors (completion

pared, they are assembled in a box-shaped Steel Industry Organizations of training course is an essential require-

structure or a house. Both sides of the In November 1994, steel-framed housing ment for association membership);

light-gauge steel shapes used for the walls, was selected as a research topic by the ● Promotional activities that include the dis-

floors and roof are covered with plywood, Urban Steel Research Group, the Ministry of tribution of sales promotion tools, such as

gypsum board and other materials. The di- International Trade and Industry (currently pamphlets, publication of house magazines

verse performance characteristics–struc- the Ministry of Economy, Trade and Indus- and hosting of website;

tural stability, fire resistance, durability, try). Developmental work on steel-framed ● Delivery of formal documents required for

thermal insulation and sound insulation- houses in Japan began with the participation construction confirmation applications,

required of houses are realized by means of six major steelmakers (Nippon Steel, loan applications to the Housing Loan Cor-

of entire composite-section frame struc- NKK, Kawasaki Steel, Sumitomo Metals, poration and housing performance assess-

tures. From the perspective of "product Kobe Steel and Nisshin Steel) and the Kozai ments; and

making," these houses are high–perfor- Club (currently the Japan Iron and Steel ● Operation of approval systems for plants to

mance units that can be introduced with Federation) who acted as project coordina- manufacture the light-gauge steel shapes,

lower initial investment due to the follow- tor. In January 1996, the six major steelmak- metal fasteners, screws and nails used in

ing reasons. ers established the Committee on Steel- steel-framed house construction

● Thin plate thickness of the light-gauge steel framed Houses within the Kozai Club and Although light-gauge steel shapes, metal

shapes permits screw joining–eliminating commenced joint research on wider topics fasteners and screws are pivotal structural

the need for welding. such as structural performance, fireproofing members for securing the quality of steel-

● The use of galvanized steel sheets removes property and fire resistance, durability, ther- framed houses, they have yet to be specified in

the need to protect cut-end surfaces and mal insulation and sound insulation to pre- JIS (Japanese Industrial Standards). To

connections against corrosion due to the pare for full-scale development of steel- compensate for this, the Japan Iron and Steel

sacrificial corrosion protection provided by framed houses in Japan. Their r e s e a r c h Federation Standards have been established

the zinc–eliminating the need for corrosion s u c c e s s f u l l y r e s u l t e d i n t h e develop- as a substitute for JIS with regard to these

protection painting. ment of “KC (Kozai Club)-Type Steel- structural members. By doing so, both a stan-

● The use of design and production systems framed Houses. (Fig. 1, Photo 2) dardized level of quality for steel-framed

by means of IT allows every steel shape to

be accurately cut per the requirements of

Table 1 Comparison between Conventional Steel-frame Structure and

each house and shipped from the fabrica-

Steel-framed House

tion plant–eliminating the need for on-site

fabrication. Conventional Steel-framed house

steel-frame structure

● The major steelmakers in Japan have ac-

quired the necessary approval for steel- Structural materials Steel Steel; Sheathing board

framed house construction, which they

Thickness of steel Thickness≥ 2.3 mm Thickness≤ 1.6 mm

then provide to the builders–simplifying

Joining Mainly welding Mainly screwing (no need for welding)

design.

(Table 1) Corrosion protection Coating (after welding) Galvanized sheet (no need for coating)

Steel member fabrication Fabricator or user plant Steel shape plant (no need for fabrication)

December 2012 Steel Construction Today & Tomorrow 14

Fig. 1 Structures of Steel-framed House

Roof panel

Blocking Top chord member Web member

Roof truss

Roof sheathing

Web member

Bottom chord member

Blocking

Gusset plate

Gusset plate

Hurricane tie

Wall panel

Top track Verge rafter

Top track

Exterior sheathing

Stud Stud Header

Bottom track Gable wall stud

Track joist 2nd-floor floor joist Exterior sheathing

Window sill

Window frame

Top track

Exterior sheathing Bottom track Interior sheathing

Joist

Stud

Header

support

Header Floor panel

Bottom track

Floor sheathing

Continuous footing Sleeper Floor joist

Floor sheathing

Anchor bolt Joist track

Anchor holdown

Corner post (assembled)

Continuous footing

Joist

houses and a system for approving the plants

that will manufacture the parts have been se-

cured.

Growing Construction of

Steel-framed Housing

After enforcement by the Ministry of Con-

struction in November 2001 of Technical

Standard Notification No. 1641 Concerning

Light-gauge Steel Shape Structures, the

above-mentioned steel-framed housing

method was formally prescribed as a gener-

al housing method in the Building Standard

Law of Japan. The number of steel-framed

housing starts has shown steady growth due

to this public notification and to its increas-

ing adoption by major homebuilders as

well. ■

Photo 2 Framing of steel-framed house employing light-gauge steel shapes

15 Steel Construction Today & Tomorrow December 2012

Steel Application Technology

Basic Details about Welding

In order to compare the differences in yield strength between scallop

and non-scallop methods, a test was made using the beam-to-column

and Welding Control

joint specimen shown in Fig. 3. The test was conducted by setting

the loading amplitude as the steady increment positive-negative alter-

—Welding of Steel-frame Structures— nating loading. The test results for load-displacement relations are

shown in Figs. 4 and 52),3). As shown in the figures, the yield strength of

by Tadao Nakagomi on-site scallop welding shows extremely low values compared to those

Professor, Department of Architecture of non-scallop welding done in the shop. Accordingly, the non-scallop

Shinshu University method is adopted because sufficient deformation capacity is provided

for shop-welded beam-to-column joints.

For Japan with its frequent great earthquakes, seismic design is very On the other hand, in order to provide sufficient yield strength even

important. In a great earthquake, while it is assumed that collapse will for beam-to-column joints that are welded on-site, it is necessary to use

occur in wooden and concrete structures, it is commonly understood the drilled flange method (Fig. 7) to improve the deformation capacity of

that seismic design has provided steel structures with sufficient seismic beam-to-column joints by using a haunch to expand the beam width

resistance. However, there are cases in which inappropriately applied (Fig. 6). Figs. 8 and 9 show the difference in deformation capacity of

welds can become the starting points of fractures that lead to steel beam-to-column joints when the drilled flange method is applied and

structure collapse. when it is not2).

The following presents the basic details about welding and welding

control in steel-frame building structures and regarding key dynamic

performance characteristics of welds. Fig. 4 Test Results for Fig. 5 Test Results for Relation

Relation between Load between Load and

Non-scallop Method and Displacement in Displacement in Shop

In the welding of steel-frame structures, two methods—scallop and On-site Scallop Method Non-scallop Method

non-scallop—are used. In Japan, the scallop method is more exten-

sively adopted. Fig. 1 shows an example of the non-scallop method,

and Fig. 2 an example of the scallop method. In welding operations

using the scallop method, because grooves can be prepared inward,

welding can be conducted at both the fabrication plant and the con-

struction site. On the other hand, with the non-scallop method, because

grooves are prepared outward, welding can be applied only in a flat

position and, accordingly, cannot be applied at the construction site.

Fig. 1 Non-scallop Method

Web

Fig. 6 Example of Horizontal Fig. 7 Example of Drilled

Haunch Method Flange Method

Diaphragm Flange

Fig. 2 Scallop Method

Fig. 8 Deformation Capacity Fig. 9 Deformation Capacity

of Beam-to-Column of Beam-to-Column

Joint by No Use of Joint by Use of

Web

Haunch and Drilled Drilled Flange

Flange Method Method

Diaphragm Flange

Fig. 3 Configuration of

Test Specimen for

Beam-to-Column

Joint

December 2012 Steel Construction Today & Tomorrow 16

Welding Conditions End Tabs and Backing Metal

The mechanical properties of the weld metal, whether good or bad, are ● Kind and Performance of End Tabs

strongly related to the welding conditions. In particular, it is known that Steel end tabs are auxiliary devices attached to both ends of a groove

heat input and interpass temperature have a considerable effect on the and are used to eliminate non-uniform welding from occurring at either

tensile strength, yield point and toughness of the weld metal. The heat the starting point or the finish point in groove welding. It is feared that

input is calculated using Equation 1. stress builds up in the slit section formed between the steel end tabs

and the base metal, thereby forming starting points for fracturing. How-

60×E×I ・・・(Equation 1)

ever, when the welding conditions mentioned earlier are satisfied, suffi-

cient deformation will occur in beam-to-column joints to cause fracture.

H= 1)

Solid end tabs are ceramic and are easily attached to the base

V metal by pressing them against the metal with galvanized wire, rather

than by welding. Because solid end tabs are removed after welding,

Where stress concentration caused by the slits does not occur. However,

depending on the skill of the welding operators, weld defects are still

H : Welding heat input (J/cm) liable to remain at the start and finish points in groove welding.

I : Welding current (A) In order to compare the effect of weld defects on weld joint deforma-

E : Arc voltage (V) tion, a test similar to that used in the “Non-scallop Method” described

V : Welding speed (cm/min) above was conducted using a test specimen employing an

H-400×200×13×21 beam member. Fig. 12 shows the deformation test

As shown in Fig. 10, as the heat input and interpass temperature increase, results for a beam end with a weld defect located 40 mm in the beam-

the yield strength drops regardless of the kind of welding wire adopted. The flange width direction and 10 mm in the thickness direction (Fig. 11);

appropriate heat input and interpass temperature differ depending on the Fig. 13 shows the results when no weld defect is present4)5). As shown

type of steel product used. To illustrate, in order to secure dynamic properties in the figures, the deformation capacity of a weld joint drops remarkably

for welds of steel products equivalent to SM490, the appropriate heat input when a weld defect is present. Accordingly, it is necessary to use ultra-

and interpass temperature are: an interpass temperature maintained at sonic flaw detection tests to confirm that weld defects do not occur.

350°C or lower, a heat input of 40 kJ/cm or less, and a wire extension of

20~30 mm. In cases where the wire extension is excessive, the welding

current and voltage become unstable, thereby causing inadequate shield Fig. 11 Position of Providing Welding Defect

effect and deterioration in toughness.

Fig. 10 Relation between Interpass Temperature and Diaphragm

Yield Point

Flange

Backing metal

Fig. 12 Test Results for Fig. 13 Test Results for

Deformation Capacity Deformation Capacity

of Beam-to-Column of Beam-to-Column

Joint in Provision of Joint in No Provision of

Weld Defect Weld Defect

17 Steel Construction Today & Tomorrow December 2012

Fig. 14 Shop Assembly of Backing Metal and End Tab2)

Direct assembly welding on

flange should not be applied.

Assembly welding of end tab

is made on backing metal.

Assembly welding of backing metal is made

centering on the position 1/4 of beam flange

width and in length of 40~60 mm.

Assembly welding of end tab

is made on backing metal.

Assembly welding of backing metal is made

centering on the position 1/4 of beam flange

width and in length of 40~60 mm.

● Tack Welding of the Backing Metal and End Tabs Reference

In beam-to-column welding, backing metal is used to prevent the weld 1) Architectural Institute of Japan (AIJ): Steel Construction Technical

metal from falling off. In assembly welding that uses backing metal, weld- Guidelines—Shop Manufacture, Feb. 2007

ing that is 4~6 mm wide and about 40~60 mm long are made on both the 2) T. Nakgomi, T. Yamada, M. Murai, K. Matoba and K. Aida: Experimental

column and beam flange sides and are placed at four locations centered Research on Effects of Beam-end Details on Deformation Capacity of

on positions 1/4 of the beam flange width. When attaching the backing Beam-Column Weld Joint in Non-scallop Method (546), 121-128, Aug.

metal and end tabs, the end tabs are tightly attached to both the beam 30, 2001

flange and the backing metal, but welding is conducted only on the back- 3) K.Hattori, T. Nakagomi and Y. Ichikawa: Experimental Research on

ing metal and should not be applied to sections where the end tabs and Deformation Capacity of On-site Welded Beam-Column Weld Joint

beam flanges are in mutual contact (Fig. 14). In the case of on-site weld- Employing Drilled Flange Method, AIJ Journal of Structural Systems

ing, it is feared that when welding is conducted in the periphery of scallops (585), 155-161, Nov. 30, 2004

or when lower-flange backing metal is welded from its lower side (Fig. 15), 4) T. Nakagomi, K. Hattori, Y. Ichikawa, K. Matoba and M. Iwata: Experi-

brittle fracturing will result, and thus, such welding should not be mental Research on Deformation Capacity of Beam-Column Weld Joint

applied1)6). ■ with Defect, AIJ Journal of Structural Systems (556), 145-150, Jun. 30,

2002

5) C. Ozawa, T. Nakagomi, Y. Ichikawa and T. Mutaguchi: Experimental

Fig. 15 On-site Assembly Welding of Lower Beam Flange Research on Effects of Weld Defect and Beam Member Dynamic Prop-

erties on Deformation Capacity of Beam-Column Weld Joint, Research

Assembly welding Report of AIJ Hokuriku Office (47), 100-103, Jul. 17, 2004

6) Architectural Institute of Japan: Steel Framework Guidelines—On-site

Construction Work, Feb. 2007

Avoidance of welding

December 2012 Steel Construction Today & Tomorrow 18

Steel Construction in Thailand (kg)

–Current Situation and Future Directions–

by S. Leelataviwat, Assistant Professor, Department of Civil Engineering, King

Mongkut’s University of Technology Thonburi; Member of the Committee on Steel

Structures, Engineering Institute of Thailand

Construction is one of the most important steel- Stringent fire resistance requirements:

consumption industries in Thailand, accounting Thailand has a very stringent fire code

for up to 60% of the nation’s total steel consump- requiring unnecessarily high fire rating, in

tion. Despite key advantages of steel structures, most cases. The costs of fireproofing can

the construction in Thailand is mainly dominated amount to a significant portion of the Fig. 1 Crude Steel Consumption Per Capita

by concrete. The use of steel has been primarily entire structural costs in some projects. (World Steel Association 2011)

limited to bridges and to industrial and landmark Lack of knowledgeable and qualified

buildings. Compared to other countries in the professionals: The majority of the architects, steel structures are therefore very important.

same region, per capita consumption of crude engineers, and contractors have been trained Foreign knowledge and technology can not be

steel for Thailand is remarkably low (Fig. 1). and worked primarily with concrete structures. At merely imported. Local construction conditions,

Hence, there still exists a significant growth the moment, there is a shortage of qualified customs, and practices require that research

potential for Thailand in terms of steel usage. professionals involved in the design and con- and development are needed to create solu-

Records of steel structures in Thailand dated struction of steel structures. tions that are distinct and original. The industry

back to the later part of 1800s. The influx of must search and develop solutions that fit with

western technology and expansion of Bangkok Advancing the Use of Steel Structures local environment. Development of design

brought along the first applications of steel struc- in Thailand codes and guidelines that incorporates state-

tures. The early use was limited mainly to small The low steel consumption in Thailand has of-the-art knowledge from research and local

bridges and railway stations. By the 1910s, most generally been attributed to the lack of domes- design practices is important to increase design

of the early steel bridges had been replaced by tic upstream production facilities. However, it efficiency. Research and development

concrete bridges. The main reasons for replac- takes more than just steel production plants to processes are also vital in training the much

ing steel structures with concrete structures were advance the use of steel structures in Thailand. needed knowledgeable and qualified profes-

lack of maintenance and the general belief that At the moment, the deciding factor in selecting sionals. Human resources are always the bed-

concrete structures would be more durable in a structural system is still mostly the construc- rock for any successful industries. Additionally,

humid environment typically experienced in Thai- tion cost. A recent study by the Iron and Steel the supports from the government can also

land. With the first introduction of relatively- Institute of Thailand indicates that, when time- help increase the number of players in the capi-