Professional Documents

Culture Documents

Statistical Evaluation of Data QA050-02

Statistical Evaluation of Data QA050-02

Uploaded by

Ahmed HadadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Statistical Evaluation of Data QA050-02

Statistical Evaluation of Data QA050-02

Uploaded by

Ahmed HadadCopyright:

Available Formats

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 1 of 10

Title

Statistical Evaluation of data

:

TABLE OF CONTENTS

S. No. Description Page

1.0 Objective 2 of 10

2.0 Scope 2 of 10

3.0 Responsibilities 2 of 10

4.0 Procedure 2 of 10

5.0 Abbreviations 10 of 10

6.0 References 10 of 10

7.0 Annexure 10 of 10

1.0 Objective

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 2 of 10

Title

Statistical Evaluation of data

:

1.1 To establish a procedure for identifying basic statistical tools used for evaluation of data in

pharmaceutical industries.

2.0 Scope

2.1 This procedure applies to the Pharmaceutical Manufacturing Facility (Finished Dosage

Forms) of Pharmed Health Care, Sadat City.

3.0 Responsibilities

3.1 All department heads to identify basic statistical tools used and supervise implementation.

3.2 Training coordinator to training of relevant staff using statistical tools.

3.3 Quality Assurance Head to assure training and implementation.

4.0 Procedure

4.1 Basic statistics

4.1.1 Mean:

The mean is a measure of how close the data are to a certain figure.

It is the average of a set of n data xi =

4.1.2 Standard deviation:

It is a measure of dispersion or spread of data.

This is the most commonly used measure of the spread or dispersion of data around

the mean. The standard deviation is defined as the square root of the variance (V).

The variance is defined as the sum of the squared deviations from the mean, divided

by n-1.

4.1.3 Relative standard deviation (Coefficient of variation).

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 3 of 10

Title

Statistical Evaluation of data

:

Because the standard deviation usually depends on the magnitude of the data, the

larger the figures, the larger the standard deviation. Therefore, it is better to use an

absolute term that doesn't depend on the magnitude of the data. This is called relative

standard deviation (RSD).

The RSD is expressed as a fraction, but more usually we use the percentage and is

then called coefficient of variation (CV).

4.2 Confidence limit of measurement.

4.2.1 In case of a single measurements:

In routine analytical work, results are usually single values obtained in batches of

several test samples. No laboratory will analyze a test sample 50 times to be

confident that the result is reliable.

Therefore, the statistical parameters have to be obtained in another way. Most usually

by method validation and/or by keeping control charts.

The equation is here reduced to be:

= x + ts

where

= "true" mean value.

x = single measurement.

t = applicable t (from tables).

s = standard deviation of set of previous measurements.

4.2.1 In case of replicate measurements:

The more an analysis or measurement is replicated, the closer the mean x of the

results will approach the "true" value , (assuming absence of bias).

A single analysis of a test sample can be regarded as literally sampling the imaginary

set of a multitude of results obtained for that test sample. The uncertainty of such sub

sampling is expressed by

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 4 of 10

Title

Statistical Evaluation of data

:

where

= "true" mean value (mean of large set of replicates)

x¯ = mean of subsamples

t = a statistical value which depends on the number of data and the required

confidence (usually 95%).

s = standard deviation of mean of subsamples

n = number of subsamples

The critical values for t are tabulated in special tables.

To find the applicable value, identify the number of degrees of freedom df as follows:

df = n -1

N.B.: The term is known as the standard error of the mean

4.3 Control charts

A statistical tool used to distinguish between process variation resulting

from common causes and variation resulting from special causes.

4.3.1 In each batch of test samples at least one control sample is analyzed and the result is

plotted on the control chart of the attribute.

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 5 of 10

Title

Statistical Evaluation of data

:

4.3.1.1 The basic assumption is that when a control result falls within a distance of 2s from the

mean, the system was under control and the results of the batch as a whole can be

accepted. A control result beyond the distance of 2s from the mean (the "Warning

Limit") signals that something may be wrong or tends to go wrong.

4.3.1.2 While a control result beyond 3s (the "Control Limit" or "Action Limit")

indicates that the system was statistically out of control and that the results have to be

rejected.

4.3.2 Before constructing a control chart, a run chart is constructed to collect data.

A control chart can be started when a sufficient number of data of an attribute of the

control sample is available (or data of the performance of an analyst in analyzing an

attribute, or of the performance of an instrument on an analyte).

4.3.3 Constructing the control chart:

Calculate the mean and the standard deviation of the previous chart (or of the

initial data set).

Five lines are drawn on the next control chart as follows:

- One for the Mean (x¯),

- One for upper warning (alert) limit (x¯ + 2*SD)

- One for lower warning (alert) limit (x¯ - 2*SD)

- One for upper control (action) limit (x¯ + 3*SD)

- One for lower control (action) limit (x¯ - 3*SD)

4.3.4 Interpreting data:

4.3.4.1 Warning rule (if occurring, then data require farther inspection):

- One control result beyond Warning Limit.

The Warning Rule is exceeded by mere chance in less than 5% of the cases.

4.3.4.2 Rejection rules (if occurring, then data are rejected):

1. One control result beyond Action Limit.

2. Two successive control results beyond same Warning Limit.

3. Ten successive control results are on the same side of the Mean.

4.4 Process Capability:

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 6 of 10

Title

Statistical Evaluation of data

:

4.4.1 Introduction:

Process capability is a statistical tool which compares the output of an in-control

process to the specification limits by using capability indices.

This can be represented pictorially by the plot below:

4.4.2 A capable process is one where almost all the measurements (6) fall inside the

specification limits.

4.4.3 There are several statistics to measure capability index, the most applicable among

them is CpK.

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 7 of 10

Title

Statistical Evaluation of data

:

Where:

Cp = Process capability (Two-sided).

Cpu = Upper process capability (One-sided).

Cpl = Lower process capability (One-sided).

CpK = Process capability index.

USL = Upper specifications limit.

LSL = Lower specifications limit.

µ = "true" mean value (mean of large set of replicates).

= "true" standard deviation (of large set of replicates).

4.4.4 Acceptance Criteria:

- Recommended process capability index for processes that are stable and normally

distributed is NLT 1.33.

4.5 Linear correlation and regression:

The technique the same for both, but there is a fundamental difference in concept:

4.5.1 Correlation analysis is applied to independent factors: if X increases, what will Y do

(increase, decrease, or perhaps not change at all)?

4.5.2 In regression analysis a unilateral response is assumed: changes in X result in

changes in Y, but changes in Y do not result in changes in X.

4.5.3 In analytical work, correlation analysis can be used for comparing methods or

laboratories, whereas regression analysis can be used to construct calibration graphs.

Laboratories or methods are in fact independent factors. However, for regression

analysis one factor has to be the independent or "constant" factor.

This factor is by convention designated X, whereas the other factor is then the

dependent factor Y (thus, we speak of "regression of Y on X").

4.5.4 The principle is to establish a statistical linear relationship between two sets of

corresponding data by fitting the data to a straight line by means of the "least squares"

technique.

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 8 of 10

Title

Statistical Evaluation of data

:

Such data are, for example, analytical results of two methods applied to the same

samples (correlation), or the response of an instrument to a series of standard

solutions (regression).

The resulting line takes the general form:

y = bx + a

where

a = intercept of the line with the y-axis

b = slope (tangent)

In laboratory work ideally, when there is perfect positive correlation without bias, the

intercept a = 0 and the slope = 1. This is the so-called "1:1 line" passing through the

origin.

If the intercept a ≠ 0 then there is a systematic discrepancy (bias, error) between X

and Y.

When b ≠ 1 then there is a proportional response or difference between X and Y.

The correlation between X and Y is expressed by the correlation coefficient r which

can be calculated with the following equation:

where

xi = data X

x¯ = mean of data X

yi = data Y

y¯ = mean of data Y

It can be shown that r can vary from 1 to -1:

r = 1 perfect positive linear correlation

r = 0 no linear correlation (maybe other correlation)

r = - 1 perfect negative linear correlation

4.5.5 r2 = the coefficient of determination or coefficient of variance.

The advantage of r2 is that, when multiplied by 100, it indicates the percentage of

variation in Y associated with variation in X.

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 9 of 10

Title

Statistical Evaluation of data

:

Thus, for example, when r = 0.71 (r2 = 0.504), about 50% of the variation in Y is due

to the variation in X.

4.5.6 The line parameters b and a are calculated with the following equations:

a = y¯ - b x¯

4.5.7 It is worth to note that r is independent of the choice which factor is the independent

factory and which is the dependent Y. However, the regression parameters a and do

depend on this choice as the regression lines will be different (except when there is

ideal 1:1 correlation).

Example of calibration curve. The dashed lines delineate the 95% confidence area of

the graph. Note that the confidence is highest at the centroid of the graph.

5.0 Abbreviations

N/A.

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

SOP Number : QA050–02

STANDARD OPERATING Effective Date :

PROCEDURE

Review Date :

Department : Quality Assurance Page Number : 10 of 10

Title

Statistical Evaluation of data

:

6.0 References

N/A.

7.0 Annexure

N/A.

END OF THE DOCUMENT

PREPARED BY REVIEWED BY APPROVED BY

User Department

User Department Quality Assurance

Head

(Sign & Date) (Sign & Date) (Sign & Date)

Format Number: QA001/F01–04

You might also like

- Mercury Service Manual 40-50-55-60-90Document566 pagesMercury Service Manual 40-50-55-60-90Will Gates86% (210)

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- (QSP MR 03) Internal AuditDocument3 pages(QSP MR 03) Internal AuditBASAVA ENGINEERINGNo ratings yet

- Test Plan Test Strategy TemplateDocument29 pagesTest Plan Test Strategy TemplateAnil KumarNo ratings yet

- 1210 Statistical Tools For Procedure Validation UspDocument14 pages1210 Statistical Tools For Procedure Validation UspalexanderaristizabalNo ratings yet

- Sample Risk RegisterDocument19 pagesSample Risk RegisterRich De GuzmanNo ratings yet

- Quality Manual: Subject: Procedure For PFMEADocument3 pagesQuality Manual: Subject: Procedure For PFMEAPk Nimiwal75% (4)

- The Reliable Change Index - 1 Slide Per PageDocument8 pagesThe Reliable Change Index - 1 Slide Per PageWilliam CuevasNo ratings yet

- The Reliable Change IndexDocument8 pagesThe Reliable Change Indexana.marcela.gzz4083No ratings yet

- My Homemade PBXDocument11 pagesMy Homemade PBXaarshpatelNo ratings yet

- Project Quality Management: Quality Planning Quality Assurance Quality Control Quality Improvement Within Quality SystemDocument64 pagesProject Quality Management: Quality Planning Quality Assurance Quality Control Quality Improvement Within Quality SystemsunildpunjabiNo ratings yet

- Some Basic Qa QC Concepts: Quality Assurance (QA) Refers To The Overall ManagementDocument8 pagesSome Basic Qa QC Concepts: Quality Assurance (QA) Refers To The Overall ManagementUltrichNo ratings yet

- R & R Traditional ExplanationDocument29 pagesR & R Traditional ExplanationBiopharmaNo ratings yet

- 1210 Statistical Tools For Procedure Validation 1658413356Document14 pages1210 Statistical Tools For Procedure Validation 1658413356Krishna Kishore Malladi100% (1)

- Laboratory Quality Management - Day 1Document12 pagesLaboratory Quality Management - Day 1andres ferardoNo ratings yet

- Unit 5 PPT Quality Assurance ControlDocument70 pagesUnit 5 PPT Quality Assurance ControlAditya KonkarNo ratings yet

- Uncertainty Measurement Procedure PDFDocument3 pagesUncertainty Measurement Procedure PDFediwskiNo ratings yet

- Software Test Metrics: I) IntroductionDocument4 pagesSoftware Test Metrics: I) Introductionkola_sivaprasad3391No ratings yet

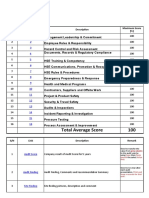

- HSE Form No 338 HSE Subcontractor Selection Forms IndoDocument37 pagesHSE Form No 338 HSE Subcontractor Selection Forms IndoQHSE BTGNo ratings yet

- Test Results Template: InternalDocument8 pagesTest Results Template: Internalخليل الكرامةNo ratings yet

- Test Strategy Template 04Document28 pagesTest Strategy Template 04Tuyen DinhNo ratings yet

- A Brief Overview of Software Testing MetricsDocument8 pagesA Brief Overview of Software Testing MetricsPrasad DannapaneniNo ratings yet

- Measurement Function/Parameter: Revision: 0Document6 pagesMeasurement Function/Parameter: Revision: 0JGlobexNo ratings yet

- QualityManagement - 01 IntroductionDocument24 pagesQualityManagement - 01 IntroductionOlufemi OlubiNo ratings yet

- Software Test MetricsDocument13 pagesSoftware Test MetricsBhattahcarjee RupakNo ratings yet

- Statistical Process Control - QPSPDocument166 pagesStatistical Process Control - QPSPkashifbutty2k100% (3)

- TQM, Lecture-11+12Document18 pagesTQM, Lecture-11+12Shakeel AhmadNo ratings yet

- Quality Criteria of Profilingvalues ReportsDocument15 pagesQuality Criteria of Profilingvalues ReportsJinsong ZhangNo ratings yet

- Unit 4-1Document12 pagesUnit 4-1Ayush KushwahaNo ratings yet

- Assessment - Forklift OperatorDocument13 pagesAssessment - Forklift OperatorGeorge LameyNo ratings yet

- Anne Mette Jonassen Hass Guide To Software Testing - Ejemplo PDFDocument7 pagesAnne Mette Jonassen Hass Guide To Software Testing - Ejemplo PDFurielNo ratings yet

- Dimensional Verification Test Protocol TempDocument8 pagesDimensional Verification Test Protocol TempMarianna GofmanNo ratings yet

- Test Case DesignDocument30 pagesTest Case Designapi-199791940% (1)

- Quality Management ProgramDocument31 pagesQuality Management ProgramBibo RamirezNo ratings yet

- Policies and Procedures On Continuous Quality ImprovementDocument16 pagesPolicies and Procedures On Continuous Quality ImprovementSooraj ThomasNo ratings yet

- Master Verification and Validation Plan TempDocument5 pagesMaster Verification and Validation Plan TempMarianna GofmanNo ratings yet

- Assessment - Crane OperatorDocument19 pagesAssessment - Crane OperatorGeorge LameyNo ratings yet

- Chapter 4Document9 pagesChapter 4BangTanBoys FanNo ratings yet

- Back To Original Page: Quality System Requirements 9001 9000Document9 pagesBack To Original Page: Quality System Requirements 9001 9000Shreenivas ThakurNo ratings yet

- 03 Aspect Identification & AssessmentDocument11 pages03 Aspect Identification & AssessmentdsnrmrbdrdNo ratings yet

- Defect ManagementDocument9 pagesDefect ManagementLucian CNo ratings yet

- Chap-10 Quality ControlDocument51 pagesChap-10 Quality Controlsushant chaudharyNo ratings yet

- Refer To The Instructions Overleaf: Evaluation Plan Form Version 2.0 25/january/2013 Page 1 of 2Document2 pagesRefer To The Instructions Overleaf: Evaluation Plan Form Version 2.0 25/january/2013 Page 1 of 2Jimmy HaddadNo ratings yet

- Defect Age: Defect Age in Time Defect Fix Date (OR Current Date) - Defect Detection DateDocument6 pagesDefect Age: Defect Age in Time Defect Fix Date (OR Current Date) - Defect Detection DatesyellaneniNo ratings yet

- Quality DictionaryDocument101 pagesQuality DictionaryDeepak KrishnaNo ratings yet

- Execution and Reporting FileDocument50 pagesExecution and Reporting Fileraoufluck4520No ratings yet

- ASTM E2587.cartas ControlDocument29 pagesASTM E2587.cartas Controlmajose019No ratings yet

- FA Lecture 3Document31 pagesFA Lecture 3jm luNo ratings yet

- A Test Managers Guide - Back To The BasicsDocument34 pagesA Test Managers Guide - Back To The BasicsLucian CNo ratings yet

- Key Performance Indicators (KPIs) Workshop - PresentationDocument42 pagesKey Performance Indicators (KPIs) Workshop - Presentationzsx4s9fts8No ratings yet

- 2022 - 02 - 27 - Quality AssuranceDocument12 pages2022 - 02 - 27 - Quality AssuranceMandula AbeyrathnaNo ratings yet

- New SyllabusDocument4 pagesNew SyllabusKunwar Singh RathoreNo ratings yet

- Welcome To PMCDP 2003 PMP Training at Mumbai Day - 3Document66 pagesWelcome To PMCDP 2003 PMP Training at Mumbai Day - 3sunildpunjabiNo ratings yet

- RIQAS Evaluation of PerformanceDocument18 pagesRIQAS Evaluation of PerformanceВалерия БедоеваNo ratings yet

- QSP 10 - 7.6 - Measurement Uncertainity - IEC 17025-17, Cl. No. 7.6, Pg. 6 OBSDocument5 pagesQSP 10 - 7.6 - Measurement Uncertainity - IEC 17025-17, Cl. No. 7.6, Pg. 6 OBSV VijayNo ratings yet

- RE: What Document We Need For QA / QC / Testing: Data IntegrityDocument18 pagesRE: What Document We Need For QA / QC / Testing: Data Integrityapi-19820505No ratings yet

- Chapter 6Document17 pagesChapter 6Selamawit AmanNo ratings yet

- Measurement Uncertainty ChemicalDocument8 pagesMeasurement Uncertainty ChemicalGanesh KashinathNo ratings yet

- KTB-QA-013-V01 Data Analysis ProcedureDocument6 pagesKTB-QA-013-V01 Data Analysis Procedureinfo.glconsultinqNo ratings yet

- Test Case PrioritizationDocument19 pagesTest Case PrioritizationFlaviu LupanNo ratings yet

- Org Design Jan. 2021 SentDocument54 pagesOrg Design Jan. 2021 SentAhmed HadadNo ratings yet

- Amazon CaseDocument3 pagesAmazon CaseAhmed HadadNo ratings yet

- Kotter Sent June. 2021Document33 pagesKotter Sent June. 2021Ahmed HadadNo ratings yet

- Running Head: Amazon Case Analysis 1Document30 pagesRunning Head: Amazon Case Analysis 1Ahmed HadadNo ratings yet

- Environmental Ethics and Economics: Values and ChoicesDocument44 pagesEnvironmental Ethics and Economics: Values and ChoicesAhmed HadadNo ratings yet

- Business Ethics - Org. CultureDocument41 pagesBusiness Ethics - Org. CultureAhmed HadadNo ratings yet

- Ethical Issues in MarketingDocument16 pagesEthical Issues in MarketingAhmed HadadNo ratings yet

- Flexit CASESTUDY 2020Document3 pagesFlexit CASESTUDY 2020Ahmed HadadNo ratings yet

- Seminar in Business Ethics & Social Responsibility - 1 - : MBA ProgramDocument20 pagesSeminar in Business Ethics & Social Responsibility - 1 - : MBA ProgramAhmed HadadNo ratings yet

- Startup Funding: Entrepreneurship and StartupsDocument95 pagesStartup Funding: Entrepreneurship and StartupsAhmed Hadad0% (1)

- Path Goal TheoryDocument16 pagesPath Goal TheoryAhmed HadadNo ratings yet

- PTWP2 PDF EngDocument79 pagesPTWP2 PDF EngAhmed Hadad100% (2)

- Situational LeadershipDocument13 pagesSituational LeadershipAhmed HadadNo ratings yet

- Case StudyDocument1 pageCase StudyAhmed HadadNo ratings yet

- Situational LeadershipDocument13 pagesSituational LeadershipAhmed HadadNo ratings yet

- Flexit CASESTUDY 2020Document3 pagesFlexit CASESTUDY 2020Ahmed HadadNo ratings yet

- Team Innovators: Names 1-Ahmed Hassan Ibrahim Elhadad 2 - Ahmed Sobhy Attia 3 - Aya Said 4 - Mohamed Rafat 5 - Mahmoud HosamDocument5 pagesTeam Innovators: Names 1-Ahmed Hassan Ibrahim Elhadad 2 - Ahmed Sobhy Attia 3 - Aya Said 4 - Mohamed Rafat 5 - Mahmoud HosamAhmed HadadNo ratings yet

- Managing Productivity: Mohamed Nabil MostafaDocument3 pagesManaging Productivity: Mohamed Nabil MostafaAhmed HadadNo ratings yet

- Fiedler's Contingency ModelDocument14 pagesFiedler's Contingency ModelAhmed HadadNo ratings yet

- نسخة امتحان ال operation PDFDocument3 pagesنسخة امتحان ال operation PDFAhmed HadadNo ratings yet

- Case StudyDocument1 pageCase StudyAhmed HadadNo ratings yet

- Ricoh IM C3000 Marketing PlanDocument16 pagesRicoh IM C3000 Marketing PlanAhmed HadadNo ratings yet

- Team Innovators: Names 1-Ahmed Hassan Ibrahim Elhadad 2 - Ahmed Sobhy Attia 3 - Aya Said 4 - Mohamed Rafat 5 - Mahmoud HosamDocument5 pagesTeam Innovators: Names 1-Ahmed Hassan Ibrahim Elhadad 2 - Ahmed Sobhy Attia 3 - Aya Said 4 - Mohamed Rafat 5 - Mahmoud HosamAhmed HadadNo ratings yet

- COVID-19 Corona Virus: Prepared By: Sarah Magdy 17 March 2020Document14 pagesCOVID-19 Corona Virus: Prepared By: Sarah Magdy 17 March 2020Ahmed HadadNo ratings yet

- Decision Making Styles: NAME: Ahmed Hassan Ibrahim Elhadad GROUP: 1KDocument5 pagesDecision Making Styles: NAME: Ahmed Hassan Ibrahim Elhadad GROUP: 1KAhmed HadadNo ratings yet

- Team Building StagesDocument5 pagesTeam Building StagesAhmed HadadNo ratings yet

- Annexure of Change Request Note: CRN No: Point No: Existing Proposed Reasons For ChangeDocument1 pageAnnexure of Change Request Note: CRN No: Point No: Existing Proposed Reasons For ChangeAhmed HadadNo ratings yet

- Decision Making Styles: NAME: Ahmed Hassan Ibrahim Elhadad GROUP: 1KDocument3 pagesDecision Making Styles: NAME: Ahmed Hassan Ibrahim Elhadad GROUP: 1KAhmed HadadNo ratings yet

- DiabetesDocument2 pagesDiabetesAhmed HadadNo ratings yet

- Marketing Strategy & Planning: Ikea 12/13/2018Document41 pagesMarketing Strategy & Planning: Ikea 12/13/2018Ahmed HadadNo ratings yet

- Simulink Bms Development White PaperDocument15 pagesSimulink Bms Development White PaperDIMI EKONGA NZELLYNo ratings yet

- Prasetyawan 2020Document9 pagesPrasetyawan 2020Tania CanchanyaNo ratings yet

- Thermoelectric RefrigeratorDocument33 pagesThermoelectric RefrigeratorVikash Singh Rajput100% (3)

- Doc024 Uk Ins Securope Cold Deck Ldv023 - 036Document15 pagesDoc024 Uk Ins Securope Cold Deck Ldv023 - 036Dpto Ingenieria PROINTENo ratings yet

- Temperature Influence in Cornstarch Gelatinization For Froth FlotationDocument5 pagesTemperature Influence in Cornstarch Gelatinization For Froth FlotationRougeeeNo ratings yet

- PHY 101 Lecture - 1 - 2023Document29 pagesPHY 101 Lecture - 1 - 2023sharmaaditya21925No ratings yet

- Equivalent Lengths - Engineered Software Knowledge Base - Global SiteDocument2 pagesEquivalent Lengths - Engineered Software Knowledge Base - Global SitemachinemanNo ratings yet

- İng Us CG ExamDocument383 pagesİng Us CG ExamMustafaNo ratings yet

- Deliver Ads Using Google Ad ManagerDocument6 pagesDeliver Ads Using Google Ad ManagersuhasNo ratings yet

- KV-1000 700 Im 96M12876 GB WW 1123-1 PDFDocument8 pagesKV-1000 700 Im 96M12876 GB WW 1123-1 PDFSanti ElisahNo ratings yet

- 45F RCF 795691Document19 pages45F RCF 795691milton apraezNo ratings yet

- Textiles - High Density Polyethylene (HDPE) / Polypropylene (PP) Woven Sacks For Packaging of 50 KG Food Grains - SpecificationDocument15 pagesTextiles - High Density Polyethylene (HDPE) / Polypropylene (PP) Woven Sacks For Packaging of 50 KG Food Grains - SpecificationVishalNo ratings yet

- Borsafe ™ He3490-Ls-H: PolyethyleneDocument3 pagesBorsafe ™ He3490-Ls-H: Polyethylenedeep patelNo ratings yet

- Unit 3 Reference and SenseDocument10 pagesUnit 3 Reference and SenseHuynh Thi Cam NhungNo ratings yet

- General Chemistry 1 (Grade 11-STEM) : Gas LawDocument5 pagesGeneral Chemistry 1 (Grade 11-STEM) : Gas Lawlui yangyangNo ratings yet

- Tugas RutinDocument6 pagesTugas RutinYogi SihiteNo ratings yet

- FoundationEngineeringNotes PDFDocument253 pagesFoundationEngineeringNotes PDFNabin YadavNo ratings yet

- Wirtgen Group Parts and More 2008Document476 pagesWirtgen Group Parts and More 2008IBah Zaxapko83% (6)

- (WWW - Entrance-Exam - Net) - Gujarat Technological University ME 1st Sem - Advanced Fluid Mechanics Sample Paper 5Document2 pages(WWW - Entrance-Exam - Net) - Gujarat Technological University ME 1st Sem - Advanced Fluid Mechanics Sample Paper 5Anas ElshabliNo ratings yet

- PHD Thesis Al-Ajmi PDFDocument134 pagesPHD Thesis Al-Ajmi PDFarief_7100% (1)

- Robotics Unit-4 RBTDocument60 pagesRobotics Unit-4 RBTRagava TalluriNo ratings yet

- DCS SystemDocument19 pagesDCS Systemubaid100% (1)

- Express 45 As A Product of Primes Express 50 As A Product of PrimesDocument10 pagesExpress 45 As A Product of Primes Express 50 As A Product of PrimesHalieem YousefNo ratings yet

- Telling Compelling Stories With Numbers PDFDocument99 pagesTelling Compelling Stories With Numbers PDFJuYoung LimNo ratings yet

- Tube Bending Design Guide 1Document24 pagesTube Bending Design Guide 1Yasmin 2021No ratings yet

- Earth Science ReviewerDocument2 pagesEarth Science ReviewerElizabeth OctavianoNo ratings yet

- Beekeepingfor Honey Productionin Sri Lanka Basedon Forage Distance 1Document5 pagesBeekeepingfor Honey Productionin Sri Lanka Basedon Forage Distance 1oshiniNo ratings yet

- Evaporation NewDocument64 pagesEvaporation NewshashwatNo ratings yet