Professional Documents

Culture Documents

Useful Information On Scuffing Load Tests

Useful Information On Scuffing Load Tests

Uploaded by

Jean OliveiraCopyright:

Available Formats

You might also like

- Isuzu D-Max 2011 Transfer Case Service ManualDocument92 pagesIsuzu D-Max 2011 Transfer Case Service ManualWilmer Huanga92% (13)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- H1 Service ManualDocument864 pagesH1 Service ManualFrank Ch Ccaico50% (2)

- Ak Master (Sae j2522)Document18 pagesAk Master (Sae j2522)Diego ChavezNo ratings yet

- DC-3 Operations ManualDocument20 pagesDC-3 Operations ManualGrzegorz PiasecznyNo ratings yet

- Saej1469v003 Air Brake Actuator Test ProcedureDocument22 pagesSaej1469v003 Air Brake Actuator Test ProcedureDaniel Farfan100% (1)

- Dongfeng Cummins Dongfeng Cummins Technical Operations: Engine Model QSZ13-G2Document8 pagesDongfeng Cummins Dongfeng Cummins Technical Operations: Engine Model QSZ13-G2Franyusmid Gomez Bolivar100% (2)

- Brake Accumulator - Test and ChargeDocument8 pagesBrake Accumulator - Test and Chargemoammer100% (2)

- BG6 TransmissionDocument198 pagesBG6 TransmissionBYRONGOSNo ratings yet

- JTP425 HFC Refrigerant Retrofit R134a PDFDocument74 pagesJTP425 HFC Refrigerant Retrofit R134a PDFNick LesterNo ratings yet

- Gear Oils Part 5Document2 pagesGear Oils Part 5RamiNo ratings yet

- ScuffingDocument3 pagesScuffingVelshankar MJNo ratings yet

- Failure ModesDocument6 pagesFailure Modesfaisal ali khanNo ratings yet

- High Temperature Grease Performance LubricationDocument2 pagesHigh Temperature Grease Performance LubricationJohndelon Platino MendozaNo ratings yet

- Dilución Del Combustible en El MotorDocument5 pagesDilución Del Combustible en El MotorSandra Salome Quea TiconaNo ratings yet

- ASME Oil Selection For Precision Ball Bearing F2161.5237 1Document15 pagesASME Oil Selection For Precision Ball Bearing F2161.5237 1vyhtran4731100% (1)

- Especificaciones Bomba Levante y Enfriamiento CAT789CDocument3 pagesEspecificaciones Bomba Levante y Enfriamiento CAT789CRafael RodriguezNo ratings yet

- Weatherford MP8 MP10 Mud PumpDocument38 pagesWeatherford MP8 MP10 Mud PumpDavid OrtegaNo ratings yet

- Surface Vehicle Standard: Rev. JUN2005Document4 pagesSurface Vehicle Standard: Rev. JUN2005JOSE ANDRES OCHOA ORELLANANo ratings yet

- Tightening Torques Items N.M KGF.M LB-FT: 4 Wheel Drive (4WD) SystemDocument35 pagesTightening Torques Items N.M KGF.M LB-FT: 4 Wheel Drive (4WD) SystemZM OhnNo ratings yet

- ARP6255-Aviation Lubricant Tribology Evaluator (ALTE) Method To Determine The Lubricating Capability of Gas Turbine LubricantsDocument9 pagesARP6255-Aviation Lubricant Tribology Evaluator (ALTE) Method To Determine The Lubricating Capability of Gas Turbine LubricantsJicheng PiaoNo ratings yet

- Brake Accumulator Test and ChargeDocument8 pagesBrake Accumulator Test and ChargeBarzola Soto Omar100% (1)

- TD06 00033Document6 pagesTD06 00033boris345678No ratings yet

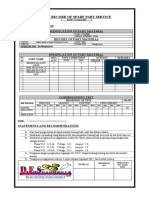

- Test Record of Spare Part Service: Spesification of Part Material History of Part MaterialDocument4 pagesTest Record of Spare Part Service: Spesification of Part Material History of Part MaterialKhalidperkasaNo ratings yet

- Synthetic Oil TestingDocument12 pagesSynthetic Oil TestingamsoildealerNo ratings yet

- SAEJ651v002Document17 pagesSAEJ651v002Marcelo ColomboNo ratings yet

- Identification and MitigationDocument16 pagesIdentification and Mitigation103 Syed Ismail SNo ratings yet

- Surface Vehicle Recommended Practice: Reaf. OCT93Document12 pagesSurface Vehicle Recommended Practice: Reaf. OCT93Glauco SantosNo ratings yet

- 33 - Eaton 4106 5206 Transmission Service Manual PDFDocument90 pages33 - Eaton 4106 5206 Transmission Service Manual PDFSomadbsi100% (1)

- HFF Carquest Friction 2010Document29 pagesHFF Carquest Friction 2010gearhead1No ratings yet

- StallDocument3 pagesStallnamduong368100% (1)

- Determining Cause of Fuel Dilution of EnginesDocument6 pagesDetermining Cause of Fuel Dilution of EnginespedriscoNo ratings yet

- 121 ScribdManual eDocument1 page121 ScribdManual eKrishna PrasadNo ratings yet

- Lubrication TestDocument12 pagesLubrication TestIrsa Septiawan100% (1)

- Gerry FarellmodsDocument11 pagesGerry Farellmodssunthron somchaiNo ratings yet

- User - Manual - Rally - Caja de CambiosDocument116 pagesUser - Manual - Rally - Caja de CambiosoliverjavieramadorNo ratings yet

- Modeling TransientDocument23 pagesModeling TransientsiritapeNo ratings yet

- Multiple Cyl Cutout TestDocument13 pagesMultiple Cyl Cutout Testvova0lopuxNo ratings yet

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- Chassis Dyno TestingDocument5 pagesChassis Dyno TestingcharulapNo ratings yet

- SL 1285B - Proper Tire Pressure Maintenance 2021-06-15Document4 pagesSL 1285B - Proper Tire Pressure Maintenance 2021-06-15Alexander Graytrouses100% (2)

- Устройство PMS часть 1Document9 pagesУстройство PMS часть 1Achmad AminNo ratings yet

- Acumulador de FrenoDocument7 pagesAcumulador de FrenoUlises BarreraNo ratings yet

- 2015 - Polyakov - Improving Worm-Gear Performance Optimal Lubricant Selection Accelerated TestsDocument3 pages2015 - Polyakov - Improving Worm-Gear Performance Optimal Lubricant Selection Accelerated TestsGustavo FagundesNo ratings yet

- 65 - REHS3007-Determining The Cause of Fuel Dilution of Engine OilDocument7 pages65 - REHS3007-Determining The Cause of Fuel Dilution of Engine OilFranklin LezamaNo ratings yet

- Radical SR3 Owners ManualDocument12 pagesRadical SR3 Owners ManualDavid DomínguezNo ratings yet

- Saej 135 V 001Document5 pagesSaej 135 V 001BonnerNo ratings yet

- FZG enDocument12 pagesFZG enrbulnes2350No ratings yet

- Ficha Tecnica Castrol Optigear SyntheticDocument2 pagesFicha Tecnica Castrol Optigear SyntheticVictor Manuel Gonzalez PerezNo ratings yet

- Sae J109-2014Document4 pagesSae J109-2014Marcos RosenbergNo ratings yet

- SAEJ108 V 001Document8 pagesSAEJ108 V 001Marcos Verissimo Juca de PaulaNo ratings yet

- Paper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFDocument11 pagesPaper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFbigsteve9088No ratings yet

- Gates Developmentofafour BallweartestproceduretoevaluateoilsDocument10 pagesGates Developmentofafour Ballweartestproceduretoevaluateoilsdebisi14140No ratings yet

- Performance Report SBTDocument3 pagesPerformance Report SBTOscar SandovalNo ratings yet

- SL 912 016Document6 pagesSL 912 016Pedro SousaNo ratings yet

- VS1400Document512 pagesVS1400justin VerhoogNo ratings yet

- Fluid Sealing Association Fluid Sealing Association: Standard StandardDocument16 pagesFluid Sealing Association Fluid Sealing Association: Standard StandardmansurudinNo ratings yet

- Suspension Fluid - PvdwikiDocument7 pagesSuspension Fluid - Pvdwiki154776No ratings yet

- Greasetech India Oct Dec 2012Document32 pagesGreasetech India Oct Dec 2012prasad24488No ratings yet

- Fatigue Life PredictionsDocument12 pagesFatigue Life PredictionsChristian CotteNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Engineering Encyclopedia: Evaluating The Material Requirements of Compressor Mechanical ComponentsDocument126 pagesEngineering Encyclopedia: Evaluating The Material Requirements of Compressor Mechanical ComponentsAfzaalUmair100% (1)

- Launch Tech Usa: CRP 12X PremiumDocument20 pagesLaunch Tech Usa: CRP 12X PremiumToto Slamet Priyadi100% (1)

- Medklinn Autoplus User Manual 1Document7 pagesMedklinn Autoplus User Manual 1Jophy LeeNo ratings yet

- Obzor Neispravnostey Cayenne DME 7.1.1 955Document22 pagesObzor Neispravnostey Cayenne DME 7.1.1 955bakriramziNo ratings yet

- Engine Controls Engine Controls: Page 1 of 3Document4 pagesEngine Controls Engine Controls: Page 1 of 3jonattanNo ratings yet

- Paper Moving Head LightDocument5 pagesPaper Moving Head Lightsamadhan khaireNo ratings yet

- Sinotruk Operation Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDDocument10 pagesSinotruk Operation Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDamonNo ratings yet

- Jap Co IndiaDocument14 pagesJap Co IndiaompatelNo ratings yet

- Norriseal Level ControllerDocument4 pagesNorriseal Level ControllerRio WitcandraNo ratings yet

- 2954 4650 00 - Qas 600 - enDocument58 pages2954 4650 00 - Qas 600 - enKari MohamedNo ratings yet

- Installation Instructions Complete Set Active Sound Incl. Soundbooster Audi A4 8K / A5 8TDocument16 pagesInstallation Instructions Complete Set Active Sound Incl. Soundbooster Audi A4 8K / A5 8TIstván PatakiNo ratings yet

- KIA Obd Ii: Scanner - Diagnostico - CodigosDocument20 pagesKIA Obd Ii: Scanner - Diagnostico - Codigosmarquin84No ratings yet

- 303-12 Intake Air Distribution and Filtering - Removal and Installation - Charge Air Cooler CAC Intake PipeDocument4 pages303-12 Intake Air Distribution and Filtering - Removal and Installation - Charge Air Cooler CAC Intake PipeCARLOS LIMADANo ratings yet

- SAEJ216V002Document4 pagesSAEJ216V002Nijanthan G. VasudevanNo ratings yet

- Circuit DiagramsDocument110 pagesCircuit Diagramsslam9No ratings yet

- Platina BS Vi Rev04 Feb 2021Document48 pagesPlatina BS Vi Rev04 Feb 2021Sujin100% (1)

- Ex Motor Manual 3gzf500730-47 Rev G 06-2019 en FR de It PT Es TR LQPDocument254 pagesEx Motor Manual 3gzf500730-47 Rev G 06-2019 en FR de It PT Es TR LQPChrist Rodney MAKANANo ratings yet

- 992220M BRO Pressure Washing SolutionsDocument20 pages992220M BRO Pressure Washing SolutionsАндрейNo ratings yet

- HERE Maps and Location Services Technical GuideDocument15 pagesHERE Maps and Location Services Technical GuideVaibhav ZadeNo ratings yet

- Engines 2G40 EngDocument6 pagesEngines 2G40 EngKenan TiroNo ratings yet

- Compact Valve - 1/2: Series DS2 Manually Operated Valve - G1/2Document6 pagesCompact Valve - 1/2: Series DS2 Manually Operated Valve - G1/2Biswanath LenkaNo ratings yet

- ZF Transmition OilDocument16 pagesZF Transmition OilSamwelNo ratings yet

- 14H Motor Grader ASE00001-) - Document StructureDocument3 pages14H Motor Grader ASE00001-) - Document StructureAHMED2ALINo ratings yet

- Renault CLIO: 8th March 2021Document40 pagesRenault CLIO: 8th March 2021Zied KhalkiNo ratings yet

- 9320, 9420 and 9520 Scraper Tractors (Serial No. E040001-)Document364 pages9320, 9420 and 9520 Scraper Tractors (Serial No. E040001-)Cristian GuerreroNo ratings yet

- MC 10121790 9999Document3 pagesMC 10121790 9999Amged MechanicmanNo ratings yet

- 320D/320D L Medium Hydraulic Excavators Parts Reference GuideDocument9 pages320D/320D L Medium Hydraulic Excavators Parts Reference GuideNilton VengoaNo ratings yet

Useful Information On Scuffing Load Tests

Useful Information On Scuffing Load Tests

Uploaded by

Jean OliveiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Useful Information On Scuffing Load Tests

Useful Information On Scuffing Load Tests

Uploaded by

Jean OliveiraCopyright:

Available Formats

Useful information on scuffing load tests

What are the FZG scuffing load tests all about?

FZG is the Technical Institute for the Study of Gears and Drive Mechanisms (Forschungsstelle für

Zahnräder und Getriebebau) of the Technical University in Munich, where this test rig was devel-

oped. The several scuffing load tests performed on the FZG test rig serve for determining the ex-

tent to which gear lubricants help to prevent scuffing on the tooth faces at the lubrication gap.

Scuffing occurs locally where the gears are in mesh, i.e. where at roughness peaks in contact

temperatures rise sharply ('flash temperatures'), depending on the load, peripheral speed and oil

sump temperature. At these contact points, the surfaces weld together briefly and are torn apart

again as the gears revolve, which leads to partial destruction of the surfaces. The scuffing load

capacity of a lubricant depends primarily on the base oils and additives used, and the consequent

lubricant film thickness.

1. Test pinion

2. Test wheel

3. Drive gear case

4. Rotating coupling

5. Locking pin

6. Load lever with weights

7. Torque gauge

8. Temperature sensor

Drawing of an FZG four square gear oil tester

Test gear pair type A for scuffing load tests

Hints for practice: 07 Edition 09.06, replaces edition 11.00

MA-TM/HSI

Useful information on scuffing load tests

The gear pair type A shows a considerable profile offset, which causes the tooth flanks to move

at higher speeds relative to each other. This in turn increases the percentage of sliding movement

on the flanks, which makes the teeth more susceptible to scuffing.

In the FZG standard scuffing load test, a defined load is applied to a pair of spur wheels, which is

increased after a certain run time. After each load stage, the gear wheels are inspected visually

and wear is measured. If wear exceeds a certain limit, the test is terminated and the last load sta-

ge documented as scuffing load step.

However, there is a variety of different FZG scuffing load tests with different peripheral speeds, oil

sump temperatures, gear pairs and senses of rotation. Different tests and consequently different

scuffing load steps are listed for the various lubricants. The following list is to help make the dif-

ferent results comparable by taking into account the flash temperatures to be theoretically ex-

pected.

Another classification based on scuffing load capacities is provided by API GL4 and GL5 specifi-

cations. For these, FZG tests (step or leap tests) generating the same flash temperatures can

also be used.

Please note that this list does not indicate if a lubricant is suitable for a particular applica-

tion, but solely serves for comparing the various scuffing load tests by the different flash

temperatures.

List for comparing the various FZG scuffing load tests:

The various scuffing load tests can be classified according to the occurring flash temperatures,

which renders a list as follows.

Scuffing load test Flash temp. ∆ϑ [K]

FZG (A/8.3/90) sls > 11 ≈ 370

FZG (A/8.3/90) sls > 12 ≈ 420

FZG (A/16.6/90) sls > 11 ≈ 460

FZG (A/8.3/90) sls > 13 ≈ 500

FZG (A/16.6/90) sls > 12 ≈ 520

FZG (A/8.3/90) sls > 14 ≈ 570

FZG (A/16.6/90) sls > 13 ≈ 610

FZG (A10/16.6R/90) sls > 10 = API GL 4 ≈ 620

FZG (S-A10/16.6R/90) ls 8 PASS = API GL 4 ≈ 770

FZG (S-A10/16.6R/90) ls 9 PASS = API GL 5 ≈ 950

sls = scuffing load step ls = load step

In this list, the requirements to be met by the lubricant in order to pass the tests increase from top

to bottom.

Hints for practice: 07 Edition 09.06, replaces edition 11.00

MA-TM/HSI

Useful information on scuffing load tests

The scuffing load tests listed refer to the use of gear oils. Scuffing load tests for gear greases,

where peripheral speeds and temperatures are lower, have not been considered.

Comments on scuffing load capacity and the individual tests

The indicated flash temperatures (temperature increase over tooth bulk temperature 1) we-

re determined by means of the integral temperature method DIN 3990

Standard scuffing load test acc. to DIN 51354 FZG (A/8.3/90)

Gear pair type A, peripheral speed 8.3 m/s, oil sump temperature 90 °C, centre distance in test

gear 91.5 mm;

At first, the gear pair is run in at low load stages. Then the load stages are increased, which leads

to higher flash temperatures occurring in the gears. The running-in smoothens the surfaces.

Enhanced scuffing load test FZG (A/16.6/90)

The peripheral speed is increased ot 16.6 m/s;

In this test, the flash temperature level is higher. Running-in at low load stages is as in the normal

scuffing load test.

Step test FZG (A10/16.6R/90)

Sense of rotation is reversed (gear wheel driving the pinion), a narrower pinion is used (A10);

This change of operating conditions increases pressure and makes it more difficult for the lubri-

cant to reach the friction points.

Leap test FZG (S-A10/16.6R/90)

The load is not increased gradually, but the load of a certain stage is applied without running-in.

The result obtained is PASS or FAIL.

There is no running-in, so the surfaces are not smoothened, which leads to higher flash tempera-

tures.

However, it should be noted that a lubricant should normally possess certain running-in charac-

teristics, especially for use in gears. These characteristics will eventually increase the scuffing

load capacity of the gear pair.

For this reason it is essential to always bear in mind the conditions under which a particular suf-

fing load test is performed.

We hope this will contribute to a little "enlightenment" regarding the testing of gear lubricants.

References

1

B.-R. Höhn, P. Oster, K. Michaelis: New test methods for the evaluation of wear, scuffing and

pitting capacity of gear lubricants. AGMA Technical Paper 98FTM8 (1998)

Hints for practice: 07 Edition 09.06, replaces edition 11.00

MA-TM/HSI

You might also like

- Isuzu D-Max 2011 Transfer Case Service ManualDocument92 pagesIsuzu D-Max 2011 Transfer Case Service ManualWilmer Huanga92% (13)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- H1 Service ManualDocument864 pagesH1 Service ManualFrank Ch Ccaico50% (2)

- Ak Master (Sae j2522)Document18 pagesAk Master (Sae j2522)Diego ChavezNo ratings yet

- DC-3 Operations ManualDocument20 pagesDC-3 Operations ManualGrzegorz PiasecznyNo ratings yet

- Saej1469v003 Air Brake Actuator Test ProcedureDocument22 pagesSaej1469v003 Air Brake Actuator Test ProcedureDaniel Farfan100% (1)

- Dongfeng Cummins Dongfeng Cummins Technical Operations: Engine Model QSZ13-G2Document8 pagesDongfeng Cummins Dongfeng Cummins Technical Operations: Engine Model QSZ13-G2Franyusmid Gomez Bolivar100% (2)

- Brake Accumulator - Test and ChargeDocument8 pagesBrake Accumulator - Test and Chargemoammer100% (2)

- BG6 TransmissionDocument198 pagesBG6 TransmissionBYRONGOSNo ratings yet

- JTP425 HFC Refrigerant Retrofit R134a PDFDocument74 pagesJTP425 HFC Refrigerant Retrofit R134a PDFNick LesterNo ratings yet

- Gear Oils Part 5Document2 pagesGear Oils Part 5RamiNo ratings yet

- ScuffingDocument3 pagesScuffingVelshankar MJNo ratings yet

- Failure ModesDocument6 pagesFailure Modesfaisal ali khanNo ratings yet

- High Temperature Grease Performance LubricationDocument2 pagesHigh Temperature Grease Performance LubricationJohndelon Platino MendozaNo ratings yet

- Dilución Del Combustible en El MotorDocument5 pagesDilución Del Combustible en El MotorSandra Salome Quea TiconaNo ratings yet

- ASME Oil Selection For Precision Ball Bearing F2161.5237 1Document15 pagesASME Oil Selection For Precision Ball Bearing F2161.5237 1vyhtran4731100% (1)

- Especificaciones Bomba Levante y Enfriamiento CAT789CDocument3 pagesEspecificaciones Bomba Levante y Enfriamiento CAT789CRafael RodriguezNo ratings yet

- Weatherford MP8 MP10 Mud PumpDocument38 pagesWeatherford MP8 MP10 Mud PumpDavid OrtegaNo ratings yet

- Surface Vehicle Standard: Rev. JUN2005Document4 pagesSurface Vehicle Standard: Rev. JUN2005JOSE ANDRES OCHOA ORELLANANo ratings yet

- Tightening Torques Items N.M KGF.M LB-FT: 4 Wheel Drive (4WD) SystemDocument35 pagesTightening Torques Items N.M KGF.M LB-FT: 4 Wheel Drive (4WD) SystemZM OhnNo ratings yet

- ARP6255-Aviation Lubricant Tribology Evaluator (ALTE) Method To Determine The Lubricating Capability of Gas Turbine LubricantsDocument9 pagesARP6255-Aviation Lubricant Tribology Evaluator (ALTE) Method To Determine The Lubricating Capability of Gas Turbine LubricantsJicheng PiaoNo ratings yet

- Brake Accumulator Test and ChargeDocument8 pagesBrake Accumulator Test and ChargeBarzola Soto Omar100% (1)

- TD06 00033Document6 pagesTD06 00033boris345678No ratings yet

- Test Record of Spare Part Service: Spesification of Part Material History of Part MaterialDocument4 pagesTest Record of Spare Part Service: Spesification of Part Material History of Part MaterialKhalidperkasaNo ratings yet

- Synthetic Oil TestingDocument12 pagesSynthetic Oil TestingamsoildealerNo ratings yet

- SAEJ651v002Document17 pagesSAEJ651v002Marcelo ColomboNo ratings yet

- Identification and MitigationDocument16 pagesIdentification and Mitigation103 Syed Ismail SNo ratings yet

- Surface Vehicle Recommended Practice: Reaf. OCT93Document12 pagesSurface Vehicle Recommended Practice: Reaf. OCT93Glauco SantosNo ratings yet

- 33 - Eaton 4106 5206 Transmission Service Manual PDFDocument90 pages33 - Eaton 4106 5206 Transmission Service Manual PDFSomadbsi100% (1)

- HFF Carquest Friction 2010Document29 pagesHFF Carquest Friction 2010gearhead1No ratings yet

- StallDocument3 pagesStallnamduong368100% (1)

- Determining Cause of Fuel Dilution of EnginesDocument6 pagesDetermining Cause of Fuel Dilution of EnginespedriscoNo ratings yet

- 121 ScribdManual eDocument1 page121 ScribdManual eKrishna PrasadNo ratings yet

- Lubrication TestDocument12 pagesLubrication TestIrsa Septiawan100% (1)

- Gerry FarellmodsDocument11 pagesGerry Farellmodssunthron somchaiNo ratings yet

- User - Manual - Rally - Caja de CambiosDocument116 pagesUser - Manual - Rally - Caja de CambiosoliverjavieramadorNo ratings yet

- Modeling TransientDocument23 pagesModeling TransientsiritapeNo ratings yet

- Multiple Cyl Cutout TestDocument13 pagesMultiple Cyl Cutout Testvova0lopuxNo ratings yet

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- Chassis Dyno TestingDocument5 pagesChassis Dyno TestingcharulapNo ratings yet

- SL 1285B - Proper Tire Pressure Maintenance 2021-06-15Document4 pagesSL 1285B - Proper Tire Pressure Maintenance 2021-06-15Alexander Graytrouses100% (2)

- Устройство PMS часть 1Document9 pagesУстройство PMS часть 1Achmad AminNo ratings yet

- Acumulador de FrenoDocument7 pagesAcumulador de FrenoUlises BarreraNo ratings yet

- 2015 - Polyakov - Improving Worm-Gear Performance Optimal Lubricant Selection Accelerated TestsDocument3 pages2015 - Polyakov - Improving Worm-Gear Performance Optimal Lubricant Selection Accelerated TestsGustavo FagundesNo ratings yet

- 65 - REHS3007-Determining The Cause of Fuel Dilution of Engine OilDocument7 pages65 - REHS3007-Determining The Cause of Fuel Dilution of Engine OilFranklin LezamaNo ratings yet

- Radical SR3 Owners ManualDocument12 pagesRadical SR3 Owners ManualDavid DomínguezNo ratings yet

- Saej 135 V 001Document5 pagesSaej 135 V 001BonnerNo ratings yet

- FZG enDocument12 pagesFZG enrbulnes2350No ratings yet

- Ficha Tecnica Castrol Optigear SyntheticDocument2 pagesFicha Tecnica Castrol Optigear SyntheticVictor Manuel Gonzalez PerezNo ratings yet

- Sae J109-2014Document4 pagesSae J109-2014Marcos RosenbergNo ratings yet

- SAEJ108 V 001Document8 pagesSAEJ108 V 001Marcos Verissimo Juca de PaulaNo ratings yet

- Paper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFDocument11 pagesPaper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFbigsteve9088No ratings yet

- Gates Developmentofafour BallweartestproceduretoevaluateoilsDocument10 pagesGates Developmentofafour Ballweartestproceduretoevaluateoilsdebisi14140No ratings yet

- Performance Report SBTDocument3 pagesPerformance Report SBTOscar SandovalNo ratings yet

- SL 912 016Document6 pagesSL 912 016Pedro SousaNo ratings yet

- VS1400Document512 pagesVS1400justin VerhoogNo ratings yet

- Fluid Sealing Association Fluid Sealing Association: Standard StandardDocument16 pagesFluid Sealing Association Fluid Sealing Association: Standard StandardmansurudinNo ratings yet

- Suspension Fluid - PvdwikiDocument7 pagesSuspension Fluid - Pvdwiki154776No ratings yet

- Greasetech India Oct Dec 2012Document32 pagesGreasetech India Oct Dec 2012prasad24488No ratings yet

- Fatigue Life PredictionsDocument12 pagesFatigue Life PredictionsChristian CotteNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Engineering Encyclopedia: Evaluating The Material Requirements of Compressor Mechanical ComponentsDocument126 pagesEngineering Encyclopedia: Evaluating The Material Requirements of Compressor Mechanical ComponentsAfzaalUmair100% (1)

- Launch Tech Usa: CRP 12X PremiumDocument20 pagesLaunch Tech Usa: CRP 12X PremiumToto Slamet Priyadi100% (1)

- Medklinn Autoplus User Manual 1Document7 pagesMedklinn Autoplus User Manual 1Jophy LeeNo ratings yet

- Obzor Neispravnostey Cayenne DME 7.1.1 955Document22 pagesObzor Neispravnostey Cayenne DME 7.1.1 955bakriramziNo ratings yet

- Engine Controls Engine Controls: Page 1 of 3Document4 pagesEngine Controls Engine Controls: Page 1 of 3jonattanNo ratings yet

- Paper Moving Head LightDocument5 pagesPaper Moving Head Lightsamadhan khaireNo ratings yet

- Sinotruk Operation Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDDocument10 pagesSinotruk Operation Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDamonNo ratings yet

- Jap Co IndiaDocument14 pagesJap Co IndiaompatelNo ratings yet

- Norriseal Level ControllerDocument4 pagesNorriseal Level ControllerRio WitcandraNo ratings yet

- 2954 4650 00 - Qas 600 - enDocument58 pages2954 4650 00 - Qas 600 - enKari MohamedNo ratings yet

- Installation Instructions Complete Set Active Sound Incl. Soundbooster Audi A4 8K / A5 8TDocument16 pagesInstallation Instructions Complete Set Active Sound Incl. Soundbooster Audi A4 8K / A5 8TIstván PatakiNo ratings yet

- KIA Obd Ii: Scanner - Diagnostico - CodigosDocument20 pagesKIA Obd Ii: Scanner - Diagnostico - Codigosmarquin84No ratings yet

- 303-12 Intake Air Distribution and Filtering - Removal and Installation - Charge Air Cooler CAC Intake PipeDocument4 pages303-12 Intake Air Distribution and Filtering - Removal and Installation - Charge Air Cooler CAC Intake PipeCARLOS LIMADANo ratings yet

- SAEJ216V002Document4 pagesSAEJ216V002Nijanthan G. VasudevanNo ratings yet

- Circuit DiagramsDocument110 pagesCircuit Diagramsslam9No ratings yet

- Platina BS Vi Rev04 Feb 2021Document48 pagesPlatina BS Vi Rev04 Feb 2021Sujin100% (1)

- Ex Motor Manual 3gzf500730-47 Rev G 06-2019 en FR de It PT Es TR LQPDocument254 pagesEx Motor Manual 3gzf500730-47 Rev G 06-2019 en FR de It PT Es TR LQPChrist Rodney MAKANANo ratings yet

- 992220M BRO Pressure Washing SolutionsDocument20 pages992220M BRO Pressure Washing SolutionsАндрейNo ratings yet

- HERE Maps and Location Services Technical GuideDocument15 pagesHERE Maps and Location Services Technical GuideVaibhav ZadeNo ratings yet

- Engines 2G40 EngDocument6 pagesEngines 2G40 EngKenan TiroNo ratings yet

- Compact Valve - 1/2: Series DS2 Manually Operated Valve - G1/2Document6 pagesCompact Valve - 1/2: Series DS2 Manually Operated Valve - G1/2Biswanath LenkaNo ratings yet

- ZF Transmition OilDocument16 pagesZF Transmition OilSamwelNo ratings yet

- 14H Motor Grader ASE00001-) - Document StructureDocument3 pages14H Motor Grader ASE00001-) - Document StructureAHMED2ALINo ratings yet

- Renault CLIO: 8th March 2021Document40 pagesRenault CLIO: 8th March 2021Zied KhalkiNo ratings yet

- 9320, 9420 and 9520 Scraper Tractors (Serial No. E040001-)Document364 pages9320, 9420 and 9520 Scraper Tractors (Serial No. E040001-)Cristian GuerreroNo ratings yet

- MC 10121790 9999Document3 pagesMC 10121790 9999Amged MechanicmanNo ratings yet

- 320D/320D L Medium Hydraulic Excavators Parts Reference GuideDocument9 pages320D/320D L Medium Hydraulic Excavators Parts Reference GuideNilton VengoaNo ratings yet