Professional Documents

Culture Documents

SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedure

SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedure

Uploaded by

loveson709Copyright:

Available Formats

You might also like

- Executive Protection ChecklistsDocument35 pagesExecutive Protection ChecklistsGallg Baron92% (26)

- L48 - Owner's Manual - EnglishDocument209 pagesL48 - Owner's Manual - EnglishRandall P. BancroftNo ratings yet

- Risk Assessment Asphalt WorksDocument7 pagesRisk Assessment Asphalt Workskannanjaduzz100% (1)

- 015-Lifting Plan Method & Risk AssessmentDocument3 pages015-Lifting Plan Method & Risk AssessmentMAB AliNo ratings yet

- Crane Assembly and Dismantling and ModificationDocument1 pageCrane Assembly and Dismantling and Modificationsrinibas mohapatraNo ratings yet

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- App-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.Document15 pagesApp-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.loveson709100% (2)

- ABS CLASS ChecklistDocument36 pagesABS CLASS Checklistapi-372122995% (22)

- Generic Lifting PlanDocument4 pagesGeneric Lifting Planayman coreNo ratings yet

- Jsa For Pilling WorkDocument12 pagesJsa For Pilling WorkLakhan kumar100% (1)

- Lifting Plan For Erection of 2nd To 6th Rev.3Document11 pagesLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNo ratings yet

- Planned Critical Lift Crane PermitDocument5 pagesPlanned Critical Lift Crane PermitsurnaikNo ratings yet

- Rigging Plan FormatDocument3 pagesRigging Plan FormatuzairmetallurgistNo ratings yet

- Emergency Rescue Plan For Operatives Working at HeightDocument9 pagesEmergency Rescue Plan For Operatives Working at Heightloveson709100% (2)

- Emergency Rescue Plan For Operatives Working at HeightDocument9 pagesEmergency Rescue Plan For Operatives Working at Heightloveson709100% (2)

- QDC No ObjectionDocument1 pageQDC No Objectionloveson70950% (2)

- Loveson Resume HSE ManagerDocument7 pagesLoveson Resume HSE Managerloveson709No ratings yet

- M50 12.76 Volvo B12BDocument49 pagesM50 12.76 Volvo B12Bmanhlinh08cdNo ratings yet

- GMSB - Level 3 - SWI - 006 - Crane and Lifting WorkDocument16 pagesGMSB - Level 3 - SWI - 006 - Crane and Lifting WorkZulhaidy Salim100% (1)

- Plant 6 3: Risk Assessment For Lifting OperationsDocument4 pagesPlant 6 3: Risk Assessment For Lifting OperationsIdris AdeniranNo ratings yet

- 55 T Lifting PlanDocument5 pages55 T Lifting PlanRestu Putra100% (1)

- Lifting Plan FormDocument2 pagesLifting Plan FormezuanNo ratings yet

- Crane LiftsDocument1 pageCrane LiftsJasonNo ratings yet

- Lifting Plan: Lifting Appointed Person / Supervisor Site InspectionDocument4 pagesLifting Plan: Lifting Appointed Person / Supervisor Site Inspectionkhaled redaNo ratings yet

- Lifting Plan Registration PDFDocument1 pageLifting Plan Registration PDFScribdTranslationsNo ratings yet

- Lifting Plan Calculation (QTZ200 Tower Crane)Document3 pagesLifting Plan Calculation (QTZ200 Tower Crane)Ilham KelanaNo ratings yet

- Flowchart Hpg1034Document1 pageFlowchart Hpg1034SharulNo ratings yet

- Stc1300 Truck Crane: 130t Lifting CapacityDocument15 pagesStc1300 Truck Crane: 130t Lifting CapacityDicky KurniantoNo ratings yet

- Construction Job Hazards Analysis: DemolitionDocument2 pagesConstruction Job Hazards Analysis: Demolitionchirese2000No ratings yet

- Method Statement For Lifting Operations - Builders SafetyDocument2 pagesMethod Statement For Lifting Operations - Builders SafetyMuhammad Sami Parvez100% (1)

- Fes TBT Mobile CraneDocument1 pageFes TBT Mobile CraneMohammed AtefNo ratings yet

- MFD Procedure: Lifting & HoistingDocument16 pagesMFD Procedure: Lifting & HoistingMohammed JassimNo ratings yet

- Crane Safety V0911.1Document1 pageCrane Safety V0911.1Nasir Mehmood AryaniNo ratings yet

- Crane Lifting Plan and Method StatementDocument5 pagesCrane Lifting Plan and Method StatementLawrence adeleke OmisakinNo ratings yet

- Risk Assessment Erection of Precast Concrete ElementsDocument2 pagesRisk Assessment Erection of Precast Concrete ElementsBunyamin Selimoglu100% (1)

- Work Method Statement: Wms Rev. NoDocument5 pagesWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- Tandem Lifting Container SWGDocument1 pageTandem Lifting Container SWGarifNo ratings yet

- Anthony James CV Feb 24 - 2023 PDFDocument3 pagesAnthony James CV Feb 24 - 2023 PDFanthony jamesNo ratings yet

- Appendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormDocument1 pageAppendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormharryNo ratings yet

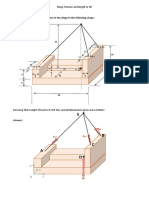

- Apolo Additional Attachments (Slings Tension in 3d)Document4 pagesApolo Additional Attachments (Slings Tension in 3d)Mo'tasem SerdanehNo ratings yet

- FC 4.1.8 - Critical Lift PlanDocument1 pageFC 4.1.8 - Critical Lift PlanJosef Demner Tiu PaspeNo ratings yet

- Lifting Work Permit ColoredDocument2 pagesLifting Work Permit ColoredAJEET SINGHNo ratings yet

- Onshore Critical Lift Plan FormDocument2 pagesOnshore Critical Lift Plan FormSyaiful Akhmad100% (1)

- Ity of Ilpitas Inspection Checklist: Asphalt Pavement Inspection ProceduresDocument4 pagesIty of Ilpitas Inspection Checklist: Asphalt Pavement Inspection ProceduresLazar AndonovNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- Guidelines Flagmen - Banksmen (English)Document1 pageGuidelines Flagmen - Banksmen (English)Pirlo PoloNo ratings yet

- Non Routine Lift Plan Check ListDocument2 pagesNon Routine Lift Plan Check Listmohamed atef0% (1)

- Lifting PlanDocument2 pagesLifting PlansivaavissriNo ratings yet

- 8 - Lifting Plan For Transfering Engine (z1) Landing Area Then Loading From Ground To Truck and Vice VersaDocument24 pages8 - Lifting Plan For Transfering Engine (z1) Landing Area Then Loading From Ground To Truck and Vice VersaMo'tasem SerdanehNo ratings yet

- 3 Green Lift Checklist FormDocument2 pages3 Green Lift Checklist FormHưng Hoàng DuyNo ratings yet

- Few Words About Crane Few Words About CraneDocument42 pagesFew Words About Crane Few Words About CraneSamuel GeorgeNo ratings yet

- Presentation For RiggingDocument18 pagesPresentation For RiggingRameese MuhammedNo ratings yet

- TBT RiggingDocument2 pagesTBT RiggingAl DubNo ratings yet

- Oversized & Project CargoDocument2 pagesOversized & Project CargoEric PanNo ratings yet

- Site:FSW - Major Overhaul GTG#1: Alstom Zero Deviation Plan Audit ReportDocument26 pagesSite:FSW - Major Overhaul GTG#1: Alstom Zero Deviation Plan Audit ReportRoy MangaraNo ratings yet

- Zoomlion RT60ton PDFDocument47 pagesZoomlion RT60ton PDFYohan Nafisa NetNo ratings yet

- Sample JHADocument5 pagesSample JHAKen100% (1)

- Construction Lifting PlanDocument5 pagesConstruction Lifting PlanJuma KavesuNo ratings yet

- Mobile Crane Permit, Lifting Plan Method & Risk AssessmentDocument3 pagesMobile Crane Permit, Lifting Plan Method & Risk AssessmentfaizelNo ratings yet

- Lifting Procedure With AttachmentDocument16 pagesLifting Procedure With AttachmentIshak MalimNo ratings yet

- Strong Dual Hawk Tandem Rev H 2008Document70 pagesStrong Dual Hawk Tandem Rev H 2008FaderNo ratings yet

- Document No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomDocument3 pagesDocument No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomShaikh Mohd QaisarNo ratings yet

- Safety Bulletin: Setting Outriggers To Prevent AccidentsDocument12 pagesSafety Bulletin: Setting Outriggers To Prevent AccidentsericNo ratings yet

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadNo ratings yet

- LKC - Lifting Risk AssessmentDocument4 pagesLKC - Lifting Risk AssessmentAdam EatonNo ratings yet

- 1a. Lifting Data Sheet (Cage 24m)Document4 pages1a. Lifting Data Sheet (Cage 24m)Mohd FadliNo ratings yet

- Lifting Plan Vibro Hammer GEO 2021Document7 pagesLifting Plan Vibro Hammer GEO 2021bangunNo ratings yet

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Document3 pagesStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Upper Mast Section Lifting PlanDocument7 pagesUpper Mast Section Lifting PlanDurgham Adel EscanderNo ratings yet

- App-16.2 - Risk Assessment For Vermeer Axis WorksDocument13 pagesApp-16.2 - Risk Assessment For Vermeer Axis Worksloveson709No ratings yet

- App-16.2 - Risk Assessment For Traffic Signal SystemDocument13 pagesApp-16.2 - Risk Assessment For Traffic Signal Systemloveson709100% (2)

- Maintenance Log - TemplateDocument2 pagesMaintenance Log - Templateloveson709No ratings yet

- App-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair RoadDocument15 pagesApp-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair Roadloveson709No ratings yet

- Near Miss Report: Complete This Form and Email It ToDocument1 pageNear Miss Report: Complete This Form and Email It Toloveson709No ratings yet

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pages3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pages3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- INV Inv Ass Form TemplateDocument4 pagesINV Inv Ass Form Templateloveson70950% (2)

- INV Action Plan TemplateDocument2 pagesINV Action Plan Templateloveson709No ratings yet

- Assmt 1 Incident PhotosDocument3 pagesAssmt 1 Incident Photosloveson709No ratings yet

- N.Selvam:, BE (Mechanical)Document2 pagesN.Selvam:, BE (Mechanical)loveson709No ratings yet

- Scaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557Document2 pagesScaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557loveson709No ratings yet

- Loveson Glariyans: (Address, City, ST ZIP Code)Document2 pagesLoveson Glariyans: (Address, City, ST ZIP Code)loveson709No ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Yam Bahadur Budha CV PDFDocument2 pagesYam Bahadur Budha CV PDFloveson709No ratings yet

- Scaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557Document2 pagesScaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557loveson709No ratings yet

- RA082-C Grinding - ThornliebankDocument2 pagesRA082-C Grinding - Thornliebankloveson709No ratings yet

- 005 Ohs-Cop-Starrt & JhaDocument10 pages005 Ohs-Cop-Starrt & Jhaloveson709No ratings yet

- Epoxy COSHHDocument3 pagesEpoxy COSHHloveson709No ratings yet

- PMC-FM-HSS-024 Near Miss ReportDocument1 pagePMC-FM-HSS-024 Near Miss Reportloveson709No ratings yet

- Po Ak-00076 - MR 534Document1 pagePo Ak-00076 - MR 534loveson709No ratings yet

- Salary Incement Letter - DotDocument1 pageSalary Incement Letter - Dotloveson709100% (1)

- HSE Department Demobilization List: Trade May 2016Document1 pageHSE Department Demobilization List: Trade May 2016loveson709No ratings yet

- HSE Department Demobilization List: Trade May 2016Document1 pageHSE Department Demobilization List: Trade May 2016loveson709No ratings yet

- Board Reqd From AlkheesaDocument1 pageBoard Reqd From Alkheesaloveson709No ratings yet

- Bosiet / Huet (Basic Offshore Safety Induction & Emergency Training)Document3 pagesBosiet / Huet (Basic Offshore Safety Induction & Emergency Training)Ronald AranhaNo ratings yet

- M/S L.M.Das: Job Hazard AnalysisDocument3 pagesM/S L.M.Das: Job Hazard AnalysisDwitikrushna Rout100% (1)

- Manual Operador MT732 PDFDocument154 pagesManual Operador MT732 PDFBastian Tapia LopezNo ratings yet

- BA100.User ManualDocument40 pagesBA100.User ManualBaltija MechanikasNo ratings yet

- Beirut ExplosionDocument10 pagesBeirut ExplosionChannis ExoNo ratings yet

- SOP Loading Unloading Line PipeDocument10 pagesSOP Loading Unloading Line PipeSomnath DasNo ratings yet

- Parts of The ShipDocument28 pagesParts of The ShipDonsumit PrajapatiNo ratings yet

- Sound Transit - Draft 2022 Service Plan With AppendicesDocument197 pagesSound Transit - Draft 2022 Service Plan With AppendicesThe UrbanistNo ratings yet

- 2023 NYS State of The State BookDocument277 pages2023 NYS State of The State BookCarl AldingerNo ratings yet

- Especialidades2020 ENGDocument26 pagesEspecialidades2020 ENGjoseNo ratings yet

- Lesson 1 Emergency SituationsDocument9 pagesLesson 1 Emergency SituationsFACIArnold Sean l QuiaoNo ratings yet

- My Preparation Samir RasulDocument38 pagesMy Preparation Samir RasulAung Htet KyawNo ratings yet

- Ranchi To Patna TicketDocument2 pagesRanchi To Patna TicketSmart CADDesign100% (1)

- UK - Dangerous Goods Emergency Action Code List 2015Document200 pagesUK - Dangerous Goods Emergency Action Code List 2015Gabriel JáureguiNo ratings yet

- Safety Alert For Gantry CraneDocument2 pagesSafety Alert For Gantry CraneporbyNo ratings yet

- Training Circular No9999111Document10 pagesTraining Circular No9999111Prashant RamdasNo ratings yet

- (Class D) : Endorsement IMT - 44 or IMT - 45, As Applicable, Is To Be UsedDocument10 pages(Class D) : Endorsement IMT - 44 or IMT - 45, As Applicable, Is To Be UsedRamraj VishwakarmaNo ratings yet

- JND320 Presentation 9 Command AspectsDocument22 pagesJND320 Presentation 9 Command AspectssimonborauNo ratings yet

- Idge System 20121Document6 pagesIdge System 20121jkgfgNo ratings yet

- Breakdown ProcedureDocument6 pagesBreakdown ProcedureIrfan AliNo ratings yet

- Module 012 GmdssDocument234 pagesModule 012 Gmdssallan kasem alcazarenNo ratings yet

- Ilovepdf MergedDocument154 pagesIlovepdf MergedadarciotoaNo ratings yet

- Product Sheet Sigma Multi Mission Frigate 10514Document2 pagesProduct Sheet Sigma Multi Mission Frigate 10514ALEXC100% (2)

- JHA For Cable Tray Installation REV ADocument6 pagesJHA For Cable Tray Installation REV Aputrisherilain khairuldinNo ratings yet

- Air Paper-11-15Document5 pagesAir Paper-11-15comecomegopalNo ratings yet

SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedure

SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedure

Uploaded by

loveson709Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedure

SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedure

Uploaded by

loveson709Copyright:

Available Formats

SACYR MEDGULF HSE MANAGEMENT SYSTEMS MANUAL

CRANE LIFT PROCEDURE

1. SCOPE:

This procedure applies to ALL lifts made by mobile cranes including drotts, galions, cherrypickers, etc. to

the extent all lifts should be assessed under the risk assessment section of this procedure. “Critical Lifts

“defined as medium or high risk, will require full implementation of this procedure. “Routine Lifts “defined

as low risk, do not require implementation of this procedure. Lifts made by permanent or fixed lifting

equipment are not covered by this procedure.

2. PURPOSE:

The purpose of this procedure is to reduce the risk of personnel injury, property damage, and business

interruption when performing crane lifts any of Sacyr Megulf JV site & facilities. This procedure is intended

to ensure proper planning; hazard assessment, authorization, and recognized safe crane operating

methods are performed.

3. PROCEDURE:

A. Crane Lift Assessment

A risk assessment must be completed for all crane lifts in the facility. The Crane Lift

Assessment Table that is included must be utilized to conduct the crane lift assessment. Any

Medium or High level designation for any risk factor is considered a critical lift and will require

completion of a Critical Lift Permit and a pre-meeting to be conducted.

B. Hazard Assessment

A Job Safety Analysis must be conducted for lifts with multiple high risk factors to identify each

step in the lift, the hazards associated with each step, and any necessary safeguards relating

those job steps.

C. Equipment Setup and Operation

All instructions in the manufacturer’s operating manual for cranes to be used must be

referenced and followed. Any deviation from manufacturer’s instruction must be noted on the

Critical Lift Permit and approved by all personnel involved in the lift.

D. Pre-Lift Meeting

A pre-lift meeting must be held for all critical lifts (medium or high risk) with all personnel

involved in the lift present. All personnel involved in the lift must sign the Critical Lift Permit

acknowledging that the preparations are in place and the lift can be safely performed.

E. Critical Lift Permitting

A Critical Lift Permit for each crane used in the lift must be completed and signed by

applicable personnel prior to conducting a critica l lift. Whenever conditions or job steps are

changed or added, a new risk assessment, job safety analysis (for lifts with multiple high risk

factors), and a lift permit must be completed before the lift can proceed.

JVHSE Manual AWD/2020 1

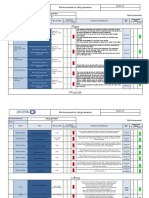

4. CRANE LIFT RISK ASSESSMENT TABLE

The following table is intended to identify the risks associated with a particular crane lift. This

table may not cover all risk factors associated with crane lifts. Existence of multiple risk factors

may increase the risk of a particular lift. The person(s) performing the risk assessment should

always be conservative when assigning risk to a crane lift in order to ensure that all

precautions and safeguards associated with the risk level will be included.

CRANE LIFT RISK ASSESSMENT TABLE

Factor Risk High Level Risk Medium Level Risk Low Level Risk

Process Lifting over operating Lifting over equipment which Lifting over equipment

Condition process equipment is non-operating and isolated cleared of hazardous

containing hazardous from the process but which materials.

material. Lifting over non- contains hazardous

operating process materials (i.e., C5’s and

equipment containing very above, chemicals, high

hazardous materials or pressure steam, etc.).

high volume high pressure

hazardous materials (i.e.,

hydrogen sulfide, liquefied

petroleum gas). Lifting

over equipment or facilities

that if damaged will have a

significant effect on the

integrity of process

operation. (MCCs, cable

trays,etc.)

Proximity to Operating equipment, Operating equipment, All other lifts not within the

Personnel and control rooms, occupied control rooms, occupied medium or high risk

Equipment buildings within a distance Buildings within a distance of proximity.

of 120% of the boom 150% of the boom length

length and load radius and load radius centered on

centered on crane the crane turntable.

turntable. See Lift Area

Diagram.

Property Loss Load to be lifted is high Load to be lifted is moderate Load to be lifted is low cost.

And/Or cost (>$100,000) Long cost $50,000 to $100,000 (<$50,000) with

Business lead time or project critical with some project schedule replacement readily

Interruption path. impact or some business available. Minor or no

interruption. business interruption.

JVHSE Manual AWD/2020 2

Factor Risk High Level Risk Medium Level Risk Low Level Risk

Complexity Load exceeds 90% of the Lift presents limited Clearance is no concern,

crane’s charted capacity clearance, multiple routine rigging, single crane.

and: lift presents limited maneuvers, multiple cranes,

clearance, multiple difficult

maneuvers, multiple alignment/placement,

cranes, difficult specialized jib required,

alignment/placement, and/or complicated rigging

specialized jib required,

and/or complicated

rigging.

Lift Equipment Any lift requiring a crane Crane base rated at 180 Routine plant lifting

with heavy lift metric tonnes or greater. equipment without

attachments, guy wires, additional attachments.

poles, or derricks

Height of Lift Any lift in which the Any lift in which the greatest All other boom length and

greatest length of the length of the boom utilized crane ratings.

boom utilized during the during the lift is 80% or more

lift is 80% or more of the of the maximum boom

maximum boom length length and the crane is base

and the crane is base rated at 70 to 135 metric

rated at 135 metric tonnes tonnes.

or greater.

Weight of Load Any lift using an estimated Any lift using an known Weight determined to be

weight which exceeds weight which exceeds 90% less than 90% of the crane

80% or more of crane or more of crane rated rated capacity.

rated capacity. capacity. Counter weights

added per manufacturer’s

instruction.

Weather High wind velocity with Unstable weather conditions Low or no winds or known

potential to interfere with with potential for sudden potential for winds to

load/crane stability. high winds that may interfere develop and interfere with

with the safety of the lift. the lift.

JVHSE Manual AWD/2020 3

5. RESPONSIBILITIES

A. Crane Operator

1. Must have approved operator’s certification and crane inspection certificate.

2. Participate in the risk assessment to determine the risk category for the lift.

3. Participate in the lift job safety analysis for lifts with two or more high risk factors.

4. Have current authorization to perform the lift with the applicable crane/equipment

5. Ensure the weight of the load and accessories has been established.

6. Assess the lift including weight of load, radius of boom, boom angle, weather

conditions, levelness of crane set-up, etc. to ensure the lift is within the load ratings

(load chart) of the crane as provided by the manufacturer.

7. Set-up crane in accordance with manufacturer’s equipment-specific instructions.

8. Perform a daily equipment inspection of the crane in accordance with manufacturer’s

equipment-specific instructions.

9. Ensure proper barricades are utilized to prevent unauthorized personnel from entering

crane and lift area.

10. Ensure flagman and signalman are used whenever necessary for safe travel and/or

operation.

11. Participate in the pre-lift meeting

12. Complete and sign Critical Lift Permit authorizing that all preparations and safeguards

are in place prior to making the lift.

13. Perform unloaded lift cycle test if the risk assessment includes 1 or more High Level

Risk factors.

14. Perform suspended load test by suspending load slightly above grade/equipment base

prior to making full lift cycle.

15. Perform the lift in accordance with recognized safe operating methods outlined by the

manufacturer and with the precautions listed in the lift job safety analysis (for lifts involving two

or more high risk factors).

16. Return completed Critical Lift Permit and Job Safety Analysis to supervisor in charge of the lift.

B. Rigger

1. Must have approved competence certification.

2. Participate in the risk assessment to determine the risk category for the lift.

3. Participate in lift job safety analysis for lifts with two or more high risk factors.

4. Have current authorization to perform rigging for the lift.

5. Ensure daily and periodic inspections are performed on all rigging and attachments prior to use.

6. Ensure the weight of the load and accessories has been established.

JVHSE Manual AWD/2020 4

7. Participate in the pre-lift meeting.

8. Review and sign Critical Lift Permit authorizing that all preparations and safeguards are in place

prior to making the lift.

9. Rig the load in accordance with precautions listed in the lift job safety analysis and recognized

safe rigging methods.

C. Flagman/Signalman

1. Must have approved competence certification

2. Participate in the risk assessment as necessary to determine the risk category for the lift.

3. Participate in the lift job safety analysis for lifts with two or more high risk factors.

4. Have current authorization to perform signaling for the crane travel and/or lift.

5. Participate in the pre-lift meeting.

6. Review and sign Critical Lift Permit authorizing that all preparations and safeguards are in place

prior to making the lift.

7. Assist the crane operator with the unloaded lift cycle test.

8. Signal for the lift in accordance with precautions listed in the lift job safety analysis and

recognized safe methods.

D. Operations Team Leader/Supervisor

1. Participate in crane lift planning and crane lift process for lifts over process equipment.

2. Participate in the lift job safety analysis.

3. Assist the crane operator with preparing the area where the lift will occur.

4. Participate in the pre-lift meeting.

5 Review and sign the Critical Lift Permit authorizing that all preparations and safeguards are in

place prior to making the lift.

E. Maintenance Superintendent and/or Contractor Foreman

1. Responsible for the lift.

2. Participate in crane lift planning and crane lift permit process for lifts involving two or more high

risk factors.

3. Ensure lift preplanning is conducted including a lift job safety analysis.

4. Evaluate the need for outside expertise in planning and conducting the lift.

5. Ensure that authorized personnel are assigned to the lift.

6. Participate in the pre-lift meeting.

7. Review and sign the Critical Lift Permit authorizing that all preparations and safeguards are in

place prior to making the lift.

JVHSE Manual AWD/2020 5

F. Safety Supervisor

1. Participate in the lift job safety analysis whenever lifts will be made over processes or equipment

AND the lift involves two or more high risk factors.

2. Ensure lift pre-planning is conducted including a lift job safety analysis.

3. Participate in the pre-lift meeting.

4. Review and sign the Critical Lift Permit authorizing that all preparations and safeguards are in

place prior to making the lift.

G. Safety Representative

1. Participate in the job safety analysis as necessary for lifts involving two or more high risk factors.

2. Participate in the pre-lift meeting.

3. Review and sign the Critical Lift Permit authorizing that all preparations and safeguards are in

place prior to making the lift.

H. Emergency Response Supervisor

1. Participate in the lift job safety analysis whenever lifts will be made over processes or equipment

containing hazardous materials AND the lift involves two or more high risk factors.

2. Identify potential incident scenarios resulting from lift failure and conduct emergency response

pre-planning.

3. Ensure adequate emergency response resources are available or staged in accordance with pre-

plans.

4. Participate in the pre-lift meeting.

I. Contract Management

1. Ensure that all contractors providing crane services are evaluated and qualified

2. Ensure all contractors providing crane services are qualified for crane inspection, repair, and

operation.

3. Ensure all contractors providing crane services have training programs and personnel are

properly trained and competent.

4. Maintain records of contractor qualifications, completed Critical Lift Permits, and completed Job

Safety Analysis.

7. DEFINITIONS

A. Anti Two-Block Device

A device which, when activated, disengages all crane functions that can cause two-blocking.

B. Authorization/Qualification

Approval and designation to perform crane operation, rigging, or signaling. Authorization will be

JVHSE Manual AWD/2020 6

granted based on experience, training and/or certification.

C. Boom

A member hinged to the rotating superstructure and used for supporting the hoisting tackle.

D. Boom Angle

The angle above or below the horizontal measured from the longitudinal axis of the crane

turntable.

E. Boom Length

True length of the boom installed on the crane including any jibs, or extensions.

F. Counterweight

Weight used to supplement the weight of the crane to provide additional stability for lifting loads.

G. Critical Lift

Any crane lift that is determined to be” Medium” or “High” level risk for any of the risk factors listed

in the Crane Lift Risk assessment Table.

H. Jib

An extension attached to the end of the boom to provide added boom length for lifting specified

loads. The jib may be vertically in line with the boom or offset to various angles in the vertical

plane of the boom.

I. Load Rating

Crane capacity ratings in metric tonnes established by the crane manufacturer as provided in the

crane load chart.

J. Outriggers

Extendible or fixed members attached to the crane base used to support the crane.

K. Routine Lift

Any crane lift that is determined to be “Low” level risk for any of the risk factors listed in the Crane

Lift Risk Assessment Table.

L. Two-Blocking

The condition in which the lower load block or hook assembly comes in contact with the upper

load block or sheave assembly near the end of the boom.This condition can cause crane damage

and may cause the load to drop.

8. CRITICAl LIFT PERMIT

(See attachment)

JVHSE Manual AWD/2020 7

CRITICAL LIFT PERMIT

LOAD

LOAD CONDITION: ( ) NEW ( ) USED

LOAD WEIGHT (metric tonnes) ڤ ESTIMATEDڤ PROVIDED BY: ________

JIB

JIB TO BE USED: ( ) NO ( ) YES ( ) ERECTED ( ) STOWED

LENGTH OF JIB: ANGLE OF JIB: WEIGHT OF JIB:

RIGGING

SLINGS/CHOKERS RATING: LENGTH: NUMBER: SIZE: WEIGHT:

METAL

FABRIC

SHACKLES: RATING: NUMBER: SIZE: WEIGHT:

SPREADER BAR: RATING: NUMBER: SIZE: WEIGHT:

TAG LINES: LENGTH: NUMBER: SIZE: WEIGHT:

WIRE / CABLE: SIZE: WEIGHT:

BALL / HOOK: RATING: WEIGHT:

OTHER LIFTING RATING: NUMBER: SIZE: WEIGHT:

DEVICES

TOTAL RIGGING

WEIGHT:

LOAD WEIGHT:

WEIGHT OF JIB:

TOTAL WEIGHT

LIFTED AT BOOM

POINT:

CRANE

TYPE OF CRANE: CRANE SIZE/CAPACITY:

BOOM LENGTH: WORKING RADIUS: MAX BOOM ANGLE:

PARTS OF LINE: SWL OF LINE: MIN BOOM ANGLE:

HOIST: ( ) MAIN ( ) AUXILIARY

RATINGS OF ALL RIGGING COMPONENTS, BALL, HOOK, AND SWL OF LINE ADEQUATELY ( ) YES ( ) NO

ABOVE TOTAL WEIGHT LIFTED AT BOOM POINT

LOAD RATING OF CRANE FROM LOAD CHART

(mt)

LOAD RATING OF JIB FROM LOAD CHART

(mt)

TOTAL WEIGHT LIFTED IS % OF CRANE LOAD RATING

TOTAL WEIGHT LIFTED IS % OF JIB LOAD RATING

CRITICAL LIFT PERMIT

DATE: LOCATION: JOB/WO NUMBER:

JVHSE Manual AWD/2020 8

LIFT DESCRIPTION:

RISK LEVEL ASSIGNED FROM RISK ASSESSMENT TABLE:

All applicable items on the permit have been answered “YES”

and communicated to all personnel involved with the lift:

JOB SAFETY ANALYSIS COMPLETE YES NA CRANE OPERATOR (all lifts)

EMERGENCY RESPONSE PRE-PLANNING COMPLETE AND YES NA RIGGER (all lifts)

RESOURCES AVAILABLE

AUTHORIZED/QUALIFIED CRANE OPERATOR YES

AUTHORIZED/QUALIFIED RIGGER YES FLAGMAN/SIGNALMAN (if required for lift)

FLAGMAN / SIGNALMAN AVAILABLE IF REQUIRED YES NA OPERATIONS TEAM LEADER (lifts over process

equipment)

CRANE HAS CURRENT PERIODIC INSPECTION YES

DAILY CRANE INSPECTION COMPLETED * YES MAINTENANCE TL / CONTRACTOR SUPERVISOR

ALL SLINGS, CHOKERS, ROPES, AND OTHER RIGGING H YES PLANT MANAGER (lifts over process equipment AND

AVE CURRENT PERIODIC INSPECTION * existence of two or more high risk factors)

PRE-USE INSPECTION OF SLINGS, ROPES, CHOKERS AND YES SAFETY REPRESENTATIVE (two or more high risk

o OTHER RIGGING COMPLETED * factors)

CRANE SET-UP IN ACCORDANCE WITH MANUFACTURER’S YES EMERGENCY RESPONSE SUPERVISOR (lifts over

INSTRUCTIONS/MANUAL process

SMOOTH SOLID FOUNDATION IN THE CRANE SET-UP YES equipment AND existence of two or more high risk factors)

AREA WITH NO DEVIATIONS. UNDERGROUND

INSTALLATIONS CONSIDERED AND NOT IMPACTED

OUTRIGGERS EXTENDED AS FAR AS POSSIBLE, ON YES NA ADDITIONAL COMMENTS:

LEVEL, FIRM GROUND WITH SUPPORTS (MATS)

INSTALLED WHERE REQUIRED

TIRES COMPLETELY OFF GROUND WHEN OUTRIGGERS YES NA

USED

TIRES FULLY PRESSURED WHEN LIFTING OFF RUBBER YES NA

EXTENDIBLE COUNTERWEIGHT OUT IF PROVIDED YES NA

AREA COMPLETELY BARRICADED TO REMOVE YES

PERSONNEL FROM AROUND CRANE AND LIFT AREA

ANTI TWO BLOCKING SAFEGUARD IN PLACE AND TESTED YES NA

ALL NECESSARY CLEARANCES EVALUATED INCLUDING YES

OVERHEAD POWER LINES

UNLOADED LIFT CYCLE TEST PERFORMED IF REQUIRED YES NA

ALL REQUIRED SAFEGUARDS AND ACTIONS OF THE JOB YES NA

SAFETY ANALYSIS IN PLACE AND COMMUNICATED

SUSPENDED LOAD TEST PERFORMED YES

*Copies of these inspections are to be included with Critical Lift Permit

JVHSE Manual AWD/2020 9

9. Crane Lift Flow Chart

START

NO NO

Conduct Crane Medium Risk

Multiple High

Crane Lift (s) Lift Assesment Low Risk OR

Risks

High Risk

YES YES

YES

Prpeare Critical Prepare Critical

Conduct Lift Lift Permit Lift Permit

Conduct Pre-Lift

Conduct JSA

Meeting

Sign Critical Lift

Conduct Pre-Lift

permit

Meeting

Sign Critical Lift

Conduct Lift Permit.

Requires

signatures from

Plant MGR.

Safety Rep

Emergency

Resp.

Conduct Lift

JVHSE Manual AWD/2020 10

You might also like

- Executive Protection ChecklistsDocument35 pagesExecutive Protection ChecklistsGallg Baron92% (26)

- L48 - Owner's Manual - EnglishDocument209 pagesL48 - Owner's Manual - EnglishRandall P. BancroftNo ratings yet

- Risk Assessment Asphalt WorksDocument7 pagesRisk Assessment Asphalt Workskannanjaduzz100% (1)

- 015-Lifting Plan Method & Risk AssessmentDocument3 pages015-Lifting Plan Method & Risk AssessmentMAB AliNo ratings yet

- Crane Assembly and Dismantling and ModificationDocument1 pageCrane Assembly and Dismantling and Modificationsrinibas mohapatraNo ratings yet

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- App-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.Document15 pagesApp-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.loveson709100% (2)

- ABS CLASS ChecklistDocument36 pagesABS CLASS Checklistapi-372122995% (22)

- Generic Lifting PlanDocument4 pagesGeneric Lifting Planayman coreNo ratings yet

- Jsa For Pilling WorkDocument12 pagesJsa For Pilling WorkLakhan kumar100% (1)

- Lifting Plan For Erection of 2nd To 6th Rev.3Document11 pagesLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNo ratings yet

- Planned Critical Lift Crane PermitDocument5 pagesPlanned Critical Lift Crane PermitsurnaikNo ratings yet

- Rigging Plan FormatDocument3 pagesRigging Plan FormatuzairmetallurgistNo ratings yet

- Emergency Rescue Plan For Operatives Working at HeightDocument9 pagesEmergency Rescue Plan For Operatives Working at Heightloveson709100% (2)

- Emergency Rescue Plan For Operatives Working at HeightDocument9 pagesEmergency Rescue Plan For Operatives Working at Heightloveson709100% (2)

- QDC No ObjectionDocument1 pageQDC No Objectionloveson70950% (2)

- Loveson Resume HSE ManagerDocument7 pagesLoveson Resume HSE Managerloveson709No ratings yet

- M50 12.76 Volvo B12BDocument49 pagesM50 12.76 Volvo B12Bmanhlinh08cdNo ratings yet

- GMSB - Level 3 - SWI - 006 - Crane and Lifting WorkDocument16 pagesGMSB - Level 3 - SWI - 006 - Crane and Lifting WorkZulhaidy Salim100% (1)

- Plant 6 3: Risk Assessment For Lifting OperationsDocument4 pagesPlant 6 3: Risk Assessment For Lifting OperationsIdris AdeniranNo ratings yet

- 55 T Lifting PlanDocument5 pages55 T Lifting PlanRestu Putra100% (1)

- Lifting Plan FormDocument2 pagesLifting Plan FormezuanNo ratings yet

- Crane LiftsDocument1 pageCrane LiftsJasonNo ratings yet

- Lifting Plan: Lifting Appointed Person / Supervisor Site InspectionDocument4 pagesLifting Plan: Lifting Appointed Person / Supervisor Site Inspectionkhaled redaNo ratings yet

- Lifting Plan Registration PDFDocument1 pageLifting Plan Registration PDFScribdTranslationsNo ratings yet

- Lifting Plan Calculation (QTZ200 Tower Crane)Document3 pagesLifting Plan Calculation (QTZ200 Tower Crane)Ilham KelanaNo ratings yet

- Flowchart Hpg1034Document1 pageFlowchart Hpg1034SharulNo ratings yet

- Stc1300 Truck Crane: 130t Lifting CapacityDocument15 pagesStc1300 Truck Crane: 130t Lifting CapacityDicky KurniantoNo ratings yet

- Construction Job Hazards Analysis: DemolitionDocument2 pagesConstruction Job Hazards Analysis: Demolitionchirese2000No ratings yet

- Method Statement For Lifting Operations - Builders SafetyDocument2 pagesMethod Statement For Lifting Operations - Builders SafetyMuhammad Sami Parvez100% (1)

- Fes TBT Mobile CraneDocument1 pageFes TBT Mobile CraneMohammed AtefNo ratings yet

- MFD Procedure: Lifting & HoistingDocument16 pagesMFD Procedure: Lifting & HoistingMohammed JassimNo ratings yet

- Crane Safety V0911.1Document1 pageCrane Safety V0911.1Nasir Mehmood AryaniNo ratings yet

- Crane Lifting Plan and Method StatementDocument5 pagesCrane Lifting Plan and Method StatementLawrence adeleke OmisakinNo ratings yet

- Risk Assessment Erection of Precast Concrete ElementsDocument2 pagesRisk Assessment Erection of Precast Concrete ElementsBunyamin Selimoglu100% (1)

- Work Method Statement: Wms Rev. NoDocument5 pagesWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- Tandem Lifting Container SWGDocument1 pageTandem Lifting Container SWGarifNo ratings yet

- Anthony James CV Feb 24 - 2023 PDFDocument3 pagesAnthony James CV Feb 24 - 2023 PDFanthony jamesNo ratings yet

- Appendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormDocument1 pageAppendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormharryNo ratings yet

- Apolo Additional Attachments (Slings Tension in 3d)Document4 pagesApolo Additional Attachments (Slings Tension in 3d)Mo'tasem SerdanehNo ratings yet

- FC 4.1.8 - Critical Lift PlanDocument1 pageFC 4.1.8 - Critical Lift PlanJosef Demner Tiu PaspeNo ratings yet

- Lifting Work Permit ColoredDocument2 pagesLifting Work Permit ColoredAJEET SINGHNo ratings yet

- Onshore Critical Lift Plan FormDocument2 pagesOnshore Critical Lift Plan FormSyaiful Akhmad100% (1)

- Ity of Ilpitas Inspection Checklist: Asphalt Pavement Inspection ProceduresDocument4 pagesIty of Ilpitas Inspection Checklist: Asphalt Pavement Inspection ProceduresLazar AndonovNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- Guidelines Flagmen - Banksmen (English)Document1 pageGuidelines Flagmen - Banksmen (English)Pirlo PoloNo ratings yet

- Non Routine Lift Plan Check ListDocument2 pagesNon Routine Lift Plan Check Listmohamed atef0% (1)

- Lifting PlanDocument2 pagesLifting PlansivaavissriNo ratings yet

- 8 - Lifting Plan For Transfering Engine (z1) Landing Area Then Loading From Ground To Truck and Vice VersaDocument24 pages8 - Lifting Plan For Transfering Engine (z1) Landing Area Then Loading From Ground To Truck and Vice VersaMo'tasem SerdanehNo ratings yet

- 3 Green Lift Checklist FormDocument2 pages3 Green Lift Checklist FormHưng Hoàng DuyNo ratings yet

- Few Words About Crane Few Words About CraneDocument42 pagesFew Words About Crane Few Words About CraneSamuel GeorgeNo ratings yet

- Presentation For RiggingDocument18 pagesPresentation For RiggingRameese MuhammedNo ratings yet

- TBT RiggingDocument2 pagesTBT RiggingAl DubNo ratings yet

- Oversized & Project CargoDocument2 pagesOversized & Project CargoEric PanNo ratings yet

- Site:FSW - Major Overhaul GTG#1: Alstom Zero Deviation Plan Audit ReportDocument26 pagesSite:FSW - Major Overhaul GTG#1: Alstom Zero Deviation Plan Audit ReportRoy MangaraNo ratings yet

- Zoomlion RT60ton PDFDocument47 pagesZoomlion RT60ton PDFYohan Nafisa NetNo ratings yet

- Sample JHADocument5 pagesSample JHAKen100% (1)

- Construction Lifting PlanDocument5 pagesConstruction Lifting PlanJuma KavesuNo ratings yet

- Mobile Crane Permit, Lifting Plan Method & Risk AssessmentDocument3 pagesMobile Crane Permit, Lifting Plan Method & Risk AssessmentfaizelNo ratings yet

- Lifting Procedure With AttachmentDocument16 pagesLifting Procedure With AttachmentIshak MalimNo ratings yet

- Strong Dual Hawk Tandem Rev H 2008Document70 pagesStrong Dual Hawk Tandem Rev H 2008FaderNo ratings yet

- Document No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomDocument3 pagesDocument No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomShaikh Mohd QaisarNo ratings yet

- Safety Bulletin: Setting Outriggers To Prevent AccidentsDocument12 pagesSafety Bulletin: Setting Outriggers To Prevent AccidentsericNo ratings yet

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadNo ratings yet

- LKC - Lifting Risk AssessmentDocument4 pagesLKC - Lifting Risk AssessmentAdam EatonNo ratings yet

- 1a. Lifting Data Sheet (Cage 24m)Document4 pages1a. Lifting Data Sheet (Cage 24m)Mohd FadliNo ratings yet

- Lifting Plan Vibro Hammer GEO 2021Document7 pagesLifting Plan Vibro Hammer GEO 2021bangunNo ratings yet

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Document3 pagesStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Upper Mast Section Lifting PlanDocument7 pagesUpper Mast Section Lifting PlanDurgham Adel EscanderNo ratings yet

- App-16.2 - Risk Assessment For Vermeer Axis WorksDocument13 pagesApp-16.2 - Risk Assessment For Vermeer Axis Worksloveson709No ratings yet

- App-16.2 - Risk Assessment For Traffic Signal SystemDocument13 pagesApp-16.2 - Risk Assessment For Traffic Signal Systemloveson709100% (2)

- Maintenance Log - TemplateDocument2 pagesMaintenance Log - Templateloveson709No ratings yet

- App-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair RoadDocument15 pagesApp-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair Roadloveson709No ratings yet

- Near Miss Report: Complete This Form and Email It ToDocument1 pageNear Miss Report: Complete This Form and Email It Toloveson709No ratings yet

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pages3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pages3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- INV Inv Ass Form TemplateDocument4 pagesINV Inv Ass Form Templateloveson70950% (2)

- INV Action Plan TemplateDocument2 pagesINV Action Plan Templateloveson709No ratings yet

- Assmt 1 Incident PhotosDocument3 pagesAssmt 1 Incident Photosloveson709No ratings yet

- N.Selvam:, BE (Mechanical)Document2 pagesN.Selvam:, BE (Mechanical)loveson709No ratings yet

- Scaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557Document2 pagesScaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557loveson709No ratings yet

- Loveson Glariyans: (Address, City, ST ZIP Code)Document2 pagesLoveson Glariyans: (Address, City, ST ZIP Code)loveson709No ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Yam Bahadur Budha CV PDFDocument2 pagesYam Bahadur Budha CV PDFloveson709No ratings yet

- Scaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557Document2 pagesScaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557loveson709No ratings yet

- RA082-C Grinding - ThornliebankDocument2 pagesRA082-C Grinding - Thornliebankloveson709No ratings yet

- 005 Ohs-Cop-Starrt & JhaDocument10 pages005 Ohs-Cop-Starrt & Jhaloveson709No ratings yet

- Epoxy COSHHDocument3 pagesEpoxy COSHHloveson709No ratings yet

- PMC-FM-HSS-024 Near Miss ReportDocument1 pagePMC-FM-HSS-024 Near Miss Reportloveson709No ratings yet

- Po Ak-00076 - MR 534Document1 pagePo Ak-00076 - MR 534loveson709No ratings yet

- Salary Incement Letter - DotDocument1 pageSalary Incement Letter - Dotloveson709100% (1)

- HSE Department Demobilization List: Trade May 2016Document1 pageHSE Department Demobilization List: Trade May 2016loveson709No ratings yet

- HSE Department Demobilization List: Trade May 2016Document1 pageHSE Department Demobilization List: Trade May 2016loveson709No ratings yet

- Board Reqd From AlkheesaDocument1 pageBoard Reqd From Alkheesaloveson709No ratings yet

- Bosiet / Huet (Basic Offshore Safety Induction & Emergency Training)Document3 pagesBosiet / Huet (Basic Offshore Safety Induction & Emergency Training)Ronald AranhaNo ratings yet

- M/S L.M.Das: Job Hazard AnalysisDocument3 pagesM/S L.M.Das: Job Hazard AnalysisDwitikrushna Rout100% (1)

- Manual Operador MT732 PDFDocument154 pagesManual Operador MT732 PDFBastian Tapia LopezNo ratings yet

- BA100.User ManualDocument40 pagesBA100.User ManualBaltija MechanikasNo ratings yet

- Beirut ExplosionDocument10 pagesBeirut ExplosionChannis ExoNo ratings yet

- SOP Loading Unloading Line PipeDocument10 pagesSOP Loading Unloading Line PipeSomnath DasNo ratings yet

- Parts of The ShipDocument28 pagesParts of The ShipDonsumit PrajapatiNo ratings yet

- Sound Transit - Draft 2022 Service Plan With AppendicesDocument197 pagesSound Transit - Draft 2022 Service Plan With AppendicesThe UrbanistNo ratings yet

- 2023 NYS State of The State BookDocument277 pages2023 NYS State of The State BookCarl AldingerNo ratings yet

- Especialidades2020 ENGDocument26 pagesEspecialidades2020 ENGjoseNo ratings yet

- Lesson 1 Emergency SituationsDocument9 pagesLesson 1 Emergency SituationsFACIArnold Sean l QuiaoNo ratings yet

- My Preparation Samir RasulDocument38 pagesMy Preparation Samir RasulAung Htet KyawNo ratings yet

- Ranchi To Patna TicketDocument2 pagesRanchi To Patna TicketSmart CADDesign100% (1)

- UK - Dangerous Goods Emergency Action Code List 2015Document200 pagesUK - Dangerous Goods Emergency Action Code List 2015Gabriel JáureguiNo ratings yet

- Safety Alert For Gantry CraneDocument2 pagesSafety Alert For Gantry CraneporbyNo ratings yet

- Training Circular No9999111Document10 pagesTraining Circular No9999111Prashant RamdasNo ratings yet

- (Class D) : Endorsement IMT - 44 or IMT - 45, As Applicable, Is To Be UsedDocument10 pages(Class D) : Endorsement IMT - 44 or IMT - 45, As Applicable, Is To Be UsedRamraj VishwakarmaNo ratings yet

- JND320 Presentation 9 Command AspectsDocument22 pagesJND320 Presentation 9 Command AspectssimonborauNo ratings yet

- Idge System 20121Document6 pagesIdge System 20121jkgfgNo ratings yet

- Breakdown ProcedureDocument6 pagesBreakdown ProcedureIrfan AliNo ratings yet

- Module 012 GmdssDocument234 pagesModule 012 Gmdssallan kasem alcazarenNo ratings yet

- Ilovepdf MergedDocument154 pagesIlovepdf MergedadarciotoaNo ratings yet

- Product Sheet Sigma Multi Mission Frigate 10514Document2 pagesProduct Sheet Sigma Multi Mission Frigate 10514ALEXC100% (2)

- JHA For Cable Tray Installation REV ADocument6 pagesJHA For Cable Tray Installation REV Aputrisherilain khairuldinNo ratings yet

- Air Paper-11-15Document5 pagesAir Paper-11-15comecomegopalNo ratings yet