Professional Documents

Culture Documents

Explanation of Pump Nomenclature: Your Model #

Explanation of Pump Nomenclature: Your Model #

Uploaded by

Sandy BottomsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Explanation of Pump Nomenclature: Your Model #

Explanation of Pump Nomenclature: Your Model #

Uploaded by

Sandy BottomsCopyright:

Available Formats

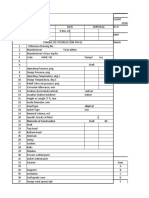

Explanation of Pump Nomenclature

Your Model

#: __ __ _____ __ ___ __ __ __

(fill in from pump

nameplate)

Pump Pump Pump Discharge Diaphragm/ Design

Options Construction

Series Design Size Porting Valve Level

XX X

Model #: XXXX, X XX X XX X

Pump Series Diaphragm Check Valve Materials Design Level

S SANDPIPER® B Nitrile 5

C FKM with PTFE

Pump Design F FDA Accepted White Nitrile

Construction

B Soilid Ball A Aluminum Wetted, Aluminum Air

GN Neoprene Backup with PTFE Overlay

SI Stainless Steel Wetted, Cast Iron Air

Pump Size and PTFE Check Balls

1 1" GR Hytrel Backup w/ SS Stainless Steel Wetted, Aluminum Air

25 1" BSPT (Tapered Thread) PTFE Overlay/PTFE Balls HC Alloy-C Wetted, Aluminum Air

GZ PTFE/Nitrile Bonded HI Alloy-C Wetted, Cast Iron Air

Discharge Porting Position One-Piece/PTFE Balls

D Bottom Options

H EPDM with PTFE

S Side P1 Intrinsically Safe ATEX Compliant

N Neoprene

T Top Pulse Output

R Hytrel

ET Dual Top S Santoprene

ES Dual Side V FKM

Your Serial #: (fill in from pump nameplate)______________________________________

ATEX Detail

(1) II 1G c T5

II 2GD T5

Models equipped with Construction designations

SI or HI. Note: See ATEX Explanation of Type

(2) IIII 2G

IIII 3/2

ExiaiaccIIC

2G Ex

2D cGiaD

Ex20

IICT5T5

iaIP67

c IICT100˚C

T5

II 3/1 G c T5

Certificate II 2D Ex c ia 20 IP67

II 1D c T100°C

I M1 c T100°C

I M2 c Note: Pumps ordered with the options listed in (1) to the left are

ATEX compliant when ordered with kit option P1.

II 2G c T5 Models equipped with Construction designations A,

II 2GD

II T5c T5

3/2 G SI, SS, HC, or HI. Note: See ATEX Explanation of

II 2D c T100°C Type Examination Certificate

1 • Model SB1 & SB25 www . sandpiperpump . com

sb1dl5ds-rev0813

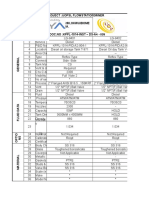

Performance

SB1 & SB25

Suction/Discharge Port Size AIR CONSUMPTION MODEL SB1/SB25 Performance Curve

BAR

PSI

• SB1: 1” (25.4mm) NPT(F) SCFM (M3/hr) Performance based on the following: elastomer fitted pump, flooded suction,

• SB25: 1” (25.4mm) BSP Tapered 7 100 water at ambient conditions. The use of other materials and varying hydraulic

conditions may result in deviations in excess of 5%.

100 PS 10(17)

Capacity I

15(25.5)

• 0 to 42 gallons per minute 90

6 20(34)

(0 to 159 liters per minute) 80 80 PS 25(42.5)

I

Air Distribution Valve 5 30(51)

• No-lube, no-stall design

70

35(59.5)

Solids-Handling 60 60

HEAD

4 PSI 40(68)

• Up to nearly .25 in. (6.3mm)

Heads Up To

50

45(76.5)

3

• 125 psi or 289 ft. of water 40 40 PS

I 50(85)

(8.8 Kg/cm2 or 88 meters)

2 30

Maximum Operating Pressure

• 125 psi (8.6 bar) 20 20 PS

I Air Inlet Pres

Displacement/Stroke 1 sure

10

• .09 Gallon / .34 liter

SHIPPING WEIGHT 0 0

0 4 8 12 16 20 24 28 32 36 40

• Aluminum 31 lbs. (14kg)

U.S. Gallons per minute

• Stainless Steel 45 lbs. (20kg)

• Alloy C 45 lbs. (20kg) 0 25 50 75 100 125 150

• Stainless Steel with Cast Iron Center 65 lbs. (30kg) Liters per minute

• Alloy C with Cast Iron Center 65 lbs. (30kg) CAPACITY

Materials

Material Profile: Operating Polypropylene: A thermoplastic polymer. Moderate tensile

and flex strength. Resists stong acids and alkali. Attacked by

180°F

82°C

32°F

0°C

Temperatures:

CAUTION! Operating temperature limitations are as follows: chlorine, fuming nitric acid and other strong oxidizing agents.

Max. Min.

PVDF: (Polyvinylidene Fluoride) A durable fluoroplastic with 250°F 0°F

Conductive Acetal: Tough, impact resistant, ductile. Good 190°F -20°F excellent chemical resistance. Excellent for UV applications. 121°C -18°C

abrasion resistance and low friction surface. Generally inert, with 88°C -29°C High tensile strength and impact resistance.

good chemical resistance except for strong acids and oxidizing

agents. Santoprene®: Injection molded thermoplastic elastomer with 275°F -40°F

no fabric layer. Long mechanical flex life. Excellent abrasion 135°C -40°C

EPDM: Shows very good water and chemical resistance. Has 280°F -40°F resistance.

poor resistance to oils and solvents, but is fair in ketones and 138°C -40°C

alcohols. UHMW PE: A thermoplastic that is highly resistant to a broad 180°F -35°F

range of chemicals. Exhibits outstanding abrasion and impact 82°C -37°C

FKM: (Fluorocarbon) Shows good resistance to a wide range 350°F -40°F resistance, along with environmental stress-cracking resistance.

of oils and solvents; especially all aliphatic, aromatic and 177°C -40°C

halogenated hydrocarbons, acids, animal and vegetable oils. Urethane: Shows good resistance to abrasives. Has poor 150°F 32°F

Hot water or hot aqueous solutions (over 70°F(21°C)) will resistance to most solvents and oils. 66°C 0°C

attack FKM. Virgin PTFE: (PFA/TFE) Chemically inert, virtually impervious. 220°F -35°F

Hytrel®: Good on acids, bases, amines and glycols at room 220°F -20°F Very few chemicals are known to chemically react with PTFE; 104°C -37°C

temperatures only. 104°C -29°C molten alkali metals, turbulent liquid or gaseous fluorine and

a few fluoro-chemicals such as chlorine trifluoride or oxygen

Neoprene: All purpose. Resistance to vegetable oils. Generally 200°F -10°F difluoride which readily liberate free fluorine at elevated

not affected by moderate chemicals, fats, greases and many 93°C -23°C temperatures.

oils and solvents. Generally attacked by strong oxidizing acids,

ketones, esters and nitro hydrocarbons and chlorinated aromatic Maximum and Minimum Temperatures are the limits for which these materials can be operated.

Temperatures coupled with pressure affect the longevity of diaphragm pump components.

hydrocarbons. Maximum life should not be expected at the extreme limits of the temperature ranges.

Nitrile: General purpose, oil-resistant. Shows good solvent, oil, 190°F -10°F

water and hydraulic fluid resistance. Should not be used with 88°C -23°C

Metals:

highly polar solvents like acetone and MEK, ozone, chlorinated Alloy C: Equal to ASTM494 CW-12M-1 specification for nickel and nickel alloy.

hydrocarbons and nitro hydrocarbons.

Stainless Steel: Equal to or exceeding ASTM specification A743 CF-8M for corrosion

Nylon: 6/6 High strength and toughness over a wide 180°F 32°F resistant iron chromium, iron chromium nickel and nickel based alloy castings for

temperature range. Moderate to good resistance to fuels, oils 82°C 0°C general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

and chemicals.

For specific applications, always consult the Chemical Resistance Chart.

Ambient temperature range: -20°C to +40°C

Process temperature range: -20°C to +80°C for models rated as category 1 equipment

-20°C to +100°C for models rated as category 2 equipment

In addition, the ambient temperature range and the process temperature range do not exceed the operating temperature range of the applied non-metallic parts as listed in the manuals of the pumps.

www . sandpiperpump . com Model SB1 & SB25 • 2

sb1dl5ds-rev0813

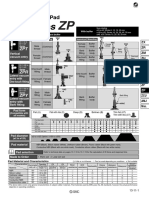

Dimensional Drawings

SB1 & SB25 Heavy

8 7 Duty Ball Valve

6 5 4 3

"C"

"B"

11.36 6.12

288 "A"

DISCHARGE PORT 155

1" NPTF (SB1) AIR EXHAUST

1" BSPF (SB25) 3/4" NPTM

6 5 4 3 2 1

"C"

"B"

6.12 AIR INLET

"A" 1/2" NPTF

DISCHARGE PORT 155

"D" 1" NPTF (SB1)

12.50 AIR EXHAUST

1" BSPF (SB25) 3/4" NPTM

317

6.89

4.63

175

118 SUCTION PORT

1" NPTF (SB1) AIR INLET

1" BSPF (SB25) 1/2" NPTF

12.50

317

.72

18

6.89

4.63

175

118 SUCTION PORT 4X .28 [7] MOUNTING HOLE

1" NPTF (SB1)

1" BSPF (SB25) NOTE:

UNIT FURNISHED WITH SUB-BASE PLATE

SB1 / SB

HEAVY DUTY BALL VA

AND RUBBER FEET AS STANDARD. FOR DIMENSIONAL TOLERAN

STATIONARY BOLT DOWN USE, RUBBER [XX] = MILLIMETE

.72 FEET CAN BE REMOVED.

18 PUMP

DIM "A" DIM "B"

COFIGURATION

ALUMINUM

9.00 CENTER SECTION

3.95 [100] 5.86 [149

229 4X .28 [7] MOUNTING HOLE CAST IRON

CENTER SECTION

SB1 / SB25

4.10 [104] 5.54 [141

PULSE OUTPUT

NOTE: CONFIGURATION

UNIT FURNISHED WITH SUB-BASE PLATE HEAVY DUTY BALL VALVE PUMP

AND RUBBER FEET AS STANDARD. FOR DIMENSIONAL TOLERANCE 1/8 [3]

STATIONARY BOLT DOWN USE, RUBBER [XX] = MILLIMETERS

FEET CAN BE REMOVED.

PUMP DIM "A" DIM "B" DIM "C" DIM "D"

PART NUMBER MADE FROM

COFIGURATION

MATERIAL

ALUMINUM

8.56 CENTER SECTION

3.95 [100] 5.86 [149] 13.90 [353] 14.55 [370]

217 CAST IRON

CENTER SECTION

F.1 4.10 [104]

REVISED VALVE CONFIGURATION 5.54 [141] 13.60

MF [345]

11/9/2011 15.75 [400] PUMP REFERENCE PR

8 7 6 REV PULSE OUTPUT REVISION CHG DATE APP DATE ECN 450.060.000

CONFIGURATION

WARREN RUPP I

PART NUMBER MADE FROM UNLESS OTHERWISE

SPECIFIED

TOLEARNCES

,

MATERIAL THIS IS A PROPRIETARY DOCUMENT. DO NOT REPRODUCE OR DISCLOS

EXPRESS WRITTEN PERMISSION OF WARREN RUPP, INC

.XX .010

.XXX .005 DESCRIPTION

ANGULAR 1/2 OUTLINE, DIMENSIONAL, SB1

63

SURFACE FINSH DRAWING NUMBER

6

F.1

REV

REVISED VALVE CONFIGURATION

REVISION

MF

CHG

11/9/2011

DATE APP DATE ECN

PUMP REFERENCE

450.060.000

PROJECT

DO NOT SCALE DRAWING

DIMENSIONS ARE INCHES 450.073.000

SH

3 • Model SB1 & SB25 www . sandpiperpump . com

sb1dl5ds-rev0813

You might also like

- Ice Bucket TestingDocument1 pageIce Bucket TestingSandy Bottoms100% (1)

- Molyklenz - English SDS - I24feb2017Document8 pagesMolyklenz - English SDS - I24feb2017Sandy BottomsNo ratings yet

- BS en 01040-2005Document44 pagesBS en 01040-2005mamatnamaku100% (5)

- Tutorial Chapter 1-ThermochemistryDocument3 pagesTutorial Chapter 1-ThermochemistrysyazaNo ratings yet

- SicmeDocument12 pagesSicmeTraian SerbanNo ratings yet

- 250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Document3 pages250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Vamshika SutarNo ratings yet

- Actuated Valve Data SheetDocument1 pageActuated Valve Data SheetVivi OktaviantiNo ratings yet

- PARK QA10-G-1060 - Rev0 - Data SheetsDocument2 pagesPARK QA10-G-1060 - Rev0 - Data SheetssalmanNo ratings yet

- Hoja de Datos Tanque de AlmacenamientoDocument8 pagesHoja de Datos Tanque de AlmacenamientoRodrigo Gracia100% (1)

- Reactor HOJA DE DATOSDocument4 pagesReactor HOJA DE DATOSRodrigo GraciaNo ratings yet

- EN Double Offset 2E SmallDocument12 pagesEN Double Offset 2E SmallEduardo TapiaNo ratings yet

- Model Direct Mount, Cross Pilot: Cavity: T-17ADocument4 pagesModel Direct Mount, Cross Pilot: Cavity: T-17AenovanovaNo ratings yet

- Volute Pumps Sihi: SupernovaDocument10 pagesVolute Pumps Sihi: SupernovaLuis Fernando collazosNo ratings yet

- Mve 800 - 3Document2 pagesMve 800 - 3Amol SarinNo ratings yet

- FlowBiz Double Block & Bleed Plug ValveDocument4 pagesFlowBiz Double Block & Bleed Plug ValveSHAKIR ANSARINo ratings yet

- Series Explosion-proof Junction box e、i、tD: HLBH52Document3 pagesSeries Explosion-proof Junction box e、i、tD: HLBH52RisOne Aiiyankx AiiNo ratings yet

- Double OffsetDocument10 pagesDouble Offsetkrbabu1969No ratings yet

- Folhas de Dados - CondensadorDocument6 pagesFolhas de Dados - Condensadorvazzoleralex6884No ratings yet

- PCR SvformDocument5 pagesPCR SvformHendrias A.SNo ratings yet

- J002-001 S-N S-N S1Document5 pagesJ002-001 S-N S-N S1LuisQuispeRojas100% (1)

- Model All Gasket Ports: Cavity: T-22ADocument4 pagesModel All Gasket Ports: Cavity: T-22ALennyn Mamani VenturaNo ratings yet

- Contractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)Document4 pagesContractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)BABILIN VNo ratings yet

- Ptfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-ADocument4 pagesPtfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-AFernando Ortiz De La CruzNo ratings yet

- Cortem - Round Junction BoxDocument16 pagesCortem - Round Junction BoxRagu RajanNo ratings yet

- 02.ex EnclosuresDocument52 pages02.ex EnclosuresJavier Enrrique Iglesias PelcastreNo ratings yet

- 84-45-003 Avk002ax Eni 432444Document3 pages84-45-003 Avk002ax Eni 432444Gotica ManagementNo ratings yet

- Marbore Ex D Iib+h2 Catalog 2018Document3 pagesMarbore Ex D Iib+h2 Catalog 2018TTRRTTGFNo ratings yet

- Model ISO 08: On B, Port 3 To A and Port 4 ExternalDocument1 pageModel ISO 08: On B, Port 3 To A and Port 4 ExternalRonildo - HydraparNo ratings yet

- Peppers - CABLE GLANDDocument1 pagePeppers - CABLE GLANDcahyo SNo ratings yet

- EBRODocument4 pagesEBROramNo ratings yet

- Kingsley Flame Arrester Tech SpecificationsDocument3 pagesKingsley Flame Arrester Tech SpecificationsJason Wei Han LeeNo ratings yet

- Liquip TrapDocument1 pageLiquip TrapKhánh TrầnNo ratings yet

- St-Sx-Data SheetDocument16 pagesSt-Sx-Data SheetkskadryNo ratings yet

- Bobinas Atex Serie SG AscoDocument2 pagesBobinas Atex Serie SG AscoBase SistemasNo ratings yet

- TM Ceiling Cassette E McQuayDocument120 pagesTM Ceiling Cassette E McQuaySalamet TeguhNo ratings yet

- ASME Section I Product Scope: Understanding What The Customer Wants Making It Happen!Document19 pagesASME Section I Product Scope: Understanding What The Customer Wants Making It Happen!Marcelo Kleber FelisbertoNo ratings yet

- 22004-O-01-00000-MEC-EQL-0001 - D2 - AFD - Marked-Up - Working FileDocument75 pages22004-O-01-00000-MEC-EQL-0001 - D2 - AFD - Marked-Up - Working FileHandriansyah DoelNo ratings yet

- HC Atex 2016enDocument6 pagesHC Atex 2016enEmad AkleNo ratings yet

- Zero Loss Drain by QPPDocument2 pagesZero Loss Drain by QPPMod KaewdaengNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- Sumy Npo Oil Gas Catalog EnglDocument47 pagesSumy Npo Oil Gas Catalog Englرائد عبد العزيز فرحانNo ratings yet

- Reflector Led Antiexplosion Clase1 Division2 Epc A3n50d120Document3 pagesReflector Led Antiexplosion Clase1 Division2 Epc A3n50d120cristolhmNo ratings yet

- LH AD CatálogoDocument3 pagesLH AD CatálogoAlanNo ratings yet

- PBV Como OrdenarDocument1 pagePBV Como OrdenarauxiliaradministrativoNo ratings yet

- Reflector Led Explosion Proof Clase 1 Div 2 Light-A EpcDocument7 pagesReflector Led Explosion Proof Clase 1 Div 2 Light-A EpcjoelcarhuanchoNo ratings yet

- DSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesDocument32 pagesDSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesJordan Magaña MoralesNo ratings yet

- Top Entry Ball ValvesDocument8 pagesTop Entry Ball ValvesHuda LANo ratings yet

- HRLM - Catalogue # Ex Apparatus - AC-Z Series Explosion Proof Plug and ReceptaclesDocument2 pagesHRLM - Catalogue # Ex Apparatus - AC-Z Series Explosion Proof Plug and Receptaclesa wsNo ratings yet

- L-101 (Insulation Specification) Rev0Document48 pagesL-101 (Insulation Specification) Rev0Herman SyahNo ratings yet

- Reliable F1FR80 - HSWDocument8 pagesReliable F1FR80 - HSWVINOD PAULNo ratings yet

- Dau Sprinklers TYCO - TY315Document4 pagesDau Sprinklers TYCO - TY315hungNo ratings yet

- JC TDS 1515 1530 Rev.0Document5 pagesJC TDS 1515 1530 Rev.0Nourdine EL-HASANYNo ratings yet

- TC FLS Sihi ZTND enDocument19 pagesTC FLS Sihi ZTND enFosseni DialloNo ratings yet

- 1604HTC/2609HTC/3609HTC: Performance Capabilities Product DescriptionDocument8 pages1604HTC/2609HTC/3609HTC: Performance Capabilities Product DescriptionedrNo ratings yet

- Polyester Cabinets-/distribution Boxes With DoorDocument2 pagesPolyester Cabinets-/distribution Boxes With DoorRoberto Matilla CatesNo ratings yet

- 5SV9FA30: Operating DataDocument4 pages5SV9FA30: Operating DataJehana NaolNo ratings yet

- Technical Documents 8787Document459 pagesTechnical Documents 8787Anonymous 3akQhQFJSL100% (1)

- 150 MW Reheat LP-A1Document4 pages150 MW Reheat LP-A1DeepikaNo ratings yet

- Technical Datasheet For Instrument Air DryersDocument5 pagesTechnical Datasheet For Instrument Air DryersVăn HùngNo ratings yet

- Reliable Sprinkler Product Services Bulletin 71Document6 pagesReliable Sprinkler Product Services Bulletin 71thebrightsNo ratings yet

- Dfu Ti D148 01 BRDocument2 pagesDfu Ti D148 01 BRNoo SokiNo ratings yet

- Manual Calc. Welded Storage Tank API-650Document1 pageManual Calc. Welded Storage Tank API-650safar bahariNo ratings yet

- Modelling a Sturmgeschütz III Sturmgeschütz IIIG early version (December 1942 production): In 1/35 scaleFrom EverandModelling a Sturmgeschütz III Sturmgeschütz IIIG early version (December 1942 production): In 1/35 scaleNo ratings yet

- Maxson Automatic Machinery CompanyDocument1 pageMaxson Automatic Machinery CompanySandy BottomsNo ratings yet

- Rittal 3127100 Instructions 3 50Document32 pagesRittal 3127100 Instructions 3 50Sandy BottomsNo ratings yet

- Best Sand Silica Sand and Gravel TDS 417Document2 pagesBest Sand Silica Sand and Gravel TDS 417Sandy BottomsNo ratings yet

- Heating Cooling Curve SolutionsDocument37 pagesHeating Cooling Curve Solutionspipay vlogsNo ratings yet

- Fluid Mechanics White 7th SOL Part1 Part11Document5 pagesFluid Mechanics White 7th SOL Part1 Part11Jose EscobarNo ratings yet

- Mce30Tl Mce30Tc MCA-26G MCA-30ADocument1 pageMce30Tl Mce30Tc MCA-26G MCA-30AFarzad SagharchiNo ratings yet

- AstronomyformulaDocument30 pagesAstronomyformulapalharjeetNo ratings yet

- Identifikasi Geological Strike Dan Dimensionalitas Berdasarkan Analisis Bumi "GYF"Document8 pagesIdentifikasi Geological Strike Dan Dimensionalitas Berdasarkan Analisis Bumi "GYF"anon_684322156No ratings yet

- Geo EngineeringDocument9 pagesGeo EngineeringNoel FelicianoNo ratings yet

- Geas Iecep PDFDocument32 pagesGeas Iecep PDFCedieMancillaNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument16 pagesCambridge International Advanced Subsidiary and Advanced LevelTanjamul Morsalin SreayashNo ratings yet

- Material Safety Data Sheet For Portable and Stationary X-Ray Systems v9Document7 pagesMaterial Safety Data Sheet For Portable and Stationary X-Ray Systems v9RNDS TechnologiesNo ratings yet

- PM328-21 Hipoclorito de Calcio 70% Lote Feb-012Document1 pagePM328-21 Hipoclorito de Calcio 70% Lote Feb-012Maseri MASERINo ratings yet

- Aeration and AgitationDocument40 pagesAeration and Agitationnurul nabilah bt khairul anuarNo ratings yet

- FOREX & Integrated Pitchfork Analysis - Part IDocument7 pagesFOREX & Integrated Pitchfork Analysis - Part InettideNo ratings yet

- Devolatilization Characteristics of Large Particles of Tyre Rubber Under Combustion Conditions PDFDocument11 pagesDevolatilization Characteristics of Large Particles of Tyre Rubber Under Combustion Conditions PDFclaralisieNo ratings yet

- Model Question Paper Engineering Physics (14PHY12/14PHY22)Document3 pagesModel Question Paper Engineering Physics (14PHY12/14PHY22)prabs20069178No ratings yet

- Miniature Refrigeration SystemDocument7 pagesMiniature Refrigeration SystemRameshkumar RNo ratings yet

- Iaea Nds 0206 200806Document92 pagesIaea Nds 0206 200806Umair RasheedNo ratings yet

- Projek Skor Kimia 2014 Siri 3Document9 pagesProjek Skor Kimia 2014 Siri 3Zul BaidiNo ratings yet

- Electronics Reviewer (Lecture - Quarter 3)Document12 pagesElectronics Reviewer (Lecture - Quarter 3)Patricia VinuyaNo ratings yet

- Republic of The Philippines Cagayan State UniversityDocument8 pagesRepublic of The Philippines Cagayan State UniversityyashishineNo ratings yet

- Gce o Level Physics MatterDocument8 pagesGce o Level Physics MatterBakhita Maryam100% (1)

- BAUL ReportDocument24 pagesBAUL ReportArnold ApostolNo ratings yet

- School of Infrastructure Department of Civil Engineering: Cec 2103-Mechanics of FluidsDocument36 pagesSchool of Infrastructure Department of Civil Engineering: Cec 2103-Mechanics of FluidsDhiraj PuriNo ratings yet

- Classplusapp - NEET CHEM-Ch 3Document16 pagesClassplusapp - NEET CHEM-Ch 3Muhammad AliNo ratings yet

- 9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel GensetDocument19 pages9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel Gensetpradeep kumarNo ratings yet

- Series: Vacuum PadDocument83 pagesSeries: Vacuum PadJorge Luis Apaza GutierrezNo ratings yet

- Atomic Radius: Figure 1 Shows The Atomic Radius Between Two NucleicDocument6 pagesAtomic Radius: Figure 1 Shows The Atomic Radius Between Two NucleicJun Hong TeeNo ratings yet

- Homework Chapter 22 Solutions PDFDocument16 pagesHomework Chapter 22 Solutions PDFbidinNo ratings yet

- Spectrophotometric Determination of The Stoichiometry of A ComplexDocument6 pagesSpectrophotometric Determination of The Stoichiometry of A ComplexDean Dela CruzNo ratings yet