Professional Documents

Culture Documents

1-Catalytic Cracking:: Table (1) Compartion Between Catalytic Cracking, Catalytic Hydrocracking and Hydrotreating

1-Catalytic Cracking:: Table (1) Compartion Between Catalytic Cracking, Catalytic Hydrocracking and Hydrotreating

Uploaded by

مصطفى سعد0 ratings0% found this document useful (0 votes)

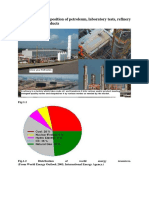

16 views3 pagesCatalytic cracking, catalytic hydrocracking, and hydrotreating are important refinery processes. Catalytic cracking converts heavy oils into gasoline and lighter products using heat and catalysts. Catalytic hydrocracking uses hydrogen in addition to heat and catalysts to produce high ratios of gasoline and jet fuel by converting heavy cracking stocks, aromatics, and cycle oils. Hydrotreating removes sulfur, nitrogen, and converts aromatics to paraffins using hydrogen and catalysts without changing the boiling range. It can process a wide range of feedstocks including naphtha and olefins.

Original Description:

Original Title

H.W(3)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCatalytic cracking, catalytic hydrocracking, and hydrotreating are important refinery processes. Catalytic cracking converts heavy oils into gasoline and lighter products using heat and catalysts. Catalytic hydrocracking uses hydrogen in addition to heat and catalysts to produce high ratios of gasoline and jet fuel by converting heavy cracking stocks, aromatics, and cycle oils. Hydrotreating removes sulfur, nitrogen, and converts aromatics to paraffins using hydrogen and catalysts without changing the boiling range. It can process a wide range of feedstocks including naphtha and olefins.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

16 views3 pages1-Catalytic Cracking:: Table (1) Compartion Between Catalytic Cracking, Catalytic Hydrocracking and Hydrotreating

1-Catalytic Cracking:: Table (1) Compartion Between Catalytic Cracking, Catalytic Hydrocracking and Hydrotreating

Uploaded by

مصطفى سعدCatalytic cracking, catalytic hydrocracking, and hydrotreating are important refinery processes. Catalytic cracking converts heavy oils into gasoline and lighter products using heat and catalysts. Catalytic hydrocracking uses hydrogen in addition to heat and catalysts to produce high ratios of gasoline and jet fuel by converting heavy cracking stocks, aromatics, and cycle oils. Hydrotreating removes sulfur, nitrogen, and converts aromatics to paraffins using hydrogen and catalysts without changing the boiling range. It can process a wide range of feedstocks including naphtha and olefins.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

الرابعة:المرحلة مصطفى سعد جاسم: اسم الطالب

2020\6\20:التاريخ )3(:رقم الواجب

Q(1)

1-Catalytic Cracking: Catalytic cracking is the most important and widely used

refinery process for converting heavy oils into more valuable gasoline and lighter

products.

2-Catalytic Hydrocracking: Chemical process that in addition to using heat

and catalytic ,hydrogen is used to produce high ratio of gasoline and jet fuel.

3-Hydrotreating:The process that converting aromatics to paraffins and reduce

the sulfur and/or nitrogen content without change in boiling range of the feed.

Table(1) Compartion between Catalytic Cracking, Catalytic Hydrocracking and Hydrotreating

Different according Catalytic Cracking Catalytic Hydrotreating

Hydrocracking

1- purpose converting heavy converting high Converting

oils into more ratios of gasoline aromatics to

valuable gasoline and jet fuel paraffins and

and lighter reduce the sulfur

products and/or nitrogen

content

2-feedstock Heavy vacuum gas heavy cracking Wide range as

oil and vacuum stocks, aromatics, unsaturated

distillation residue cycle oils, and coker hydrocarbons such

oils as olefins

3-change in boiling With change With change Without change

range

4-catalytic used ZEALOTS silica-alumina cobalt and

molybdenum oxides

on alumina

catalysts

5-hydrogen With hydrogen With hydrogen Without hydrogen

6-opereting reactor OPERATING Temperature of

condition temperatures are in CONDITIONS 520–645 F (270–

the range 900 to ranging from 660 to 340 C), Pressure of

1000 ºF , with oil 785°F 100–3,000 psig (690–

feed temperatures and from 1000 to 20,700 kPag).

from 500 to 800 ºF 2000 psig (350–

and regenerator exit 420°C and 6900–

temperatures for 13,800 kPa).

catalyst from 1200

to 1500 ºF .

The reaction endothermic endothermic endothermic

الرابعة:المرحلة مصطفى سعد جاسم: اسم الطالب

2020\6\20:التاريخ )3(:رقم الواجب

Q(2)//ANS

1- Catalytic Hydrocracking

1.1-purpose of Catalytic Hydrocracking:

converting high ratios of gasoline and jet fuel and to obtained high octane number.

1.2-feedstock of Catalytic Hydrocracking

1.2.1- heavy cracking stocks, aromatics, cycle oils, and coker oils

1.2.2- Vacuum and coker gas oils

1.3- products of Catalytic Hydrocracking

gasoline, jet fuels, and light fuel oils

2- Hydrotreating

2.1- purpose of Hydrotreating:

to remove objectionable elements from products or feedstocks by reacting them with

hydrogen. Stabilization usually involves converting unsaturated hydrocarbons such

as olefins to paraffins.

2.2- feedstock of Hydrotreating:

Wide range as naphtha and unsaturated hydrocarbons such as olefins.

2.3- products of Hydrotreating:

H2S removal ,parraffins and desulfurized product

الرابعة:المرحلة مصطفى سعد جاسم: اسم الطالب

2020\6\20:التاريخ )3(:رقم الواجب

Q(3)//ANS

Describe of Catalytic Cracking process

1- The hot oil feed is contacted with the catalyst in either the feed riser line or

the reactor.

2- the catalyst is progressively deactivated by the formation of coke on the

surface of the catalyst.

3- The catalyst and hydrocarbon vapors are separated mechanically, and oil

remaining on the catalyst is removed by STEAM STRIPPING before the

catalyst enters the regenerator.

4- The oil vapors are taken overhead to a FRACTIONATION TOWER for

separation into streams having the desired boiling ranges.

5- THE SPENT CATALYST flows into the regenerator and is reactivated by

burning off the coke deposits with air

6- - THE FLUE GAS AND CATALYST are separated by cyclone separators and

electrostatic precipitators. The catalyst in some units is steam-stripped as it

leaves the regenerator to remove adsorbed oxygen before the catalyst is

contacted with the oil feed.

You might also like

- Name of Report: Production of Mythel Tertiary Butyl Ether (MTBE) From Methanol & ButyleneDocument12 pagesName of Report: Production of Mythel Tertiary Butyl Ether (MTBE) From Methanol & Butyleneمصطفى سعدNo ratings yet

- Petroleum Technology Two MarkDocument26 pagesPetroleum Technology Two Markdhanagopal saiNo ratings yet

- Hydrocracking TechnologyDocument11 pagesHydrocracking TechnologyAsad SaeedNo ratings yet

- Design of Dieselmax UnitDocument168 pagesDesign of Dieselmax Unitengr_aqeel0% (1)

- CrackingDocument32 pagesCrackingMuhammad HAmAd QureshiNo ratings yet

- FALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFDocument77 pagesFALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFJateni GedaNo ratings yet

- Catalytic Cracking PDFDocument96 pagesCatalytic Cracking PDFSri NivasNo ratings yet

- Chapter 5a - HydrocrackingDocument26 pagesChapter 5a - Hydrocrackingazizia harmes0% (1)

- Petroleum IndustryDocument39 pagesPetroleum IndustryQuenie Rose RontalNo ratings yet

- RefiningDocument49 pagesRefininghiuNo ratings yet

- CrackingDocument28 pagesCrackingzaraNo ratings yet

- An Oil Refinery Production OptimizationDocument28 pagesAn Oil Refinery Production OptimizationCarlos Arentz100% (1)

- Quiz Mohd Rafiq Mohd ZubirDocument11 pagesQuiz Mohd Rafiq Mohd ZubirMohd RafiqNo ratings yet

- Oil-Degassing:: 1-SeparationDocument34 pagesOil-Degassing:: 1-SeparationAhmed AbdullaNo ratings yet

- PetroluemDocument37 pagesPetroluemAhmed AbdullaNo ratings yet

- Oil Refining 04Document16 pagesOil Refining 04Nisha KrishnanNo ratings yet

- Simple Guide To Oil RefiningDocument5 pagesSimple Guide To Oil RefiningPatel AshokNo ratings yet

- Advanced Petroleum Processing-Summary ProjectDocument76 pagesAdvanced Petroleum Processing-Summary ProjectJohn WinstonNo ratings yet

- Refining 06 Hydrotreating Process CompleteDocument31 pagesRefining 06 Hydrotreating Process CompletetalhawasimNo ratings yet

- Overview - PREDocument19 pagesOverview - PREayush gandhiNo ratings yet

- Introduction of Catalytic Reforming ProcessDocument10 pagesIntroduction of Catalytic Reforming Processsagarchawla13100% (1)

- Oil Refining and ProductsDocument15 pagesOil Refining and Productsdie_1No ratings yet

- CH414 PRE (Hydrocracking)Document22 pagesCH414 PRE (Hydrocracking)Ali Daniyal AwanNo ratings yet

- What Is NaphthaDocument7 pagesWhat Is Naphthamsabah bugtigNo ratings yet

- RefiningDocument105 pagesRefiningLuis AcidNo ratings yet

- Hydroprocessing Pilot PlantsDocument4 pagesHydroprocessing Pilot PlantsNattapong PongbootNo ratings yet

- Click To Edit Master Subtitle StyleDocument16 pagesClick To Edit Master Subtitle StyleMUHAMMAD AKRAMNo ratings yet

- ,, Naphtha Cracking ,,: Duhok Polytechnic University Technical College of Engineering Petrochemical DepartmentDocument28 pages,, Naphtha Cracking ,,: Duhok Polytechnic University Technical College of Engineering Petrochemical DepartmentIbrahim DewaliNo ratings yet

- Hydro CrackingDocument25 pagesHydro CrackingBharat KumarNo ratings yet

- Introduction To Petroleum Technology - 3Document21 pagesIntroduction To Petroleum Technology - 3Anish VazeNo ratings yet

- Petro Unit 3Document109 pagesPetro Unit 3Atharva ShrivastavNo ratings yet

- Petroleum Refinery: Soran University Petroleum Engineering DepartmentDocument24 pagesPetroleum Refinery: Soran University Petroleum Engineering Departmentmustafa sfNo ratings yet

- Fuel Upgrading IIDocument64 pagesFuel Upgrading IIJoannaJamesNo ratings yet

- Thermal and Catalytic CrackingDocument60 pagesThermal and Catalytic CrackingMALIK ZARYABBABARNo ratings yet

- Final Assignment: Soran University Faculty of Engineering Third Stage CHEDDocument10 pagesFinal Assignment: Soran University Faculty of Engineering Third Stage CHEDاسماعیل ادریس عبدالعزیزNo ratings yet

- Final Assignment: Soran University Faculty of Engineering Third Stage CHEDDocument10 pagesFinal Assignment: Soran University Faculty of Engineering Third Stage CHEDاسماعیل ادریس عبدالعزیزNo ratings yet

- Introduction To RefineryDocument6 pagesIntroduction To RefinerydyarNo ratings yet

- Thermal and Catalytic Convesion ProcessDocument54 pagesThermal and Catalytic Convesion ProcessSaiPavanNo ratings yet

- Hydro ProcessingDocument56 pagesHydro ProcessinggeorgiadisgNo ratings yet

- Purifier Maintenance 1Document54 pagesPurifier Maintenance 1Noel Nico FernandoNo ratings yet

- HydrocrackingDocument24 pagesHydrocrackingSaj BhaiNo ratings yet

- Catalytic CrackingDocument17 pagesCatalytic Crackingtariq fareedNo ratings yet

- UntitledDocument11 pagesUntitledapi-256504985No ratings yet

- Uop Unicracking Process For Hydrocracking: Donald AckelsonDocument12 pagesUop Unicracking Process For Hydrocracking: Donald AckelsonNguyễn Hoàng Bảo TrânNo ratings yet

- Learning EvidenceDocument12 pagesLearning EvidenceKassiel Hdz ꧂No ratings yet

- Petroleum Refining and PetrochemicalsDocument76 pagesPetroleum Refining and PetrochemicalsJosephine NarcisoNo ratings yet

- GBPummus Crude To chemicaGBPs Part 1 The Basic Concept of CrudesDocument6 pagesGBPummus Crude To chemicaGBPs Part 1 The Basic Concept of CrudesKemkengNo ratings yet

- Petroleum Refining ProcessesDocument21 pagesPetroleum Refining ProcessesJimNo ratings yet

- Producing Naphtha and KeroseneDocument10 pagesProducing Naphtha and KeroseneSelvia Pratiwi100% (1)

- W6 HydrocrackingDocument36 pagesW6 HydrocrackingIkhmal FirdausNo ratings yet

- Petroleum and Natural Gas: Octane Number-Ability of Gasoline To Withstand Compression in Engines.Document8 pagesPetroleum and Natural Gas: Octane Number-Ability of Gasoline To Withstand Compression in Engines.Kelly Sheine SisonNo ratings yet

- Background And: Introducti OnDocument173 pagesBackground And: Introducti Onengr_aqeelNo ratings yet

- Crude Oil RefiningDocument37 pagesCrude Oil RefiningAli Alengineer100% (1)

- Ref 111Document111 pagesRef 111AbidHussainBhattiNo ratings yet

- Unit 2 Chemistry Crude Oil and AmmoniaDocument40 pagesUnit 2 Chemistry Crude Oil and AmmoniaCrisa ChinaNo ratings yet

- PRE 2 MidT SepProc 10 Jun 2014 PArt 1Document34 pagesPRE 2 MidT SepProc 10 Jun 2014 PArt 1Shabbir AliNo ratings yet

- Liquid Fuels: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Metallurgy DivisionFrom EverandLiquid Fuels: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Metallurgy DivisionRating: 4.5 out of 5 stars4.5/5 (2)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Name of Report:Controlling of Pyrolysis Reactor in Production of EthyleneDocument16 pagesName of Report:Controlling of Pyrolysis Reactor in Production of Ethyleneمصطفى سعدNo ratings yet

- Production of Mythel Tertiary Butyl Ether (MTBE) From Methanol & ButyleneDocument71 pagesProduction of Mythel Tertiary Butyl Ether (MTBE) From Methanol & Butyleneمصطفى سعدNo ratings yet

- University of Technology: Chemical Engineering DepartmentDocument14 pagesUniversity of Technology: Chemical Engineering Departmentمصطفى سعدNo ratings yet

- The Velocity of Particles Moving in A Fluid: F F + F F - F FDocument13 pagesThe Velocity of Particles Moving in A Fluid: F F + F F - F Fمصطفى سعدNo ratings yet

- نموذج لرسالة اقرار المشرف والممتحنين وترتيب المحتوياتDocument5 pagesنموذج لرسالة اقرار المشرف والممتحنين وترتيب المحتوياتمصطفى سعدNo ratings yet

- Fixed Bed Reactor Dynamics and Control - A ReviewDocument14 pagesFixed Bed Reactor Dynamics and Control - A Reviewمصطفى سعدNo ratings yet

- Chapter One +two PDFDocument44 pagesChapter One +two PDFمصطفى سعدNo ratings yet

- TR4 Shaper AlonzoDocument7 pagesTR4 Shaper AlonzoIsaiah Benjamin AlonzoNo ratings yet

- CD DVD EnvelopeDocument1 pageCD DVD EnvelopeMary Ann NazarNo ratings yet

- Product List Additives For Coatings - SynthronDocument20 pagesProduct List Additives For Coatings - SynthronbexigaobrotherNo ratings yet

- EagleBurgmann - AN Type Expansion Joints - ENDocument7 pagesEagleBurgmann - AN Type Expansion Joints - ENArzu AliyevaNo ratings yet

- Painting SpecificationDocument19 pagesPainting Specificationamirthraj74No ratings yet

- HFY-PIP-SP-00004 X Specification For Sour Service - A-CommentedDocument9 pagesHFY-PIP-SP-00004 X Specification For Sour Service - A-CommentedVignesh PanchabakesanNo ratings yet

- Radiographic Interpretation: Radiographs of WeldsDocument22 pagesRadiographic Interpretation: Radiographs of WeldsManoj BallaNo ratings yet

- III 12 2009 UllmannEncycl HetCatal Turek Deutschmann-666931330Document153 pagesIII 12 2009 UllmannEncycl HetCatal Turek Deutschmann-666931330Dragon's Sin of Wrath MeliodasNo ratings yet

- Catalysis & Catalysts - Impregnation and Reaction MechanismDocument19 pagesCatalysis & Catalysts - Impregnation and Reaction MechanismZamri Fadilah IINo ratings yet

- Processing of Ceramics, Glass, and SuperconductorsDocument17 pagesProcessing of Ceramics, Glass, and SuperconductorsQuốc HoàngNo ratings yet

- Fits and Tolerences - AEDocument65 pagesFits and Tolerences - AERaghavendra Kilari100% (1)

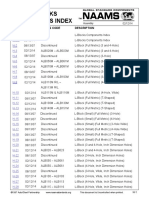

- L-Blocks Components Index: Page Date Naams Code DescriptionDocument54 pagesL-Blocks Components Index: Page Date Naams Code DescriptioncblairNo ratings yet

- Solution Poly-Round Bearings in Polymer OR Stainless HousingsDocument3 pagesSolution Poly-Round Bearings in Polymer OR Stainless HousingsLeroy AraoNo ratings yet

- 312 - Welding of Domex and Docol Advanced High Strength SteelsDocument24 pages312 - Welding of Domex and Docol Advanced High Strength SteelsmustafagoresNo ratings yet

- Recycled Wood Bark of MalunggayDocument2 pagesRecycled Wood Bark of Malunggaye_geanga75% (8)

- Din 6914 PDFDocument2 pagesDin 6914 PDFvpjagannaathNo ratings yet

- Techno PlasmaDocument7 pagesTechno PlasmaMiklós GordosNo ratings yet

- Sample 2Document6 pagesSample 2Er Sarvjeet YadavNo ratings yet

- Design Criteria - Corrosion Control Rev 0Document1 pageDesign Criteria - Corrosion Control Rev 0kapsarcNo ratings yet

- Adicomp - Air Treatment - ENDocument44 pagesAdicomp - Air Treatment - ENDe RaNo ratings yet

- Cupping1 1Document3 pagesCupping1 1Mahesh KhadeNo ratings yet

- 7a Zinc Tape For Pipes Poles EtcDocument2 pages7a Zinc Tape For Pipes Poles EtcKen SidhartaNo ratings yet

- TDS - TERRAWET Primer G 9 - 733 Inline - 060 - enDocument2 pagesTDS - TERRAWET Primer G 9 - 733 Inline - 060 - enJavier Martinez CañalNo ratings yet

- Appendix S - Welding Provisions - BNBC 2020 CommentaryDocument5 pagesAppendix S - Welding Provisions - BNBC 2020 CommentaryTarif Aziz MarufNo ratings yet

- Lathe Tooling: # Answer 1. 2Document4 pagesLathe Tooling: # Answer 1. 2David BumbaloughNo ratings yet

- ROYALPOXY UW 410-tdsDocument3 pagesROYALPOXY UW 410-tdsSyed FaridNo ratings yet

- Basic Workshop ModuleDocument76 pagesBasic Workshop ModuleTeklu AnbeseNo ratings yet

- Painting EstimatesDocument3 pagesPainting EstimateskjohnlopezNo ratings yet

- Sa 203 PDFDocument4 pagesSa 203 PDFRaju SkNo ratings yet

- My New ResumeDocument4 pagesMy New ResumeSurajNo ratings yet