Professional Documents

Culture Documents

Bentonite Adsorption Coagulation Treatment of Recy

Bentonite Adsorption Coagulation Treatment of Recy

Uploaded by

AnujKumarVermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bentonite Adsorption Coagulation Treatment of Recy

Bentonite Adsorption Coagulation Treatment of Recy

Uploaded by

AnujKumarVermaCopyright:

Available Formats

Engineering, 2013, 5, 314-320

http://dx.doi.org/10.4236/eng.2013.510B064 Published Online October 2013 (http://www.scirp.org/journal/eng)

Bentonite Adsorption & Coagulation Treatment of

Recycled Fiber Pulping Wastewater

Tingzhi Liu, Kaiyang Zheng, Defa Wang, Shuai Li, Haoyu Wang

School of Material Science& Technology, Tianjin University of Science & Technology,

Tianjin Key Laboratory of Pulp & Paper, Tianjin, China

Email: liutz@tust.edu.cn

Received July 2013

ABSTRACT

A bentonite & PAM particle flocculation system was employed in recycled fiber pulp wastewater treatment in this pa-

per. The optimum conditions of the adsorption & coagulation treatment was explored and optimized and effects of the

treatment were focused on, especially stickies substances removal. Under the optimal conditions, the removal of MTBE

extract and cationic demand reached 91.26% and 86.93%, and the average particle size in the treated wastewater pollu-

tants is reduced from 40.95 μm to 0.5 μm. In this treatment the removal of CODcr, turbidity, SS and color were 89.67%,

99.56%, 95.58% and 93.08%, respectively. The results showed that the particle flocculation system was effective for

the treatment of recycled fiber pulp wastewater, especially for controlling the stickies.

Keywords: Recycled Fiber Pulp; Wastewater; Stickies, Bentonite; Coagulation

1. Introduction 2. Material and Methods

Increased consumption of recycled fiber in paper indus- The wastewater was collected at a laboratory installation,

try not only reduced the dependence on forest resource include wastewater from pulping, floatation deinking. It

requirements, but also the pollution of environment. On was stored in a refrigerator until use. Its initial properties

the other hand, the impurities from the waste paper bring were shown in Table 1. The bentonite (800 mesh,

about more and more serious problems, and the accumu- Na-bentonite) and the PAM (medium cationic, MW

lation problems of stickies are especially paid attention. about 10 million daltons) were obtained from YaGuang

The accumulation of stickies in waste paper stock and Development Co., Ltd, Ningbo, Zhejiang province of

follow-up white water system will make drainage in the China.

wet-end of the paper machine become uneven, resulting Put appropriate amount recycled fiber pulp wastewater

in paper flaws such as paper hole and stain. Sorting of liquor into a beaker and the pH and temperature of the

waste paper, flocculation deinking, screening of pulp, wastewater sample were first adjusted. Then put into

dispersion, process water treatment, chemical agent ap-

Table 1. Index of routine analysis for original wastewater

plication and bio-treatment, all these technologies can be

and those after treatment.

used to control the stickies troubles of recycle fiber pulp

[1-5]. All these mentioned technological measures aimed wastewater Treated water Removal (%)

at recycle fiber pulp and pulping process, but reducing CODcr (mg/L) 3020 312 89.67

the stickies content of pulping wastewater is useful and

helpful to control the stickies troubles, too. In this article, SS (mg/L) 860 38 95.58

a bentonite & PAM particle flocculation system was em- Turbidity( NTU) 108.00 1.03 99.56

ployed in recycled fiber pulping wastewater treatment.

pH 6.4 7.9 -

Bentonite, clay, coke, activated sludge and some other

materials were used as adsorption aids to improve floc- color (C.U.) 867.4 58.2 93.08

culation efficiency [6,7]. Bentonite, which is available in MTBE extract (mg/L) 236.8 20.7 91.26

large quantities, can be used as an adsorbent for the re-

CD (μmol/L) 1065.4 150.0 85.92

moval of dissolved organic compounds from pulp & pa-

per mill effluent with appreciably lower cost [8]. particle size(μm) 40.95 0.51 -

Copyright © 2013 SciRes. ENG

T. Z. LIU ET AL. 315

appropriate amount bentonite and Stiring at 150 rpm for wastewater were reduced with the increase of bentonite

30 min for adsorption. After adsorption reaction, put dosage, and reached the minimum at the same dosage

PAM into beaker and string for a few minutes, then con- which was about 250 mg/L. It is because that the SS of

tent settle for 30 min, the supernatant in the beaker was the treated water was devoted by fines concentration. The

taken out and used for the analyses. light beam will be scattered and reflected by the small

The chemical oxygen demand (CODcr) of the water particles. This is exactly corresponds with the determina-

sample was determined by colorimetric methods. The tion theory of turbidity. So the turbidity of the water in

turbidity of the water sample was measured by an ASN this study was linear with the content of SS. The CD and

2000 turbidity meter [9]. The MBTE extract of effluent 465 nm OD of the treated water were decreased with the

was determined according to the method described in an increase of bentonite dosage, and reached the minimum

article [10]. And the Cationic demand (CD), mean di- at about 150 mg/L dosage, but increased at the dosage of

ameter of particles of wastewater were measured by 250 mg/L, then drop again while the dosage reached at

PCD-03 particle charge analyzer (Mütek). The color of 400 mg/L. This was most likely caused by that the re-

wastewater was determined by spectrophotometer at 465 moval of CD and color substances due to the two ways:

nm and converts to Pt-Co C.U. adsorption and coagulation mechanism.

Figure 1 further showed that the removal of the four

3. Results and Discussion index were significant only when the dosage from 50

mg/L to 150 mg/L, and the maximum color and CD re-

The optimal conditions of recycled fiber pulp wastewater

movals were observed at about 150 mg/L. So the 150

treatment were studied. This article was focused on ef-

mg/L was the optimal bentonite dosage.

fects of bentonite, PAM dosages, pH, temperature of

wastewater and the stir speed and time on removal of

pollutions. The CD, SS, turbidity and OD of 465 nm

3.2. Effect of the PAM Dosage

were determined to optimize the treatment conditions. The Figure 2 showed that the curve trends of turbidity

Table 1 offered an index of routine analysis for original and SS of the treated wastewater were similar with the

wastewater and those after treatment under the optimal increase of PAM dosage. The SS and turbidity of treated

conditions. As shown in Table 1, the results of routine water reached the minimum points at the same dosage

tested of recycled fiber pulp wastewater were: The which was about 50 mg/L PAM, and then increased

CODcr was 3020 mg/L, pH was 6.4. The average particle while the PAM dosage increased to 100 mg/L, the max-

size was 40.95 μm and the turbidity was 108.0NTU. The imum dosage of this study. The similar result of SS and

contents of SS and MTBE extract were 860 mg/L and Turbidity removal with the increase of PAM dosage was

236.8 mg/L, respectively. The CD of the wastewater was also reported by Angela C.R while they used a Fe- culant

as high as 1065.4 μmol/L. These anionic constituents to treated pulp effluent [12]. The CD of the treated water

were related to the content of stickies in wastewater [11]. reduced sharply with the increase of PAM dosage while

the dosage lower than 10 mg/L, then increased slightly

3.1. Effect of the Bentonite Dosage with the dosage from 20 mg/L increased to 100 mg/L.

As shown in Figure 1, the turbidity and SS of the treated The changes of color of the treated water with the

400 400 1.0 50

CD 0.9

350 SS 0.8 40

350 OD of 465nm

Turbidity 0.7

CD(umol·L-1)

300 0.6 30

Turbidity(NTU)

465nm OD

SS(mg·L-1)

300 0.5

250 0.4 20

0.3

250

200 0.2 10

0.1

150 200 0.0 0

0 50 100 150 200 250 300 350 400

Dosage of bentonite(mg.L-1)

Figure 1. Effect of the bentonite dosage on adsorption & coagulation treatment.

Copyright © 2013 SciRes. ENG

316 T. Z. LIU ET AL.

increase of PAM dosage were far more complicated than raw material puling effluent will change very signifi-

the other three indexes. The 465 nm OD of the treated cantly because the acidic precipitation of lignin that con-

water decreased sharply with the increase of the PAM tributes to the color of these effluents. The SS of the

dosage from 2 to 10 mg/L, and then increased from 10 treated water increased slightly with the pH from 2.0 to

mg/L to 100 mg/L. The OD had a minimum at the PAM 6.0, and from 8.0 to 12.0, but decreased at the pH8.0.

dosage about 10 mg/L and a maximum at about 100 The turbidity of the treated water shows two inflection

mg/L. This confused curve trend can be explained through points at pH value 4.0 and 8.0. The turbidity decreased

understanding how the objects of PAM flocculation. As a with the pH from 2.0 to 4.0, and then increased from pH

kind of macromolecular flocculant, the function of PAM 4.0 to 8.0, after pH 8.0, with the increase of pH value, the

in the wastewater treatment is mainly due to the reaction turbidity increased significantly. It was maybe due to the

of adsorption bridging mechanism. This can be explained good dispersion of bentonite at alkaline environment.

the sharply decreasing with the increase of the PAM do- The dispersion of absorbed water and expanded bentonite

sage from 2 to 10 mg/L. When the dosage of PAM was in water caused the increasing of turbidity.

too big, the positive electricity charges of the excessive The above mentioned factors should be under consid-

PAM (medium cationic PAM) will adsorb and coagulate eration choice of pH value. Except for the SS of the

the fines concentration by compression of double treated water, the other three indexes are good enough

charged. It was very difficult to precipitate and demix, for the treatment at pH6.0. Choose the pH 6.0 as the op-

because there was so much substantial macromolecular timal value was under consideration not only the treated

floc in the treated water. It was also explained why the efficiency but also the cost of the treatment, because the

SS, CD, turbidity and 465 nm OD of treated water in- pH value of the origin water was about 6.0.

creased with the PAM from 50 mg/L to 100 mg/L. Con-

clusions as a result, the 10 mg/L was the choice dosage 3.4. Effect of the Wastewater Temperature

of PAM.

The temperature of wastewater will affect the adsorption

and coagulation efficiency of bentonite. As shown in

3.3. Effect of the Initial pH

Figure 4, the CD, 465 nm OD, SS and turbidity of the

Figure 3 Showed the effects of initial pH on the bento- treated water decreased with the increase of the tempera-

nite treatment of recycled fiber pulp wastewater. As a ture from 30˚C to 60˚C, and reached a desired treated

whole, all of CD, SS, 465 nm OD and turbidity of the effect at 60˚C. Then the CD, 465 nm OD, SS and turbid-

treated water were increased with the initial pH value ity of the treated water increased with the increase of the

increased. The color and CD of the treated water in- temperature from 60˚C to 80˚C. Figure 4 also shows that

creased slightly with the increased of pH, the acidic the temperature affects the index of SS and turbidity

property of water becomes stronger, the CD and color of more weakly than those of CD and 465 nm OD. The CD

treated water will become smaller. It is different that the value of the water was to indicate the negative electric

color of the treated water altered little with the pH from 2 charge. Another perspective reflects the content of nega-

to 6 to that of raw material puling effluent. The color of tive substances. These substances are mainly composed

200 250 0.20 10

190 240 CD 9

230 SS 0.18 8

180 OD of 465nm

220 Turbidity 7

170

CD(umol·L-1)

210 0.16 6

465nm OD

Turbidity(NTU)

160 200 5

SS(mg·L-1)

150 190 0.14 4

180 3

140

170 0.12 2

130

160 1

120 150 0.10 0

0 10 20 30 40 50 60 70 80 90 100 110

Dosage of PAM(mg.L-1)

Figure 2. Effect of the PAM dosage on bentonite adsorption & coagulation treatment.

Copyright © 2013 SciRes. ENG

T. Z. LIU ET AL. 317

400 400 1.0 16

CD 14

SS 0.8

300 300 OD of 465nm 12

Turbidity

10

CD(umol·L-1)

0.6

Turbidity(NTU)

465nm OD

8

SS (mg·L-1)

200 200

0.4 6

4

100 100

0.2 2

0

0 0 0.0

2 4 6 8 10 12

pH

Figure 3. Effect of the initial pH on bentonite adsorption & coagulation treatment.

200 160 9.0

150

CD 0.14 8.5

190 SS

OD of 465nm

140 8.0

Turbidity

180 0.12

130 7.5

CD(umol·L-1)

Turbidity(NTU)

465nm OD

SS(mg·L-1)

170 120 7.0

0.10

110 6.5

160

100 6.0

0.08

150

90 5.5

140 80 0.06 5.0

30 40 50 60 70 80

Temperature(℃)

Figure 4. Effect of the wastewater temperature on bentonite adsorption & coagulation treatment.

of soluble and colloidal constituents. The color is mainly tantly. So 60˚C was the optimal temperature for adsorp-

contributed by these soluble and colloidal constituents tion & coagulation treatment.

too. Except effect of adsorption & coagulation of the

bentonite, the temperature of water also affects the ener- 3.5. Effect of the Stir Speed

gy of motion of these soluble and colloidal constituents.

As Figure 5 shown, the CD and 465 nm OD of treated

The energy of motion of these soluble and colloidal con-

stituents was up to the status in adsorption & coagulation water decreased and then increased with the increase of

treatment. So the temperature of water affects the CD stir speed, and they all reached the maximum color and

and 465 nm OD strongly than those of SS and turbidity. CD removals at 200 rpm speed. Figure 5 also shows that

By contrast, the components that influence the detections the curve trends of turbidity and SS of the treated waste-

of SS and turbidity index were composed of colloidal and water were similar to these of the CD and 465 nm OD

dispersive constituents. The energy motion of these col- with the increase of stir speed. However, the lowest

loidal and dispersive constituents will be affected slightly points of the SS and turbidity of the treated water were

by temperature change than it of soluble and colloidal observed at the 150 rpm. The appearance of the maxi-

constituents. So that the force of gravity and volume fac- mum removal speed of CD and 465 nm OD different to

tors of these colloidal and dispersive constituents affect that of SS and turbidity attributes to the different removal

the status settlement and separation much more impor- mechanism of them. For the removal of CD and color

Copyright © 2013 SciRes. ENG

318 T. Z. LIU ET AL.

constituents, the fast Stir not only enhances the mass effect of speed on turbidity in their studies [12,15].

transfer capability of the water but also gives those more

chance to come into contact with the others. So the 3.6. Effect of the Stir Time

minimum points of the CD and color reached at more Figure 6 showed that a short time stirring could obtain a

fast stirring speed than those of the SS and turbidity. But very good effect of SS, turbidity and 465 nm OD remo-

over—rapid stirring will broke up the floc and disperse val. From Figure 6, the SS, turbidity and 465 nm OD

the constituents into the water again, this can explain the decreased significantly with the stirring time form 0 pro-

increases of CD and 465 nm OD with the speed from 200 long to 2min, and reached to the good removal point at 2

rpm to 300 rpm. Stir speed affects the turbidity and SS - 5 min, then increased with the stirring time extended

not only on capability of mass transfer, but also on status again. It was different to the other three indexes, the CD

of the floc. A slight over stirring will give the floc appre- of the treated water increased stably with the stirring time

ciable damage effects, so the ideal stir speed for turbidity extended. Removal of the material that indicated CD of

and SS removal was lower than it of CD and 465 nm OD, the water mainly depends on the adsorption of the bento-

it was 150 rpm. Figure 5 also shows that the turbidity nite. Before the addition of PAM, the bentonite has been

changed slightly with the speed from 50 rpm to 100 rpm, added into the water and adsorbed the material for 30min,

but significantly when the speed is over 100 rpm, and so the content of CD materials has reduced to a limited

will increase while the speed is more than 150 rpm. status. When the stirring beginning, the materials of CD

Many researchers had obtained the same rule on the resolved into the water, so the CD increased.

200 0.5 20.0

240

190 CD

SS 17.5

180 220 0.4

OD of 465nm

170 Turbidity

200 15.0

CD(umol·L-1)

160 0.3

Turbidity(NTU)

465nm OD

180

SS(mg·L-1)

150 12.5

140 160 0.2

10.0

130

140

120 0.1

7.5

120

110

100 100 0.0 5.0

50 100 150 200 250 300

Stir(rpm)

Figure 5. Effect of the stir speed on bentonite adsorption & coagulation treatment.

220 200 0.30 20

CD 18

SS

200 OD of 465nm 16

180 Turbidity 0.25

14

CD(umol·L-1)

180 12

Turbidity(NTU)

465nm OD

SS(mg·L-1)

160 0.20 10

160 8

6

140 0.15

140 4

2

120 120 0.10 0

0 5 10 15 20

Stir time(min)

Figure 6. Effect of the stir time on bentonite adsorption & coagulation treatment

Copyright © 2013 SciRes. ENG

T. Z. LIU ET AL. 319

3.7. The Removal Efficiency of Bentonite ment Grants Planning Projects for Tianjin High Educa-

Adsorption & Coagulation Treatment tion Colleges (SW20080001).

Through the studies of influence factors we draw up the

optimal conditions for recycled fiber pulp wastewater REFERENCES

treatment. The optimal conditions were: bentonite dosage [1] J. Chen, “Judgment of Microstickies Removability with

was 150 mg/L, PAM dosage was 10 mg/L, the adsorption Minerals During Paper Recycling,” China pulp & paper,

reaction temperature was 60˚C, pH value was 6.4, the Vol. 23, No. 3, 2004, pp. 50-52.

original pH of the wastewater, after PAM addition, stir- [2] J. Chen, “New Methods for Removal of Wax and Stickies

ring at the speed of 150 rpm for 2 - 5 min. Table 1 shows from OCC,” China Pulp & Paper Industry, Vol. 25, No. 7,

an index of routine analysis for original wastewater and 2004, pp. 37-38.

those after treatment under the optimal conditions. [3] L. Wang, L. Luo and H. Xiao, “Controlling Polysaccha-

From Table 1, under these optimal conditions, the ride-Based Anionic Trashes Using Low-Molecular-wei-

COD of the wastewater from 3020 mg/L reduced to 312 ghted HCS,” China pulp & paper, Vol.28, No. 1, 2009,

mg/L, and the removal rate reached about 90%. The tur- pp. 25-29.

bidity and the SS of the wastewater reduced from 108 .00 [4] L. Wang, Y. Yu and Y. Chen, “Boosting AKD Neutral

NTU and 860 mg/L to 1.03NTU and 38 mg/L, and the Sizing of APMP by Anionic Trash Catchers,” China pulp

& paper, Vol. 29, No. 3, 2009, pp. 10-13.

removal of them were 99.56%, 95.58%, respectively.

The color of the wastewater from 867.4 C.U. reduces to [5] T. Liu, D. Wang, H. Zhao and K. Zheng, “Stickies

Treatments of Recycled Fiber Pulping Wastewater by Li-

58.2 C.U., and the removal rate was 93.08%. All these pases,” Advanced Materials Research, Vol. 534, 2012, pp.

lead up to the conclusion that the particle flocculation 225-229.

system was effective for the treatment of recycled fiber http://dx.doi.org/10.4028/www.scientific.net/AMR.534.2

pulp wastewater. Figure 6 also shows that the average 25

particle size in the treated wastewater pollutants is re- [6] T. Liu and E Zheng, “Improving Flocculation Effect in

duced from 40.95 μm to 0.5 μm. It shows that the ad- Pre-treating High Yield Pulping Effluents of Cotton Staff

sorption coagulation aid treatment which is mainly used by Using Active Sludge,” 2nd International Papermaking

and Environment Conference Proceeding books A and B,

to remove larger particles and colloids suspended materi-

Tianjin, 1-3 May 2008, pp. 1101-1105.

al. It is worthwhile noting that the removal of MTBE

[7] T. Liu, X. Duan and E Zheng, “Adsorbent & Treatment

extract reached 91.26%. The stickes materials are mainly

for High Yield Pulp Effluents of Cotton Staff by Coke,”

composed of these constituents that can be extracted by Progress in Environmental Science and Technology, In-

organic solvents. The removal of organic solvents extract ternational Symposium on Environmental Science and

always reached to about 90% [13-15]. But those studies Technology, Vol. II, Beijing, 12-14 May 2009, pp. 2378-

were almost though the biological treatment to reach the 2383.

removal rate. And the removal of CD of the waste water [8] X. Duan, T. Liu and W. Duan, “Adsorption and Coagula-

was about 87% reflecting that the bentonite adsorption & tion Tertiary Treatment of Pulp & Paper Mills Wastewa-

coagulation Treatment was a very good treatment and the ter,” 4th International Conference on Bioinformatics and

Biomedical Engineering, Chengdu, 15-18 June 2010, pp.

removal of stickies was very efficiently. 1110-1114.

[9] E. Magnus, G. Carlberg andH. Hoel, “TMP Wastewater

4. Conclusion Treatment, Including Biological High-efficiency Compact

The bentonite, which is available in large quantities, can Biological Reactor Removal and Characterisation of Or-

be used as an adsorbent for the removal of dissolved or- ganic Components,” Nordic Pulp and Paper Research

Journal, Vol. 15, No. 1, 2000, p. 29.

ganic compounds from pulp & paper mill effluent with http://dx.doi.org/10.3183/NPPRJ-2000-15-01-p029-036

appreciably lower cost. Under the optimal conditions, the

[10] T. Liu, Z. He, H. Hu and Y. Ni, “Treatment of APMP

removal of MTBE extract and cationic demand reached Pulping Effluent based on Aerobic Fermentation with

91.26% and 86.93%. The results show that the particle Aspergillus Niger Fungi and Post-Coagulation/Floccula-

flocculation system is effective for the treatment of re- tion,” Bioresource Technology, Vol. 102, No. 7, 2011, pp.

cycled fiber pulp wastewater, and the control of stickes 4712-4717.

of recycle fiber pulp wastewater is very efficient. http://dx.doi.org/10.1016/j.biortech.2011.01.047

[11] T. Liao and H. He, “Research and Discuss about Anionic

5. Acknowledgements (Heading 5) Trash in DIP,” Paper and Paper Making, Vol. 30 No. 2,

2011, pp. 23-27.

Financial support from National “Twelfth five-year”

[12] C. R. Angela and B. Marcela, “Treatment of Paper Pulp

Science & Technology Key Project of China and Paper Mill Wastewater by Coagulation-Flocculation

(2011BAC11B04) and Science & Technology Develop- Followed by Heterogeneous Photocatalysis,” Journal of

Copyright © 2013 SciRes. ENG

320 T. Z. LIU ET AL.

Photochemistry and Photobiology, Vol. 194, No. 1, 2008, with Aerobic and Anaerobic Biomass-1,” Water Research,

pp. 1-10. Vol. 30, No. 3, 1996, p. 663.

[13] S. N. Lo and H. W. Liu, “Characterization of Pollutants at http://dx.doi.org/10.1016/0043-1354(95)00215-4

Source and Biological Treatment of a CTMP Effluents,” [15] L. LaFleur, E. Barton and D. Aret, “Pulp Mill Effluents

Appita Journal, Vol. 44, No. 2, 1991, p. 133. Characterization and Treatment: An Update, Fate and Ef-

http://dx.doi.org/10.1016/j.jphotochem.2007.07.007 fects of Pulp and Paper Mill Effluent,” 3rd International

[14] S. F. Liver and E. R. Hall, “Interactions of Resin Acids Conference on Environmental Pollution, Rotorua, 1997.

Copyright © 2013 SciRes. ENG

You might also like

- Metcalf and Eddy Wastewater Engineering Free Download PDFDocument2 pagesMetcalf and Eddy Wastewater Engineering Free Download PDFAnonymous eKB0qRUpq33% (3)

- Aoac 991.07Document7 pagesAoac 991.07Javier muñozNo ratings yet

- B-80 To 100 CMD MBBR - Technical OfferDocument15 pagesB-80 To 100 CMD MBBR - Technical OfferYegetafikerNo ratings yet

- Coagulation Adsorption Ultrafiltration For Wastewater Treatment and Reuse - 2000 - DesalinationDocument8 pagesCoagulation Adsorption Ultrafiltration For Wastewater Treatment and Reuse - 2000 - DesalinationAlvaro HueteNo ratings yet

- Treatment of Tunnel Construction Wastewater Using Chitosan CoagulantDocument9 pagesTreatment of Tunnel Construction Wastewater Using Chitosan CoagulantepebeNo ratings yet

- Jurnal AmamiDocument12 pagesJurnal AmamiSany FathinurNo ratings yet

- Water Quality Effect On Retention Aids Efficiency in The Paper IndustryDocument7 pagesWater Quality Effect On Retention Aids Efficiency in The Paper Industryjohn.sehtNo ratings yet

- Combination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryDocument8 pagesCombination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryChittaranjan SahooNo ratings yet

- Nghiên C U UmbrDocument5 pagesNghiên C U UmbrDUY TONGNo ratings yet

- Adsorptive Removal of Methylene Blue Onto ZnCl2 AcDocument12 pagesAdsorptive Removal of Methylene Blue Onto ZnCl2 AcHazel Rene Gallegos MorenoNo ratings yet

- Tsioptsias 20151Document10 pagesTsioptsias 20151Violeta GarciaNo ratings yet

- Comparing The Effectiveness of Chitosan and Conventional Coagulants For Coal Wastewater TreatmentDocument8 pagesComparing The Effectiveness of Chitosan and Conventional Coagulants For Coal Wastewater TreatmentUtami IrawatiNo ratings yet

- Miaz CopsDocument5 pagesMiaz CopsMelese DagnawNo ratings yet

- Pulp and Paper Liquid Waste Treatment Using Electro Coagulation MembraneDocument7 pagesPulp and Paper Liquid Waste Treatment Using Electro Coagulation MembraneRobby KurniawanNo ratings yet

- Column Performance in Lead (Ii) Removal From Aqueous Solutions by Fixed-Bed Column of Mango Wood Sawdust (Mangifera Indica)Document9 pagesColumn Performance in Lead (Ii) Removal From Aqueous Solutions by Fixed-Bed Column of Mango Wood Sawdust (Mangifera Indica)Miranti PuspitasariNo ratings yet

- Study On Ozone Treatment Technology of Waste Paper Pulping WastewaterDocument6 pagesStudy On Ozone Treatment Technology of Waste Paper Pulping WastewaterMi doremiNo ratings yet

- Mechanisms of Retention and Flux Decline For The Nanofiltration of Dye Baths From The Textile IndustryDocument10 pagesMechanisms of Retention and Flux Decline For The Nanofiltration of Dye Baths From The Textile IndustryOmaya TariqNo ratings yet

- Removal of SNRP From ENi Wastewater-2019-08-22-22-08 PDFDocument3 pagesRemoval of SNRP From ENi Wastewater-2019-08-22-22-08 PDFAnonymous XywQTiNo ratings yet

- Mechanism Study On Flocculating Organnic Pollutants by Chitosan With Different Molecular in WastewaterDocument5 pagesMechanism Study On Flocculating Organnic Pollutants by Chitosan With Different Molecular in WastewaterAJER JOURNALNo ratings yet

- Experimental Comparison Between MBBR and Activated Sludge System For The Treatment of Municipal WastewaterDocument8 pagesExperimental Comparison Between MBBR and Activated Sludge System For The Treatment of Municipal WastewaterAssad MahmoudNo ratings yet

- Removal of Methylene Blue From Waste Water Using Activated Carbon Prepared From Rice HuskDocument5 pagesRemoval of Methylene Blue From Waste Water Using Activated Carbon Prepared From Rice HuskIpsita ChakravartyNo ratings yet

- Feasibility Study On Petrochemical Wastewater Treatment and Reuse Using Submerged MBRDocument6 pagesFeasibility Study On Petrochemical Wastewater Treatment and Reuse Using Submerged MBRhesammorNo ratings yet

- Removal of Methyl Orange From Effluent Water by Silver/Copper Nanoparticles Deposited On Antigonon Leptopus Leaf Powder An AdsorbentDocument7 pagesRemoval of Methyl Orange From Effluent Water by Silver/Copper Nanoparticles Deposited On Antigonon Leptopus Leaf Powder An AdsorbentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Preliminary Study On Low-Density Polystyrene Microplastics Bead Removal From Drinking Water by Coagulation-Flocculation and SedimentationDocument7 pagesPreliminary Study On Low-Density Polystyrene Microplastics Bead Removal From Drinking Water by Coagulation-Flocculation and SedimentationRodrigo MoruzziNo ratings yet

- IMP - Separation of Methylene Blue From Aqueous Solution by Micellar Enhanced UltrafiltrationDocument8 pagesIMP - Separation of Methylene Blue From Aqueous Solution by Micellar Enhanced UltrafiltrationSanat MishraNo ratings yet

- Combination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryDocument8 pagesCombination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustrywaqaskhanNo ratings yet

- MBR +ozonoDocument12 pagesMBR +ozonoAlvaro HueteNo ratings yet

- Determination of Lead in River Water by Flame Atomic Absorption SpectrometryDocument8 pagesDetermination of Lead in River Water by Flame Atomic Absorption SpectrometryputriNo ratings yet

- OzonoDocument8 pagesOzonoDaniella CelisNo ratings yet

- Preparation and Characterization of Cellulose Nanofibers From Cassava PulpDocument7 pagesPreparation and Characterization of Cellulose Nanofibers From Cassava Pulpsuzie annNo ratings yet

- GarlicDocument11 pagesGarlicFarandy ArlianNo ratings yet

- Civil - Dairy Waste - Sheetal S Karale-With-Cover-Page-V2Document7 pagesCivil - Dairy Waste - Sheetal S Karale-With-Cover-Page-V2ShabanaNo ratings yet

- Treatment of Slaughterhouse Plant Wastewater by Using A Membrane BioreactorDocument6 pagesTreatment of Slaughterhouse Plant Wastewater by Using A Membrane BioreactornvtrungvnNo ratings yet

- 2008 Huang&Logan AMBDocument7 pages2008 Huang&Logan AMBJayabrata DasNo ratings yet

- BambooDocument8 pagesBambooCatastroNo ratings yet

- Review Activated Carbonn..Document21 pagesReview Activated Carbonn..Hari priyaNo ratings yet

- Removal of Melanoidins From An Industrial WastewaterDocument6 pagesRemoval of Melanoidins From An Industrial WastewaterIshwar ChandraNo ratings yet

- MetododologiaDocument16 pagesMetododologiaLuis Lozano SNo ratings yet

- Purification of Automobile Wastewater Using Fly Ash-ClayDocument3 pagesPurification of Automobile Wastewater Using Fly Ash-Clayuniversity notesNo ratings yet

- Chao 1999Document10 pagesChao 1999yeshiduNo ratings yet

- Performance Study of Ceramic Micro FiltrationDocument7 pagesPerformance Study of Ceramic Micro FiltrationAntonio SempereNo ratings yet

- Paper 8843Document4 pagesPaper 8843IJARSCT JournalNo ratings yet

- Coupling of Membrane Filtration With Biological Methods For Textile Wastewater TreatmentDocument10 pagesCoupling of Membrane Filtration With Biological Methods For Textile Wastewater Treatmentpnjohn2822No ratings yet

- Anaerobic Treatment of Domestic Wastewater With EGSB ReactorDocument4 pagesAnaerobic Treatment of Domestic Wastewater With EGSB ReactorGurusangmeshHiremathNo ratings yet

- Ozonation of Dyes and Textile Wastewater in A Rotating Packed BedDocument13 pagesOzonation of Dyes and Textile Wastewater in A Rotating Packed BedJorge VecinoNo ratings yet

- 1 PBDocument10 pages1 PBAriz febhianNo ratings yet

- Zinc BagasseDocument6 pagesZinc BagassePRATYUSH TRIPATHYNo ratings yet

- Coagulation Flocculation Process and Slu PDFDocument6 pagesCoagulation Flocculation Process and Slu PDFJaberNo ratings yet

- 2179 4218 1 SMDocument6 pages2179 4218 1 SMclaudiaNo ratings yet

- Dasc 2007Document8 pagesDasc 2007SUMAN SAHANo ratings yet

- Preparation and Characterization of Chitosan-Based DispersionsDocument8 pagesPreparation and Characterization of Chitosan-Based DispersionsCypriano NetoNo ratings yet

- Zhang 2017Document36 pagesZhang 2017Nermeen ElmelegaeNo ratings yet

- Design and Commissioning of The Landfill LeachateDocument7 pagesDesign and Commissioning of The Landfill LeachateShriprakash SpNo ratings yet

- Development and Validation of RP - HPLC Method For The Estimation of Tylosin Tartrate in Pure and Pharmaceutical FormulationDocument8 pagesDevelopment and Validation of RP - HPLC Method For The Estimation of Tylosin Tartrate in Pure and Pharmaceutical FormulationSriram NagarajanNo ratings yet

- Biosorption of Methylene Blue Dye by RicDocument9 pagesBiosorption of Methylene Blue Dye by RicElizabeth BenedictaNo ratings yet

- Nanofiltration of Textile Plant Effluent For Color Removal and Reduction in CODDocument11 pagesNanofiltration of Textile Plant Effluent For Color Removal and Reduction in CODOmaya TariqNo ratings yet

- BATCH ADSORPTION STUDIES ON REMOVAL OF DYES FROM WASTE WATER USING MODIFIED SEASHELLS AS ADSORBENTS Ijariie5776Document7 pagesBATCH ADSORPTION STUDIES ON REMOVAL OF DYES FROM WASTE WATER USING MODIFIED SEASHELLS AS ADSORBENTS Ijariie5776Karthik Kalasipalya Vinod KumarNo ratings yet

- Electrochemical Textile PDocument6 pagesElectrochemical Textile PRohan BachhavNo ratings yet

- Photocatalytic and Electrochemical Combined Treatment of Textile Wash WaterDocument8 pagesPhotocatalytic and Electrochemical Combined Treatment of Textile Wash Waterapi-3828788No ratings yet

- 924 FTPDocument6 pages924 FTPWulan SafrihatiniNo ratings yet

- Carbon Nanomaterials for Advanced Energy Systems: Advances in Materials Synthesis and Device ApplicationsFrom EverandCarbon Nanomaterials for Advanced Energy Systems: Advances in Materials Synthesis and Device ApplicationsWen LuNo ratings yet

- Graphene-Based Antibacterial PaperDocument7 pagesGraphene-Based Antibacterial PaperAnujKumarVermaNo ratings yet

- Acschemneuro 0c00609Document3 pagesAcschemneuro 0c00609AnujKumarVermaNo ratings yet

- Der Pharmacia Lettre 2018Document14 pagesDer Pharmacia Lettre 2018AnujKumarVermaNo ratings yet

- 110820final Combine Brochure With List of ExpertsDocument4 pages110820final Combine Brochure With List of ExpertsAnujKumarVermaNo ratings yet

- B Tech C T - III toVIIIDocument54 pagesB Tech C T - III toVIIIAnujKumarVermaNo ratings yet

- Kandi - 502 285, Sangareddy, Telangana, INDIA: Indian Institute of Technology HyderabadDocument1 pageKandi - 502 285, Sangareddy, Telangana, INDIA: Indian Institute of Technology HyderabadAnujKumarVermaNo ratings yet

- Dental Biomedical Waste Management: Review ArticleDocument3 pagesDental Biomedical Waste Management: Review ArticleAnujKumarVermaNo ratings yet

- PGP July 2020 Batch Fee Structure Wef 11 05Document1 pagePGP July 2020 Batch Fee Structure Wef 11 05AnujKumarVermaNo ratings yet

- A Review On Utilization of Coconut Shell As Coarse Aggregate in ConcreteDocument3 pagesA Review On Utilization of Coconut Shell As Coarse Aggregate in ConcreteAnujKumarVermaNo ratings yet

- Winnefeld-2016-Phase Equilibria in The System - (Published Version)Document7 pagesWinnefeld-2016-Phase Equilibria in The System - (Published Version)AnujKumarVermaNo ratings yet

- Lecture 2. Portland Cement: CIV-E2020 Concrete Technology (5 CR)Document31 pagesLecture 2. Portland Cement: CIV-E2020 Concrete Technology (5 CR)AnujKumarVermaNo ratings yet

- Ordinance and Syllabus: M.Sc. Biomedical ScienceDocument26 pagesOrdinance and Syllabus: M.Sc. Biomedical ScienceAnujKumarVermaNo ratings yet

- NTHU - Spring 2021 - Application Guideline - v2Document104 pagesNTHU - Spring 2021 - Application Guideline - v2AnujKumarVermaNo ratings yet

- Program Schedule For International Conference On Innovations in Clean Energy Technologies, 2020 Energy Centre, Manit Bhopal DAY 1 (27 August 2020)Document3 pagesProgram Schedule For International Conference On Innovations in Clean Energy Technologies, 2020 Energy Centre, Manit Bhopal DAY 1 (27 August 2020)AnujKumarVermaNo ratings yet

- HARCOURT BUTLER TECHNICAL UNIVERSITY (HBTU) Job 6Document2 pagesHARCOURT BUTLER TECHNICAL UNIVERSITY (HBTU) Job 6AnujKumarVermaNo ratings yet

- Problems in The Cement Industry PDFDocument35 pagesProblems in The Cement Industry PDFAnujKumarVermaNo ratings yet

- Havan,: F - E - 2 ST IDocument3 pagesHavan,: F - E - 2 ST IAnujKumarVermaNo ratings yet

- Program Schedule For International Conference On Innovations in Clean Energy Technologies, 2020 Energy Centre, Manit Bhopal DAY 1 (27 August 2020)Document3 pagesProgram Schedule For International Conference On Innovations in Clean Energy Technologies, 2020 Energy Centre, Manit Bhopal DAY 1 (27 August 2020)AnujKumarVermaNo ratings yet

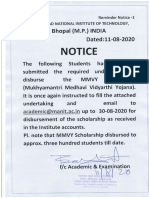

- 100820NOTICE For MMVY ScholarshipDocument4 pages100820NOTICE For MMVY ScholarshipAnujKumarVermaNo ratings yet

- All Physical & Financial Information of Incubation SchemeDocument24 pagesAll Physical & Financial Information of Incubation SchemeAnujKumarVermaNo ratings yet

- White Cane Sugar ProductionDocument16 pagesWhite Cane Sugar ProductionAnujKumarVermaNo ratings yet

- 12 THDocument2 pages12 THAnujKumarVermaNo ratings yet

- General NotesDocument1 pageGeneral NotesMae JungNo ratings yet

- Tutorial 2Document3 pagesTutorial 2Nitin RautNo ratings yet

- ReportDocument6 pagesReportHassan AliNo ratings yet

- Validation of Water Purification SystemDocument9 pagesValidation of Water Purification SystemJohan orlando Castro BeltranNo ratings yet

- Acknowledgement: Shankar Ranjit, As Well As The Other Professors in The Division For Giving Us Such ADocument6 pagesAcknowledgement: Shankar Ranjit, As Well As The Other Professors in The Division For Giving Us Such AKshitiz ShresthaNo ratings yet

- Projects Identification: CDP of Nashik Municipal Corporation Under JNNURMDocument39 pagesProjects Identification: CDP of Nashik Municipal Corporation Under JNNURMPranav. ThubeNo ratings yet

- Day 15 Water Pollution Ielts NguyenhuyenDocument1 pageDay 15 Water Pollution Ielts NguyenhuyenAn QuanNo ratings yet

- RA 9275 Clean Water Act (2004)Document43 pagesRA 9275 Clean Water Act (2004)asombrado_jeraldNo ratings yet

- GuidelinesDocument218 pagesGuidelinesSunny MukherjeeNo ratings yet

- FMDS0140Document36 pagesFMDS0140Carlos AlvarezNo ratings yet

- Bhopal Upper LakeDocument8 pagesBhopal Upper LakeshilpiNo ratings yet

- Week 9,10 Distribution of WaterDocument39 pagesWeek 9,10 Distribution of WaterWarid BangashNo ratings yet

- Water Quality Conservation For The Citarum River in West Java PDFDocument10 pagesWater Quality Conservation For The Citarum River in West Java PDFWildan HakimNo ratings yet

- XcfbrochuDocument6 pagesXcfbrochuuniversal8888No ratings yet

- Storm Water Management Plan: El Dorado CountyDocument393 pagesStorm Water Management Plan: El Dorado CountySean CrossNo ratings yet

- Slaughterhouse Wastewater Treatment ManagementDocument23 pagesSlaughterhouse Wastewater Treatment ManagementOc WilliamNo ratings yet

- One Watershed, One Plan Funding Goals by Region, March 3, 2022Document15 pagesOne Watershed, One Plan Funding Goals by Region, March 3, 2022Michael AchterlingNo ratings yet

- Water CalcDocument58 pagesWater CalcahmedNo ratings yet

- WRE Microproject Roll No 12Document27 pagesWRE Microproject Roll No 12Piyush ShahaneNo ratings yet

- Rainout Shelter For Tall Crop Irrigation Research: Roof Structure, Track, Drive and ControlDocument4 pagesRainout Shelter For Tall Crop Irrigation Research: Roof Structure, Track, Drive and ControlMoqaNo ratings yet

- Ass 6Document10 pagesAss 6jhess QuevadaNo ratings yet

- Isobaric Device Brine/ Seawater Mixing Effect - What Does It Mean To The SWRO Plant Designer and Operator?Document3 pagesIsobaric Device Brine/ Seawater Mixing Effect - What Does It Mean To The SWRO Plant Designer and Operator?Befal desalinasi indonesiaNo ratings yet

- Scribd Fundamentals of Wastewater Treatment and Engineering - Google SearchDocument2 pagesScribd Fundamentals of Wastewater Treatment and Engineering - Google SearchzoksiNo ratings yet

- Water of The SeasDocument82 pagesWater of The SeasBeauNo ratings yet

- Geo RexDocument4 pagesGeo RexRitesh AgarwalNo ratings yet

- Iiecl 200 KLD STPDocument16 pagesIiecl 200 KLD STPDesign100% (1)

- Street SweepDocument2 pagesStreet SweepLokesh SahuNo ratings yet