Professional Documents

Culture Documents

WCE2010 pp2292-2296 PDF

WCE2010 pp2292-2296 PDF

Uploaded by

viktorija bezhovskaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WCE2010 pp2292-2296 PDF

WCE2010 pp2292-2296 PDF

Uploaded by

viktorija bezhovskaCopyright:

Available Formats

Proceedings of the World Congress on Engineering 2010 Vol III

WCE 2010, June 30 - July 2, 2010, London, U.K.

Simulation of a Libyan Cement Factory

Elbahlul M. Alghadafi and Muhammad Latif

Abstract-Due to the inherent complexity of decision making in continual flow of cement from the raw materials source to the

supply chain management (SCM), there is a growing need for final customers [3].

modelling supply chain systems with different methodologies. A

large number of manufacturing organisations in particular the Libya has recently started their economic and structural

cement industry in Libya is seeking techniques that can help,

identify and implement strategies for developing and improving

growth. This growth will need to be increased in order for the

their supply chain network. Developing a supply chain infrastructure to be developed within five years [1]. This

management system requires the analysis of the manufacturing requires extensive and intensive operational and country-wide

processes from the initial sourcing to the end customers. efforts. Libya will face challenges in the future, more so than

they do at present [4].

The paper reports that the Libyan cement industry has problems

related to its productivity. In order to face these problems, 2. Cement Manufacture

cement factories need to increase their production. To Cement plays a key role in our lives; it is a basic material for

accomplish this, they require a clear strategy towards an all types of construction, including housing, roads, schools,

efficient supply chain.

hospitals, dams and ports and may even be used in decorative

The paper discusses the need to investigate SCM strategies that items such as tables and bookcases. In general, cement is a

will enable the cement manufacturing industry of Libya to move mixture of limestone, sand, clay and iron. The most common

towards an increase in cement production and reduce its costs. type of hydraulic cement is Portland cement. The term

Witness simulation software has been used to model the hydraulic cement is used because cement hardens when mixed

manufacturing operations at a specific cement plant in Libya. with water. According to the Portland Cement Association

The various stages of cement production are identified and used [5], Portland cement is a closely controlled chemical

in the model construction. It is believed the model constructed combination of calcium, aluminium, iron and small amounts

through experimentation and optimisation will enable the most of other ingredients to which gypsum is added in the final

productive and cost effective changes to be made to improve

their SCM and performance.

grinding process. Portland cement may be grey or white, but

blends can be generated based on the two products. Cement is

Keywords: Supply Chain Management, Cement, Simulation the major component of concrete. Concrete is an artificial

.Elbahlul M.Alghadafi PhDStudent in Manchester Metropolitan (E- rock, a material made from a proportioned mix of hydraulic

mail:ElbahlulAlghadafi@stu.mmu.ac.uk) cement, water, fine and coarse aggregates, air [6], and

Muhammad Latif Lecture in Manchester Metropolatin University

sometimes additive concrete can also be made from a ready-

(E-mail M.L@MMU.ac.uk)

mix formula in a concrete plant. Concrete is one of the most

1. Introduction important and widely spread building materials in the world.

Libya like many countries in the Middle East has been facing The process of cement supply chain is shown in figure 1 [7].

productivity-related problems in its manufacturing industries. Figure 1 show how the upstream cement supply chain

More specifically, in the coming years, Libyan cement operates, including sourcing of raw material, manufacturing

factories have realised the need to increase their production to and delivery from the plant.

achieve the construction demand of the country [1]. One

methodology being considered is to review Supply Chain There are two main steps in cement production. The first step

Management (SCM) of the cement industry. is the production of clinker from raw materials. The second

step is the production of cement from clinker. The first step

requires raw materials to be transported to the plant and to be

Supply Chain Management refers to a managerial process, crushed and homogenized using a large rotating drum called a

concerned with the process of planning, organizing, and kiln. The kiln is heated to very high temperatures, and then it

controlling the flow of materials and services from suppliers is inclined, allowing the raw materials to roll to other end,

to the end users/customers [2]. This integrated approach where they are quickly cooled. The result is a solid grain

incorporates suppliers, customers and logistics. SCM is often called clinker. The second step is the transformation of clinker

used to balance customer’s demands with the need for into cement in the grinding mill. Additional elements like

profitable growth; many companies worldwide have moved gypsum, and perhaps other minerals, might be aggregated to

aggressively to improve SCM. Management of the cement obtain a fine powder called cement. Finally, cement is moved

supply chains will enable manufacturing operations and into storage until a customer places an order.

integrated logistics into seamless pipelines to maintain the

ISBN: 978-988-18210-8-9 WCE 2010

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2010 Vol III

WCE 2010, June 30 - July 2, 2010, London, U.K.

QUARRIES that will contribute to competitiveness and growth of the

country.

The international cement production industry is considered to

RAW MATERIAL STORAGE be a highly competitive industry. It is important to Libya

CRUSHER

because of its strong contribution to GDP. Libya has paid

strong attention to this industry as all the raw materials

RAW MATERIAL GRINDING

required to produce the cement are internally available. The

importance of cement to the construction sector as well as

infrastructure development is paramount because it is

extensively used in most major civil engineering projects. The

government should be planning a new strategy to reach

requirement national market. This makes the cement industry

PREHEATER TOWER

BUILDING AND STORAGE an extremely important manufacturing entity requiring further

TERTIARY AIR DUCT

CHIMNLY

development and better organisation. Because of its

importance, the cement industry in Libya has been targeted as

P R E C A L C IN E R

ROTARY KILN

a high priority for upgrade with advanced manufacturing

technologies. It must be managed effectively, requiring

FEED AIR application of recent advances in manufacturing technologies

and managerial techniques. The country is committed to

FUEL

developing its manufacturing ability to produce cement

effectively, to meet the needs of the present markets and aims

GRATE COOLER to achieve World Class Manufacturing (WCM) status.

DUST REMOVAL

1 2 3 4 5

4. Research Objectives

The problem is that cement production in Libya is operating

GYPSUM at substantially below full capability. Modern manufacturing

CEMENT STORAGE SILOS

methodologies, such as Just in Time (JIT), Manufacturing

Resource Planning (MRPII) and Total Quality Management

(TQM) are known to have solved some capacity problems

within other manufacturing industries of Libya [4]. However

due to inherent localised operational issues such

CLINKER STORAGE

methodologies are likely to face severe implementation

CEMENT GRINDING MILL problems. To assess the management commitments on

implementing the most effective managerial and philosophies

techniques are JIT, MRPII and TQM [10]. Implementation of

these techniques could play a big role in increasing the

cement production and reducing the cost [4]. Libya is

committed to satisfy the customer needs, and this satisfaction

cannot be achieved without using computing models as

success has been achieved using these techniques in the

cement industry of Romania [11]. Solving the problem by

Figure 1: Upstream Cement Supply Chain [7] using computer based simulation would minimise the risks

associated with any operation changes and could play a big

role in leading to an increase in production and reduction in

3. Current Status of the Libyan Cement Industry cost [12].

Libya is a developing country located on the coast of the

Mediterranean Sea. It is mainly a petroleum producing The overall aim of the research is to investigate SCM

country with a cement industry, required to develop the strategies that will enable the cement manufacturing industry

country’s infrastructure. However, it is recognised that the of Libya move towards (WCM). However, this paper focuses

cement industry is unable to meet the construction demands on exploring cement manufacture in Libya and the

of Libya and international markets [8] According to World development of a simulation model using Witness software.

Report International [9] some industrial companies and plants

within Libya are operating below their potential, achieving 5. Simulation of Cement Manufacture

only 50% of their full production capacity. The current status, Modelling and computer simulation are accepted problem

taking into consideration all the facts, suggests opportunities solving methodologies for the solution of many real-world

exist to improve the manufacturing sectors in Libya [4]. The problems [13]. One of the largest application areas for

Libyan cement industry primarily needs to meet the internal simulation modelling is that of manufacturing systems.

demand. The International Advisory Board [9] concludes that Computer simulation refers to methods for studying a wide

there is no overarching strategic plan in Libya; it points out variety of models of real-world systems by numerical

the need for better management of industrial organisations evaluation using software designed to imitate the system’s

ISBN: 978-988-18210-8-9 WCE 2010

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2010 Vol III

WCE 2010, June 30 - July 2, 2010, London, U.K.

operations or characteristics, often over time [14]. SCM is 6. Stages of Cement Manufacture

used by every successful organization, thus, a production

planning and control model that focuses on all the aspects of The production of cement involves a number of processes and

the operations is needed. The supply chain management stages as shown in figure 2, these are introduced next.

model should also perform the task of managing and

coordinating activities upstream and downstream in the

supply chain. Of course, such a model in its entirety becomes

very complex and can not be used without a sufficient

computational infrastructure.

Simulation is a concept that involves building a model, which

mimics reality. Visual interactive simulation software creates

a dynamic, computer-based model representing a physical

system. Several processes may take place and includes

simulation structure, resources and activities. Simulation

involves the modelling of a system as it progresses through

time. It gives the ability to model random events based on

standard or non-standard distributions and to predict the

complex interactions between those events. The process of

designing a Mathematical-logical model of a real system and

experimenting with that model using a computer is the basis

of computer simulation [15].

Simulation is used to describe and analyze the behaviour of a

system, ask what if questions about the real system, and aid in

the design of real system both existing and conceptual

systems can be modelled with simulation. Also simulations

are helpful for managers to understand their working

environment for solving the complexity of system,

documentation and to produce quick reports [16].

In the first instance it was decided to use Discrete Event

Simulation (DES) and then migrate to a combination of

discrete and continuous simulation. DES is a process through

which a model mimics the behaviour of a discrete system

event by event. Qualitative and quantitative data from the

process are obtained to predict the behaviour of the system

and its level of performance. Simulation has two basic

motives, quick response to determine the correctness of

system behaviour and performance prediction. Some

performance measures of interest are throughput, resource Figure 2: Stages in Cement Production

utilization, buffer capacity, yield, and effects of failures. The

software model can capture all the dynamics and interactions Stage1: Quarry

of real system. Since real manufacturing systems are Typically limestone, and clays as well as other materials

expensive to build. Simulation is an important means to containing the required proportions of calcium, silicon,

predict performance accurately, investigate effects of aluminium and iron oxides are extracted using drilling and

parameter changes, identify bottlenecks and choose the best blasting techniques. In this stage transportation of raw

design among alternative [17]. A model contains entities, materials from the quarry using trucks and loading/unloading

attributes, events, activities and the interrelationships among facilities specific to the cement plant are also considered

them. The collection of entities and their statuses define the Stage 2: Crusher (Grinding)

system state [15]. A system state may change only at discrete The quarried material is then reduced in size by compression

points in time. and/or impact in various mechanical crushers, Crushed rock is

reduced in size from 120 cm to between 1.2 and 8 cm drying

Cement manufacture is inherently complex to model and of raw material may also be necessary for efficient crushing

simulate. In this respect, company X (a Libyan cement and blending.

factory) agreed to participate in the research project and Stage 3: Conveyor

provide the necessary operational information for the Transportation of the crushed material throughout the plant is

construction of a simulation model using Witness software. achieved using some form of powered conveyor.

ISBN: 978-988-18210-8-9 WCE 2010

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2010 Vol III

WCE 2010, June 30 - July 2, 2010, London, U.K.

Stage 4: Mixing bed

The crushed limestone and clay is homogenized by stacking

and reclaiming in a long layered stockpile. The material is

then ready for milling and drying in the kiln.

Stage 5: Raw mill

The raw materials are milled and dried in a roller mill. Heavy

rollers are held over a rotating table and the course material is

milled until it is fine enough to be carried by air to a

homogenizing silo.

Stage 6: Filter

Bag filters comprise filters of either woven fabric or needle

felts to remove particles from kiln exhaust. The exhaust gas

from many kilns is used for drying raw materials, thus Figure 3: Model Stage 1

improving the energy efficiency of the plant.

Stage 7: Preheating

Model Stage 2

Cyclone pre-heaters enable the raw material of cement

production to be preheated before entry in to the kiln. This

increases the energy efficiency of the kiln as the material is

20-40% calcined at the point of entry into the kiln.

Stage 8: Kiln

The kiln is designed to maximize the efficiency of heat

transfer from fuel burning to the raw material. In the

preheated tower, the raw materials are heated rapidly to a

temperature of about 1000oc, where the limestone forms burnt

lime. In the rotating kiln, the temperature reaches up to

2000oc. At this high temperature, minerals fuse together to

form predominantly calcium silicate crystals-cement clinker.

Stage 9: Cooler

The molten cement clinker is then cooled as rapidly as

possible. The ambient air used to cool the clinker is then fed

into the kiln as combustion air-ensuring high utilization of the Figure 4: Model Stage 2

heat produced.

Stage 10: Clinker silo Figure 4 illustrates the grinding process. The grinding process

The clinker may be either stored on site in preparation for in cement industries is performed by addition of liquid. So

grinding to form cement or transported to other sites. after preparing the raw material it is necessary to store the raw

Stage 11: Cement mill material for further processes in preparation for the next stage.

Finish milling (cement) is the grinding together of cement

clinker, with around 5% of natural or synthetic gypsum. Model Stage 3-11

Stage 12: Logistics These stages were implemented as appropriate using the

Final cement is stored or transported. necessary Witness modelling elements. Details of these stages

are not given here but will form the basis of another

7. Model Building using Witness publication.

To model the manufacture of cement in company X it

appeared logical to use the stages already described in the Model Stage 12

earlier section. Figure 5 illustrates the final stage. The final stage is filtration

Each processing stage was mapped directly into the discrete and packaging. After filtration, another machine dries the

elements available within Witness. The basic elements product and the packaging process starts. Finally cement may

enabled entities (quarry materials) to the flow through the be transported pre-bagged or as a bulk powder. The method of

manufacturing processes using activities, buffers, resources, transportation varies according to location – and may include

transporting elements etc. transport via truck, rail or ship.

Model Stage 1 8. Simulation Run

The first stage of the model is demonstrating the initial steps

of the cement manufacturing processes. Raw material(s) from The length of the simulation was 14 hours (840 mins) as this

the Quarry is transported by vehicles (trucks) that move on a reflected the observational data that was available. In addition

track that follow a truck route to the separator machine (figure the time period was chosen in order to detect any variance in

3). The separator machine separates the heavy and light the time scale with relation to the system. For example the

weight raw materials into two different process lines for the separator period may be apparent or the lead- time may have

crushing (grinding) operation. After grinding the raw material notable peaks.

a conveyer transfers the raw material to a pre-blending plant.

ISBN: 978-988-18210-8-9 WCE 2010

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering 2010 Vol III

WCE 2010, June 30 - July 2, 2010, London, U.K.

disturbing the ongoing production process. Variant

disturbances of duration affect the production schedules can

be configured with the use of simulation. A change in the

production can be investigated for plausibility before being

implemented. Production times can be recorded from the

simulation software and a comparison made to other

operations. Alternative statistics may be produced from the

system at any given stage in a production run, for example

increase the capacity feed bin, increase supply of raw

materials. The second major objective is to validate and

verify the simulation model by using pilot data obtained from

company X. The simulation model constructed so far has

huge potential as a test bed to perform experimentation. It is

planned to verify and validate the current simulation model

until strong confidence in its results is obtained.

References

[1] R.A.Hokoma, (2007)” the status of manufacturing and quality control

Figure 5: Model Stage 12 techniques and philosophies within the Libyan manufacturing

industries”, PhD thesis. University of Bradford, Bradford, UK

The simulation model was executed and the resulting [2] D.peidro, J.Mula. et. al. (2009),” Quantitative models for supply chain

planning under uncertainty”: a review, Int. Jou. Adv. Manufacturing

animation observed to verify its correctness. Technology 43(5), pp 400-420.

The model verification process at this stage is incomplete but [3] V.R Kannn. And K.C Tan. (2005), “Just in time, total quality

is being performed to ensure that the constructed computer management, and supply chain management: understanding their

simulation models the system properly. After numerous linkages and impact on business performance”. The Int. Journal of

Management Science, , pp153-162.

iterations and careful examination of the logic structure,

[4] R.A. Hokoma, M.K Khan. And K. Hussain (2008), “Investigation into

inputs, and outputs were correctly represented in the computer the implementation stages of manufacturing and quality techniques and

model, verification is still ongoing. Simple cases and common philosophies within the Libyan cement industry”, Journal of

sense will form the basis of the verification process. Manufacturing Technology Management, 19(7), pp 893-907.

[5] Anon, “Industry Overview (2008), Portland Cement Association”,

It is planned that Witness animation and associated techniques

http://www.cement.org/basics/cementindustry.asp

will facilitate the validation process; this ensures that the [6] Oss.Van H.G. (2009), “Background Facts and issues Concerning

model is an accurate representation of real system. Once this Cement and Cement Data, Clean technologies and Environmental

is achieved the model developed has the potential to be used policy” 10(3) ISBN-1618954x.

[7] Anon, (2008), “Upstream Cement Supply Chain. Cemex”,

as substitute for the actual system for experimentation and the

http:/rugby.cemex.co.uk/images/howcementismade

predication of performance with a high level of confidence. [8] Anon, “World Report International Ltd (2008). Demand of cement

From the simulation runs, it became obvious some construction in Libya”. Interview with Dr. Hassen Hammed Bokzam,

inconsistencies existed as bottlenecks exist in various stages Secretary of the Libyan cement company.

[9] Anon, International Advisory Board (2006). Journal of North African

of the model. Therefore it is inappropriate to discuss results

studies, 12(2) pp 203-218.

obtained so far. [10] N.Selvaraj (2009),” Performance evaluation of single pull production

control systems”, Int. Jou of Engineering Studies 1(1) pp 47-58

9. Conclusion [11] S., Arad, V.Arad. And B.Bobora. (2006), “Cement production at Deva

cement factory from Romania”, International Symposium on

SCM often spans a large number of inter business

Automation and Robotics in Construction ISARC2006, 3-5 October,

departments and across several businesses to deliver the 2006, Tokyo (Japan).

product that the customer requires. In this research more [12] J.A.B.Montevechi, F.Leal. et. al (2008),” Combined use of modelling

emphasis is given to the design of supply chain management techniques for the development of the conceptual model in simulation

projects”, Proceedings of the 2008 Winter Simulation Conference, pp

by simulation processing industry (Libyan cement industry).

987-995.

It addresses the importance to implement computer simulation [13] P.Lendermann,N.Julka., et. al. (2003), “Distributed supply chain

through a system example. Simulation would support and simulation as a decision support tool for the semiconductor industry,

develop the present SCM of the cement factory X. Simulation” 79(3), pp 126-138.

[14] J.C.Carnahan, P.F Reynolds. And D.C, Brogan (2005), “Simulation-

Simulations can be created modelling each separate part of

Specific characteristics and software reuse, Proceedings” of 2005

cement supply chain. To begin building the model, there was Winter Simulation Conference, pp 2492-2499.

a need to divide the cement manufacture processes into [15] I.;Manuj J.T. Mentzer andM.R Bowers. (2009), “Improving the rigor of

stages; each stage would be directly mapped into the discrete-event simulation in logistics and supply chain research”, Int.

Jou. Of Physical Distribution & Logistics Management, 39(3), pp 172-

simulation model. The idea of the model was to create a

201.

working map of any stage considered. Stages were used in [16] Anon, (2007), “Dynamic simulation and supply-chain management”,

Witness as they provided a timed event when the entity The GoldSim Technology Group, http://www.goldsim.com

flowed through the processes modelled. The time between [17] M.C Zhou and K, Venkatesh (2001) “Modeling, Simulation, and

Control of Flexible Manufacturing Systems”, Mechatronics, pp 947-

manufacturing stages can be reduced. A manufacturing

950.

system can be changed, analysed and reported without

ISBN: 978-988-18210-8-9 WCE 2010

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

You might also like

- Project Report On R M CDocument41 pagesProject Report On R M Csunny84% (77)

- Ultratech RMCDocument59 pagesUltratech RMCChanchal Vishnoi100% (2)

- Greenbook Research Industry Trends Report 2020Document126 pagesGreenbook Research Industry Trends Report 2020Paul KendallNo ratings yet

- Quality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas LikeDocument15 pagesQuality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas Likeee iabNo ratings yet

- Executive SummaryDocument14 pagesExecutive Summaryfaraz khanNo ratings yet

- Solar Water Heater Distributor Business PlanDocument32 pagesSolar Water Heater Distributor Business Planlutos267% (3)

- Simulation of A Libyan Cement Factory: Elbahlul M. Alghadafi and Muhammad LatifDocument5 pagesSimulation of A Libyan Cement Factory: Elbahlul M. Alghadafi and Muhammad LatifMohammed AbdoNo ratings yet

- Cement Production Output and Prices Trends in Mozambique: Daniel BaloiDocument6 pagesCement Production Output and Prices Trends in Mozambique: Daniel BaloiMustafa YılmazNo ratings yet

- 1.1 Brief Introduction To Concrete Construction IndustryDocument12 pages1.1 Brief Introduction To Concrete Construction IndustryGauresh GawasNo ratings yet

- RMC ProductivityDocument10 pagesRMC Productivityeyob yohannesNo ratings yet

- TharanyaDocument41 pagesTharanya9922015020No ratings yet

- RMC RMC 2-MergedDocument36 pagesRMC RMC 2-MergedBharthi 2GO20CV004No ratings yet

- Eyu Internship ReportDocument12 pagesEyu Internship ReportAbel Lema100% (2)

- Cement Industry AmbujaDocument21 pagesCement Industry Ambujaakhil janjirala100% (1)

- Ready-Mixed Concrete Growth Prospects in IndiaDocument9 pagesReady-Mixed Concrete Growth Prospects in IndiaVinoop OkvNo ratings yet

- Small-Scale Production of Cementitious Materials 1980Document56 pagesSmall-Scale Production of Cementitious Materials 1980papedi1576No ratings yet

- Quality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas LikeDocument11 pagesQuality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas Likeee iabNo ratings yet

- Setting Up A Ready-Mix Concrete Manufacturing Plant-875187 PDFDocument73 pagesSetting Up A Ready-Mix Concrete Manufacturing Plant-875187 PDFGaneshNo ratings yet

- Ready Mix ConcreteDocument5 pagesReady Mix ConcreteSanu GhoshNo ratings yet

- An Approach For Ready Mixed Concrete Selection For Construction Companies Through Analytic Hierarchy ProcessDocument8 pagesAn Approach For Ready Mixed Concrete Selection For Construction Companies Through Analytic Hierarchy ProcessJerry AbebeNo ratings yet

- Use of Ggbs As Mineral Admixture in ConcDocument7 pagesUse of Ggbs As Mineral Admixture in ConcSumanNo ratings yet

- Sustainability 13 00214 v2Document13 pagesSustainability 13 00214 v2neetika tiwariNo ratings yet

- Cement Concrete Hollow BlocksDocument10 pagesCement Concrete Hollow Blocksjohn koraNo ratings yet

- Industry Analysis of CementDocument19 pagesIndustry Analysis of CementKajal SharmaNo ratings yet

- Research Paper Ready Mix Concrete: An Industry Perspective On Challenges & Opportunities For Growth Shailendra ChoukseyDocument3 pagesResearch Paper Ready Mix Concrete: An Industry Perspective On Challenges & Opportunities For Growth Shailendra ChoukseyAlex WilsonNo ratings yet

- Influence of Supplementary Cementitious Materials On The Sustainability Parameters of Cements and Concretes in The Indian ContextDocument11 pagesInfluence of Supplementary Cementitious Materials On The Sustainability Parameters of Cements and Concretes in The Indian ContextVikas SharmaNo ratings yet

- Cement and Concrete ResearchDocument10 pagesCement and Concrete ResearchCarol BelFonsNo ratings yet

- 16) Klemm A.J. Et Al 2019 Supplementary Cementitous Materials and Their Impact On Sustainable ConstructionDocument11 pages16) Klemm A.J. Et Al 2019 Supplementary Cementitous Materials and Their Impact On Sustainable ConstructionSOMNo ratings yet

- E Classes For Designing Concrete: Xposure DurableDocument20 pagesE Classes For Designing Concrete: Xposure Durablevignesh kumarNo ratings yet

- (PAPER) V.R. Kulkarni (2009) Exposure Classes For Designing Durable ConcreteDocument17 pages(PAPER) V.R. Kulkarni (2009) Exposure Classes For Designing Durable ConcreteO SNo ratings yet

- Cement Industry of BangladeshDocument22 pagesCement Industry of BangladeshAfrin Tonni33% (3)

- Exposure Classes For Designing Durable ConcreteDocument17 pagesExposure Classes For Designing Durable ConcreteJevgenijsKolupajevsNo ratings yet

- Some Trends in The Use of Concrete: Indian ScenarioDocument6 pagesSome Trends in The Use of Concrete: Indian ScenarioHarry SidhuNo ratings yet

- Jainish Shah Chapter 2Document13 pagesJainish Shah Chapter 2Shubham SinghNo ratings yet

- Mivan 9Document40 pagesMivan 9vishaliNo ratings yet

- Literature Review On Cement ProductionDocument4 pagesLiterature Review On Cement Productionafmzrsqklrhbvb100% (1)

- Cement Industry: Factor EndowmentsDocument1 pageCement Industry: Factor Endowmentsgokul9rovNo ratings yet

- 1 s2.0 S000888461930362X MainDocument18 pages1 s2.0 S000888461930362X Mainbetroune asmaNo ratings yet

- Eia Report of A CEMENT INDUSTRYDocument19 pagesEia Report of A CEMENT INDUSTRYabdullah al mahinNo ratings yet

- Cement Industry in India by SaurabhDocument36 pagesCement Industry in India by SaurabhMadanKarkiNo ratings yet

- Fauji Cement Company Limited UPDocument15 pagesFauji Cement Company Limited UPfarrukhhameed646No ratings yet

- Point of ViewDocument5 pagesPoint of ViewdownloadsanthoshNo ratings yet

- Performance of Indian Cement Industry THDocument41 pagesPerformance of Indian Cement Industry THSrinath RaoNo ratings yet

- Achieving Net Zero Greenhouse Gas Emissions in The Cement Industry Via Value Chain Mitigation StrategiesDocument14 pagesAchieving Net Zero Greenhouse Gas Emissions in The Cement Industry Via Value Chain Mitigation Strategieszhor El hallaouiNo ratings yet

- Report On Suppy Chain in Cement Industry1Document13 pagesReport On Suppy Chain in Cement Industry1SmritiNo ratings yet

- Some Trends in The Use of Concrete Indian ScenarioDocument7 pagesSome Trends in The Use of Concrete Indian ScenarioSmit KotakNo ratings yet

- Seminar On Mivan TechnologyDocument33 pagesSeminar On Mivan TechnologyRajNo ratings yet

- An Evaluation of Ready-Mixed Concrete Plants Operating at Khartoum State, SudanDocument19 pagesAn Evaluation of Ready-Mixed Concrete Plants Operating at Khartoum State, SudanJerry AbebeNo ratings yet

- SPPP'S, Karmayogi Engineering College, Pandharpur: & Organize Special IssueDocument8 pagesSPPP'S, Karmayogi Engineering College, Pandharpur: & Organize Special IssueAnonymous Ygz2shJhJaNo ratings yet

- ConcreteDocument1 pageConcreteMahendra Kumar MalviyaNo ratings yet

- Optimization of Ready Mix Concrete (RMC)Document6 pagesOptimization of Ready Mix Concrete (RMC)JuanCarlosCarrilloNo ratings yet

- Ready Mix ConcreteDocument8 pagesReady Mix ConcreteOm ChakorNo ratings yet

- Ready Mix ConcreteDocument8 pagesReady Mix Concreteshivang vivekNo ratings yet

- Proposal RMCDocument8 pagesProposal RMCghabtNo ratings yet

- Assignment 1 Cive523Document10 pagesAssignment 1 Cive523Lawrence MagagaNo ratings yet

- Rilem Review PDFDocument9 pagesRilem Review PDFMohd AtaNo ratings yet

- Marble Powder in HmaDocument15 pagesMarble Powder in HmaRoshan GuptaNo ratings yet

- 1 s2.0 S0950061820315944 MainDocument12 pages1 s2.0 S0950061820315944 MainReaditReaditNo ratings yet

- Mini CementDocument15 pagesMini CementAitzaz Saeed0% (1)

- Ready Mix ConcreteDocument57 pagesReady Mix Concreteeyob yohannesNo ratings yet

- Sustainability in Structural Concrete DesignFrom EverandSustainability in Structural Concrete DesignJorge de BritoNo ratings yet

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

- 13IsotLangyFreund 14229Document7 pages13IsotLangyFreund 14229viktorija bezhovskaNo ratings yet

- BiosorptioninHRAS AR BEJDocument14 pagesBiosorptioninHRAS AR BEJviktorija bezhovskaNo ratings yet

- 166-Gregor KravanjaDocument1 page166-Gregor Kravanjaviktorija bezhovskaNo ratings yet

- PDFDocument17 pagesPDFviktorija bezhovskaNo ratings yet

- Zhang IEEE Transactions Industrial Electronics 2017bDocument9 pagesZhang IEEE Transactions Industrial Electronics 2017bviktorija bezhovskaNo ratings yet

- Walakira Paul PDFDocument68 pagesWalakira Paul PDFviktorija bezhovskaNo ratings yet

- Etd1866 PDFDocument88 pagesEtd1866 PDFviktorija bezhovskaNo ratings yet

- 10 11648 J Ajac 20180601 14Document10 pages10 11648 J Ajac 20180601 14viktorija bezhovskaNo ratings yet

- Strategies For Managing Plastic Waste From Construction and Manufacturing ProjectsDocument9 pagesStrategies For Managing Plastic Waste From Construction and Manufacturing Projectsviktorija bezhovskaNo ratings yet

- Tantalum Based Materials For Implants and Prostheses ApplicationsDocument8 pagesTantalum Based Materials For Implants and Prostheses Applicationsviktorija bezhovskaNo ratings yet

- Design and Construction of A Vegetable Drier: Aminusaleh MohammedDocument7 pagesDesign and Construction of A Vegetable Drier: Aminusaleh Mohammedviktorija bezhovskaNo ratings yet

- Unclanssif"L: Nujla S SDocument314 pagesUnclanssif"L: Nujla S Sviktorija bezhovskaNo ratings yet

- Real-Time Modelling of Dynamic Behaviour For Clinker Rotary Kilns: Learning FromDocument17 pagesReal-Time Modelling of Dynamic Behaviour For Clinker Rotary Kilns: Learning Fromviktorija bezhovskaNo ratings yet

- Synthesis, Pp. 215 218Document3 pagesSynthesis, Pp. 215 218viktorija bezhovskaNo ratings yet

- DissertationDocument105 pagesDissertationviktorija bezhovskaNo ratings yet

- p1835 PDFDocument12 pagesp1835 PDFviktorija bezhovskaNo ratings yet

- RunEco EP600 Datasheet 2018Document2 pagesRunEco EP600 Datasheet 2018widnu wirasetiaNo ratings yet

- Solved Examples: Axes-Zz and - YyDocument8 pagesSolved Examples: Axes-Zz and - YyDeepak SahNo ratings yet

- Basic Law 01Document33 pagesBasic Law 01MitchNo ratings yet

- Introduction To Industrial Relations and Performance ManagementDocument5 pagesIntroduction To Industrial Relations and Performance ManagementAchalKumarGargNo ratings yet

- Lesson A Worksheets. Print or Copy in Your Notebook-1Document3 pagesLesson A Worksheets. Print or Copy in Your Notebook-1Martha Lucia Arcila HenaoNo ratings yet

- DLL - Co.q2 Science IVDocument16 pagesDLL - Co.q2 Science IVAllyn MadeloNo ratings yet

- International Documentary Festival of Ierapetra Awards - 2016 ProgrammeDocument26 pagesInternational Documentary Festival of Ierapetra Awards - 2016 ProgrammeZois PagNo ratings yet

- The Wexford Carol (Arr Victor C Johnson)Document13 pagesThe Wexford Carol (Arr Victor C Johnson)Macdara de BurcaNo ratings yet

- 11th Bio NotesDocument167 pages11th Bio NotesKomalNo ratings yet

- Economic and Political WeeklyDocument8 pagesEconomic and Political WeeklynaveensarimallaNo ratings yet

- Esoteric Christianity 06 Being Born AgainDocument15 pagesEsoteric Christianity 06 Being Born AgainTortura ChinaNo ratings yet

- Review Questions IODocument9 pagesReview Questions IOMarionne DagolsapoNo ratings yet

- Routing CodesDocument4 pagesRouting CodesScribdTranslationsNo ratings yet

- Studies in The Psychology of Sex, Volume 3 Analysis of The Sexual Impulse Love and Pain The Sexual Impulse in Women by Ellis, Havelock, 1859-1939Document242 pagesStudies in The Psychology of Sex, Volume 3 Analysis of The Sexual Impulse Love and Pain The Sexual Impulse in Women by Ellis, Havelock, 1859-1939Gutenberg.org100% (3)

- Ax88796B With Ali M3602 Mcu Reference Schematic IndexDocument4 pagesAx88796B With Ali M3602 Mcu Reference Schematic IndexdistefanoNo ratings yet

- CAN LIN ProtocolDocument60 pagesCAN LIN ProtocolBrady BriffaNo ratings yet

- (LN) Gamers! - Volume 03Document246 pages(LN) Gamers! - Volume 03DEATHSTROKENo ratings yet

- Broadwater Farm Estate - The Active CommunityDocument5 pagesBroadwater Farm Estate - The Active CommunitycvaggasNo ratings yet

- ReadrDocument34 pagesReadrSceptic GrannyNo ratings yet

- Resource AllocationDocument10 pagesResource AllocationZoe NyadziNo ratings yet

- Land Titles and DeedsDocument1 pageLand Titles and DeedsIanLightPajaroNo ratings yet

- Assignment2 1Document16 pagesAssignment2 1api-335877104No ratings yet

- Notice 1658958950Document64 pagesNotice 1658958950Subrat NaikNo ratings yet

- Form 2: Xds Consumer Relations Dispute / Query FormDocument2 pagesForm 2: Xds Consumer Relations Dispute / Query FormForster BossfilaNo ratings yet

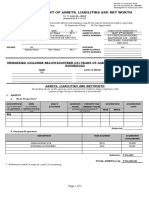

- Sworn Statement of Assets, Liabilities and Net WorthDocument2 pagesSworn Statement of Assets, Liabilities and Net WorthKal El DadiNo ratings yet

- Module 4Document5 pagesModule 4Engelbert RespuestoNo ratings yet

- Marketing Approach To Promoting Banking ServicesDocument8 pagesMarketing Approach To Promoting Banking Servicessubbaiah aNo ratings yet

- Combichem: Centrifugal PumpsDocument8 pagesCombichem: Centrifugal PumpsrizkyNo ratings yet