Professional Documents

Culture Documents

Cyclonic Furnace Sizing Example

Cyclonic Furnace Sizing Example

Uploaded by

Rufus D SOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cyclonic Furnace Sizing Example

Cyclonic Furnace Sizing Example

Uploaded by

Rufus D SCopyright:

Available Formats

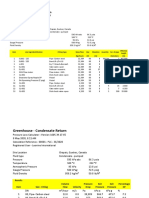

Cyclonic Furnace Design Program - CFD version 8.3.8.

094

Calculation done 17-March-2008

For Leonine International

Result file is

Run number - 1/3

Customer – Input name

Client Unknown

Calculation ID - 00009 - CFD - Mar/2008

Job number - Canada

Enquiry number - Leonine International

Files used

Data file - CWD20-25-350-Howick.cf6

Site file - City, South Africa

Calculation by Gary

Registration status - Legal copy.

This program run 1/3

This calculation

______________________________________________________________________

Furnace data - CCS 800

______________________________________________________________________

Furnace model = CCS 800

Internal diameter = 3900 [mm]

Internal length = 5750 [mm]

Brick length = 230 [mm]

Exit diameter = 1700 [mm]

Number of layers = 6

Emissivity = .9 []

Fuel air nozzle inlet velocity = 30 [m/s]

Secondary air nozzle inlet velocity = 30 [m/s]

Refractory/Layer type = Superduty fire brick

Thickness = 115 [mm]

Refractory/Layer type = Insulating brick

Thickness = 115 [mm]

Refractory/Layer type = Insulating brick

Thickness = 115 [mm]

Refractory/Layer type = Insulating brick

Thickness = 115 [mm]

Refractory/Layer type = CalSi board

Thickness = 50 [mm]

Refractory/Layer type = Steel

Thickness = 15 [mm]

______________________________________________________________________

Cyclonic furnace results

______________________________________________________________________

Heat duty (output) of the furnace is 20584.9 kW

Boiler output 15211.2 kWth

Recommended heat release maximum is 445.0 kW/m³

Heat released in the furnace (Gross) 340.7 kW/m³

Heat duty (Gross) 84.25 GJ/hour

Heat duty (Net) 74.11 GJ/hour

Recommended net heat release maximum is 1.60 GJ/hour/m³

Heat release (Gross) 1.23 GJ/hour/m³

Heat release (Net) 1.08 GJ/hour/m³

Fuel Net Calorific Value 12.051 MJ/kg

NREL Modified CV (see note below) 1.484 MJ/kg products

Effective gas residence time 0.98 seconds

Furnace heat loss 0.30 % based on gross

Furnace external surface temperature 66.3 °C

Refractory surface temperature 1099.8 °C

Furnace gas exit temperature is 1098.6 °C

Estimated combustion air preheat temperature 110.0 °C (min)

Preheat air to evaporate all fuel moisture 22.0 °C (max)

Actual combustion air temperature used 110.0 °C

Hot gas mass flow from furnace 56769.8 kg/hour

Hot gas mass flow from furnace 15.77 kg/s

Hot gas volume no cooling 69.761 m³/s

Normal gas volume 12.285 Nm³/s

Furnace gas constant 289.309 kJ/kg K

Furnace pressure 89.61 kPa g

Density of furnace gas 0.226 kg/m³

Normal density 1.3 kg/Nm³

Fan and ducting requirements 100.0 % excess air...

The furnace exit temperature is NOT controlled.

Cyclonic furnace - induced draft fan

ID fan mass flow 56769.75 kg/hour

ID fan mass flow 15.77 kg/s

ID fan volume flow 22.26 m³/s

ID fan normal flow 12.30 Nm³/s

Static pressure of IDF 2500.0 Pa

Typical operating pressure of IDF 1700.0 Pa

Efficiency of IDF at duty point 50.0 %

Temperature of hot gas 164.5 °C

Pressure of hot gas 89.7 kPa g

Specific volume of ID gas 1.411 m³/kg

Density of ID gas 0.709 kg/m³

Normal density 1.282 kg/Nm³

Gas constant 289.309 kJ/kg K

Estimated power absorbed 111.28 kW

Total combustion air required 13.57 m³/s

Cyclonic furnace - fuel air fan

Mass flow of air 12682.4 kg/hour

Mass flow of air 3.52 kg/s

Total air for fuel - FAF at 22 °C 3.39 m³/s

Volume flow per fan 0.85 m³/s

Normal fuel air fan flow 0.70 Nm³/s

Static pressure of FAF 1120.0 Pa

Typical operating pressure of FAF 560.0 Pa

Efficiency of FAF at duty point 50.0 %

Estimated power absorbed 7.60 kW

FAF air temperature 22.0 °C

Atmospheric pressure 89.7 kPa

Density 1.038 kg/m³

Normal density 1.267 kg/Nm³

Size of fuel nozzles - DN 200

Number of fuel inlets 4

Velocity in fuel duct 24.8 m/s

Cyclonic furnace - combustion air fan

Combustion air mass flow 38047.3 kg/hour

Combustion air mass flow 10.57 kg/s

Combustion air (secondary and tertiary) 10.18 m³/s

Combustion air fan at 22 °C 13.57 m³/s

Normal combustion air flow 11.12 Nm³/s

Combustion air - duct at 110 °C 10.18 m³/s

Static pressure of CAF 1500.0 Pa

Typical operating pressure of CAF 1000.0 Pa

Efficiency of CAF at duty point 50.0 %

Estimated power absorbed 40.72 kW

CAF air temperature 22.0 °C

Atmospheric pressure 89.7 kPa

Density 1.038 kg/m³

Normal density 1.267 kg/Nm³

Size of air nozzles - DN 200

Number of air inlets 10

Air velocity in duct 29.8 m/s

IFS recommend primary air 30.0 % of total

IFS recommend secondary air 70.0 %

Raymond Combustion Engineering excess air 20.0 %

Exit velocity is recommended at 15 m/s, but up to 30 m/s has been used.

Hot gas exit velocity is 30.7 m/s

Chimney results...

Mass flow 56769.8 kg/hour

Mass flow 15.77 kg/s

Volume flow 22.1 m³/s

Volume normal flow 12.2 Nm³/s

Gas constant 286.928 kJ/kg K

Gas temperature 164.5 °C

Gas density 0.714 kg/m³

Gas normal density 1.293 kg/Nm³

Minimum ID 1367.8 mm

Maximum ID 2013.7 mm

ID recommended 2004.0 mm

Exit velocity 7.0 m/s

Grits 108.2 kg/h

Preheater results...

Hot gas exit temperature 164.5 °C

Ratio of furnace diameter to exit diameter- recommended 1.5 : 1.0.

Diameter ratio is 2.29

Recommended steel shell thickness 15.0 mm

Mass flows...

Steam - actual 19973.5 kg/hour

Fuel burnt in the furnace is 6149.4 kg/hour

Combustion air - FAF 12682.4 kg/hour

Combustion air - CAF 38047.3 kg/hour

Total combusion air 50729.8 kg/hour

Hot gas to the boiler 56769.8 kg/hour

Grit from furnace 108.2 kg/hour

Ash in furnace 1.1 kg/hour

Total waste from furnace 109.3 kg/hour

ID products 56769.8 kg/hour

Chimney grits 108.2 kg/hour

Heat balance...

Useful heat - steam 54.76 GJ/h

Air preheater 4.74 GJ/h

Air preheater - loss 0.14 GJ/h

Heat loss - furnace surface 0.25 GJ/h

Heat loss - boiler stack 8.65 GJ/h

Heat loss - boiler 20.57 GJ/h

Heat loss - boiler and stack losses 29.22 GJ/h

Heat loss - fuel moisture 10.14 GJ/h

Gross heat into furnace 84.25 GJ/h

Net heat into furnace 74.11 GJ/h

Overall efficiency 65.00 % gross

Overall efficiency 73.89 % net

______________________________________________________________________

Notes:

Normal temperature = 0 °C

Normal pressure = 101.325 kPa

A more useful number for comparing the thermal contribution of fuels to

boilers is the amount of heat released during complete oxidation of a fuel divided

by the

sum of the fuel and oxidizer, or alternatively, divided by the total mass of

products.

Fuel-bound oxygen decreases the amount of air required to burn a fuel.

Dry air is nearly 80 % nitrogen and other inerts. These inert gases tend to dilute

the

heat released. Ref. NREL

______________________________________________________________________

You might also like

- Sample Calculation For FM 200 Clean Agent: STEP 1: Determined Room VolumeDocument6 pagesSample Calculation For FM 200 Clean Agent: STEP 1: Determined Room VolumeMohd Zulhairi Mohd Noor100% (9)

- JMS 616 GS-N.L: Technical SpecificationDocument4 pagesJMS 616 GS-N.L: Technical SpecificationMohammad SarjoghiNo ratings yet

- Safety, Operating & Maintenance Instructions Marine Auxiliary Boiler - GK SeriesDocument40 pagesSafety, Operating & Maintenance Instructions Marine Auxiliary Boiler - GK SeriesAMG QAQCDEPTNo ratings yet

- Centrifugal Compresor CalculationDocument2 pagesCentrifugal Compresor CalculationgrabettyNo ratings yet

- Fire Tube Boiler DesignDocument3 pagesFire Tube Boiler DesignRajendraNo ratings yet

- Calculated Primary Air Flow and MomentumDocument4 pagesCalculated Primary Air Flow and MomentummadhuNo ratings yet

- DP - TXT (2021-01-18 4:12:14 PM)Document4 pagesDP - TXT (2021-01-18 4:12:14 PM)Rufus D SNo ratings yet

- Calciner Resitence TimeDocument2 pagesCalciner Resitence TimeIrfan Ahmed100% (1)

- HRSG BurnerDocument1 pageHRSG Burneranon_9324536No ratings yet

- 3.1 + 3.2 + 3.3 Ventilation CalculationDocument3 pages3.1 + 3.2 + 3.3 Ventilation Calculationabuya3kubmNo ratings yet

- Technical Data BoilerDocument1 pageTechnical Data BoilerJon LopezNo ratings yet

- Thermal 3TPH 12Kg FO Fired Boiler R0Document6 pagesThermal 3TPH 12Kg FO Fired Boiler R09913489806No ratings yet

- Performance Calculation Sheet: Air DataDocument1 pagePerformance Calculation Sheet: Air DataAppleuk SudarNo ratings yet

- IncineratorDocument6 pagesIncineratorKamal DeshapriyaNo ratings yet

- Impact of SC On Specific EnergyDocument33 pagesImpact of SC On Specific EnergyManish GautamNo ratings yet

- Burner Operating and Flame Momentum Calculation: InputsDocument6 pagesBurner Operating and Flame Momentum Calculation: InputsIrfan Ullah100% (1)

- BF6M 1013ec - 9997264Document2 pagesBF6M 1013ec - 9997264Yader SanchezNo ratings yet

- Heat Balance GCLDocument6 pagesHeat Balance GCLIrshad HussainNo ratings yet

- Boiler Design DataDocument8 pagesBoiler Design Dataramnath008100% (1)

- BF4M 1013FC - Epa2Document2 pagesBF4M 1013FC - Epa2Yader SanchezNo ratings yet

- TUTORIAL1 WeweDocument3 pagesTUTORIAL1 Weweprasadp2No ratings yet

- 14 ACC Air Side Performance PDFDocument24 pages14 ACC Air Side Performance PDFDSGNo ratings yet

- Steam Generator: Safety: Critical ConcernDocument59 pagesSteam Generator: Safety: Critical ConcernpatlninadNo ratings yet

- Calculation of Boiler EfficiencyDocument43 pagesCalculation of Boiler EfficiencyTamer Abd ElrasoulNo ratings yet

- Combustion CalcsDocument8 pagesCombustion Calcs31331311313No ratings yet

- Combustion CalcsDocument8 pagesCombustion CalcsZhaqir HusseinNo ratings yet

- Plant InvesticationDocument3 pagesPlant InvesticationirfanNo ratings yet

- HeaterSimulationResults 20112022 872204Document17 pagesHeaterSimulationResults 20112022 872204Hamid MansouriNo ratings yet

- Tutorials 3Document2 pagesTutorials 3David ChikuseNo ratings yet

- BF4L914 Epa2Document2 pagesBF4L914 Epa2LUIS ANGELNo ratings yet

- Design of Gasifier System For Diesel Engine PPT FinaleDocument28 pagesDesign of Gasifier System For Diesel Engine PPT FinaleNitu ShresthaNo ratings yet

- Steam Calculation On Basis of Flow-Temperature (1) 2222Document5 pagesSteam Calculation On Basis of Flow-Temperature (1) 2222hmaza shakeelNo ratings yet

- 4.HVAC and Refrigeration SystemDocument32 pages4.HVAC and Refrigeration SystemPrudhvi RajNo ratings yet

- JMS 620 GS-N.L: Technical SpecificationDocument4 pagesJMS 620 GS-N.L: Technical SpecificationjoellopezzNo ratings yet

- PPP 5Document4 pagesPPP 5Smit patelNo ratings yet

- Fiche TechniqueDocument3 pagesFiche Techniquenacer zidiNo ratings yet

- Metalurgi VDocument20 pagesMetalurgi VChandra C ManurungNo ratings yet

- Thermic Fluid Heater Data Sheet - Rev 0Document10 pagesThermic Fluid Heater Data Sheet - Rev 0Dhamotharan ChinnaduraiNo ratings yet

- J 616Document4 pagesJ 616UsAmaImtiAz0% (1)

- SI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RDocument3 pagesSI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RAhmad ZaenudinNo ratings yet

- Boilers - Powerpoint PresentationDocument45 pagesBoilers - Powerpoint PresentationDuggineni RamakrishnaNo ratings yet

- Customer Date To The K. A. of Our Offer Your Reference DescriptionDocument1 pageCustomer Date To The K. A. of Our Offer Your Reference DescriptionMohammadNo ratings yet

- Heat Output Calculation Summary With Mixed Coke Oven GasDocument13 pagesHeat Output Calculation Summary With Mixed Coke Oven GasRamachandra Bhat HireNo ratings yet

- Rectangular Jet Air Nozzles and Swirler Improving Ignition and Flame FormationDocument24 pagesRectangular Jet Air Nozzles and Swirler Improving Ignition and Flame Formationhmaza shakeelNo ratings yet

- N67 Ent: Tier 3 / Stage Iii ADocument4 pagesN67 Ent: Tier 3 / Stage Iii ATruong NguyenNo ratings yet

- Calculated Primary AirDocument1 pageCalculated Primary AirBùi Hắc HảiNo ratings yet

- Co HenDocument40 pagesCo HenHiltonNo ratings yet

- Line III Heat BalanceDocument65 pagesLine III Heat Balancehmaza shakeelNo ratings yet

- Coaching SET 3 (Green) Dry Air) : 4.) Using The Psychrometric ChartDocument18 pagesCoaching SET 3 (Green) Dry Air) : 4.) Using The Psychrometric ChartRockydel MontesNo ratings yet

- Thermo Long ProblemDocument2 pagesThermo Long ProblemRajeev ValunjkarNo ratings yet

- Enapter Datasheet AEM-Multicore-225kg enDocument2 pagesEnapter Datasheet AEM-Multicore-225kg enRoque Alfredo Da Rosa AvilaNo ratings yet

- Efisiensi Tungku: Ikhwan Fajeri, M.TDocument20 pagesEfisiensi Tungku: Ikhwan Fajeri, M.Tsigit prabowoNo ratings yet

- Deutz 6 CylinderDocument2 pagesDeutz 6 Cylinderabdelrhmangbr86No ratings yet

- Applied ThermodynamicsDocument3 pagesApplied ThermodynamicsPRATAP SINGHNo ratings yet

- Savings From Surface Condenser Usage Instead of Venting The SteamDocument9 pagesSavings From Surface Condenser Usage Instead of Venting The SteamManoj BNo ratings yet

- The Process IGSDocument8 pagesThe Process IGSFaiz Ziafumi Kura'No ratings yet

- 2MW Watertube Steam Boiler DatasheetDocument1 page2MW Watertube Steam Boiler DatasheetAshan MahelaNo ratings yet

- Vapour Compression Refrigeration SlidesDocument41 pagesVapour Compression Refrigeration SlidesLesegoNo ratings yet

- JMS 612 GS-N.L: Jenbacher Gas EnginesDocument4 pagesJMS 612 GS-N.L: Jenbacher Gas EngineshadNo ratings yet

- Stratos MGM 160 Biogas: CogenerationDocument11 pagesStratos MGM 160 Biogas: CogenerationGeorge PircalabuNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Dioxin FuransDocument2 pagesDioxin FuransRufus D SNo ratings yet

- 0611 SZL25 2.45 PaDocument2 pages0611 SZL25 2.45 PaRufus D SNo ratings yet

- Vancouver HumidtyDocument2 pagesVancouver HumidtyRufus D SNo ratings yet

- Woodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursDocument30 pagesWoodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursRufus D SNo ratings yet

- VU-40 - NG - Enbridge - 8760 HoursDocument1 pageVU-40 - NG - Enbridge - 8760 HoursRufus D SNo ratings yet

- SZS35-3.0-300.Q - Methane Rich Gas - 8760 HoursDocument1 pageSZS35-3.0-300.Q - Methane Rich Gas - 8760 HoursRufus D SNo ratings yet

- Superheat HeaderDocument2 pagesSuperheat HeaderRufus D SNo ratings yet

- 8000.1700 - Wood - 30% Moisture - 8760 HoursDocument1 page8000.1700 - Wood - 30% Moisture - 8760 HoursRufus D SNo ratings yet

- S 4500 - 1100 - Wood - 55% Wood - 8760 HoursDocument1 pageS 4500 - 1100 - Wood - 55% Wood - 8760 HoursRufus D SNo ratings yet

- 0574 - CR240-80Document2 pages0574 - CR240-80Rufus D SNo ratings yet

- 0446 - MU To Surge Tank - 900Document2 pages0446 - MU To Surge Tank - 900Rufus D SNo ratings yet

- Secondary SH SummaryDocument2 pagesSecondary SH SummaryRufus D SNo ratings yet

- 0611 - HPS200-250Document2 pages0611 - HPS200-250Rufus D SNo ratings yet

- SMACNA - Panel CalcsDocument4 pagesSMACNA - Panel CalcsRufus D SNo ratings yet

- 1615.00209 - BCPDocument4 pages1615.00209 - BCPRufus D SNo ratings yet

- G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/MDocument11 pagesG/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/MRufus D SNo ratings yet

- 0259 - HMIP Chimney HeightDocument1 page0259 - HMIP Chimney HeightRufus D SNo ratings yet

- 0611 - WindLoads-R2Document2 pages0611 - WindLoads-R2Rufus D SNo ratings yet

- 0234 - Chimney Structural - R0Document7 pages0234 - Chimney Structural - R0Rufus D SNo ratings yet

- Chimney CodesDocument3 pagesChimney CodesRufus D SNo ratings yet

- Rectangular Expansion Joint: Description Section PDF Symbol NotesDocument3 pagesRectangular Expansion Joint: Description Section PDF Symbol NotesRufus D SNo ratings yet

- Maximator Test BenchesDocument16 pagesMaximator Test Benchessantu_23No ratings yet

- Week 04Document2 pagesWeek 04Balaji HimakarNo ratings yet

- 04 - Evaluasi Sifat LanjutDocument25 pages04 - Evaluasi Sifat LanjutNazril FarhanNo ratings yet

- Souza Et Al-2019-Process Safety ProgressDocument6 pagesSouza Et Al-2019-Process Safety ProgressMattNo ratings yet

- Oxy-Acetylene Safety RulesDocument5 pagesOxy-Acetylene Safety RuleschrisNo ratings yet

- Pipe Terms With AnswerDocument23 pagesPipe Terms With AnswerTIKTOK COMPILATIONNo ratings yet

- An Approach To Obtain The Heat Transfer Coefficient of Aqueous Sucrose Solutions in Agitated Boiling VesselsDocument13 pagesAn Approach To Obtain The Heat Transfer Coefficient of Aqueous Sucrose Solutions in Agitated Boiling VesselsnicolasjmunozNo ratings yet

- Heat Physics SPMDocument33 pagesHeat Physics SPMJeffrey TehNo ratings yet

- GTL WPSDocument6 pagesGTL WPSYoucef ChorfaNo ratings yet

- Hydraulics Reviewer For Civil Engineering StudentsDocument2 pagesHydraulics Reviewer For Civil Engineering StudentsKing BangngayNo ratings yet

- Module 1 Week 2-3, TVE SMAW 10Document13 pagesModule 1 Week 2-3, TVE SMAW 10Daryl TesoroNo ratings yet

- Soal Teknik Reaksi KimiaDocument5 pagesSoal Teknik Reaksi KimiafebriNo ratings yet

- Physics 05-01 Fluids and DensityDocument2 pagesPhysics 05-01 Fluids and DensityRocelin E. MolabolaNo ratings yet

- ESP Design 2018Document57 pagesESP Design 2018Mustafa0108910% (1)

- The Effect of Blades Number and Shape On The OperatingDocument9 pagesThe Effect of Blades Number and Shape On The OperatingDaniel ChambergoNo ratings yet

- 2-Fluid Statics-Lecture Note 2Document7 pages2-Fluid Statics-Lecture Note 2Ashan ShamikaNo ratings yet

- Lect - 13.1 Codensation and Evaporation Tutorial Questions With SolutionsDocument7 pagesLect - 13.1 Codensation and Evaporation Tutorial Questions With SolutionsShubham0% (1)

- (Pressure of Saturated Liquid in A Tank) : Example 12-1Document12 pages(Pressure of Saturated Liquid in A Tank) : Example 12-1Melinda100% (2)

- PIPENET - Hydraulic Fluid Flow Analysis (IGT-FFT) PDFDocument2 pagesPIPENET - Hydraulic Fluid Flow Analysis (IGT-FFT) PDFsammar_10No ratings yet

- Recommendations For A Stringent ISO Standard On The GHG Emissions From Blue Hydrogen ProductionDocument55 pagesRecommendations For A Stringent ISO Standard On The GHG Emissions From Blue Hydrogen ProductionThe International Council on Clean TransportationNo ratings yet

- Hydraulic Bench Applications Venturi MeterDocument8 pagesHydraulic Bench Applications Venturi Meter22pwind0761No ratings yet

- Me510-Syllabus sp2018Document3 pagesMe510-Syllabus sp2018ahsanshehzadNo ratings yet

- BBQ Orfice SizingDocument1 pageBBQ Orfice SizingPubcrawlNo ratings yet

- Aquamicron - Filter Elements AM: Up To 10 Bar, Filtration Rating 40 MDocument2 pagesAquamicron - Filter Elements AM: Up To 10 Bar, Filtration Rating 40 MseyedAli TabatabaeeNo ratings yet

- CFD Large Eddy Simulation of Jet in Cross-Flow Applied PDFDocument19 pagesCFD Large Eddy Simulation of Jet in Cross-Flow Applied PDFmojicapNo ratings yet

- Esp Ahu 2Document13 pagesEsp Ahu 2meesam1No ratings yet

- Utilities Weekly Maintenance Checklist Compressor-Sl270 Sno. Compressor Part Checks Manual RemarksDocument7 pagesUtilities Weekly Maintenance Checklist Compressor-Sl270 Sno. Compressor Part Checks Manual RemarksShahzad AhmedNo ratings yet

- InertecDocument17 pagesInertecShayan IrevaniNo ratings yet