Professional Documents

Culture Documents

ASME B18 8 4M 1994 Type B Pin Materials

ASME B18 8 4M 1994 Type B Pin Materials

Uploaded by

hcsharma1967Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME B18 8 4M 1994 Type B Pin Materials

ASME B18 8 4M 1994 Type B Pin Materials

Uploaded by

hcsharma1967Copyright:

Available Formats

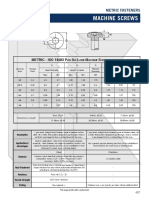

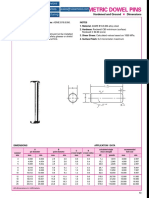

ASME B18.8.

4M PIN MATERIALS AND HARDNESS PIN FINISHES

B Carbon Steel HV 458-560 K Plain*

TYPE B C Chrome Stainless Steel HV 423-544 P Passivated

D Nickel Stainless Steel Work Hardened T Zinc Plated

LENGTH I Beryllium Copper HV 354-412 R Phosphated, Oiled

C

D * Plain carbon steel pins have a protective oil finish.

B

S D1 45˚ 45˚ D3

CHAMFER BOTH ENDS, D2

CONTOUR OF CHAMFER OPTIONAL

SPECIFICATIONS in mm

Nominal Pin Diameter Chamfer Chamfer Length Wall Thick- Recommended Double Shear Strength

Pin Diameter ness Hole Size

Carbon & Nickel Beryllium

Diameter D B C S Chrome S.S. S.S. Copper

Min.1 Max.2 Max. Min. Max. Nominal Min. Max. Minimum kN

1.5 1.58 1.66 1.4 0.15 0.7 0.35 1.5 1.56 1.8 1.0 1.1

2 2.10 2.19 1.9 0.2 0.8 0.45 2.0 2.07 3.5 2.0 2.2

2.5 2.62 2.72 2.4 0.2 0.9 0.55 2.5 2.58 5.5 3.2 3.5

3 3.14 3.25 2.9 0.2 1.0 0.65 3.0 3.10 7.8 4.5 4.9

4 4.16 4.30 3.9 0.3 1.2 0.8 4.0 4.12 12.3 7.2 7.7

5 5.17 5.33 4.8 0.3 1.4 1.0 5.0 5.12 19.6 11.4 12.3

6 6.18 6.36 5.8 0.4 1.6 1.2 6.0 6.12 28.5 16.6 17.8

8 8.22 8.45 7.8 0.4 2.0 1.6 8.0 8.15 48.8 28.4 30.5

10 10.25 10.51 9.7 0.5 2.4 2.0 10.0 10.15 79.1 46.1 49.4

12 12.28 12.55 11.7 0.6 2.8 2.5 12.0 12.18 111.6 3 60.7 65.0

14†* 14.30 14.60 13.7 0.8 2.8 3.0 14.0 14.18 170.0 4 — —

16† 16.32 16.65 15.6 1.0 3.0 3.0 16.0 16.18 190.0 4 — —

18†* 18.35 18.71 17.6 1.2 3.2 3.5 18.0 18.18 250.0 4 — —

20† 20.40 20.80 19.5 1.4 3.4 4.0 20.0 20.21 320.0 4 — —

1

Minimum diameter is the average of D1, D2, and D3. 2

Maximum measured with go-ring gauge. 3

SPIROL standard. 4

Carbon Steel only.

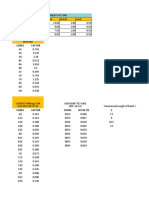

STANDARD METRIC SIZES AND WEIGHTS (Kg PER 1,000 PCS.)

Diameter

Length 1.5 2 2.5 3 4 5 6 8 10 12 14†* 16† 18†* 20†

4 0.042 0.071

5 0.052 0.089 0.136

6 0.062 0.107 0.163 0.231

8 0.083 0.143 0.218 0.308 0.512

10 0.104 0.179 0.272 0.386 0.640 1.002

12 0.125 0.214 0.327 0.463 0.768 1.203 1.723

14 0.145 0.250 0.381 0.540 0.896 1.403 2.011

16 0.166 0.286 0.436 0.617 1.024 1.604 2.298 3.947

18 0.187 0.321 0.490 0.694 1.152 1.804 2.585 4.441

20 0.208 0.357 0.545 0.771 1.280 2.005 2.872 4.934 7.640

22 0.228 0.393 0.599 0.848 1.408 2.205 3.159 5.427 8.404 12.603

24 0.249 0.429 0.653 0.925 1.536 2.406 3.447 5.921 9.168 13.749

26 0.270 0.464 0.708 1.003 1.664 2.606 3.734 6.414 9.932 14.895

28 0.291 0.500 0.762 1.080 1.792 2.807 4.021 6.907 10.696 16.041

30 0.536 0.817 1.157 1.920 3.007 4.308 7.401 11.460 17.186 23.497

32 0.571 0.871 1.234 2.048 3.208 4.596 7.894 12.224 18.332 25.064

35 0.625 0.953 1.350 2.240 3.508 5.026 8.634 13.370 20.051 27.413

40 0.714 1.089 1.542 2.560 4.010 5.744 9.868 15.280 22.915 31.330 37.729 48.872 61.319

45 1.735 2.880 4.511 6.463 11.101 17.190 25.780 35.246 42.445 54.980 68.984

50 3.200 5.012 7.181 12.335 19.100 28.644 39.162 47.162 61.089 76.649

55 Nominal Pin Length Length Tolerance 3.519 5.513 7.899 13.568 21.009 31.508 43.078 51.878 67.198 84.314

60 8.617 14.802 22.919 34.373 46.994 56.594 73.307 91.979

Up to 24 mm, incl. ±0.40 mm

65 Over 24 to 50 mm ±0.50 mm

9.335 16.035 24.829 37.237 50.911 61.310 79.416 99.643

70 Over 50 to 75 mm ±0.60 mm 10.053 17.269 26.739 40.102 54.827 66.026 85.525 107.308

75 Over 75 mm ±0.75 mm 10.771 18.502 28.649 42.966 58.743 70.742 91.634 114.973

80 19.736 30.559 45.830 62.659 75.458 97.743 122.638

85 20.969 32.469 48.695 66.575 80.175 103.852 130.303

90 22.203 34.379 51.559 70.492 84.891 109.961 137.968

95 23.436 36.289 54.423 74.708 89.607 116.070 145.633

100 24.670 38.199 57.288 78.324 94.323 122.179 153.298 5

† In conformance with but not part of ASME 18.18.4M.

* Not generally a stocked diameter.

You might also like

- CIBSE Pipe Sizing V2.2Document9 pagesCIBSE Pipe Sizing V2.2mohamed adelNo ratings yet

- ECA-00-PCS-SPE-0011 - Rev3-INSTRUMENTATION FOR PACKAGED EQUIPMENTDocument19 pagesECA-00-PCS-SPE-0011 - Rev3-INSTRUMENTATION FOR PACKAGED EQUIPMENThcsharma1967No ratings yet

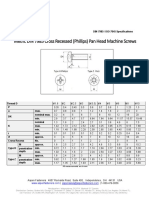

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

- Katalog TSP PTDocument24 pagesKatalog TSP PThse vje100% (1)

- ASME B18.3.2M-1979 Metric Series Hexagon Keys and BitsDocument11 pagesASME B18.3.2M-1979 Metric Series Hexagon Keys and Bitshcsharma1967No ratings yet

- ASME B18.8.2: Pin Materials and Hardness Pin FinishesDocument2 pagesASME B18.8.2: Pin Materials and Hardness Pin FinishesIvan SmolejNo ratings yet

- Screw, ISO 14583, PAN, Metric, TorxDocument1 pageScrew, ISO 14583, PAN, Metric, TorxDerekNo ratings yet

- Screw, IsO 14583, PAN, Metric, TorxDocument1 pageScrew, IsO 14583, PAN, Metric, TorxDerekNo ratings yet

- ISO 8752 EN 28752: Pin Materials and Hardness Pin FinishesDocument2 pagesISO 8752 EN 28752: Pin Materials and Hardness Pin FinishesstanyeahNo ratings yet

- ASME B18.8.2 PinsDocument2 pagesASME B18.8.2 Pinsvictor manuel flores martinezNo ratings yet

- Metric Socket Set ScrewsDocument2 pagesMetric Socket Set ScrewsvvvvvvNo ratings yet

- Metric DIN 7981 SpecDocument5 pagesMetric DIN 7981 SpecSudhanshu JainNo ratings yet

- Sltp-Standard Inch Pins UsDocument2 pagesSltp-Standard Inch Pins UsErick Frank Dueñas CudeñaNo ratings yet

- High Tensile: Hexagon Flange Bolts DIN 6921Document1 pageHigh Tensile: Hexagon Flange Bolts DIN 6921Mauro MiguelNo ratings yet

- MU19 Pinos Elasticos Din 1481 Iso 8752 TecemDocument1 pageMU19 Pinos Elasticos Din 1481 Iso 8752 Tecemmugiwara ruffyNo ratings yet

- Hdpe Pipe Specifications PDFDocument5 pagesHdpe Pipe Specifications PDFawanarifNo ratings yet

- CIBSE Pipe Sizing V2.2Document9 pagesCIBSE Pipe Sizing V2.2thanhquan nguyenNo ratings yet

- Compuerta RoscadaDocument1 pageCompuerta RoscadajuandenismamanihuancaNo ratings yet

- An800 6Document3 pagesAn800 6jcNo ratings yet

- Screw, DIN 7500TX 7500CE DIN 7500-1, Thread Forming Screw, Metric, TorxDocument1 pageScrew, DIN 7500TX 7500CE DIN 7500-1, Thread Forming Screw, Metric, TorxDerekNo ratings yet

- Data Sheet VDM Alloy 80 ADocument8 pagesData Sheet VDM Alloy 80 Agigi gigioNo ratings yet

- DIN 433 SpecDocument4 pagesDIN 433 SpecChris StefanouNo ratings yet

- Metric Dowel PinsDocument1 pageMetric Dowel Pinsashey7777No ratings yet

- LV 2012 51-60Document10 pagesLV 2012 51-60Just RysdanNo ratings yet

- 600/1000 V Xlpe Insulated and PVC Sheathed Cu / Xlpe / PVC (N2Xy) SNI IEC 60502-1: 2009 / IEC 60502-1Document4 pages600/1000 V Xlpe Insulated and PVC Sheathed Cu / Xlpe / PVC (N2Xy) SNI IEC 60502-1: 2009 / IEC 60502-1Rahmawan fiberhomeNo ratings yet

- 175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Document1 page175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Ncmii AppnNo ratings yet

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pages36CrB4 Rod - Wire Rev4 PDFKarthi KeyanNo ratings yet

- Katalog TSP PTDocument24 pagesKatalog TSP PTendroNo ratings yet

- Katalog TSP PT PDFDocument24 pagesKatalog TSP PT PDFdeniNo ratings yet

- Roofdek D32S: Ultimate Section Properties To EurocodeDocument1 pageRoofdek D32S: Ultimate Section Properties To EurocodeVolodymyr ShchurNo ratings yet

- Metric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDocument5 pagesMetric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDHEERAJ413No ratings yet

- Vestpak SpiralWound v001 01 2016 PDFDocument19 pagesVestpak SpiralWound v001 01 2016 PDFSaadEddine AtifNo ratings yet

- Dimensional Data:: Spiral Wound Gaskets ASME B16.20Document19 pagesDimensional Data:: Spiral Wound Gaskets ASME B16.20mahmoudfaragNo ratings yet

- Bolt Capacities: Grade 4.6 Bolts in S355Document3 pagesBolt Capacities: Grade 4.6 Bolts in S355Ah ChiaNo ratings yet

- BAS Castings - Ni Resist CA..Document3 pagesBAS Castings - Ni Resist CA..vijay2bhagyaNo ratings yet

- Flanges: Tables D and EDocument1 pageFlanges: Tables D and EIlse FerreiraNo ratings yet

- Stas 438-2-91 RDocument4 pagesStas 438-2-91 RSzabolcs KovacsNo ratings yet

- BS Roller Chain (British Standard Roller Chain) : Dimensional DrawingDocument1 pageBS Roller Chain (British Standard Roller Chain) : Dimensional DrawingmhNo ratings yet

- Pre-Load: Bolt Assemblies HR BS EN 14399-3:2015Document5 pagesPre-Load: Bolt Assemblies HR BS EN 14399-3:2015erharsinghNo ratings yet

- Pn40.Ball ValveDocument1 pagePn40.Ball ValvealarbajeNo ratings yet

- Datasheet Din 85Document6 pagesDatasheet Din 85yilingNo ratings yet

- Metric DIN SpecDocument1 pageMetric DIN SpecErnestNo ratings yet

- Quantity EstimateDocument59 pagesQuantity EstimateJohn Christopher JusayanNo ratings yet

- Dws Info Sheet Carbon Stainless and Alloy Slicklines - Physical PropertiesDocument1 pageDws Info Sheet Carbon Stainless and Alloy Slicklines - Physical Propertieserwin atmadjaNo ratings yet

- VBW12121 - 300PSI Wafer Butterfly ValveDocument1 pageVBW12121 - 300PSI Wafer Butterfly ValveErickNo ratings yet

- 8 Minutes SAP2000 - Pemodelan WarehouseDocument17 pages8 Minutes SAP2000 - Pemodelan WarehouseThomas dsNo ratings yet

- LV 2012 29-33Document5 pagesLV 2012 29-33Muhamad YasrinNo ratings yet

- LV PVC Cable SupremeDocument3 pagesLV PVC Cable SuprememadonxgoreNo ratings yet

- CIBSE Pipe Sizing V2.2Document9 pagesCIBSE Pipe Sizing V2.2Sarmad ShahNo ratings yet

- SSBP Company ProfileDocument10 pagesSSBP Company ProfileRian HeriawanNo ratings yet

- Bảng Độ Dày CắtDocument11 pagesBảng Độ Dày Cắta.lifelong.partner4392No ratings yet

- MS Seamless Pipe ASTM A106Document3 pagesMS Seamless Pipe ASTM A106imtz20130% (1)

- PVC Insulated, PVC Sheathed Unarmoured Cable (2-Core)Document1 pagePVC Insulated, PVC Sheathed Unarmoured Cable (2-Core)piscesguy78No ratings yet

- IPE Section Properties PDFDocument1 pageIPE Section Properties PDFpaolocparreraNo ratings yet

- Meltio-Nickel-625 Material Datasheet PDFDocument2 pagesMeltio-Nickel-625 Material Datasheet PDFJakNo ratings yet

- Pipe THK CalculationDocument2 pagesPipe THK CalculationchannajayamangalaNo ratings yet

- Metric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityShrikant DeshmukhNo ratings yet

- Tubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SDocument3 pagesTubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SSmithSaitAlarconPintoNo ratings yet

- VDM Alloy K-500: Nicorros AlDocument11 pagesVDM Alloy K-500: Nicorros AlIon PopescuNo ratings yet

- Steel ReferenceDocument2 pagesSteel Referencenkrish21856No ratings yet

- ECA-00-PCS-SPE-0015 - Rev1-TEMPERATURE INSTRUMENT SPECIFICATIONDocument14 pagesECA-00-PCS-SPE-0015 - Rev1-TEMPERATURE INSTRUMENT SPECIFICATIONhcsharma1967No ratings yet

- Steel Plates, Sheets, Strips AND Flats For Structural and General Engineering Purposes-DimensionsDocument11 pagesSteel Plates, Sheets, Strips AND Flats For Structural and General Engineering Purposes-Dimensionshcsharma1967No ratings yet

- Inspection and Test Plan For Start-Up Hot Oil Heater: Eca LNG Energia Costa Azul Phase I LNG ProjectDocument7 pagesInspection and Test Plan For Start-Up Hot Oil Heater: Eca LNG Energia Costa Azul Phase I LNG Projecthcsharma1967No ratings yet

- Abma 11 PDFDocument23 pagesAbma 11 PDFhcsharma1967No ratings yet

- Ratio of Ultimate Stress To 0.2 Percent Proof Stress Shall Be at Least 1.15Document1 pageRatio of Ultimate Stress To 0.2 Percent Proof Stress Shall Be at Least 1.15hcsharma1967No ratings yet

- ECA-00-PMT-LST-0002 - RevF-LIST OF ENGINEERING CODESDocument58 pagesECA-00-PMT-LST-0002 - RevF-LIST OF ENGINEERING CODEShcsharma1967No ratings yet

- Check of Flange Ratings - ASME B16.5Document13 pagesCheck of Flange Ratings - ASME B16.5hcsharma1967No ratings yet

- ECA-00-PCS-PHI-0002 - Rev3-PLC PACKAGE SYSTEMS ROTATING MACHINERY PHILOSOPHYDocument13 pagesECA-00-PCS-PHI-0002 - Rev3-PLC PACKAGE SYSTEMS ROTATING MACHINERY PHILOSOPHYhcsharma1967No ratings yet

- ASME B18.22M-1981 R2000 Metric Plain WashersDocument16 pagesASME B18.22M-1981 R2000 Metric Plain Washershcsharma1967No ratings yet

- ECA-00-PCS-PHI-0001 - Rev4-PROCESS MONITORING AND CONTROL PHILOSOPHYDocument31 pagesECA-00-PCS-PHI-0001 - Rev4-PROCESS MONITORING AND CONTROL PHILOSOPHYhcsharma1967No ratings yet

- ECA-00-ELE-SPE-0024 - Rev3-INSTRUMENT CABLE SPECIFICATIONDocument10 pagesECA-00-ELE-SPE-0024 - Rev3-INSTRUMENT CABLE SPECIFICATIONhcsharma1967No ratings yet

- ASNT Q&A Book HB Bubble Leak Testing Feb08Document32 pagesASNT Q&A Book HB Bubble Leak Testing Feb08hcsharma1967100% (1)

- ASME B18 8 100M 2000 Spring PinsDocument57 pagesASME B18 8 100M 2000 Spring Pinshcsharma1967No ratings yet

- Abma 14Document25 pagesAbma 14hcsharma1967No ratings yet

- ASME B18.2.4.4M-1982 R1999 Metric Hex Flange Nuts PDFDocument16 pagesASME B18.2.4.4M-1982 R1999 Metric Hex Flange Nuts PDFhcsharma1967No ratings yet

- Machine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To FasDocument6 pagesMachine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To Fashcsharma1967No ratings yet

- Machine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To FasDocument6 pagesMachine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To Fashcsharma1967No ratings yet

- Abma 13Document17 pagesAbma 13hcsharma1967No ratings yet

- ASME B18 6 2 1998 Slotted Head CapDocument34 pagesASME B18 6 2 1998 Slotted Head Caphcsharma1967No ratings yet

- Abma 199Document12 pagesAbma 199hcsharma1967No ratings yet

- ASME LECTURE-Fittings-TrainingDocument61 pagesASME LECTURE-Fittings-Traininghcsharma1967No ratings yet

- ASME B18.8.8M-1994 Headed Clevis Pins (Metric Series)Document6 pagesASME B18.8.8M-1994 Headed Clevis Pins (Metric Series)hcsharma1967No ratings yet

- Quaid e AzamDocument7 pagesQuaid e AzamFM statusNo ratings yet

- Unit Title Reading and Use of English WritingDocument1 pageUnit Title Reading and Use of English WritingAOCNo ratings yet

- Flusser - Crisis of LinearityDocument12 pagesFlusser - Crisis of LinearitynatelbNo ratings yet

- ACHALDocument10 pagesACHALSilent GirlNo ratings yet

- Portable Lamps & Converters: W 276 LEDDocument2 pagesPortable Lamps & Converters: W 276 LEDRaghu paryNo ratings yet

- Republic vs. Castelvi, 58 SCRA 336 (1974)Document4 pagesRepublic vs. Castelvi, 58 SCRA 336 (1974)Gabriel HernandezNo ratings yet

- Journal Date Account Titles Debit CreditDocument9 pagesJournal Date Account Titles Debit CreditFrances Monique AlburoNo ratings yet

- Spelling Lesson PlanDocument5 pagesSpelling Lesson Planapi-476785297100% (1)

- Why Does Ice MeltDocument11 pagesWhy Does Ice MeltLynellAlimangohanNo ratings yet

- Benveniste, Emile The Nature of Pronouns PDFDocument13 pagesBenveniste, Emile The Nature of Pronouns PDFAldana Gauto100% (1)

- Striking Out Pleadings and IndorsmentsDocument19 pagesStriking Out Pleadings and IndorsmentsNur Amirah SyahirahNo ratings yet

- Diagnostic Test Name: - DateDocument3 pagesDiagnostic Test Name: - DateVivita GuzmánNo ratings yet

- 5 Brilliant Depictions of Lucifer in Art From The Past 250 YearsDocument1 page5 Brilliant Depictions of Lucifer in Art From The Past 250 Yearsrserrano188364No ratings yet

- You Have To Choose The Best Answer To Each Questions From The Alternatives GivenDocument5 pagesYou Have To Choose The Best Answer To Each Questions From The Alternatives Givenaida FitriahNo ratings yet

- Functional Nature of PlanetsDocument15 pagesFunctional Nature of PlanetsVaraha Mihira100% (6)

- Helical Pile Behaviour Analysis in Different Soils: January 2009Document11 pagesHelical Pile Behaviour Analysis in Different Soils: January 2009mohamed magdyNo ratings yet

- Fast Easy DK HatDocument4 pagesFast Easy DK HatAdina LamasanuNo ratings yet

- Lesson 7Document20 pagesLesson 7rj libayNo ratings yet

- Common Ailments LPDocument5 pagesCommon Ailments LPJeyxa Keizz Viernes-Apostol BalanayNo ratings yet

- Full Charge Bookkeeper ResumeDocument8 pagesFull Charge Bookkeeper Resumef5d7ejd0100% (3)

- Package Contents Instruction Installation / Technical SupportDocument1 pagePackage Contents Instruction Installation / Technical SupportXseed02No ratings yet

- Pylontech - US2000C, US3000CDocument1 pagePylontech - US2000C, US3000CYC CarieloNo ratings yet

- Members 800Document62 pagesMembers 800Sandeep JainNo ratings yet

- LC Jumpers Fap 203 Web PDFDocument3 pagesLC Jumpers Fap 203 Web PDFAlejandro Humberto García QuisbertNo ratings yet

- J. of Church and State-2010-Payne-jcs - csq102Document16 pagesJ. of Church and State-2010-Payne-jcs - csq102MotricalăMihailNo ratings yet

- SFMDocument132 pagesSFMKomal BagrodiaNo ratings yet

- Life Orientation September 2023 EngDocument9 pagesLife Orientation September 2023 EngmadzhutatakalaniNo ratings yet

- The Period of Suppressed NationalismDocument9 pagesThe Period of Suppressed Nationalismkbj_batch0980% (5)

- Running Times 2014-01-02.bakDocument72 pagesRunning Times 2014-01-02.bakJsueNo ratings yet

- CH 2Document28 pagesCH 2younis ahmadNo ratings yet