Professional Documents

Culture Documents

SPE-2559-PA Shale Control With Balanced Activity Obm

SPE-2559-PA Shale Control With Balanced Activity Obm

Uploaded by

William RocaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPE-2559-PA Shale Control With Balanced Activity Obm

SPE-2559-PA Shale Control With Balanced Activity Obm

Uploaded by

William RocaCopyright:

Available Formats

Shale Control with Balanced-Activity

Oil-Continuous Muds

M. E. Chenevert, SPE-AIME, Esso Production Research Co.

Introduction

Unstable shales have plagued the petroleum industry sorb water. Problems due to hydration usually occur

for more than 30 years. All boreholes drilled into shale some time after the formation is exposed and can be

formations experience some degree of washout, which prevented by using balanced-activity oil-continuous

maybe tolerable in some wells but completely uncon- muds.

trollable in others. Many causes of shale problems Laboratory and field data have shown that many

have been postulated: mechanical factors such as mud formations are capable of adsorbing water2 . or ions

pressure, thermal stresses, pipe movement (both bang- from water-base muds and are capable of adsorbing

ing and swabbing), "rubble" shale, and plastic flow; water from oil-continuous muds. Adsorption* occurs

chemical factors such as hydration of montmorillonite because of differences in chemical potential between

clay. One paper1 describes the dehydration of plastic the mud and the formation, and continues until equi-

"gumbo" shales with invert emulsion muds. The tech- librium is achieved. When considering adsorption

nique reportedly works on soft, wet shales and re- potential for oil-continuous muds, only aqueous

quires only that the salinity of the mud be greater chemical potentials need be considered because ion

than the salinity of the water in the shale. (The salinity transfer does not occur. In the case of water-base

of such shales seldom exceeds 40,000 ppm.) muds, the problem is more complex because of ion

and clay movement as well as water movement be-

Causes of Unstable Wellbores tween the mud and the formation.

Unstable wellbores occur when formation pressures It has been found that the more deeply buried

exceed the pressure exerted by the drilling fluid. Two shales are highly compacted and contain low quanti-

situations can produce such a condition: (a) the well- ties of water. As geologic compaction occurs, water

bore fluid pressure is lower than the in-situ formation is expelled from the shale and produces a degree of

pressure and (b) the in-situ fonnation pressure in- dryness in the shale. The scarcity of water and the

creases because of water adsorption. Too Iowa fluid abundance of charged clay surfaces results in an in-

pressure occurs when mud density is too low or when crease in the adsorptive potential of the shale. S

bottom-hole pressures are reduced by swabbing with

the drill pipe. This type of instability normally can be Balanced Mud Concept

eliminated by drilling with increased mud weight or Water transfer from an oil-continuous mud to a for-

by minimizing pressure surges with low viscosity muds mation can be prevented by increasing the salinity of

and slow pipe nlovement. Another more frequent

cause' of degradation is the excessive formation pres- *The term adsorption is used in thi's paper to describe the

transfer mechanisms believed to occur. This process is also fre-

l

sure that develops when argillaceous formations ad- quently referred to as absorption.

The main cause of shale instability is water adsorption and subsequent swelling of the

wellbore. By adjusting the activity of t/1e water in the mud to that of the water in the

shale, this adsorption can be prevented and gaLlge boreholes can be drilled through

both hard and soft shales.

OCTOBER, 1970 1309

the water phase of the mud until the aqueous chemical activity of the shale were conducted under atmos-

potential of the mud is equal to that of the formation. pheric conditions. The effective stress on the shale

The aqueous chemical potential of either the mud or sample under laboratory conditions, however, is ap-

the formation relative to pure water can be written as proximately the same as the effective radial stress

acting on the shale under down-hole conditions-.

u- Uo == RT In aw , (1) The effective radial stress (Ur) is given by the equa-

tion

where u is the chemical potential of the water in the

system, ·U o is the chemical potential of pure water, R CTr = CTIl: [1 - r~2] - (Pw - PI) r~2 ,. (3)

is the gas constant, T is absolute temperature and aw

is the activity of the water of that system. For a con- where Ux is the far-field horizonal effective stress, PI

stant T, the mud and the formation will have identical the pore pressure of a nearby sand formation, Pw the

water chemical potentials only when their water actvi- wellbore pressure, rw the radius of the wellbore and

ties are equal. r the radius under investigation. At the wellbore wall,

The water activity of a system is defined 4 as the this equation reduces t05 Ur == PI - Pw. For balanced

ratio of the fugacity (f) of the water in that system to drilling where Pi == Pw, the effective radial stress is

the fugacity of pure water (fo), or zero.

Down-hole temperatures tend to lower the aqueous

f

aw == -;;- (2)

activity of the shale slightly2 and raise the activity of

fo the mud's aqueous phase slightly.6 On the average

these corrections alter the measured activity by about

For practical purposes, the fugacity ratio f/fo can be 0.05 and can be made when sufficient laboratory data

replaced by the vapor pressure ratio p/Po, where P is are available. Field results indicate that in most cases

the vapor pressure of the water in that system and Po such corrections are not necessary.

is the vapor pressure of pure water. This assumption

is acceptable because .the correction factor used in Experimental Swelling Tests

going from fugacity to vapor pressure for the pure Laboratory swelling tests have confirmed the balanced

solvent is nearly equal to the correction factor of the activity concept by showing that adsorption does not

solution. The vapor p'ressure ratio is therefore nearly take place when the activity of the water in the shale

equal to the fugacity ratio. is equal to the activity of the water in the mud.

Balanced-activity oil-continuous muds are then In our tests strain gauges were attached to the sur-

muds whose relative aqueous vapor pressure in the face of the shale samples and the samples were im-

drilling environment is essentially equal to the relative mersed in various water-base and oil-continuous

aqueous vapor pressure of the formation penetrated. muds. Fluid-rock interactions producing displace-

ments as small as 1 micro-in. were detected.

Laboratory Determination of The swelling tests showed that hard illitic shales,

Water Activity previously thought to be inert, experience substantial

The water activity of various shales was determined alteration when placed in water-base muds or un-

from the adsorption characteristics of the drilled chips treated oil muds. Fig. 2 shows data for samples of a

recovered from each formation. For each formation hard West Texas illitic shale that were immersed in

we developed an adsorption isotherm that related the six different oil-continuous emulsion fluids. Each fluid

shale's activity to its water content. contained a different amount of salt dissolved in the

The adsorption isotherms were obtained by plac- water phase of the mud and therefore had a different

ing clean, dried drilled chips in desiccators having water activity. The activity value of. the mud was

controlled activity atmospheres. The samples were obtained from standard tables. 6 The muds had a high-

weighed daily until they were in equilibrium with the temperature, high-pressure API fluid loss less than

atmosphere in the desiccator. The final sample weights 2 cc (all oil). The upper curve is for a mud whose

were then used to calculate the weight percent water water phase was essentially fresh water, and its water

adsorbed. Normally, 2 weeks were required to attain activity was 1.0. After 24 hours, the shale had experi-

complete equilibrium; however, 90 percent of equi- enced about 0.3 percent swelling in this mud. This

librium was usually attained in 1 day. A desorption curve demonstrates that the hard shale is capable of

isotherm was obtained in the same way, except that removing water from highly stable oil-continuous

the samples were first hydrated in a 98 percent relative fluids. As salt was added to the mud, the amount of

vapor pressure environment before they were placed swelling decreased after a given period of time. We

in the desiccators. The adsorption-desorption iso- found that when enough salt was added to the oil mud,

therms were then plotted as shown in Fig. 1. The the aqueous activity of the mud was nearly equal to

in-situ weight percent water of the shale was calcu- the aqueous activity of the shale, and there was no

lated from shale density data and then the estimated swelling. By adding too much salt, as reflected by the

activity of the shale was determined by the use of the bottom curve, it was possible to desorb water from

adsorption-desorption isotherms. the shale, but at a rate much slower than the adsorbed

The West Texas hard shale shown in Fig. 1 had rate. The swelling data of Fig. 2 indicate that to pre-

2.2 weight percent water; thus its average water vent swelling of this particular West Texas hard shale

activity is 0.75. the activity of the internal phase of the mud should

The laboratory tests for detennining the water be approximately 0.75 to 0.70.

1310 JOURNAL OF PETROLEUM TECHNOLOGY

A response similar to that in Fig. 2, was obtained be 0.14.

for all tested oil-continuous fluids that contain emulsi- Although the elongation of illltic shales is much

fied water. We also observed that the rate of swelling less than that of montmorillonite shales, illitic shales

was decreased by simply decreasing the amount of can develop as much swelling pressure as montmoril-

water in the oil mud. Fig. 3 shows linear swelling lonite shales if they are confined and their expansion

obtained after exposing the West Texas hard shale is prevented. An earlier publication2 presents swelling

to different oil muds for a period of 24 hours. These pressure data for such shales and shows that the swell-

data suggest that untreated, low-water-content muds ing pressures can be calculated provided the activity

probably allow longer drilling before shale problems of the water in the shale is known.

occur.

Swelling tests were also run on an offshore Louisi-

Design and Control of Balanced-Activity

ana soft shale. These tests (Fig. 4) show that swelling Oil-Continuous Muds

of this shale can be prevented by matching the activity Because of the differences among shales, balanced-

of the water in the shale with the activity of the water activity oil muds should be specifically designed for

in the mud. The upper curve was obtained with an oil each troublesome formation encountered. The basic

mud containing a total salinity of 65,000 ppm, a value objective in designing an oil-continuous mud for a

more than twice the salinity of the water in the shale. specific troublesome formation is to adjust the activity

At this salinity the oil mud's activity was 0.94. Swell- of the water phase of the mud so that the water is

ing still occurred and showed that to prevent shale essentially inert to the formation drilled; that is, so

swelling it is not enough simply to exceed shale water that there is no significant water transfer from the mud

salinities. to the formation. With restricted water transfer, the

A cross-plot of swelling at 24 hours vs water ac- formation experiences little swelling and remains

tivity suggested that no swelling would occur when competent while being drilled. This balance cannot

the mud had an activity of 0.75. The adsorption iso- be achieved if the activity of the water in the mud is

therm for this shale predicted its water activity to significantly greater or less than the activity of the

0.75.-------r---.,..--..--...---

o c~ 0 .80 t----- -~------+---------l

~

a:C

W::J

:(~

~V)

u..::J

00::J 0.90 r-----+----~-~-___l

D::

4 t---r----t---+---+--+--+----l--------+--~

-... ...

>-z

>z

-

u.I

~

~

t=o

Uu

0.95 EMULSION CONTAINS

~ 3 r------j-----+---+---+---+---+----l--~£J____l

<t • 35% SALTWATER

~

~

• 20% SALTWATER

~ 2 t---r----t------+---+--+~=---t--~---+-------J 1.00 ~_~_ _" - - _ - - - J . - _ - - - - J

~

~

DESORPTION

--.:

o 0.05 0.10 0.15 0.20

::.----

t----------+---+-~~--=-~=--------+- AD SORPTION - - - + - - - - - 1 LINEAR % SWELLING

AFTER 24 HOURS

Fig. 3-Swelling response, sal,ty oil muds.

0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 100

WATER ACTIVITY - Ow

0.5,-------y-------,..----....".--.........,

0.94

Fig. I-Sorption isotherm, West Texas hard shale.

ACTIVITY OF .INTERNAL PHASE

0.4r-------+------+--~'-----------1

0.4 r - - - - - - , - - - - - - - - - - - r - - - - - - - - ,

~

I 0.3 r - - - - - - - - - - t - - - - - - + - I - - - - - - - - J

~ 0.3 r------+-------+-----~

C)

Z

C) ACTIVITY OF INTERNAL PHASE :::i

Z 1.00 .....

LI.I 0.2

0.2

...

:::i

w

~

V)

0.80

S 0.91 ~

V)

~

0.1 0.88 «

LI.I

0.1

0.84 z

«

LLI 0.75 ~

z

::; 0 0

0.25 ______+-__ ~0.58

-OJ -0.1

.01 0.1 1.0 10 0.1 10 100

TIME - HOURS TIME - HOURS

fig. 2-Swelling-time curves, West Texas hard shale. Fig. 4-Swelling-time curves, offshore Louisiana soft shale.

OCTOBER, 1970 1311

water in the shale. developed to provide such measurements. Field re-

If several shales of different activities are exposed sults to date with early models have shown that on

in a given well, it is advisable to add enough salt to some wells it is possible to detect quickly the activity

balance the activity of the shale that has the lowest differences between mud and shale. On several

activity. In doing so, water will be removed from the troublesome wells the salinity of the mud was suc-

other shales. Fortunately, this "shrinking" of the shale cessfully adjusted) either higher or lower, and the

penetrated by the wellbore is a very slow process. If shale problems were readily eliminated. Sometimes

it is excessive, there is some indication that flaking of it is difficult to determine the in-situ water activity of

the wellbore will develop. the fornlation by direct measurement made on drilled

Unfortunately, it has not been possible to develop cuttings with the activity meters. This usually occurs

a simple relationship between water activity and when the cuttings are very small and are significantly

depth. It appears that since tectonic stresses and altered by the drilling mud before they reach the sur-

geologic history vary ·between fields, the activity of face. In such cases, the adsorption isotherm method

the water in the shale varies with location as well as may be used.

with depth. Activity meters have also proved useful for deter-

The procedures for obtaining a shale's in-situ water mining the activity of oil muds that contain several

activity are followed as outlined in the previous sec- different salts. Because of common ion effects, existing

tion. Once the adsorption isotherm is obtained, the methods for making such determinations are both

activity of the shale down hole is estimated by enter- cumbersome and time-consuming.

ing the plot with the down-hole or natural water con-

tent of the shale. This water content can be deter- Field Verification of Balanced

mined by using shale density measurements and the Mud Concept

formula About 25 wells have been drilled through 100,000 ft

of formation using balanced-activity oil-continuous

Weight percent water == Yma - Yb X 100, (4) muds. In all tests, gauge holes were produced. Maxi-

Yb (Yma - 1)

mum enlargements of lh in. were recorded and these

where Yma is grain specific gravity and Yb is bulk enlargements occurred in less than 5 percent of the

specific gravity. If no wellsite density measurements footage drilled. These balanced muds appear useful

are available, Fig. 5 can be used as an approximation. 7 for any type of shale. Following are field results for

After the activity of the water in the shale is deter- three different shales; a hard illitic shale found in West

mined, a salt is added to an oil-continuous mud until Texas, a hard shale found in South Louisiana, and

the activity of the water in the mud is equal to the soft shale found offshore Louisiana.

estimated activity of the water in the shale. Figs. 6

and 7 give the pounds of salt needed per barrel of West Texas Shale

mud per percent water in the oil mud. As shown in The West Texas shale occurs at a depth of 9,000 to

Fig. 6, the maximum effect that can be realized from 16,000 ft. It contains 57 percent quartz, 26 percent

saturated NaCI is a water activity of 0.75. With feldspar, 1 percent calcite and 2 percent dolomite,

CaCl2 (Fig. 7), it is possible to reduce the activity of with only illite (15 percent) and chlorite (5 percent)

the water in the mud to a value of about 0.32. clays present. The shale has been analyzed by X-ray

Early in this study, it was recognized that it would diffraction and no trace of montmorillonite clay has

be advantageous to monitor the activity values of the ever been observed. This absence is significant be-

shale and the mud daily at the wellsite. Several types cause previous theory assumed montmorillonite clay

of instruments (activity meters) are presently being to be the only clay capable of causing hole problems

by expansion. The shale was also found to contain

2.2 weight percent water with a total salinity of

20,000 ppm.

3.0 1.5

0 Using balanced-activity oil-continuous muds, five

1000

wells have been drilled through the shale with com-

plete shale stability. By contrast, one control well

2000 drilled earlier with a commercially available invert

3000 emulsion mud and one control well drilled with· a

~

LU RECENT TO lignosulfonate water-base mud had severe shale

LU

~ 4000 MIOCENE sloughing and hole problems. Results from these seven

::z::

~

a.

LU

Q

5000

6000 EOCENE

--I

--PLIOCENE TO LOWER-

wells show that balanced-activity oil-continuous muds

can stabilize holes drilled through troublesome, hard,

illitic shales.

MIOCENE

7000

8000 Control Well, Water-Base Mud. A lignosulfonate mud

9000 used to drill the control well illustrated problems ex-

perienced in the West Texas hard shale with water-

% POROSITY based muds. As the shale was penetrated, the walls of

2.7 GRAIN DENSITY ASSUMED the borehole caved in, producing a considerable

Fig. 5-Effect of age and depth on shale density, Dallmus. amount of fill. As shown in Fig. 8, these cavings were

1312 JOURNAL OF PETROLEUM TECHNOLOGY

9,000 rather large and angular. Such cavings must be drilled

into smaller pieces before they can be circulated out

of the borehole. Fig. 9 shows a bar graph of the

amount of fill recorded after each trip into the hole.

TOTAL FILL = 774FT At depths of 11,000 and 15,000 ft, more than 600 ft of

;: 10,000 fill was recorded. In this well the total section of shale

0. was 7,000 ft thick, and there was more than 7,000 ft

w

C of fill. A caliper log run after the hole was drilled

showed serious enlargements. Fig. 10 shows that at a

I depth of 10,500 ft the hole had enlarged from 9th

I in. to about 18 in.

11,000

o 200 400 600

Control Well, Commercial Invert Emulsion Mud. The

FEET OF FILL

use of water-base muds had demonstrated that the

Fig. II-Shale fill, oil-continuous mud. West Texas hard shale was water-sensitive. A com-

mercially available invert emulsion mud with a salinity

of 50,000 ppm CaCl2 was then used in an attempt to

control the shale. The amount of salt was considered

9,000

sufficient because the water in the shale had a salinity

of only 20,000 ppm.

>-----

10,000 The low-salinity invert emulsion mud was used to

drill from 9,000 to 11,000 ft. During drilling, there

11,000

was serious shale sloughing and the inve·rt mud was

I removed at 11,000 ft. Fig. 11 shows a bar graph of

I

fill that occurred while drilling with this mud. At about

1----

12,000 11,000 ft, more than 550 ft of fill was recorded, and

DEPTH - FT there were severe bit-sticking, high torque, and other

13,000 symptoms of an unstable wellbore. A caliper log

• showed that the section drilled with the invert mud

had severely washed out.

14,000

Wells Drllied with Balanced-Activity Oil-Continuous

• 15,000 Muds. More than 30,000 ft of gauge hole has been

TEST WELL 1 TEST WELL 2 drilled through the West Texas hard shale using bal-

TOTAL FILL

I

30 FT =I

TOTAL FILL = 21 FT

I I anced-activity oil-continuous muds. In each well, the

16,000

o 200 400 600 o 200 400 600 water phase of the oil-continuous mud, as dictated by

FEET OF FILL . FEET OF FILL laboratory tests, had about 270,000 ppm NaCI. The

activity of the mud was almost equal to the activity of

Fig. "I2-Shale fill, balanced-activity oil-continuous mUd.

the shale. During the drilling of these five wells there

were no hole problems associated with heaving shale.

On two occasions, material was easily fished from the

I I I i I I I I I I i I I I I I I I

9" 19" 9" 19"

.....- BIT SIZE - BIT SIZE Iii iii i i i I Iii iii i i i I

10,200' 8" .---BIT SIZE 19" 8" -BIT SIZE 19"

- 14,200'

--..... "

",.

!""'-

:: t=CALIPER "

t--

t--

t--

ECALIPER- I - - 1--1--

'" 10,250'

... 14,250'

- BIT RUN~;ff--;--+---+--+----+--+--+---+---l

AT 14,266' t---+-+-t--+--+---+--+--+--+-+---+---1

.......

... ,......""

.- 14,300'

10,300'

CONTROL WELL TEST WELL 1 CONTROL WELL TEST WELL 2

LlGNOSULFONATE BALANCED-ACTIVITY LlGNOSULFONATE BALAN CED-A CTIVITY

WATER-BASE MUD OIL-CONTINUOUS MUD WA TER-BASE MUD OIL-CONTINUOUS MUD

Fig. I3-Caliper logs, West Texas hard shale. Fig. I4-Caliper logs, West Texas hard shale.

1314 JOURNAL OF PETROLEUM TECHNOLOGY

LIGNOSULFONATE MUD OIL CONTINUOUS MUD BALANCED-ACTIVITY

OIL-CONTINUOUS MUD

8" 12" 16" SIt 9" 13" 5" 9" 13"

Iii iii iii DEPTH I i i i I Iii I DEPTH Iii iii iii

17,700' 17,700'

I

BIT SIZE ..... BIT SIZE -~ BIT SIZE - ..

= CAL PER ~

,

(HOLE SIZ~ ::i

~

........

-r_

\..

f

'\

~

-

17,750' 17,750' :: iF;CALIPER= --

r;;.. .... :-li CALIPER

,HOLE SIZ E)

= =(HOLE SIZE) -

......

17,800' 17,800'

Fig. 15~Caliper logs, South Louisiana hard shale.

hole because of its excellent condition. Fig. 12 shows soft shale, high in montmorillonite clay content, was

that there was negligible fill in Wells 1 and 2. Caliper encountered at a depth of about 3,200 ft in an offshore

logs from these wells and from the lignosulfonate con- Louisiana area. Attempts to drill this shale with a

trol well are shown in Figs. 13 and 14. Fig. 14 shows water-base mud resulted in severe clay swelling and

a 14-in. shift in the caliper log for Well 2 at a depth subsequent drilling difficulties. A balanced-activity

of 14,265 ft. Several other shifts were observed on oil-continuous mud was evenually used, which elimi-

this log, and in each case a new bit had been run at nated the shale swelling problem and enabled a gauge

the same depth as the shift. It is apparent that the borehole to be drilled.

wellbores are so smooth that 14 -in. variations due to Laboratory analysis showed this shale to consist of

worn bits are reflected on the caliper log. 15 percent quartz, 1 percent feldspar, 1 percent dolo-

Considerable drilling time was saved because of the mite, 38 percent illite, 35 percent montmorillonite,

elimination of rig time usually spentin drilling fill. and 10 percent kaolinite. The shale contained 11

Hazardous conditions such as stuck pipe and high weight percent water with a salinity of 30,000 ppm.

torque were eliminated. The liner for Well 2 was acci- Shale strength tests (Fig. 16) showed this shale to

dentally dropped 2,000 ft, then easily fished out of withstand a 400-psi stress differential under down-

the hole on the first try with no indications of being hole conditions. As water was added to the shale, its

stuck. strength rapidly fell to zero.

A caliper log obtained after the balanced-activity

South Louisiana Shale oil-continuous mud was used (Fig. 17) showed the

Serious washouts are often encountered in South Lou-

isianawhere water-base muds are used to drill trouble- 1000 ......-----.---~--..-------.---~-----,

some hard shale (see Well A, Fig. 15), which occurs 3500 PSI

between 17,000 and 19,000 ft. This shale contains

about 18 percent quartz, 5 percent feldspar, 1 percent c;; 800

~

calcite, 57 percent illite, and 18 percent chlorite. An

attempt was made to drill this formation with a com- :z:-

... ~v Pc

600

mercially available oil-continuous mud containing 5

percent fresh water in the internal phase. The hole

enlarged and shale cavings caused serious drilling

"

Zo

..... 0

~an

I

400

"'~

problems (see Well B, Fig. 15). A sidetrack was Q

...I

eventually set and the activity of the oil mud was ..... 3500 PSI

lowered to 0.75. A trouble-free hole and a gauge >= 200

caliper suggested that an adequate activity balance

had been achieved by saturating the water phase of the

mud with sodium chloride. 10 20 30 40 50 60

WEIGHT % WATER

Offshore Louisiana

Fig. 16--Strength-hydration relationship,

Severe drilling problems were experienced when a South Louisiana soft shale.

OCTOBER, 1970 1315

6" 10" 14" estimated by direct measurements on samples of the

I I I I I shale.

3. Water adsorption can be prevented by adjusting

BIT SIZE the activity of the water in the mud to the activity of

~CALIPER (HOLE SIZE)

the water in the shale.

4. Gauge boreholes can be drilled through both

hard and soft shale using balanced-activity oil-

continuous muds.

Acknowledgments

I should like to acknowledge the contributions of J. A.

Polasek and J. R. Scott of Esso Production Research

Co. for their assistance in the development of the

WATER-BASE

MUD USED

laboratory phase of this work.

t

SPECIAL OIL

CONTINUOUS

References

1. Mondshine, T. C. and Kercheville, J. D.: "Successful

Gumbo Shale Drilling", Oil and Gas J., March 28, 1966.

2. Chenevert, M. E.: "Shale Alteration by Water Adsorption",

J. Pet. Tech. (Sept., 1970) 1141-1147.

MUD USED 3. Chenevert, M. E., "Adsorptive Pore Pressures of Argillace-

ous Rocks", paper presented at Eleventh Symposium on

Rock Mechanics, Berkeley, Calif., June 16-19, 1969.

3350'- 4. Robinson, R. A. and Stokes, R. H.: Electrolyte Solutions,

2nd ed., Butterworths Scientific Publications, London

(1959) 25.

Fig. 17-Galiper log, offshore Louisiana soft shale.

5. Hubbert, M. K. and Willis, D. G.: "Mechanics of Hydrau-

lic Fracturing", Trans., AIME (1957) 210, 153-166.

hole to be enlarged above 3,300 ft where the water- 6. International Critical Tables, McGraw-Hill Book Co., Inc.,

base mud was used and to gauge for ·the rest of the New York (1933) 3, 297-300.

hole where the balanced oil mud was used. 7. Dallmus, K. F.: "Mechanics of Basic Evaluation and its

Relation to the Habitat of Oil in the Basin", Habitat of

Oil, AAPG (1958) 42,883-931. JPT

Conclusions

The following conclusions are based on extensive

Original manuscript received in Society of Petroleum Engineers

laboratory data and field results. office Sept. 28, 1969. Revised manuscript received May 30, 1970.

1. The main cause of shale instability for both soft Paper (SPE 2559) was presented at SPE 44th Annual Fall Meeting,

held in Denver, Colo., Sept. 28-0ct. 1, 1969. © Copyright 1970

and hard shales is water adsorption and subsequent American Institute of Mining, Metallurgical, and Petroleum Engi-

swelling of the wellbore. neers, Inc.

This paper will be printed in Transactions volume 249, which

2. The in-situ water activity of the shale can be will cover 1970.

1316 JOURNAL OF PETROLEUM TECHNOLOGY

You might also like

- How To Integrate Literacy and Numeracy Skills inDocument26 pagesHow To Integrate Literacy and Numeracy Skills inJudith Abogada92% (13)

- Drilling and Blasting of Rocks - CARLCIS LOPEZ JIMENODocument399 pagesDrilling and Blasting of Rocks - CARLCIS LOPEZ JIMENOKevin Adani100% (2)

- SPE-116364-Entrance Pressure of Oil Based Mud Into Shale Effect of Shale, WaterDocument19 pagesSPE-116364-Entrance Pressure of Oil Based Mud Into Shale Effect of Shale, WaterwjawichNo ratings yet

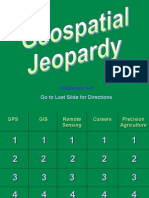

- Geospatial JeopardyDocument54 pagesGeospatial JeopardyrunnealsNo ratings yet

- Determination Formation RW Using Shale PropertiesDocument11 pagesDetermination Formation RW Using Shale PropertiesRosa K Chang HNo ratings yet

- ChapterDocument37 pagesChapterSamuel Mawutor GamorNo ratings yet

- Anderson, W. G. - Wettability Literature SurveyDocument97 pagesAnderson, W. G. - Wettability Literature SurveyMARCO100% (1)

- Wettability Literature Survey - Part 1 PDFDocument20 pagesWettability Literature Survey - Part 1 PDFaangelFINo ratings yet

- 3b - Interfacial Tension, Wettability and Capillary PressureDocument28 pages3b - Interfacial Tension, Wettability and Capillary PressureTHE TERMINATORNo ratings yet

- HHCapillary HysteresisDocument11 pagesHHCapillary Hysteresisahmed abdul razaqNo ratings yet

- SPE-1167-Wettability of Porous Rock by Amott, 1960)Document7 pagesSPE-1167-Wettability of Porous Rock by Amott, 1960)Murat SyzdykovNo ratings yet

- IMWA99 Noël & RitchieDocument12 pagesIMWA99 Noël & RitchieEduardo Alemany PerretNo ratings yet

- Special Core AnalysisDocument21 pagesSpecial Core AnalysisMuizzuddin Shidqi As-Sa'diNo ratings yet

- 1 s2.0 S0038080620319089 MainDocument16 pages1 s2.0 S0038080620319089 Maindiyah anarNo ratings yet

- Murtaza ReportDocument44 pagesMurtaza ReportGhulam MurtazaNo ratings yet

- Research ArticleDocument11 pagesResearch ArticlesifatNo ratings yet

- SPE 93000 Seawater As IOR Fluid in Fractured ChalkDocument10 pagesSPE 93000 Seawater As IOR Fluid in Fractured ChalkKonul AlizadehNo ratings yet

- Lop Report MIDSEMDocument7 pagesLop Report MIDSEMcrazyNo ratings yet

- Permeabilitas Relatif 3 FasaDocument10 pagesPermeabilitas Relatif 3 Fasawahyu kusumaNo ratings yet

- Shale: Prepared By: Wael El Essawy August, 1996Document8 pagesShale: Prepared By: Wael El Essawy August, 1996Ahmed ZeinNo ratings yet

- Nov Paper - 2016 - IIIDocument9 pagesNov Paper - 2016 - IIIVivek PatelNo ratings yet

- (2003) Wels C. & Robertson A. MacG. - Conceptual Model For Estimating Water Recovery in Tailings Impoundments PDFDocument8 pages(2003) Wels C. & Robertson A. MacG. - Conceptual Model For Estimating Water Recovery in Tailings Impoundments PDFLuis Miguel La TorreNo ratings yet

- Spe 693 GDocument8 pagesSpe 693 GKacha SmitNo ratings yet

- ResEngCh2 PDFDocument14 pagesResEngCh2 PDFriobmNo ratings yet

- Module 9: The Fresh Water/saltwater Interface and Groundwater ModelingDocument8 pagesModule 9: The Fresh Water/saltwater Interface and Groundwater ModelingDaniela Villacres MezaNo ratings yet

- Anderson 1Document20 pagesAnderson 1sadeq norooziNo ratings yet

- Otc 24470 MSDocument13 pagesOtc 24470 MSkpratik41No ratings yet

- SPWLA 2008 V49n1a2Document8 pagesSPWLA 2008 V49n1a2Shen YenNo ratings yet

- SPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionDocument13 pagesSPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionsouthliNo ratings yet

- Indian School of Mines, Dhanbad: Reservoir AssignmentDocument4 pagesIndian School of Mines, Dhanbad: Reservoir AssignmentUtkarsh AkashNo ratings yet

- Performance of RO Units at High TemperaturesDocument10 pagesPerformance of RO Units at High TemperaturesRoy JudeNo ratings yet

- Chemical Equilibrium Models: Their Use in Simulating The Injection of Incompatible WatersDocument7 pagesChemical Equilibrium Models: Their Use in Simulating The Injection of Incompatible WatersFarzad sadeghzadNo ratings yet

- Blight, 2003 Vadose Zone Soil-Water BalanceDocument10 pagesBlight, 2003 Vadose Zone Soil-Water BalanceSan DarNo ratings yet

- Fluid Pressure Gradients in Tight FormationsDocument16 pagesFluid Pressure Gradients in Tight FormationsvigneshNo ratings yet

- Strontium Sulfate Scale Control by Inhibitor Squeeze Treatment in The Fateh FieldDocument5 pagesStrontium Sulfate Scale Control by Inhibitor Squeeze Treatment in The Fateh FieldFarzad sadeghzadNo ratings yet

- Water Resources Research - 1997 - Wooding - Convection in Groundwater Below An Evaporating Salt Lake 1 Onset ofDocument19 pagesWater Resources Research - 1997 - Wooding - Convection in Groundwater Below An Evaporating Salt Lake 1 Onset ofhifan756No ratings yet

- Review of Rock Properties and Fluid FlowDocument16 pagesReview of Rock Properties and Fluid FlownijnebNo ratings yet

- Lecture Rock PropertiesDocument5 pagesLecture Rock PropertiesDavid Alfonso CaraballoNo ratings yet

- Early Water Breakthrough in Carbonate Core Samples Visualized With X-Ray CTDocument12 pagesEarly Water Breakthrough in Carbonate Core Samples Visualized With X-Ray CTRizki MuhamadNo ratings yet

- 11 GroundwaterDocument13 pages11 GroundwaterKaushal PatelNo ratings yet

- Losses From Precipitation: Module-2Document40 pagesLosses From Precipitation: Module-2rohitNo ratings yet

- Effect of Glauconite On Petrophysical Properties As Revealed by Core AnalysisDocument12 pagesEffect of Glauconite On Petrophysical Properties As Revealed by Core AnalysisanjumbukhariNo ratings yet

- Reservoir Sensitivity To Water Flooding: An Experimental Study of Seawater Injection in A North Sea Reservoir AnalogDocument20 pagesReservoir Sensitivity To Water Flooding: An Experimental Study of Seawater Injection in A North Sea Reservoir AnalogchirazNo ratings yet

- Wetting Wet T AbilityDocument383 pagesWetting Wet T AbilityAleksandar JovanovicNo ratings yet

- Determining The Capacities Slime-Thickening Tanks: Louis Meeting, SeptemberDocument24 pagesDetermining The Capacities Slime-Thickening Tanks: Louis Meeting, SeptemberMichel M.No ratings yet

- Flow-Assurance Challenges in Gas-Storage Schemes in Depleted ReservoirsDocument3 pagesFlow-Assurance Challenges in Gas-Storage Schemes in Depleted ReservoirsbibiNo ratings yet

- Ground Water Engineering Lecture NoteDocument168 pagesGround Water Engineering Lecture Notemahad mohamedNo ratings yet

- Pickell 1966Document7 pagesPickell 1966pavka789100% (1)

- Fluid-Physics-Module Experiments: Esa Special Publication No. 114Document11 pagesFluid-Physics-Module Experiments: Esa Special Publication No. 114semabayNo ratings yet

- GroundWater AssignmentDocument8 pagesGroundWater AssignmentYagami KirigayaNo ratings yet

- Comparison of Three Methods of Relative Permeability MeasurementDocument16 pagesComparison of Three Methods of Relative Permeability MeasurementRosa K Chang HNo ratings yet

- Water Influx ModelsDocument23 pagesWater Influx ModelsSajad FalahNo ratings yet

- Thought of The DayDocument54 pagesThought of The DayDarwin GaculaNo ratings yet

- Hydrogeology: HYDROGEOLOGY - Is A Subfield of Geology by Definition Specifically Ground WaterDocument10 pagesHydrogeology: HYDROGEOLOGY - Is A Subfield of Geology by Definition Specifically Ground Waterimran salarianNo ratings yet

- The Effect of Salts On The Rate of EvaporationDocument7 pagesThe Effect of Salts On The Rate of EvaporationBOOBOO100% (1)

- Pressure Transient Well Testing Encountered ComplexitiesDocument12 pagesPressure Transient Well Testing Encountered ComplexitiesBolsec14No ratings yet

- Chapter Six: Boundary Tension and Wettability WettabilityDocument24 pagesChapter Six: Boundary Tension and Wettability WettabilityAlimahmood BahraniNo ratings yet

- Reverse Osmosis: Sudhakar M RaoDocument4 pagesReverse Osmosis: Sudhakar M RaoIsabel Tacunan CastilloNo ratings yet

- Sca2014 008 PDFDocument12 pagesSca2014 008 PDFsaladinayubi1234No ratings yet

- Wettability of Reservoir RocksDocument12 pagesWettability of Reservoir RocksWassef MBNo ratings yet

- Wettability Laboratory Evaluation Under Reservoir Conditions: A ApparatusDocument12 pagesWettability Laboratory Evaluation Under Reservoir Conditions: A ApparatusRosa K Chang HNo ratings yet

- Troubleshooting Case Study: RADULKO Transport: CCNP TSHOOT: Maintaining and Troubleshooting IP NetworksDocument30 pagesTroubleshooting Case Study: RADULKO Transport: CCNP TSHOOT: Maintaining and Troubleshooting IP NetworksAustin SpillerNo ratings yet

- Transportation Asset Management GuideDocument140 pagesTransportation Asset Management GuideChewfy1100% (2)

- Quasi TurbineDocument29 pagesQuasi TurbineArun N MukundanNo ratings yet

- Chapter 2 Vectors and Two Dim Motion - Gen - Med - All SectionsDocument60 pagesChapter 2 Vectors and Two Dim Motion - Gen - Med - All Sectionsnader siamNo ratings yet

- IdeaPad 5 15ALC05 82LN00AKLMDocument2 pagesIdeaPad 5 15ALC05 82LN00AKLMChristian MendozaNo ratings yet

- 4 Elfospace sp14m001gb 04 - 1520073972076Document4 pages4 Elfospace sp14m001gb 04 - 1520073972076Justin ReyesNo ratings yet

- Derivative of Logarithmic and Exponential FunctionDocument3 pagesDerivative of Logarithmic and Exponential FunctionPrincessdy CocadizNo ratings yet

- OLGA Link User GuideDocument51 pagesOLGA Link User GuideekabudiartiNo ratings yet

- Practicum Narrative Report FormatDocument8 pagesPracticum Narrative Report FormatJC GAMINGNo ratings yet

- MScFE 620 DTSP - Compiled - Notes - M1 PDFDocument25 pagesMScFE 620 DTSP - Compiled - Notes - M1 PDFRocApplyNo ratings yet

- ApplicationDocument6 pagesApplicationRirih Arinta BautistaaNo ratings yet

- Hare OracleDocument82 pagesHare Oraclestuart billington100% (3)

- Term-2 - Grade 8 Social Science Mock Test-2Document4 pagesTerm-2 - Grade 8 Social Science Mock Test-2bhagatNo ratings yet

- Cálculus - Areas and Tangents PDFDocument599 pagesCálculus - Areas and Tangents PDFCristhian Jhiovany PerezNo ratings yet

- Design Change Request (DCR) : PT - Barata IndonesiaDocument1 pageDesign Change Request (DCR) : PT - Barata IndonesiaRhadityo Shakti BudimanNo ratings yet

- Gen Ed Prof Ed Answer Key For Self StudyDocument82 pagesGen Ed Prof Ed Answer Key For Self StudyAilene ReyesNo ratings yet

- Test Instruction For ParticipantsDocument2 pagesTest Instruction For ParticipantsAyushman DuttaNo ratings yet

- Is Homework A Noun or VerbDocument4 pagesIs Homework A Noun or Verbdvvscttif100% (1)

- Rock ExcavationDocument9 pagesRock ExcavationMohammad Hadoumi SaldanNo ratings yet

- Q02-Chem - 1023 - Final - ExamDocument5 pagesQ02-Chem - 1023 - Final - ExamRodríguez Rito AméricaNo ratings yet

- Tamil FinalDocument9 pagesTamil FinalVidyuth ThyagarajanNo ratings yet

- Eksistensi Prinsip Pencemar Membayar Dalam Sistem Penegakan Hukum AgrariaDocument21 pagesEksistensi Prinsip Pencemar Membayar Dalam Sistem Penegakan Hukum AgrariaDhisia VininsaNo ratings yet

- Design Practices in Design Thinking Kimbell 2009Document24 pagesDesign Practices in Design Thinking Kimbell 2009subirNo ratings yet

- (Worksheet 13.1) - (Power Sharing)Document5 pages(Worksheet 13.1) - (Power Sharing)DeepikaNo ratings yet

- Kwara State University, Malete: Course Lecturer: Dr. K.O OladosuDocument42 pagesKwara State University, Malete: Course Lecturer: Dr. K.O OladosuAkande HeritageNo ratings yet

- Dwnload Full Practical Research Planning and Design 11th Edition Leedy Test Bank PDFDocument35 pagesDwnload Full Practical Research Planning and Design 11th Edition Leedy Test Bank PDFtrepangenallagevx3co0100% (14)

- Cambridge IGCSE: PHYSICS 0625/32Document16 pagesCambridge IGCSE: PHYSICS 0625/32wongwahsengNo ratings yet