Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

139 viewsJsa Welding & Gas Cutting

Jsa Welding & Gas Cutting

Uploaded by

M M PRADHANThis document provides a job safety analysis for welding and gas cutting work. It outlines 8 steps for the work: 1) completing a general work permit, 2) conducting a hazard assessment and writing a job safety analysis, 3) creating a written work plan, 4) conducting job site preparation, 5) initial gas testing, 6) finalizing and issuing a hot work permit, 7) conducting a safety briefing, and 8) beginning the hot work while following controls. Personal protective equipment requirements are also listed, including hard hats, safety glasses, fire resistant clothing, welding hoods, gloves, and safety footwear.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- Becoming A Critical Thinker: A User-Friendly Manual, 6/eDocument35 pagesBecoming A Critical Thinker: A User-Friendly Manual, 6/emicklo36% (11)

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar Kashinath100% (1)

- Jsa Road BlockingDocument3 pagesJsa Road BlockingRam Krishna100% (1)

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 pagesR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNo ratings yet

- JSA OF Fabrication and Installation Work ApproviedDocument3 pagesJSA OF Fabrication and Installation Work Approviedsakthi venkatNo ratings yet

- Hotel Management System FinalDocument23 pagesHotel Management System Finalranahamid007100% (2)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- JSA #34 - N2 PurgingDocument1 pageJSA #34 - N2 PurgingHelza RahmanniaNo ratings yet

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- JSA Format Erection of Exchanger 903-E-01Document5 pagesJSA Format Erection of Exchanger 903-E-01sakthi venkatNo ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Tank ErectionDocument3 pagesTank ErectionPrasanth BharathNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Document4 pages09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- DCL (Logo) : Hand BookDocument16 pagesDCL (Logo) : Hand BookJahangir Sha100% (1)

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Risk Assessment-Lifting OperationsDocument5 pagesRisk Assessment-Lifting OperationsMuhammad Shahid IqbalNo ratings yet

- Work Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Document15 pagesWork Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Vinaye GopaulNo ratings yet

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 pagesJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Jsa of Solvent Filling in VarnishesDocument3 pagesJsa of Solvent Filling in VarnishesMuhammad AliNo ratings yet

- JSA Loading & UnloadingDocument2 pagesJSA Loading & UnloadingSodikinNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- JSA For Cleaning Boiler, SCR & ESP InternalDocument18 pagesJSA For Cleaning Boiler, SCR & ESP InternalThái Đạo Phạm LêNo ratings yet

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- Safety Plan HSDDocument110 pagesSafety Plan HSDvijayNo ratings yet

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SNo ratings yet

- Grating RemovalDocument1 pageGrating RemovalKishor KoshyNo ratings yet

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- Water Proofing JHA SummaryDocument1 pageWater Proofing JHA Summarysujith s pNo ratings yet

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- Fabrication Work Shop RADocument4 pagesFabrication Work Shop RASalah Abd Eldayem67% (3)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 pageRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo RajanNo ratings yet

- Jsa SKDocument10 pagesJsa SKTri SubaktiNo ratings yet

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahNo ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationD FiransyahNo ratings yet

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocument6 pagesSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaNo ratings yet

- JSA Hand ToolsDocument1 pageJSA Hand ToolsInoy dy hesusNo ratings yet

- Jsa For Dismantel of StructureDocument2 pagesJsa For Dismantel of StructureBaiju SinghNo ratings yet

- SSHEQ TBT Attendance SheetDocument1 pageSSHEQ TBT Attendance SheetjojoNo ratings yet

- Safety Signs On Construction SiteDocument1 pageSafety Signs On Construction SiteBëBå Wossen AssefaNo ratings yet

- Dyer JSA - Brazing CopperDocument2 pagesDyer JSA - Brazing Copperdawn yatesNo ratings yet

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- Jsa Insulation WorkDocument20 pagesJsa Insulation WorkazerNo ratings yet

- Course Outline Integral Calculus UwindsorDocument3 pagesCourse Outline Integral Calculus UwindsorNemanja DjordjevicNo ratings yet

- 13.PHI-Repport IEC 62368-1 - 2020Document164 pages13.PHI-Repport IEC 62368-1 - 2020Alex Ramadhan SabananyoNo ratings yet

- Blown Film ExtrusionDocument3 pagesBlown Film Extrusionchoirunissa setyaningrumNo ratings yet

- Softening-Point-Test OmedDocument12 pagesSoftening-Point-Test OmedOmar BokhareNo ratings yet

- Tunneling Brochure English 04Document7 pagesTunneling Brochure English 04xcvNo ratings yet

- 10th Part of GloryDocument44 pages10th Part of GloryBaljeetSinghKhosla100% (1)

- Order Letter Writing TipsDocument11 pagesOrder Letter Writing TipsFatimahNo ratings yet

- Visonic KP-140 PG2 User' S GuideDocument4 pagesVisonic KP-140 PG2 User' S GuideHome_SecurityNo ratings yet

- Properties of SteamDocument7 pagesProperties of SteamRavichandran GNo ratings yet

- Chapter 3Document23 pagesChapter 3Davith ChienNo ratings yet

- Groundwater Exploration With The Magnetic Resonance SoundingDocument9 pagesGroundwater Exploration With The Magnetic Resonance SoundingYoussef Waled MohamedNo ratings yet

- School TransportDocument2 pagesSchool Transport7B PRATYUSH JAKHARNo ratings yet

- Python Classes: ClassDocument24 pagesPython Classes: Classns0447496No ratings yet

- Berto's - G7f4pw+fe1Document1 pageBerto's - G7f4pw+fe1Thanh ThuanNo ratings yet

- DELEUZE Metcalf Repetition As Universality of The SingularDocument6 pagesDELEUZE Metcalf Repetition As Universality of The SingularGavin LeeNo ratings yet

- GM 1927-16a PWT Gear Commodity AuditDocument5 pagesGM 1927-16a PWT Gear Commodity AuditSergio BoillosNo ratings yet

- Dynamic ProgrammingDocument23 pagesDynamic ProgrammingHydroNo ratings yet

- Panasonic KX-T336 System Ref Vol 2 PDFDocument662 pagesPanasonic KX-T336 System Ref Vol 2 PDFdiki dikibulinNo ratings yet

- Advanced Bridge DesignDocument9 pagesAdvanced Bridge Designsurendra_pangaNo ratings yet

- Sunset and Sunrise TipsDocument4 pagesSunset and Sunrise TipsAvinash ReddyNo ratings yet

- Overview: Server Security PolicyDocument3 pagesOverview: Server Security PolicySanda NechiforNo ratings yet

- Feeder "Te" Rotary (Airlock) : ApplicationDocument5 pagesFeeder "Te" Rotary (Airlock) : ApplicationzementheadNo ratings yet

- GP 18-10-01Document30 pagesGP 18-10-01Anbarasan PerumalNo ratings yet

- PCW Guidelines For Developing and Implementing Gender Responsive Programs and Projects 1993Document51 pagesPCW Guidelines For Developing and Implementing Gender Responsive Programs and Projects 1993Randell ManjarresNo ratings yet

- Electrical Machine DesignDocument2 pagesElectrical Machine DesignAnonymous 1abQZINo ratings yet

- CAPE Applied Mathematics 2008 U1 P2 TTDocument9 pagesCAPE Applied Mathematics 2008 U1 P2 TTIdris SegulamNo ratings yet

- FAR-0004 Design and Test PDFDocument10 pagesFAR-0004 Design and Test PDFMSNo ratings yet

- Infrared Spectra and Bonding in Transition Metal Nitrosyl ComplexesDocument5 pagesInfrared Spectra and Bonding in Transition Metal Nitrosyl ComplexesSaurav PaulNo ratings yet

Jsa Welding & Gas Cutting

Jsa Welding & Gas Cutting

Uploaded by

M M PRADHAN0 ratings0% found this document useful (0 votes)

139 views3 pagesThis document provides a job safety analysis for welding and gas cutting work. It outlines 8 steps for the work: 1) completing a general work permit, 2) conducting a hazard assessment and writing a job safety analysis, 3) creating a written work plan, 4) conducting job site preparation, 5) initial gas testing, 6) finalizing and issuing a hot work permit, 7) conducting a safety briefing, and 8) beginning the hot work while following controls. Personal protective equipment requirements are also listed, including hard hats, safety glasses, fire resistant clothing, welding hoods, gloves, and safety footwear.

Original Description:

Original Title

JSA WELDING & GAS CUTTING.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a job safety analysis for welding and gas cutting work. It outlines 8 steps for the work: 1) completing a general work permit, 2) conducting a hazard assessment and writing a job safety analysis, 3) creating a written work plan, 4) conducting job site preparation, 5) initial gas testing, 6) finalizing and issuing a hot work permit, 7) conducting a safety briefing, and 8) beginning the hot work while following controls. Personal protective equipment requirements are also listed, including hard hats, safety glasses, fire resistant clothing, welding hoods, gloves, and safety footwear.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

139 views3 pagesJsa Welding & Gas Cutting

Jsa Welding & Gas Cutting

Uploaded by

M M PRADHANThis document provides a job safety analysis for welding and gas cutting work. It outlines 8 steps for the work: 1) completing a general work permit, 2) conducting a hazard assessment and writing a job safety analysis, 3) creating a written work plan, 4) conducting job site preparation, 5) initial gas testing, 6) finalizing and issuing a hot work permit, 7) conducting a safety briefing, and 8) beginning the hot work while following controls. Personal protective equipment requirements are also listed, including hard hats, safety glasses, fire resistant clothing, welding hoods, gloves, and safety footwear.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

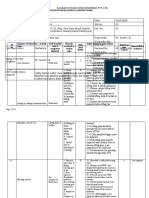

Job Safety Analysis

Control RRC/HSE/JS

Original Date: 10.09.2019

No: A

Organization: RR CONSTRUCTION

JSA NUMBER: MECH/001

Work Type: HOT WORK

Work Activity: WELDING & GAS

CUTTING

Specific Site: GENERAL

Personal Protective Equipment (PPE) Selected Comments

Hard Hat Y Required

Safety Glasses Y Required

Fire Resistant Clothing Y

Face Shields Y As required

Hearing Protection

Goggles Y As required

Lifeline/Body Harness

Air Purifying Respirator

Supplied Air Respirator - SCBA

Welding Hood Y

Welding/Pipe Clothing Y For welding jobs

Welding Mask/Goggles Y

Personal Floatation Device

Long sleeve shirt Y Local procedure

Gloves Y Leather

Other

Safety Cones/Barricades Y

Safety Vest Y

Knee Pads

Caution Tape Y

Back Belt/Support

Substantial leather footwear Y

Winter Clothing

Safety Footwear Y

Personal Gas Monitor

Long pants Y

Reviewers

PREPARED BY: DESIGNATION: SIGNATURE

ANJANAV ROY SAFETY OFFICER

JOB SEQUENCE

Sl. No Job Sequence Potential Hazard Critical Actions

High risk work

Complete Non-routine and/or periodic work Complete permit and implement

1

General Work Permit where approved work procedures controls required

do not exist

High risk work

Conduct hazard assessment Ensure qualified personnel

Non-routine and/or periodic work

2 & conduct hazard assessment &

where approved work procedures

write JSA(s) write JSA(s)

do not exist

High risk work Ensure plan describes in detail

Non-routine and/or periodic work the activities, tasks and sub-tasks

3 Create a written work plan

where approved work procedures required to complete a specific

do not exist scope of work

Ensure equipment to be worked

on is cleaned of all

flammable/combustible materials

Ensure combustible materials that

cannot be removed are covered

Conduct Job Site/Equipment

with flameproof material.

Preparation (e.g., isolation, Flammable vapors (% LFL)

Ensure oily surfaces and oil spills

depressurization, purging, Toxic gases/vapors

4 are rinsed and covered with at

flushing, sealing all drains, etc…) Oxygen deficient/enriched

least 25 mm of sand.

(separate JSA(s) may be required As determined during Step 2

Ensure trash, oily rags, grass,

to address specific job)

weeds, etc are removed.

Ensure pressure relief valves on

pipelines and vessels adjacent to

the work area are properly piped

or vented to the safe area.

Ensure gas testing performed in

surrounding area for a distance of

15 meters (50 feet)

Ensure LFL is 0%

Flammable vapors (% LFL)

Ensure no residues of

Toxic gases/vapors

5 Initial Gas Testing combustible liquids present.

Oxygen deficient/enriched

Ensure all potential areas are

As determined during Step 2

tested (e.g., adjacent to welded

seams, plates, etc…)

Determine follow-up gas testing

requirements

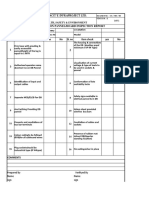

Ensure all identified requirements

Finalize & Issue and controls have been

6 As determined during Step 2

Hot Work Permit implemented before signing

permit

Ensure the following topics are

covered:

Scope of work

Conditions and requirements

Inadequate communication to all

7 Conduct Safety Briefing listed on permits and JSA(s).

personnel involved

Potential hazards and controls

Emergency response

requirements

Minimum PPE required

Wear proper PPE, including

welding helmet and respiratory

protection if applicable.

Ensure continuous gas testing

Begin Hot Work occurs, if required

Fire

(e.g., welding, cutting, etc.) Ensure fire extinguisher is readily

Flammable vapors (% LFL)

8 (separate JSA(s) may be required available

Toxic gases/vapors

to address specific job tasks Ensure fire watch is available, if

Oxygen deficiency

within this step) required

Ensure welding/cutting equipment

is in good working condition

Ensure barriers are set-up

contain any flying debris

May include but not limited to:

Change in scope of work Ensure Permit Issuer re-

Work Stoppages (permit

Change in entire work crew evaluates permit requirements

9 cancellations, extensions, and

Change in site conditions and controls if any work

revalidations)

Failure to conduct gas testing stoppages occur

Issue with permits

Job site not left in safe, clean,

and/or orderly condition Ensure Permit Issuer reviews job

Adequate time has elapsed for site prior to signing off on job

10

Work Completion the Fire Watch to verify condition Retain permits and supporting

of the job site documentation in accordance

Work performed does not meet with requirements

required scope and specifications

Assess any changing conditions,

such as weather, traffic etc

11

Update hazard and critical

actions

PREPARED BY: DESIGNATION: SIGNATURE

ANJANAV ROY SAFETY OFFICER

APPROVED BY: DESIGNATION: SIGNATURE

RAJSEKHAR PRADHAN CEO

You might also like

- Becoming A Critical Thinker: A User-Friendly Manual, 6/eDocument35 pagesBecoming A Critical Thinker: A User-Friendly Manual, 6/emicklo36% (11)

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar Kashinath100% (1)

- Jsa Road BlockingDocument3 pagesJsa Road BlockingRam Krishna100% (1)

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 pagesR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNo ratings yet

- JSA OF Fabrication and Installation Work ApproviedDocument3 pagesJSA OF Fabrication and Installation Work Approviedsakthi venkatNo ratings yet

- Hotel Management System FinalDocument23 pagesHotel Management System Finalranahamid007100% (2)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- JSA #34 - N2 PurgingDocument1 pageJSA #34 - N2 PurgingHelza RahmanniaNo ratings yet

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- JSA Format Erection of Exchanger 903-E-01Document5 pagesJSA Format Erection of Exchanger 903-E-01sakthi venkatNo ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Tank ErectionDocument3 pagesTank ErectionPrasanth BharathNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Document4 pages09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- DCL (Logo) : Hand BookDocument16 pagesDCL (Logo) : Hand BookJahangir Sha100% (1)

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Risk Assessment-Lifting OperationsDocument5 pagesRisk Assessment-Lifting OperationsMuhammad Shahid IqbalNo ratings yet

- Work Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Document15 pagesWork Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Vinaye GopaulNo ratings yet

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 pagesJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Jsa of Solvent Filling in VarnishesDocument3 pagesJsa of Solvent Filling in VarnishesMuhammad AliNo ratings yet

- JSA Loading & UnloadingDocument2 pagesJSA Loading & UnloadingSodikinNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- JSA For Cleaning Boiler, SCR & ESP InternalDocument18 pagesJSA For Cleaning Boiler, SCR & ESP InternalThái Đạo Phạm LêNo ratings yet

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- Safety Plan HSDDocument110 pagesSafety Plan HSDvijayNo ratings yet

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SNo ratings yet

- Grating RemovalDocument1 pageGrating RemovalKishor KoshyNo ratings yet

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- Water Proofing JHA SummaryDocument1 pageWater Proofing JHA Summarysujith s pNo ratings yet

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- Fabrication Work Shop RADocument4 pagesFabrication Work Shop RASalah Abd Eldayem67% (3)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 pageRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo RajanNo ratings yet

- Jsa SKDocument10 pagesJsa SKTri SubaktiNo ratings yet

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahNo ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationD FiransyahNo ratings yet

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocument6 pagesSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaNo ratings yet

- JSA Hand ToolsDocument1 pageJSA Hand ToolsInoy dy hesusNo ratings yet

- Jsa For Dismantel of StructureDocument2 pagesJsa For Dismantel of StructureBaiju SinghNo ratings yet

- SSHEQ TBT Attendance SheetDocument1 pageSSHEQ TBT Attendance SheetjojoNo ratings yet

- Safety Signs On Construction SiteDocument1 pageSafety Signs On Construction SiteBëBå Wossen AssefaNo ratings yet

- Dyer JSA - Brazing CopperDocument2 pagesDyer JSA - Brazing Copperdawn yatesNo ratings yet

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- Jsa Insulation WorkDocument20 pagesJsa Insulation WorkazerNo ratings yet

- Course Outline Integral Calculus UwindsorDocument3 pagesCourse Outline Integral Calculus UwindsorNemanja DjordjevicNo ratings yet

- 13.PHI-Repport IEC 62368-1 - 2020Document164 pages13.PHI-Repport IEC 62368-1 - 2020Alex Ramadhan SabananyoNo ratings yet

- Blown Film ExtrusionDocument3 pagesBlown Film Extrusionchoirunissa setyaningrumNo ratings yet

- Softening-Point-Test OmedDocument12 pagesSoftening-Point-Test OmedOmar BokhareNo ratings yet

- Tunneling Brochure English 04Document7 pagesTunneling Brochure English 04xcvNo ratings yet

- 10th Part of GloryDocument44 pages10th Part of GloryBaljeetSinghKhosla100% (1)

- Order Letter Writing TipsDocument11 pagesOrder Letter Writing TipsFatimahNo ratings yet

- Visonic KP-140 PG2 User' S GuideDocument4 pagesVisonic KP-140 PG2 User' S GuideHome_SecurityNo ratings yet

- Properties of SteamDocument7 pagesProperties of SteamRavichandran GNo ratings yet

- Chapter 3Document23 pagesChapter 3Davith ChienNo ratings yet

- Groundwater Exploration With The Magnetic Resonance SoundingDocument9 pagesGroundwater Exploration With The Magnetic Resonance SoundingYoussef Waled MohamedNo ratings yet

- School TransportDocument2 pagesSchool Transport7B PRATYUSH JAKHARNo ratings yet

- Python Classes: ClassDocument24 pagesPython Classes: Classns0447496No ratings yet

- Berto's - G7f4pw+fe1Document1 pageBerto's - G7f4pw+fe1Thanh ThuanNo ratings yet

- DELEUZE Metcalf Repetition As Universality of The SingularDocument6 pagesDELEUZE Metcalf Repetition As Universality of The SingularGavin LeeNo ratings yet

- GM 1927-16a PWT Gear Commodity AuditDocument5 pagesGM 1927-16a PWT Gear Commodity AuditSergio BoillosNo ratings yet

- Dynamic ProgrammingDocument23 pagesDynamic ProgrammingHydroNo ratings yet

- Panasonic KX-T336 System Ref Vol 2 PDFDocument662 pagesPanasonic KX-T336 System Ref Vol 2 PDFdiki dikibulinNo ratings yet

- Advanced Bridge DesignDocument9 pagesAdvanced Bridge Designsurendra_pangaNo ratings yet

- Sunset and Sunrise TipsDocument4 pagesSunset and Sunrise TipsAvinash ReddyNo ratings yet

- Overview: Server Security PolicyDocument3 pagesOverview: Server Security PolicySanda NechiforNo ratings yet

- Feeder "Te" Rotary (Airlock) : ApplicationDocument5 pagesFeeder "Te" Rotary (Airlock) : ApplicationzementheadNo ratings yet

- GP 18-10-01Document30 pagesGP 18-10-01Anbarasan PerumalNo ratings yet

- PCW Guidelines For Developing and Implementing Gender Responsive Programs and Projects 1993Document51 pagesPCW Guidelines For Developing and Implementing Gender Responsive Programs and Projects 1993Randell ManjarresNo ratings yet

- Electrical Machine DesignDocument2 pagesElectrical Machine DesignAnonymous 1abQZINo ratings yet

- CAPE Applied Mathematics 2008 U1 P2 TTDocument9 pagesCAPE Applied Mathematics 2008 U1 P2 TTIdris SegulamNo ratings yet

- FAR-0004 Design and Test PDFDocument10 pagesFAR-0004 Design and Test PDFMSNo ratings yet

- Infrared Spectra and Bonding in Transition Metal Nitrosyl ComplexesDocument5 pagesInfrared Spectra and Bonding in Transition Metal Nitrosyl ComplexesSaurav PaulNo ratings yet