Professional Documents

Culture Documents

SA 07.2 - SA 14.6 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 1-Phase AC Motors

SA 07.2 - SA 14.6 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 1-Phase AC Motors

Uploaded by

Luis Alberto Alzate CeballosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SA 07.2 - SA 14.6 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 1-Phase AC Motors

SA 07.2 - SA 14.6 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 1-Phase AC Motors

Uploaded by

Luis Alberto Alzate CeballosCopyright:

Available Formats

SA 07.2 – SA 14.

6

AUMA NORM

Technical data Multi-turn actuators for open-close duty with 1-phase AC motors

Type Speed rpm Torque range1) Valve attachment2) Handwheel Weight3)

S2-15 min Max. Ø

Min. Max. Standard Option rising. stem Ø Reduct. approx.

50 Hz 60 Hz [Nm] [Nm] EN ISO 5210 DIN 3210 [mm] [mm] ratio [kg]

4 4.8 11 : 1

5.6 6.7 8:1

8 9.6 11 : 1

F07 – 26 25

11 13 8:1

16 19 11 : 1

22 26 30 8:1

SA 07.2 32 38

10 160

11 : 1

45 54 8:1

63 75 11 : 1

F10 G0 34 28

90 108 8:1

125 150 5.5 : 1

180 216 25 4:1

4 4.8 11 : 1

5.6 6.7 8:1

8 9.6 11 : 1

F07 – 26 25

11 13 8:1

16 19 11 : 1

22 26 60 8:1

SA 07.6 20 160

32 38 11 : 1

28

45 54 8:1

63 75 11 : 1

F10 G0 34

90 108 8:1

37

125 150 5.5 : 1

180 216 50 4:1

4 4.8 11 : 1

28

5.6 6.7 8:1

8 9.6 11 : 1

11 13 8:1

31

16 19 11 : 1

22 26 120 8:1

SA 10.2 40 F10 G0 40 200

32 38 11 : 1

40

45 54 8:1

63 75 11 : 1

90 108 8:1

43

125 150 5.5 : 1

180 216 100 4 :1

4 4.8 11 : 1

5.6 6.7 8:1

59

8 9.6 11 : 1

11 13 8:1

SA 14.2 100 250 F14 G1/2 57 315

16 19 11 : 1

61

22 26 8:1

32 38 11 : 1

63

45 54 8:1

4 4.8 11 : 1

500

5.6 6.7 8:1

63

8 9.6 11 : 1

SA 14.6 200 F14 G1/2 57 400

11 13 8:1

400

16 19 11 : 1

66

22 26 8:1

General information

AUMA NORM multi-turn actuators require electric controls.

For sizes SA 07.2 – SA 14.6, AUMA offer AM or AC actuator controls. These can also easily be mounted to the actuator at a later date.

Notes on table

1) Torque range The tripping torque is adjustable for directions OPEN and CLOSE within the indicated torque range.

2) Valve attachment Indicated flange sizes apply for output drive types A and B1.

Refer to dimension sheets for further output drive types.

3) Weight Indicated weight includes for AUMA NORM multi-turn actuator with 1-phase AC motor, standard electrical

connection, output drive type B1 and handwheel.

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y005.281/003/en Issue 1.13 Page 1/3

SA 07.2 – SA 14.6

AUMA NORM

Technical data Multi-turn actuators for open-close duty with 1-phase AC motors

Features and functions

Type of duty Short-time duty S2 - 15 min

For nominal voltage and 40 °C ambient temperature and at average load with 35 % of the max. torque

Motors 1-phase AC motor, type IM B9 according to IEC 60034

Mains voltage, mains frequency Standard voltages:

1-phase AC current

voltages/frequencies

Volt 110 – 120 220 – 240 220 – 240

Hz 60 50 60

Permissible variation of mains voltage: ±10 %

Permissible variation of mains frequency: ±5 %

Overvoltage category Category III according to IEC 60364-4-443

Insulation class F, tropicalized

Motor protection Thermoswitches (NC)

Self-locking Self-locking: Output speeds up to 90 rpm (50 Hz) or 108 rpm (60 Hz)

NOT self-locking: Output speeds from 125 rpm (50 Hz) or 150 rpm (60 Hz)

Multi-turn actuators are self-locking, if the valve position cannot be changed from standstill while torque acts

upon the output drive.

Motor heater (option) Voltages: 110 – 120 V AC, 220 – 240 V AC or 400 V AC (externally supplied)

Power depending on the size 12.5 – 25 W

Manual operation Manual drive for setting and emergency operation, handwheel does not rotate during electrical operation

Option: Handwheel lockable

Indication for manual operation Indication whether manual operation is active/not active via single switch (1 change-over contact)

(option)

Electrical connection AUMA plug/socket connector with screw-type connection

Threads for cable entries Standard: Metric threads

Options: Pg-threads, NPT-threads, G-threads

Terminal plan TPA01R1AA-101-000

TPA02R1AA-101-000

TPA03R1AA-101-000

Depending on the motor type/output speed. Refer also to Electrical data SA 07.2 – SA 14.6 with 1-phase AC

motors.

Valve attachment Standard: B1 according to EN ISO 5210

Options: A, B2, B3, B4 according to EN ISO 5210

A, B, D, E according to DIN 3210

C according to DIN 3338

Special output drive types: AF, B3D, ED, DD, IB1, IB3

A prepared for permanent lubrication of stem

Electromechanical control unit

Limit switching Counter gear mechanism for end positions OPEN and CLOSED

Turns per stroke: 2 to 500 (standard) or 2 to 5,000 (option)

Standard: Single switches (1 NC and 1 NO) for each end position, not galvanically isolated

Options: Tandem switches (2 NC and 2 NO) for each end position, switches galvanically isolated

Triple switches (3 NC and 3 NO) for each end position, switches galvanically isolated

Intermediate position switch (DUO limit switching), adjustable for any position

Torque switching Torque switching adjustable for directions OPEN and CLOSE

Standard: Single switches (1 NC and 1 NO) for each direction, not galvanically isolated

Options: Tandem switches (2 NC and 2 NO) for each direction, switches galvanically isolated

Position feedback signal, analogue Potentiometer or 0/4 – 20 mA (RWG)

(options)

Mechanical position indicator Continuous indication, adjustable indicator disc with symbols OPEN and CLOSED

(option)

Running indication Blinker transmitter

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y005.281/003/en Issue 1.13 Page 2/3

SA 07.2 – SA 14.6

AUMA NORM

Technical data Multi-turn actuators for open-close duty with 1-phase AC motors

Heater in switch compartment Standard: Self-regulating PTC heater, 5 – 20 W, 110 – 250 V AC/DC

Options: 24 – 48 V AC/DC or 380 – 400 V AC

A resistance type heater of 5 W, 24 V AC is installed in the actuator in combination with AM or AC actuator

controls.

Electronic control unit (only in combination with AC actuator controls)

Non-intrusive setting (option) Magnetic limit and torque transmitter MWG

for 1 to 500 turns per stroke or

10 to 5,000 turns per stroke

Position feedback signal Via actuator controls

Torque feedback signal Via actuator controls

Mechanical position indicator Continuous indication, adjustable indicator disc with symbols OPEN and CLOSED

(option)

Running indication Blinking signal via controls

Heater in switch compartment Resistance type heater with 5 W, 24 V AC

Service conditions

Use Indoor and outdoor use permissible

Mounting position Any position

Installation altitude ≤ 2,000 m above sea level

> 2,000 m above sea level, please contact AUMA

Ambient temperature Standard: –40 °C to +80 °C

Options: –50 °C to +60 °C

Enclosure protection according to Standard: IP 68 with 1-phase AC motors of types AE..., VE..., AC..., VC...

EN 60529 For special motors differing enclosure protection: refer to name plate

Option: DS Terminal compartment additionally sealed against interior (double sealed)

According to AUMA definition, enclosure protection IP 68 meets the following requirements:

• Depth of water: maximum 8 m head of water

• Duration of continuous immersion in water: Max. 96 hours

• Up to 10 operations during continuous immersion

Pollution degree Pollution degree 4 (when closed) according to EN 50178

Corrosion protection Standard: KS Suitable for installation in industrial units, in water or power plants with a low pollut-

ant concentration as well as for installation in occasionally or permanently aggressive

atmosphere with a moderate pollutant concentration (e.g. wastewater treatments

plants, chemical industry)

Options: KX Suitable for installation in extremely aggressive atmospheres with high humidity and

high pollutant concentration

Finish coating Powder paint

Two-component iron-mica combination

Colour Standard: AUMA silver-grey (similar to RAL 7037)

Option: Other colours are possible on request.

Lifetime AUMA multi-turn actuators meet or even exceed the lifetime requirements of EN 15714-2. Detailed informa-

tion can be provided on request.

Further information

EU Directives Electromagnetic Compatibility (EMC): (2004/108/EC)

Low Voltage Directive: (2006/95/EC)

Machinery Directive: (2006/42/EC)

Reference documents Product description Electric multi-turn actuators SA .2 with AM .1 and AC .2

Electrical data SA 07.2 – SA 14.6 with 1-phase AC motors

Technical data for switches

Technical data Electronic position transmitter/potentiometer

Technical data Output speeds, motors, reduction ratios and blinker transmitters

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y005.281/003/en Issue 1.13 Page 3/3

You might also like

- Troubleshooting Guide CDI ELECTRONICSDocument124 pagesTroubleshooting Guide CDI ELECTRONICSMišo Vučko100% (1)

- Lab 1 Pneumatic FullDocument22 pagesLab 1 Pneumatic Fullbella100% (12)

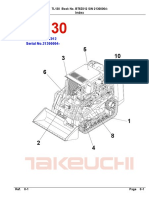

- Takeuchi Parts - Manual - TL130 - BT8Z012 (21300004 ) PDFDocument495 pagesTakeuchi Parts - Manual - TL130 - BT8Z012 (21300004 ) PDFGustavo100% (1)

- Saex 07.2 - Saex 16.2 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 3-Phase Ac MotorsDocument4 pagesSaex 07.2 - Saex 16.2 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 3-Phase Ac MotorsAndrzej BąkałaNo ratings yet

- SA 07.2 - SA 16.2 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 3-Phase AC MotorsDocument4 pagesSA 07.2 - SA 16.2 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 3-Phase AC Motorstoto.gmbhNo ratings yet

- Guide 4Document2 pagesGuide 4sgdgtfNo ratings yet

- TD Sa2 Uw 3ph enDocument4 pagesTD Sa2 Uw 3ph enbisondaniel3No ratings yet

- TD Sa2 1ph enDocument4 pagesTD Sa2 1ph enGerson OrtizNo ratings yet

- TD - Sa1 - 3ph - en - PDF (AUMA)Document4 pagesTD - Sa1 - 3ph - en - PDF (AUMA)andy175No ratings yet

- Technical Data Multi-Turn Actuators For Open-Close Duty With 1-Phase AC Motors SA 07.1 - SA 14.5 Auma NormDocument3 pagesTechnical Data Multi-Turn Actuators For Open-Close Duty With 1-Phase AC Motors SA 07.1 - SA 14.5 Auma NormHairulIzhamIshakNo ratings yet

- Technical Data Auma Multi-Turn Actuators For Open-Close Duty With 3-Phase Ac Motors Saexc 07.1 - Saexc 16.1 Auma NormDocument3 pagesTechnical Data Auma Multi-Turn Actuators For Open-Close Duty With 3-Phase Ac Motors Saexc 07.1 - Saexc 16.1 Auma NormDinesh ChouguleNo ratings yet

- SA 07.2 - SA 16.2 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 3-Phase AC MotorsDocument4 pagesSA 07.2 - SA 16.2 Auma Norm: Technical Data Multi-Turn Actuators For Open-Close Duty With 3-Phase AC MotorscvfNo ratings yet

- TD Sar2 1ph enDocument4 pagesTD Sar2 1ph enQ Llanos HenryNo ratings yet

- Micronics PFD550Manual SeriDocument3 pagesMicronics PFD550Manual SeriQ Llanos HenryNo ratings yet

- SA 07.2 - 14.6 Actuador Eléctrico Multivueltas MonofásicoDocument4 pagesSA 07.2 - 14.6 Actuador Eléctrico Multivueltas Monofásicoraphael31No ratings yet

- TD Sar2 3ph enDocument4 pagesTD Sar2 3ph enQ Llanos HenryNo ratings yet

- TD Sar2 Uw 3ph enDocument3 pagesTD Sar2 Uw 3ph enkd3.oriwaveNo ratings yet

- Auma Control ValveDocument3 pagesAuma Control ValveIebe SeventynineNo ratings yet

- Estimasi Daya ListrikDocument1 pageEstimasi Daya Listrikyahya nurhidayatNo ratings yet

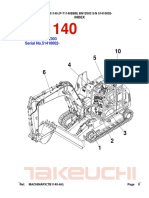

- Parts Manual TB53FR BJ1Z006Document531 pagesParts Manual TB53FR BJ1Z006Srdjan NikolicNo ratings yet

- M Vs MLDocument1 pageM Vs MLAlan GrajedaNo ratings yet

- Parts Manual Tb1140 Bn1z003 (m28-m29)Document471 pagesParts Manual Tb1140 Bn1z003 (m28-m29)Juan Antonio Cano DiazNo ratings yet

- 3127 DatasheetDocument30 pages3127 DatasheetJose David Vanegas Acero100% (3)

- Parts Manual TL150 BT7Z011 (21500004)Document621 pagesParts Manual TL150 BT7Z011 (21500004)HitachiNo ratings yet

- Potongan JuniDocument2 pagesPotongan JuniFauzan AnwariNo ratings yet

- 5Document1 page5phengNo ratings yet

- SQ 05.2 - SQ 14.2 Auma Norm: Technical Data Part-Turn Actuators For Open-Close Duty With 3-Phase AC MotorsDocument3 pagesSQ 05.2 - SQ 14.2 Auma Norm: Technical Data Part-Turn Actuators For Open-Close Duty With 3-Phase AC MotorsLASCARZAMFIRESCUNo ratings yet

- Lab 9 - 10Document12 pagesLab 9 - 10The Alien StationNo ratings yet

- JY038196 JY038196: PC400LC-7 PC400LC-7 S/N S/N 50001-UP 50001-UP (Overseas (Overseas Version) Version)Document1 pageJY038196 JY038196: PC400LC-7 PC400LC-7 S/N S/N 50001-UP 50001-UP (Overseas (Overseas Version) Version)theunauthorisedNo ratings yet

- TB153FRDocument405 pagesTB153FRzaferzafer720No ratings yet

- Sqex 05.2 - Sqex 14.2 Auma Norm: Technical Data Part-Turn Actuators For Open-Close Duty With 1-Phase Ac MotorsDocument4 pagesSqex 05.2 - Sqex 14.2 Auma Norm: Technical Data Part-Turn Actuators For Open-Close Duty With 1-Phase Ac MotorsshaonaaNo ratings yet

- CPCB 1PC Ee483 Tci - 62.5kva TC-40 & 50 KvaDocument96 pagesCPCB 1PC Ee483 Tci - 62.5kva TC-40 & 50 Kvavikrant dalviNo ratings yet

- Performance Data p-100 EductorDocument1 pagePerformance Data p-100 EductorIonCube KhanzNo ratings yet

- Activity Time Estimates: A M B TDocument3 pagesActivity Time Estimates: A M B Tajeng.saraswatiNo ratings yet

- SQ 05.2 - SQ 14.2 Auma Norm: Technical Data Part-Turn Actuators For Open-Close Duty With 1-Phase AC MotorsDocument4 pagesSQ 05.2 - SQ 14.2 Auma Norm: Technical Data Part-Turn Actuators For Open-Close Duty With 1-Phase AC MotorsagrovadoNo ratings yet

- Coluna1 Coluna2 Coluna3Document12 pagesColuna1 Coluna2 Coluna3João PedroNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (13/14) (N0.1 Pump)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Pump (13/14) (N0.1 Pump)midalllllNo ratings yet

- TB153FR Parts Manual BJ2Z004Document389 pagesTB153FR Parts Manual BJ2Z004alfonso.tabuencaNo ratings yet

- Instalaciones ElectricasDocument2 pagesInstalaciones ElectricasDiego SanchezNo ratings yet

- Audio Transformer/Moving Coil Input Transformer LL9206Document2 pagesAudio Transformer/Moving Coil Input Transformer LL9206Pino Giuseppe GraccioneNo ratings yet

- Products Bag Dimension (MM) No. A B C L4 Indah Paper Bag Volume (m3)Document3 pagesProducts Bag Dimension (MM) No. A B C L4 Indah Paper Bag Volume (m3)juanNo ratings yet

- Zener Diode-Load RegulatorDocument1 pageZener Diode-Load Regulator2K20CEEE23 Nishi Kant KumarNo ratings yet

- Muon Decay ResponsesDocument3 pagesMuon Decay ResponsesDebayan BiswasNo ratings yet

- Zone W Zone W Zone W Zone 0 Zone 0Document10 pagesZone W Zone W Zone W Zone 0 Zone 0rsanjuanNo ratings yet

- Parts Manual TB175 BL7Z002 PDFDocument703 pagesParts Manual TB175 BL7Z002 PDFValeriy Valkovets100% (1)

- Pc800se-7-M1 S/N 40001-Up: Main Valve (5-Spool) (2/5)Document2 pagesPc800se-7-M1 S/N 40001-Up: Main Valve (5-Spool) (2/5)midalllNo ratings yet

- Curvas Pull-Out TestsDocument4 pagesCurvas Pull-Out TestsJoseAngelFernandezOrtegaNo ratings yet

- 9Document1 page9phengNo ratings yet

- W Retun SD Core With MKT Beta Beta Port SD PortDocument9 pagesW Retun SD Core With MKT Beta Beta Port SD Port13mayankNo ratings yet

- Anchor Bolt: Table J3.2 AISC ASD Table J3.2 AISC ASDDocument15 pagesAnchor Bolt: Table J3.2 AISC ASD Table J3.2 AISC ASDballisnothingNo ratings yet

- Experiment: Power Supply: Resistance, One Transistor, DC Voltmeter, Mili-Ammeter, Variable ResistorDocument3 pagesExperiment: Power Supply: Resistance, One Transistor, DC Voltmeter, Mili-Ammeter, Variable ResistorPradeep RapireddyNo ratings yet

- NKIS04-R06 V01 UBT-T UBT-S 7-8GHzDocument24 pagesNKIS04-R06 V01 UBT-T UBT-S 7-8GHzMANUEL PLAZA JIMENEZNo ratings yet

- LEE Manual LT17 - EXTDocument4 pagesLEE Manual LT17 - EXTZoran PilipovićNo ratings yet

- Plant Size Cash Outlay Demand Prob. NCF Encf Years 1 - 10: Case 12.2: Weston Plastics CompanyDocument2 pagesPlant Size Cash Outlay Demand Prob. NCF Encf Years 1 - 10: Case 12.2: Weston Plastics CompanyMukul KadyanNo ratings yet

- TL14 - BT9Z009 2Document475 pagesTL14 - BT9Z009 2Max Sashikhin100% (1)

- Merak-Pj1: This Catalog Gives The Numbers and Names of Parts On This MachineDocument12 pagesMerak-Pj1: This Catalog Gives The Numbers and Names of Parts On This Machinewilliam lozadaNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (12/14) (N0.1 Pump)Document1 pagePc800se-7-M1 S/N 40001-Up: Main Pump (12/14) (N0.1 Pump)midalllllNo ratings yet

- Lab 2Document7 pagesLab 2Exon PingoNo ratings yet

- SPC Data Sheet: X-Bar ChartDocument1 pageSPC Data Sheet: X-Bar Chartkaran singhNo ratings yet

- Volvo v70 Xc70 Xc90 2003 Wiring DiagramDocument20 pagesVolvo v70 Xc70 Xc90 2003 Wiring Diagramjoseph100% (62)

- ) 1972 GE SCR Manual 5ed PDFDocument712 pages) 1972 GE SCR Manual 5ed PDFabrap_dNo ratings yet

- Density Based Traffic Light Control SystemDocument22 pagesDensity Based Traffic Light Control Systemఉమామహేశ్వర్ పబ్బతి91% (11)

- Excellent Module No 2 CoompleteDocument38 pagesExcellent Module No 2 CoompleteVaibhav Vithoba NaikNo ratings yet

- Assembly DrawingDocument4 pagesAssembly DrawingDwiNovriadiNo ratings yet

- 5 - Power TweaksDocument9 pages5 - Power TweaksLucas100% (1)

- MidD - APS 1500A-230 SolutionsDocument25 pagesMidD - APS 1500A-230 SolutionsJoseric21No ratings yet

- Huong Dan Su Dung Tieng VietDocument1 pageHuong Dan Su Dung Tieng VietĐình ThôngNo ratings yet

- Acmepacket4500 InstallationDocument112 pagesAcmepacket4500 InstallationfujiNo ratings yet

- 118 PlotDocument7 pages118 PlotMuhammad UsamaNo ratings yet

- Bay Control & Monitoring System: Digital EnergyDocument535 pagesBay Control & Monitoring System: Digital EnergyBurak ÖzsoyluNo ratings yet

- Kte-1000baDocument6 pagesKte-1000baheroeNo ratings yet

- Pengembangan Produk Dan Komponen Otomotif - Materi4.perkembangan-Teknologi-OtomotifDocument63 pagesPengembangan Produk Dan Komponen Otomotif - Materi4.perkembangan-Teknologi-OtomotifAldi FudholiNo ratings yet

- Parker Sporlan Refrigeration & Air Conditioning Catalogue 2015Document320 pagesParker Sporlan Refrigeration & Air Conditioning Catalogue 2015Hnin PwintNo ratings yet

- M Tec Mono Mix EnglishDocument4 pagesM Tec Mono Mix EnglishjoseleonardonarvaezNo ratings yet

- Hyundai Electronics America HY6264A-I 8K X 8bit Cmos Sram Ratings InformationDocument6 pagesHyundai Electronics America HY6264A-I 8K X 8bit Cmos Sram Ratings InformationasdasdNo ratings yet

- Nec 10 11 12Document9 pagesNec 10 11 12Marie Grace DollentasNo ratings yet

- CrsemihermeticcompressorDocument75 pagesCrsemihermeticcompressorworawan nuanpleanNo ratings yet

- Vostro 3710 Service Manual en UsDocument71 pagesVostro 3710 Service Manual en Usgeorgemarina_roNo ratings yet

- Jenbacher: DisassemblyDocument4 pagesJenbacher: DisassemblyArîfNo ratings yet

- Libble EuDocument13 pagesLibble EuVasile SilvioNo ratings yet

- Magnetic BearingDocument19 pagesMagnetic BearingMamesh MathankarNo ratings yet

- ISD1760 Voice Recording and Playback ModuleDocument3 pagesISD1760 Voice Recording and Playback ModuleSethu BaalajiNo ratings yet

- ASP STERRAD 100NX SterilizerDocument2 pagesASP STERRAD 100NX SterilizerJohn Errol CabuhatNo ratings yet

- 5 - Disassembly Instructions: CCS Technical Documentation RH-12/RH-28 Series TransceiversDocument8 pages5 - Disassembly Instructions: CCS Technical Documentation RH-12/RH-28 Series TransceiverstytydumyNo ratings yet

- NOVATECH Beacons & Flashers: Operation and Maintenance ManualDocument8 pagesNOVATECH Beacons & Flashers: Operation and Maintenance ManualIRVING FRANCISCO CAMAS SARAONo ratings yet

- CVV CableDocument7 pagesCVV CableNopNo ratings yet

- Mustang Evo 3 Engine ManualDocument8 pagesMustang Evo 3 Engine ManualFernando VasquezNo ratings yet