Professional Documents

Culture Documents

K-71TM K-71TLF KX-200H: Tubular Wires Mild Steel

K-71TM K-71TLF KX-200H: Tubular Wires Mild Steel

Uploaded by

IrinaCopyright:

Available Formats

You might also like

- API 580 TrainingDocument168 pagesAPI 580 Trainingfaheem khan100% (21)

- S T A N D A R D: Finishing Protective Paint of Metallic Parts Composing BusDocument11 pagesS T A N D A R D: Finishing Protective Paint of Metallic Parts Composing Busevren meral100% (1)

- Duplex Coatings Over HDG-Researchgate ReportDocument19 pagesDuplex Coatings Over HDG-Researchgate ReportRyanNo ratings yet

- Covered Electrodes: Mild Steel High Tensile Steel Low Hydrogen Steel Stainless SteelDocument42 pagesCovered Electrodes: Mild Steel High Tensile Steel Low Hydrogen Steel Stainless SteelChainarong ArunchaiwatNo ratings yet

- Low Alloy13Document5 pagesLow Alloy13Branko FerenčakNo ratings yet

- Solliid WiireDocument6 pagesSolliid WiireVõĐìnhKhaNo ratings yet

- 4 E308 Sus FcawDocument1 page4 E308 Sus FcawMohd Farid OsmanNo ratings yet

- Filler Wire For Gtaw PDFDocument27 pagesFiller Wire For Gtaw PDFrezaNo ratings yet

- Welding Electrode PDFDocument1 pageWelding Electrode PDFBijaya RaulaNo ratings yet

- Esab 6013 PDFDocument1 pageEsab 6013 PDFBijaya RaulaNo ratings yet

- Industrial Diaphragm Valves: SaundersDocument14 pagesIndustrial Diaphragm Valves: SaundersscribdkhatnNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Welding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RiboDocument51 pagesWelding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RibojswldeepNo ratings yet

- Diamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsDocument2 pagesDiamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsRMNo ratings yet

- Prorod Spec SheetDocument2 pagesProrod Spec SheetBala SingamNo ratings yet

- Ultramag Sg3: Mild Steel Solid WireDocument1 pageUltramag Sg3: Mild Steel Solid Wireabidaliabid1No ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- COR-1076C Coreweld Brochure 141118Document28 pagesCOR-1076C Coreweld Brochure 141118Thanh TamNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Metrode Supercore 2205P: Welding Consumables Stainless SteelDocument2 pagesMetrode Supercore 2205P: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- Bohler-Welding-Germany 26Document1 pageBohler-Welding-Germany 26misthahNo ratings yet

- Professional Rolls (Ring) supplier 、Document20 pagesProfessional Rolls (Ring) supplier 、JohnNo ratings yet

- Carbide ToolingDocument90 pagesCarbide ToolingHuron Industrial SupplyNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Indian Institute of Welding - ANB Refresher Course - Module 08Document47 pagesIndian Institute of Welding - ANB Refresher Course - Module 08dayalramNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- BW FOX+EV+Pipe EN 2019 GL 232 PreviewDocument2 pagesBW FOX+EV+Pipe EN 2019 GL 232 Previewtan yahyaNo ratings yet

- Jindal Saw LTD - SeamlessDocument30 pagesJindal Saw LTD - SeamlessRajat Chhabra0% (1)

- Phoenix 7018 Phoenix 6013Document1 pagePhoenix 7018 Phoenix 6013Pedro SilvaNo ratings yet

- Material Data Sheet: Casting Material: Stainless Steel CF8MDocument9 pagesMaterial Data Sheet: Casting Material: Stainless Steel CF8MakshayNo ratings yet

- PDS - Bohler N ER 70 S-2 NACE PDFDocument1 pagePDS - Bohler N ER 70 S-2 NACE PDFwesley59No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- AISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1PrasadNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- PNA282 - C51900 - CuSn6 - PB103 - Technical Data SheetDocument2 pagesPNA282 - C51900 - CuSn6 - PB103 - Technical Data Sheetstrip1No ratings yet

- Ancon Stainless Steel Reinforcement Round Bars Australia EditionDocument12 pagesAncon Stainless Steel Reinforcement Round Bars Australia EditionBrad MannNo ratings yet

- Pr01, Pr02, Pr03: Vishay BccomponentsDocument19 pagesPr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaNo ratings yet

- sdg4 - 9 - STAINLESS STEELDocument3 pagessdg4 - 9 - STAINLESS STEELJian Ming WongNo ratings yet

- Sandvik 2RE69: Austenitic Stainless SteelDocument4 pagesSandvik 2RE69: Austenitic Stainless SteelalexmontellNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Mpi BrochureDocument6 pagesMpi BrochureStephen MalobaNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- Karakteristik Kawat LasDocument36 pagesKarakteristik Kawat LasKen RanggaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Ok Tubrod 14.30a PDFDocument1 pageOk Tubrod 14.30a PDFqaNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- AISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1diego AlvarezNo ratings yet

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- Weld Wire SpecDocument2 pagesWeld Wire SpecRajaSekarsajjaNo ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- 1.bharat Group IndiaDocument42 pages1.bharat Group Indiabharat.birjuNo ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Product Data Sheet - OK Tigrod 13.09 PDFDocument2 pagesProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuNo ratings yet

- Bohler Ti 52Document1 pageBohler Ti 52Anonymous nKOyHbNo ratings yet

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANNo ratings yet

- Metro and Tunnel Axial Fans For Fresh and Exhaust AirDocument16 pagesMetro and Tunnel Axial Fans For Fresh and Exhaust AirIrinaNo ratings yet

- Inspection of The Hot Dipped Galvanizing ProcessDocument5 pagesInspection of The Hot Dipped Galvanizing ProcessIrinaNo ratings yet

- Design of A Modern Subway Ventilation System: December 2004Document5 pagesDesign of A Modern Subway Ventilation System: December 2004IrinaNo ratings yet

- Tunnel and Metro VentilationDocument16 pagesTunnel and Metro VentilationIrinaNo ratings yet

- Stainless Steel Guide Apr19 PDFDocument151 pagesStainless Steel Guide Apr19 PDFIrinaNo ratings yet

- Api 510, Pressure Vessel Inspector Certification ExaminationDocument62 pagesApi 510, Pressure Vessel Inspector Certification ExaminationIrinaNo ratings yet

- September 10, 1999 07:26:45 Information Handling Services, 1999Document221 pagesSeptember 10, 1999 07:26:45 Information Handling Services, 1999IrinaNo ratings yet

- AmurchikDocument10 pagesAmurchikIrinaNo ratings yet

- Sys Brochure En-FullDocument44 pagesSys Brochure En-FullAndy ChristyonoNo ratings yet

- Amnd No 2 IS 6911Document16 pagesAmnd No 2 IS 6911Rakesh Soti (JSHL-QUALITY)No ratings yet

- Stainless Steel: Tables of Technical Properties: Materials and Applications Series, Volume 5Document24 pagesStainless Steel: Tables of Technical Properties: Materials and Applications Series, Volume 5process processNo ratings yet

- Btech Me 3 Sem Material Science Nme301 2020Document1 pageBtech Me 3 Sem Material Science Nme301 2020Rajulapati Sunil KumarNo ratings yet

- Is 2062Document12 pagesIs 2062ANTONYLEONo ratings yet

- Asme P NumberDocument4 pagesAsme P NumberTanveer Rajput EngrNo ratings yet

- Technical Report April 8 2014 PDFDocument117 pagesTechnical Report April 8 2014 PDFBelen TapiaNo ratings yet

- Workshop Practice Series 09 Soldering and BrazingDocument68 pagesWorkshop Practice Series 09 Soldering and BrazingAnand sNo ratings yet

- Aluminium Flat BarDocument3 pagesAluminium Flat BarjenishjsNo ratings yet

- Concept Checks SolutionsDocument8 pagesConcept Checks SolutionsTolstoy Leo0% (1)

- 27 AprvdSawDocument19 pages27 AprvdSawMarleneLopesNo ratings yet

- S.G IronDocument6 pagesS.G IronQasim BarkatNo ratings yet

- 1) State-Of-The-Art of Surface Integrity Induced by Tool Wear EffectsDocument32 pages1) State-Of-The-Art of Surface Integrity Induced by Tool Wear Effectsnishanth124acharyaNo ratings yet

- MCQ Phase DiagramsDocument3 pagesMCQ Phase DiagramsPrince AbhishekNo ratings yet

- ISOPE-I-11-533 Forgings For Low Temperature Applications - Influences of The Alloying Concept and Advanced Forging Procedures On Impact Strength and Fracture Toughness PDFDocument7 pagesISOPE-I-11-533 Forgings For Low Temperature Applications - Influences of The Alloying Concept and Advanced Forging Procedures On Impact Strength and Fracture Toughness PDFmarcos2dami2o2de2azeNo ratings yet

- SDA DirectoryDocument56 pagesSDA Directorypiv.hpNo ratings yet

- Perfect Abrasive Products Faridabad, Haryana: Welcome TODocument14 pagesPerfect Abrasive Products Faridabad, Haryana: Welcome TOSanjay BhasinNo ratings yet

- Deep Drawing Process: A Brief Overview: September 2015Document6 pagesDeep Drawing Process: A Brief Overview: September 2015novkovic1984No ratings yet

- NSSMC SuperDyma PDFDocument36 pagesNSSMC SuperDyma PDFDesign RiconsNo ratings yet

- Strengthening MechanismsDocument2 pagesStrengthening MechanismsMohamedAliNo ratings yet

- Ismail 2016 IOP Conf. Ser. Mater. Sci. Eng. 114 012108Document10 pagesIsmail 2016 IOP Conf. Ser. Mater. Sci. Eng. 114 012108Paviter SinghNo ratings yet

- Preheat Temperature Table For Different Materials in WeldingDocument1 pagePreheat Temperature Table For Different Materials in WeldingRakesh Soni0% (1)

- International Journal of Mineral ProcessingDocument19 pagesInternational Journal of Mineral ProcessingHolmes's ApprenticeNo ratings yet

- Esab Welding Filler Metal Handbook 2016 2017 PDFDocument556 pagesEsab Welding Filler Metal Handbook 2016 2017 PDFvano4906100% (2)

- NewDocument2 pagesNewBashar ToshtashNo ratings yet

- Steel, Strip, High-Carbon, Cold-Rolled: Standard Specification ForDocument4 pagesSteel, Strip, High-Carbon, Cold-Rolled: Standard Specification ForsanthakumarNo ratings yet

- Intergranular Pitting Corrosion of Cocrmo Biomedical Implant AlloyDocument10 pagesIntergranular Pitting Corrosion of Cocrmo Biomedical Implant AlloyshameekaNo ratings yet

- Class 8 Metals NewDocument3 pagesClass 8 Metals Newsidsingh2802No ratings yet

- ULO2b MetalsDocument11 pagesULO2b MetalsCHARLIE AMOGUIS JRNo ratings yet

K-71TM K-71TLF KX-200H: Tubular Wires Mild Steel

K-71TM K-71TLF KX-200H: Tubular Wires Mild Steel

Uploaded by

IrinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K-71TM K-71TLF KX-200H: Tubular Wires Mild Steel

K-71TM K-71TLF KX-200H: Tubular Wires Mild Steel

Uploaded by

IrinaCopyright:

Available Formats

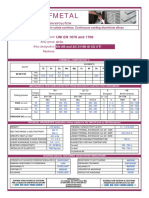

Tubular Wires Mild Steel

AWS E70T-1C/1M, 9C/9M AWS E71T-1/-1M AWS E71T-1M

KX-200H K-71TLF K-71TM

Designed for welding of 70,000 psi Formulated for welding of 71 ksi high Designed for welding of 71 ksi high

Applications

tensile steel with outstanding tensile steel with outstanding tensile steel with only Ar/C02 mixtures.

Typical

mechanical properties. Typical mechanical properties. Typical Typical applications include machinery,

applications include machinery, applications include machinery, shipbuilding, offshore structures,

shipbuilding, offshore structures, shipbuilding, offshore structures, bridges and general fabrications.

bridges and general fabrication. bridges and general fabrications.

Characteristics

1. Designed for flat and horizontal 1. Titania type for all-position welding. 1. Titanic type for all-position welding.

position welding. 2. Low fume generation, good impact 2. It provides soft, smooth welding arc

Of Usage

2. Better CVN toughness at lower temp. strength at low temperatures. with less spatter levels.

3. Good porosity resistance and used 3. Stable arc, less spatter levels, better 3. Efficient welding with deposition

for fillet welding of inorganic zinc-primer

bead appearance. rates.

coated steels.

4. 100%C02 shielding gas should be 4. Ar+20-25%CO2 should be used.

4. For semi-automatic, automatic,

single- and multiple pass welding. used.

Composition

SG CO2 SG CO2 SG Ar+20 % CO2

Weld Metal

Carbon 0.037 % Carbon 0.03 % Carbon 0.03 %

Silicon 0.56 % Silicon 0.38 % Silicon 0.59 %

Manganese 1.60 % Manganese 1.35 % Manganese 1.44 %

Phosphorus 0.013 % Phosphorus 0.015 % Phosphorus 0.013 %

Sulphur 0.012 % Sulphur 0.010 % Sulphur 0.014 %

Y-P (psi) 73,000 Y-P (psi) 75,420 Y-P (psi) 72,519

Mechanical

Properties

T-S (psi) 84,000 T-S (psi) 82,672 T-S (psi) 75,420

El 28 % El 28 % El 28 %

o o o

V-notch 68 ft/lb @ -22 F V-notch 59 ft/lb @ -4 F V-notch 59 ft/lb @ -4 F

Dia Amp Dia Amp Dia Amp

Rec. Parameters

Available Sizes /

in (mm) F H-Fil in (mm) F H V in (mm) F H-Fil V

.045 (1.2) 140-300 160-300 .045 (1.2) 120-300 120-300 120-220 .045 (1.2) 120-300 120-300 120-220

.052 (1.4) 160-380 180-360 1/16 (1.6) 200-450 200-400 180-220 1/16 (1.6) 200-450 200-450 180-240

1/16 (1.6) 180-420 220-400

Packaging

Detailed Packaging Information Detailed Packaging Information Detailed Packaging Information

Positions

Welding

Flat and Horizontal Flat, Horizontal, Vertical, Overhead and Flat, Horizontal, Vertical, Overhead and

Vertical Down Vertical Down

Approved

ABS, KR, DNV, GL, LR ABS, BV, CCS, DNV, GL, KR, LR, NK, ABS, BV, DNV, LR, RINA, TUV, JIS, KS

RINA, TUV, JIS, KS

Supplier... For The Highest Demands

WELDING PRODUCTS

You might also like

- API 580 TrainingDocument168 pagesAPI 580 Trainingfaheem khan100% (21)

- S T A N D A R D: Finishing Protective Paint of Metallic Parts Composing BusDocument11 pagesS T A N D A R D: Finishing Protective Paint of Metallic Parts Composing Busevren meral100% (1)

- Duplex Coatings Over HDG-Researchgate ReportDocument19 pagesDuplex Coatings Over HDG-Researchgate ReportRyanNo ratings yet

- Covered Electrodes: Mild Steel High Tensile Steel Low Hydrogen Steel Stainless SteelDocument42 pagesCovered Electrodes: Mild Steel High Tensile Steel Low Hydrogen Steel Stainless SteelChainarong ArunchaiwatNo ratings yet

- Low Alloy13Document5 pagesLow Alloy13Branko FerenčakNo ratings yet

- Solliid WiireDocument6 pagesSolliid WiireVõĐìnhKhaNo ratings yet

- 4 E308 Sus FcawDocument1 page4 E308 Sus FcawMohd Farid OsmanNo ratings yet

- Filler Wire For Gtaw PDFDocument27 pagesFiller Wire For Gtaw PDFrezaNo ratings yet

- Welding Electrode PDFDocument1 pageWelding Electrode PDFBijaya RaulaNo ratings yet

- Esab 6013 PDFDocument1 pageEsab 6013 PDFBijaya RaulaNo ratings yet

- Industrial Diaphragm Valves: SaundersDocument14 pagesIndustrial Diaphragm Valves: SaundersscribdkhatnNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Welding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RiboDocument51 pagesWelding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RibojswldeepNo ratings yet

- Diamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsDocument2 pagesDiamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsRMNo ratings yet

- Prorod Spec SheetDocument2 pagesProrod Spec SheetBala SingamNo ratings yet

- Ultramag Sg3: Mild Steel Solid WireDocument1 pageUltramag Sg3: Mild Steel Solid Wireabidaliabid1No ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- COR-1076C Coreweld Brochure 141118Document28 pagesCOR-1076C Coreweld Brochure 141118Thanh TamNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Metrode Supercore 2205P: Welding Consumables Stainless SteelDocument2 pagesMetrode Supercore 2205P: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- Bohler-Welding-Germany 26Document1 pageBohler-Welding-Germany 26misthahNo ratings yet

- Professional Rolls (Ring) supplier 、Document20 pagesProfessional Rolls (Ring) supplier 、JohnNo ratings yet

- Carbide ToolingDocument90 pagesCarbide ToolingHuron Industrial SupplyNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Indian Institute of Welding - ANB Refresher Course - Module 08Document47 pagesIndian Institute of Welding - ANB Refresher Course - Module 08dayalramNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- BW FOX+EV+Pipe EN 2019 GL 232 PreviewDocument2 pagesBW FOX+EV+Pipe EN 2019 GL 232 Previewtan yahyaNo ratings yet

- Jindal Saw LTD - SeamlessDocument30 pagesJindal Saw LTD - SeamlessRajat Chhabra0% (1)

- Phoenix 7018 Phoenix 6013Document1 pagePhoenix 7018 Phoenix 6013Pedro SilvaNo ratings yet

- Material Data Sheet: Casting Material: Stainless Steel CF8MDocument9 pagesMaterial Data Sheet: Casting Material: Stainless Steel CF8MakshayNo ratings yet

- PDS - Bohler N ER 70 S-2 NACE PDFDocument1 pagePDS - Bohler N ER 70 S-2 NACE PDFwesley59No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- AISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1PrasadNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- PNA282 - C51900 - CuSn6 - PB103 - Technical Data SheetDocument2 pagesPNA282 - C51900 - CuSn6 - PB103 - Technical Data Sheetstrip1No ratings yet

- Ancon Stainless Steel Reinforcement Round Bars Australia EditionDocument12 pagesAncon Stainless Steel Reinforcement Round Bars Australia EditionBrad MannNo ratings yet

- Pr01, Pr02, Pr03: Vishay BccomponentsDocument19 pagesPr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaNo ratings yet

- sdg4 - 9 - STAINLESS STEELDocument3 pagessdg4 - 9 - STAINLESS STEELJian Ming WongNo ratings yet

- Sandvik 2RE69: Austenitic Stainless SteelDocument4 pagesSandvik 2RE69: Austenitic Stainless SteelalexmontellNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Mpi BrochureDocument6 pagesMpi BrochureStephen MalobaNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- Karakteristik Kawat LasDocument36 pagesKarakteristik Kawat LasKen RanggaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Ok Tubrod 14.30a PDFDocument1 pageOk Tubrod 14.30a PDFqaNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- AISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1diego AlvarezNo ratings yet

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- Weld Wire SpecDocument2 pagesWeld Wire SpecRajaSekarsajjaNo ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- 1.bharat Group IndiaDocument42 pages1.bharat Group Indiabharat.birjuNo ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Product Data Sheet - OK Tigrod 13.09 PDFDocument2 pagesProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuNo ratings yet

- Bohler Ti 52Document1 pageBohler Ti 52Anonymous nKOyHbNo ratings yet

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANNo ratings yet

- Metro and Tunnel Axial Fans For Fresh and Exhaust AirDocument16 pagesMetro and Tunnel Axial Fans For Fresh and Exhaust AirIrinaNo ratings yet

- Inspection of The Hot Dipped Galvanizing ProcessDocument5 pagesInspection of The Hot Dipped Galvanizing ProcessIrinaNo ratings yet

- Design of A Modern Subway Ventilation System: December 2004Document5 pagesDesign of A Modern Subway Ventilation System: December 2004IrinaNo ratings yet

- Tunnel and Metro VentilationDocument16 pagesTunnel and Metro VentilationIrinaNo ratings yet

- Stainless Steel Guide Apr19 PDFDocument151 pagesStainless Steel Guide Apr19 PDFIrinaNo ratings yet

- Api 510, Pressure Vessel Inspector Certification ExaminationDocument62 pagesApi 510, Pressure Vessel Inspector Certification ExaminationIrinaNo ratings yet

- September 10, 1999 07:26:45 Information Handling Services, 1999Document221 pagesSeptember 10, 1999 07:26:45 Information Handling Services, 1999IrinaNo ratings yet

- AmurchikDocument10 pagesAmurchikIrinaNo ratings yet

- Sys Brochure En-FullDocument44 pagesSys Brochure En-FullAndy ChristyonoNo ratings yet

- Amnd No 2 IS 6911Document16 pagesAmnd No 2 IS 6911Rakesh Soti (JSHL-QUALITY)No ratings yet

- Stainless Steel: Tables of Technical Properties: Materials and Applications Series, Volume 5Document24 pagesStainless Steel: Tables of Technical Properties: Materials and Applications Series, Volume 5process processNo ratings yet

- Btech Me 3 Sem Material Science Nme301 2020Document1 pageBtech Me 3 Sem Material Science Nme301 2020Rajulapati Sunil KumarNo ratings yet

- Is 2062Document12 pagesIs 2062ANTONYLEONo ratings yet

- Asme P NumberDocument4 pagesAsme P NumberTanveer Rajput EngrNo ratings yet

- Technical Report April 8 2014 PDFDocument117 pagesTechnical Report April 8 2014 PDFBelen TapiaNo ratings yet

- Workshop Practice Series 09 Soldering and BrazingDocument68 pagesWorkshop Practice Series 09 Soldering and BrazingAnand sNo ratings yet

- Aluminium Flat BarDocument3 pagesAluminium Flat BarjenishjsNo ratings yet

- Concept Checks SolutionsDocument8 pagesConcept Checks SolutionsTolstoy Leo0% (1)

- 27 AprvdSawDocument19 pages27 AprvdSawMarleneLopesNo ratings yet

- S.G IronDocument6 pagesS.G IronQasim BarkatNo ratings yet

- 1) State-Of-The-Art of Surface Integrity Induced by Tool Wear EffectsDocument32 pages1) State-Of-The-Art of Surface Integrity Induced by Tool Wear Effectsnishanth124acharyaNo ratings yet

- MCQ Phase DiagramsDocument3 pagesMCQ Phase DiagramsPrince AbhishekNo ratings yet

- ISOPE-I-11-533 Forgings For Low Temperature Applications - Influences of The Alloying Concept and Advanced Forging Procedures On Impact Strength and Fracture Toughness PDFDocument7 pagesISOPE-I-11-533 Forgings For Low Temperature Applications - Influences of The Alloying Concept and Advanced Forging Procedures On Impact Strength and Fracture Toughness PDFmarcos2dami2o2de2azeNo ratings yet

- SDA DirectoryDocument56 pagesSDA Directorypiv.hpNo ratings yet

- Perfect Abrasive Products Faridabad, Haryana: Welcome TODocument14 pagesPerfect Abrasive Products Faridabad, Haryana: Welcome TOSanjay BhasinNo ratings yet

- Deep Drawing Process: A Brief Overview: September 2015Document6 pagesDeep Drawing Process: A Brief Overview: September 2015novkovic1984No ratings yet

- NSSMC SuperDyma PDFDocument36 pagesNSSMC SuperDyma PDFDesign RiconsNo ratings yet

- Strengthening MechanismsDocument2 pagesStrengthening MechanismsMohamedAliNo ratings yet

- Ismail 2016 IOP Conf. Ser. Mater. Sci. Eng. 114 012108Document10 pagesIsmail 2016 IOP Conf. Ser. Mater. Sci. Eng. 114 012108Paviter SinghNo ratings yet

- Preheat Temperature Table For Different Materials in WeldingDocument1 pagePreheat Temperature Table For Different Materials in WeldingRakesh Soni0% (1)

- International Journal of Mineral ProcessingDocument19 pagesInternational Journal of Mineral ProcessingHolmes's ApprenticeNo ratings yet

- Esab Welding Filler Metal Handbook 2016 2017 PDFDocument556 pagesEsab Welding Filler Metal Handbook 2016 2017 PDFvano4906100% (2)

- NewDocument2 pagesNewBashar ToshtashNo ratings yet

- Steel, Strip, High-Carbon, Cold-Rolled: Standard Specification ForDocument4 pagesSteel, Strip, High-Carbon, Cold-Rolled: Standard Specification ForsanthakumarNo ratings yet

- Intergranular Pitting Corrosion of Cocrmo Biomedical Implant AlloyDocument10 pagesIntergranular Pitting Corrosion of Cocrmo Biomedical Implant AlloyshameekaNo ratings yet

- Class 8 Metals NewDocument3 pagesClass 8 Metals Newsidsingh2802No ratings yet

- ULO2b MetalsDocument11 pagesULO2b MetalsCHARLIE AMOGUIS JRNo ratings yet