Professional Documents

Culture Documents

201901-KP-Road III-906-km - 13+670-STR-TD-Statics Attachment C - Bending Strengthening

201901-KP-Road III-906-km - 13+670-STR-TD-Statics Attachment C - Bending Strengthening

Uploaded by

mikorizCopyright:

Available Formats

You might also like

- High Mast Design Calculation PDFDocument24 pagesHigh Mast Design Calculation PDFSandip Sengupta67% (6)

- Differences Between ASTM A706 and A615Document4 pagesDifferences Between ASTM A706 and A615อภิรักษ์ มานะกิจศิริสุทธิ100% (6)

- Design of PSC Cross Girder As Per IRC 112Document2 pagesDesign of PSC Cross Girder As Per IRC 112rrajdeep54100% (4)

- Fundamentals of Metal Forming - Wagoner ChenotDocument401 pagesFundamentals of Metal Forming - Wagoner Chenotthacal67% (3)

- Sika® Carbodur® Calculation Software: PROJECT: Pontilhão ELEMENT: Potilhão MRXDocument14 pagesSika® Carbodur® Calculation Software: PROJECT: Pontilhão ELEMENT: Potilhão MRXpauloNo ratings yet

- Sample Column RetrofittingDocument17 pagesSample Column RetrofittingVictor DlreyesNo ratings yet

- IndexDocument25 pagesIndexYLENGNo ratings yet

- Crack Width CalculationsDocument1 pageCrack Width CalculationsdfdgggNo ratings yet

- FlexuralCapacity-FRP - CNR-DT200-2013 - WIPDocument55 pagesFlexuralCapacity-FRP - CNR-DT200-2013 - WIPAlberto AraújoNo ratings yet

- Concrete Section Design For Flexure:: Input DataDocument12 pagesConcrete Section Design For Flexure:: Input DataSandesh KumarNo ratings yet

- B68 BeamDocument2 pagesB68 BeamPooja C PNo ratings yet

- BeamDocument10 pagesBeamdoggNo ratings yet

- ProkonDocument12 pagesProkonHoài Thương LêNo ratings yet

- Precast PlankDocument9 pagesPrecast PlankKalpanaNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKSanjeev SanjeevNo ratings yet

- ETABS Concrete Frame Design: ETABS 19.0.0 License # 1AVSJX3S5D5WKQEDocument2 pagesETABS Concrete Frame Design: ETABS 19.0.0 License # 1AVSJX3S5D5WKQEAastha AdhiakariNo ratings yet

- Unit: 1 Residential & Commercial Building: The Area of Project 348.87 m2Document58 pagesUnit: 1 Residential & Commercial Building: The Area of Project 348.87 m2Civil SanamNo ratings yet

- 1 Input Data: Profis Anchor 2.7.1Document6 pages1 Input Data: Profis Anchor 2.7.1Shafeeq KTNo ratings yet

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- 400mm THK Raft - T25-100Document2 pages400mm THK Raft - T25-100Ihab SorourNo ratings yet

- ETABS Concrete Frame DesignDocument2 pagesETABS Concrete Frame DesignRabi DhakalNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- 1 Input Data: Profis Anchor 2.6.4Document6 pages1 Input Data: Profis Anchor 2.6.4ihpeterNo ratings yet

- Pile DesignDocument9 pagesPile DesignAmit Kumar PaulNo ratings yet

- 19052018-QATAR-MAN-CEILING MOUNTED-SPACING 1.2mDocument6 pages19052018-QATAR-MAN-CEILING MOUNTED-SPACING 1.2mRamu DNo ratings yet

- Grade Beam DesignDocument2 pagesGrade Beam Designjohnstruct archNo ratings yet

- ETABS Concrete Frame Design: ETABS 20.1.0 License # 1PWEY5GKVXGJ5BPDocument1 pageETABS Concrete Frame Design: ETABS 20.1.0 License # 1PWEY5GKVXGJ5BPTamilselvi MNo ratings yet

- 1 Input Data: Profis Anchor 2.5.2Document6 pages1 Input Data: Profis Anchor 2.5.2jasekanNo ratings yet

- BeammDocument1 pageBeammBimalBhandariNo ratings yet

- Lecture 5 Worked Example-Shear-Torsion (Part 2) PDFDocument15 pagesLecture 5 Worked Example-Shear-Torsion (Part 2) PDFAnonymous apmOvzVzmjNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRADocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRARajib MaharjanNo ratings yet

- ATRUCTDocument75 pagesATRUCTRadu StratilaNo ratings yet

- Pier CapDocument2 pagesPier CapKapukets GreyNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRADocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRARajib MaharjanNo ratings yet

- Ilovepdf MergedDocument63 pagesIlovepdf MergedVignesh VenkatasubramanianNo ratings yet

- Deck Slab Design: CK Yk CT, EffDocument3 pagesDeck Slab Design: CK Yk CT, EffBlessyNo ratings yet

- LEDGE Beam DesignDocument1 pageLEDGE Beam DesignIrfan Ali100% (1)

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UR6WTN2QF4XGQ2Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UR6WTN2QF4XGQ2Samir RawatNo ratings yet

- Tie Beam DesignDocument2 pagesTie Beam Designjohnstruct archNo ratings yet

- SLABDocument6 pagesSLABLagnajit DasNo ratings yet

- Preliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesDocument4 pagesPreliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesIoana Codrea OrtelecanNo ratings yet

- Piling CaaaaapacitiDocument1 pagePiling Caaaaapacitiprompt consortiumNo ratings yet

- General Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)Document6 pagesGeneral Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)sumit_7285No ratings yet

- Prj03 Glass Canopy (Mepla)Document32 pagesPrj03 Glass Canopy (Mepla)Filip RisteskiNo ratings yet

- 1 Input Data: Profis Anchor 2.8.3Document6 pages1 Input Data: Profis Anchor 2.8.3Upendra WalinjkarNo ratings yet

- Langkah Model Rangka Portal 3d SAP 2000Document22 pagesLangkah Model Rangka Portal 3d SAP 2000janaNo ratings yet

- 1 Input Data: Profis Anchor 2.9.4Document4 pages1 Input Data: Profis Anchor 2.9.4MohMohkNo ratings yet

- Design, Supply, Installation, Testing and Commissioning of Extension For Sgr-1 220Kv Transmission Line From Kingolwira To Msamvu Sinohydro Corporation LimitedDocument23 pagesDesign, Supply, Installation, Testing and Commissioning of Extension For Sgr-1 220Kv Transmission Line From Kingolwira To Msamvu Sinohydro Corporation LimitedBAWA ALEXNo ratings yet

- PT8'' EdificioDocument2 pagesPT8'' EdificioIvan PorrasNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- LAGOS DORMITORY-BeamDesignDocument147 pagesLAGOS DORMITORY-BeamDesignadetokunbo fapuroNo ratings yet

- Dam I33Document47 pagesDam I33Trung ConNo ratings yet

- Kopaonik Oslonac Zatege 1Document7 pagesKopaonik Oslonac Zatege 1Dejan Deki MaticNo ratings yet

- 1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderDocument18 pages1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderManoj ChaudharyNo ratings yet

- Test Beam ReportDocument35 pagesTest Beam Reportkheang mengNo ratings yet

- Isolated Foundation Calculation (ACI 318M-95)Document6 pagesIsolated Foundation Calculation (ACI 318M-95)Benmark JabayNo ratings yet

- Design Calculation Sheet: FLEXURAL DESIGN of A Singly Reinforced Rectangular Section According ToDocument6 pagesDesign Calculation Sheet: FLEXURAL DESIGN of A Singly Reinforced Rectangular Section According ToMohammed HanafiNo ratings yet

- WiMAX Evolution: Emerging Technologies and ApplicationsFrom EverandWiMAX Evolution: Emerging Technologies and ApplicationsMarcos KatzNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Video and Multimedia Transmissions over Cellular Networks: Analysis, Modelling and Optimization in Live 3G Mobile CommunicationsFrom EverandVideo and Multimedia Transmissions over Cellular Networks: Analysis, Modelling and Optimization in Live 3G Mobile CommunicationsNo ratings yet

- Extradosed BridgeDocument174 pagesExtradosed Bridgemikoriz100% (1)

- Computational Simulations of The Cable-Stayed Brid PDFDocument8 pagesComputational Simulations of The Cable-Stayed Brid PDFmikorizNo ratings yet

- Diaphragm PDFDocument54 pagesDiaphragm PDFmikorizNo ratings yet

- Modele de BearingsDocument1 pageModele de BearingsmikorizNo ratings yet

- Elastic-Plastic Fracture Mechanics Assessment of Test Data For Circumferential Cracked PipesDocument19 pagesElastic-Plastic Fracture Mechanics Assessment of Test Data For Circumferential Cracked Pipesjhon ortizNo ratings yet

- Seismic Design of Precast Prestressed Concrete Structures - PampaninDocument14 pagesSeismic Design of Precast Prestressed Concrete Structures - PampaninLuis Pablo Ramirez ZavalaNo ratings yet

- Shear Jamming and Shear Melting in Mechanically Trained Frictionless ParticlesDocument10 pagesShear Jamming and Shear Melting in Mechanically Trained Frictionless Particles晨李No ratings yet

- ADA441366Document63 pagesADA441366ReggieNo ratings yet

- ElasticityDocument18 pagesElasticityMohd Azhari Mohd RodziNo ratings yet

- High Strength CGSTDocument15 pagesHigh Strength CGSTLeonardoNo ratings yet

- Mechanical Properties of Polyurethane FoamsDocument7 pagesMechanical Properties of Polyurethane FoamsRégis OngolloNo ratings yet

- 06 ES13 Axially Loaded MembersDocument22 pages06 ES13 Axially Loaded MembersMich Angeles100% (1)

- Structural Properties of High Strength Concrete and Its Implications For Precast Prestressed ConcreteDocument16 pagesStructural Properties of High Strength Concrete and Its Implications For Precast Prestressed ConcreteShamsul IslamNo ratings yet

- Formulation, Preparation, and Mechanical Characterization of Nitrile-Butadiene Rubber (NBR) CompositesDocument18 pagesFormulation, Preparation, and Mechanical Characterization of Nitrile-Butadiene Rubber (NBR) CompositesVijay AmirtharajNo ratings yet

- Lecture 9 Examples With SolutionsDocument6 pagesLecture 9 Examples With SolutionsゆかりNo ratings yet

- Characterization of Talahib (Saccharum Spontaneum) in Natural Fiber Reinforced Polymer (NFRP) Using Xylanase As Coupling Agent PDFDocument19 pagesCharacterization of Talahib (Saccharum Spontaneum) in Natural Fiber Reinforced Polymer (NFRP) Using Xylanase As Coupling Agent PDFDos Tumolva50% (2)

- Yohannes Kebede Kassa Final 1Document80 pagesYohannes Kebede Kassa Final 1Yohannes KebedeNo ratings yet

- Mec281 NotesDocument498 pagesMec281 NotesRasyidi AhmadNo ratings yet

- Lecture-II Basics of Reinforced Concrete DesignDocument61 pagesLecture-II Basics of Reinforced Concrete Designjs kalyana rama100% (1)

- Hardened Concrete (Lec 20)Document19 pagesHardened Concrete (Lec 20)vasu khandelwalNo ratings yet

- Technical Note: NasaDocument57 pagesTechnical Note: NasaRod GilesNo ratings yet

- On The Mechanisms of Ductile Failure in High-Strength Steels Subjected To Multi-Axial Stress-StatesDocument28 pagesOn The Mechanisms of Ductile Failure in High-Strength Steels Subjected To Multi-Axial Stress-Statessgssgs1No ratings yet

- Engineering Structures: Morteza Omidi, Farhad BehnamfarDocument23 pagesEngineering Structures: Morteza Omidi, Farhad BehnamfarKenaouia BahaaNo ratings yet

- Basics of Pipe Stress AnalysisDocument79 pagesBasics of Pipe Stress Analysisarjunprasannan7100% (1)

- Axial Loading: JU. Dr. Ibrahim Abu-AlshaikhDocument88 pagesAxial Loading: JU. Dr. Ibrahim Abu-AlshaikhqusayNo ratings yet

- Aircraftmaterialsandhardware 150922063901 Lva1 App6891Document131 pagesAircraftmaterialsandhardware 150922063901 Lva1 App6891atulkumargaur26No ratings yet

- IS 15756 - N ValueDocument11 pagesIS 15756 - N ValueSuvro ChakrabortyNo ratings yet

- Comparative Study of Architectural Textile Membranes: PTFE Coated Glass Fabric and ETFE FoilDocument28 pagesComparative Study of Architectural Textile Membranes: PTFE Coated Glass Fabric and ETFE FoilSamvida11100% (1)

- Mechanical Properties of Solids and Mechanical Properties of FluidsDocument19 pagesMechanical Properties of Solids and Mechanical Properties of FluidsSasidaran SasiNo ratings yet

- Creep Behavior of MaterialsDocument55 pagesCreep Behavior of Materialsgunapalshetty100% (2)

- M11 AceroDocument187 pagesM11 Aceroleocv_7No ratings yet

- Determination of N Value-Practical-5 PDFDocument7 pagesDetermination of N Value-Practical-5 PDFMatthew HaleNo ratings yet

201901-KP-Road III-906-km - 13+670-STR-TD-Statics Attachment C - Bending Strengthening

201901-KP-Road III-906-km - 13+670-STR-TD-Statics Attachment C - Bending Strengthening

Uploaded by

mikorizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

201901-KP-Road III-906-km - 13+670-STR-TD-Statics Attachment C - Bending Strengthening

201901-KP-Road III-906-km - 13+670-STR-TD-Statics Attachment C - Bending Strengthening

Uploaded by

mikorizCopyright:

Available Formats

SIKA® CARBODUR® CALCULATION SOFTWARE

PROJECT: Път III-906 - Мост при км 13+697

ELEMENT: Главна греда - усилване за огъващ момент

INDEX

1.- DESIGN CRITERIA AND REGULATIONS......................................................................................................................... 3

2.- CALCULATION ASSUMPTIONS..................................................................................................................................... 3

2.1.- Geometry...................................................................................................................................................... 3

2.2.- Concrete........................................................................................................................................................ 3

2.3.- Reinforcing steel............................................................................................................................................ 3

2.4.- Strength reduction factors............................................................................................................................. 4

2.5.- Load factors................................................................................................................................................... 4

3.- FRP STRENGTH............................................................................................................................................................ 4

3.1.- Main FRP reinforcement................................................................................................................................ 4

4.- ANTICIPATED COMBINATIONS OF LOADS................................................................................................................... 4

4.1.- Initial loads.................................................................................................................................................... 4

4.2.- Expected loads (strengthening design)........................................................................................................... 4

5.- RESULTS..................................................................................................................................................................... 5

5.1.- Summary of results........................................................................................................................................ 5

5.2.- Ultimate limit states...................................................................................................................................... 5

5.3.- Serviceability limit states............................................................................................................................... 9

5.4.- Additional check............................................................................................................................................ 10

5.5.- FRP arrangement........................................................................................................................................... 11

6.- PRODUCT SPECIFICATION........................................................................................................................................... 11

6.1.- Bonded SikaWrap® fabrics............................................................................................................................. 11

6.1.1.- Concrete surface preparation.................................................................................................................. 11

6.1.2.- SikaWrap® fabrics.................................................................................................................................... 12

6.1.3.- Epoxy Adhesive........................................................................................................................................ 12

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

1/14

INDEX

6.1.4.- Application procedure............................................................................................................................. 13

7.- LEGAL DISCLAIMER..................................................................................................................................................... 14

8.- ABOUT SIKA® CARBODUR® CALCULATION SOFTWARE................................................................................................ 14

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

2/14

1.- DESIGN CRITERIA AND REGULATIONS

Flexural FRP strengthening of beam

Concrete Society Technical Report No. 55 (TR 55): design guidance for strengthening concrete structures using fibre

composite materials, Third Edition 2012.

EN 1992-1-1. Eurocode 2: Design of concrete structures - Part 1-1: General rules and rules for buildings.

Country: Bulgaria

2.- CALCULATION ASSUMPTIONS

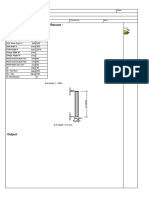

2.1.- Geometry

Cross section = T-Beam

Web width = 400 mm

Total height = 1540 mm

Width of flange = 1800 mm

Height of flange = 440 mm

1800

440

1540

400

2.2.- Concrete

Compressive strength of concrete

Concrete strength (fck) = 30 MPa

Cylinder specimen = 30 MPa

Cube specimen = 37 MPa

2.3.- Reinforcing steel

Reinforcement layers

Steel fyk Es Number x Ø

Top layer d1 mm

(MPa) (MPa) (mm)

1. 52 (B500) 500 200000 9 x 12.0

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

3/14

Steel fyk Es Area

Bottom layer d1 mm

(MPa) (MPa) (mm²)

1. 43 (B240) 240 200000 5090.00

2. 115 (B240) 240 200000 5090.00

2.4.- Strength reduction factors

Defined by (Eurocode)

Concrete

gc (Persistent and transient) = 1.50

gc (Accidental) = 1.20

gc (Fire) = 1.00

acc = 1.00

Steel

gs (Persistent and transient) = 1.15

gs (Accidental) = 1.00

gs (Fire) = 1.00

2.5.- Load factors

User values Permanent loads Imposed loads

Anticipated loads 1.35 1.35

FRP Reinforcement failure 1.00 0.50

Fire situation 1.00 0.30

SLS, characteristic 1.00 1.00

3.- FRP STRENGTH

3.1.- Main FRP reinforcement

Simply bonded. SikaWrap® C

Efk tf Width

SikaWrap® 530C - 30cm Fiber type Strength reduction factors efk Number

(MPa) (mm) (mm)

Layer: 1 Carbon gFRP,E: 1.10, gFRP,m: 1.05, gFRP,e: 1.25, gA: 4.00 0.0145 220000.00 0.290 1 300.00

Layer: 2 Carbon gFRP,E: 1.10, gFRP,m: 1.05, gFRP,e: 1.25, gA: 4.00 0.0145 220000.00 0.290 1 300.00

Layer: 3 Carbon gFRP,E: 1.10, gFRP,m: 1.05, gFRP,e: 1.25, gA: 4.00 0.0145 220000.00 0.290 1 300.00

4.- ANTICIPATED COMBINATIONS OF LOADS

4.1.- Initial loads

(Positive) Mi : 1002.00 kN·m

4.2.- Expected loads (strengthening design)

Permanent loads (Positive) MG : 1345.00 kN·m

Imposed loads (Positive) MQ : 1145.00 kN·m

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

4/14

5.- RESULTS

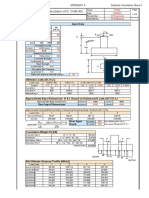

5.1.- Summary of results

ULS Anticipated loads

loading MEd (kN·m) MRd (kN·m) MRd ³ MEd (NEd = NRd)

Strengthened section

SEd = 1.35 · SG + 1.35 · SQ 3361.50 3571.55

3571.55 kN·m ³ 3361.50 kN·m

ULS Reinforcement failure

loading MEd (kN·m) MRd (kN·m) MRd ³ MEd (NEd = NRd)

Un-strengthened section

SEd = 1.00 · SG + 0.50 · SQ 1917.50 3482.48

3482.48 kN·m ³ 1917.50 kN·m

Serviceability limit states

loading Service stresses

ss ³ 0.8·fyk

SEd = 1.00 · SG + 1.00 · SQ

189.92 MPa ³ 192.00 MPa

Fire resistance (t=0 min.)

loading MEd (kN·m) MRd (kN·m) MRd ³ MEd (NEd = NRd)

Un-strengthened section

SEd = 1.00 · SG + 0.30 · SQ 1688.50 3491.05

3491.05 kN·m ³ 1688.50 kN·m

5.2.- Ultimate limit states

When analysing a cross-section to determine its ultimate moment of resistance, the following assumptions should be

made:

The strain distribution in the concrete in compression and the strains in the reinforcement, whether in tension or

compression, are derived from the assumption that plane sections remain plane and that no longitudinal slip

occurs between or within the components of the section.

The stresses in the concrete in compression are derived from the stress-strain curve in the section 3.1.7 of EN

1992-1-1.

e

n

sc fcd 1 1 c for 0 ec ec2

ec2

sc fcd for ec2 ec ecu2

with

fck

fcd acc

gc

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

5/14

fcd

ec2 ecu2 n

(MPa)

20.0 0.0020 0.0035 2

The tensile strength of the concrete is ignored.

The stresses in the steel reinforcement are derived from the stress-strain curves in the section 3.2 of EN 1992-1-1.

The strains in the cross-section should take into account the strains present in the existing structure at the time of

application of the FRP reinforcement.

The stresses in the FRP reinforcement are derived from the assumption that the FRP has a linear elastic

characteristic until rupture.

Force balance of section. Initial loads

Mi = 1002.00 kN·m

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

6/14

εmax σmax

x

ε = 0.0 ‰

εmin

Maximum and minimum strain emax = 0.12 ‰

emin = -0.39 ‰

Maximum stress in concrete fc = 2.26 MPa

Distance from extreme compression fiber to neutral axis x = 352.67 mm

Stress and strain of reinforcement

Ref. Y Coord. (mm) f (MPa) ε (‰)

No. 12 718 19.84 0.10

A. 5090 -727 -75.51 -0.38

A. 5090 -655 -70.76 -0.35

FRP Reinforcement failure. Minimum combination of loads to be resisted by the un-strengthened member.

SEd = 1.00 · SG + 0.50 · SQ

MRd MEd 3482.48 kN·m ³ 1917.50 kN·m

MRd : 3482.48 kN·m

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

7/14

εmax ε =σmax

3.5 ‰

ε = 2.0 ‰

x

ε = 0.0 ‰

εmin

Maximum and minimum strain emax = 1.38 ‰

emin = -20.51 ‰

Maximum stress in concrete fc = 22.58 MPa

Distance from extreme compression fiber to neutral axis x = 96.89 mm

Stress and strain of reinforcement

Ref. Y Coord. (mm) f (MPa) ε (‰)

No. 12 718 127.62 0.64

A. 5090 -727 -240.00 -19.90

A. 5090 -655 -240.00 -18.88

Strengthened section and expected loads.

SEd = 1.35 · SG + 1.35 · SQ

MRd MEd 3571.55 kN·m ³ 3361.50 kN·m

MRd : 3571.55 kN·m

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

8/14

εmax σmax

x

ε = 0.0 ‰

εmin

Maximum and minimum strain emax = 0.98 ‰

emin = -8.35 ‰

Maximum stress in concrete fc = 14.79 MPa

Distance from extreme compression fiber to neutral axis x = 161.69 mm

Stress and strain of reinforcement

Ref. Y Coord. (mm) f (MPa) ε (‰)

No. 12 718 132.87 0.66

A. 5090 -727 -208.70 -8.09

A. 5090 -655 -208.70 -7.65

FRP -770 -1515.56 -7.96

FRP -770 -1515.87 -7.96

FRP -771 -1516.19 -7.96

Fire situation. Un-strengthened section.

SEd = 1.00 · SG + 0.30 · SQ

MRd MEd 3491.05 kN·m ³ 1688.50 kN·m

MRd : 3491.05 kN·m

The strength of the un-strengthened member is enough to support the combination of loads corresponding to the fire

situation. The FRP strengthening is therefore not necessary during a fire situation, and does not need to be protected. If

a certain fire rating is necessary, the designer must evaluate the need for a protection of the RC element (concrete and

steel reinforcement) according to the local codes.

5.3.- Serviceability limit states

SLS stresses in the steel reinforcement at the characteristic combination of actions should not exceed the relevant

design limits in Eurocode 2, part 1-1.

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

9/14

Force balance of section. SLS Characteristic combination of loads

SEd = 1.00 · SG + 1.00 · SQ

εmax σmax

x

ε = 0.0 ‰

εmin

Maximum and minimum strain emax = 0.44 ‰

emin = -0.99 ‰

Maximum stress in concrete fc = 4.23 MPa

Distance from extreme compression fiber to neutral axis x = 473.64 mm

Stress and strain of reinforcement

Ref. Y Coord. (mm) f (MPa) ε (‰)

No. 12 718 78.25 0.39

A. 5090 -727 -189.92 -0.95

A. 5090 -655 -176.56 -0.88

FRP -770 -132.96 -0.60

FRP -770 -133.00 -0.60

FRP -771 -133.04 -0.60

In the case of significant non-static live loads during the hardening of the adhesive, the reduced adhesive strength

cannot be determined according to tabulated data as indicated in TR55, 6.9.4, considering that the acting loads during

that period correspond to the quasi-permanent load combination.

efe,curing = 0.000289 > 0.000200

5.4.- Additional check

In addition, if the ultimate moment of resistance is less than 1.15 times the required value, the section should be

proportioned such that the strain at the centroid of the tensile steel reinforcement is not less than 0.002 + fyk/(Esgs).

fyk

MRd 1,15 MEd ; es 0,002 0.00809 ³ 0.00304

Es · g s

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

10/14

5.5.- FRP arrangement

The previous results correspond to the following FRP scheme:

FRP main reinforcement: Number of layers: 3, 1 + 1 + 1 (SikaWrap® 530C - 30cm)

6.- PRODUCT SPECIFICATION

6.1.- Bonded SikaWrap® fabrics

The strengthening shall be achieved using unidirectional carbon fibre fabric, impregnated and externally bonded to the

structure with epoxy adhesive Sikadur®-300

The material shall be a pultruded, unidirectional CFRP plate, and exhibit a fibre volume content >68%.

The fibers should be aligned and free of torsion.

The material shall have a long track record (> 25 years) for structural strengthening.

The fibre fabric shall be unidirectional and fabricated of PAN based carbon fibres.

Installation in several layers shall be possible.

The material shall have a long track record for structural strengthening.

Measured values of mechanical properties of laminated fabrics shall be provided, minimum test series of 20 samples.

6.1.1.- Concrete surface preparation

Any unsound material shall be removed and removed concrete shall be repaired as described above. Large blowholes

and honeycombing shall be filled with a suitable repair mortar.

Repair materials shall be fully compatible with the adhesive.

The actual strength of the concrete substrate shall be verified with at least three pull-off tests.

The concrete shall be older than 28 days.

The laitance layer on the substrate surface shall be removed and an open-textured surface shall be created.

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

11/14

The substrate surface shall be cleaned so that it is free from oil, grease and any other contaminants as well as loose

particles and dust.

For fibre fabric application, all corners shall be rounded to a minimum radius of 20 mm and any sharp edges shall be

removed.

The substrate moisture content shall be less than 4% pbw.

6.1.2.- SikaWrap® fabrics

The materials shall comply with the performance characteristics described as follows:

6.1.2.1.- Typical Properties of SikaWrap® 530C - 30cm fabric:

Typical dry fiber properties:

E-Modulus EN 2561/ASTM D3039 » 230000 N/mm² (MPa)

Tensile Strength EN 2561/ASTM D3039 » 4000 N/mm² (MPa)

Strain at break EN 2561/ASTM D3039 1.7 %

Typical laminate properties (related to fibre thickness):

E-Modulus EN 2561/ASTM D3039 » 225000 N/mm² (MPa)

6.1.3.- Epoxy Adhesive

The adhesive shall be epoxy based.

The SikaWrap® 530C - 30cm fabric shall be impregnated with resin before placement on the structure with Sikadur-300

6.1.3.1.- Typical Properties of Sikadur®-300 adhesive

The adhesive must comply with EN 1504-4.

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

12/14

Chemical base Epoxy resin

Density 1.16 kg/l (at +23°C).

+15ºC » 2000 mPas

Viscosity (shear rate 50/S) +23ºC » 700 mPas

+40ºC » 200 mPas

Thermal expansion coefficient -20ºC to +40ºC 6.0 x 10-5 per °C

Curing

7 days, +15ºC +43ºC

Thermal stability. HDT (ASTM D648) 7 days, +23ºC +49ºC

3 days, +40ºC +60ºC

7 days, +40ºC +66ºC

Service temperature 23ºC Curing -40ºC to +45ºC

Tensile Strength DIN EN ISO 527-3 45 N/mm2 (7 days at +23°C)

Bond Strength (sandblasted substrate) DIN EN ISO 4624 Concrete fracture (> 4 N/mm²)

E-Modulus (flexural) DIN EN 1465 2800 N/mm2 (7 days at +23°C)

E-modulus in tensile DIN EN ISO 527-3 3500 N/mm2 (7 days at +23°C)

Elongation at break DIN EN ISO 527-3 1.5% (7 days at +23°C)

6.1.4.- Application procedure

The wrap shall be cut to size with special fibre scissors.

A primer layer of the impregnating resin shall be applied on the substrate surface, using a toothed trowel or a roller.

Distribute 2/3 of the expected Sikadur®-300 quantity on a clean PE sheet and then place the pre-cut fabric onto the resin

covered sheet. Saturate SikaWrap® fabric by rolling with a mohair or plastic roller in the fibre direction until the resin

penetrates through the fabric. Distribute the remaining 1/3 of the Sikadur®-300 onto the fabric and evenly spread with

roller to fully saturate fabric. Remove the excess of resin.

The fabric shall be placed on the substrate, pressed on gently, and the resin shall be worked into the fabric with an

impregnation roller until the fabric is completely saturated.

Additional layers shall be installed as described above, preferably wet-on-wet.

In case of a cementitious overcoat, the resulting resin surface shall be broadcasted with quartz sand.

Impregnation shall always be performed in fibre direction.

After application, the finished fibre fabric installation of shall be protected from rain, sand, dust and any other

contaminants.

If necessary, the applied system shall be protected with a suitable coating (compatibility tests between the coating and

the fabric shall be available).

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

13/14

7.- LEGAL DISCLAIMER

THIS SOFTWARE APPLICATION AND THE RESULTS DERIVED FROM ITS UTILIZATION ARE INTENDED ONLY FOR USE BY

PROFESSIONAL USERS WITH EXPERT KNOWLEDGE IN THE AREA OF THE INTENDED APPLICATION. USERS MUST

INDEPENDENTLY VERIFY THE RESULTS BEFORE ANY USE AND TAKE INTO ACCOUNT THE SITE AND APPLICATION

CONDITIONS, PRODUCT DATA SHEET AND PRODUCT LITERATURE, TECHNICAL STATE OF THE ART AS WELL AS LOCAL

APPLICABLE STANDARDS AND REGULATIONS.

With respect to the software application and results derived from its use, SIKA MAKES NO WARRANTIES OF ACCURACY,

RELIABILITY, COMPLETENESS, MERCHANTABILITY OR FITNESS FOR ANY PURPOSE. THE SOFTWARE APPLICATION IS

PROVIDED ON AN "AS-IS" BASIS AND SIKA EXPRESSLY DISCLAIMS ANY WARRANTIES WITH RESPECT TO THE SOFTWARE

APPLICATION AND RESULTS DERIVED FROM ITS USE.

Sika shall not be liable for any consequential, punitive, incidental, exemplary, or special damages (including but not

limited to loss of business opportunity or loss of profit) arising out of the evaluation or use of the software application

and results derived from its use.

The information, and, in particular, the recommendations relating to the application and end-use of Sika products, are

given in good faith based on Sika's current knowledge and experience of the products when properly stored, handled

and applied under normal conditions in accordance with Sika’s recommendations. In practice, the differences in

materials, substrates and actual site conditions are such that no warranty in respect of merchantability or of fitness for a

particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this

information, or from any written recommendations, or from any other advice offered. The user of the product must test

the product’s suitability for the intended application and purpose. Sika reserves the right to change the properties of its

products. The proprietary rights of third parties must be observed. All orders are accepted subject to our current terms

of sale and delivery. Users must always refer to the most recent issue of the local Product Data Sheet for the product

concerned, copies of which will be supplied on request.

Except as indicated otherwise, all information, text, graphic images, features, functions, and layout contained in this

software are the exclusive property of Sika and may not be copied or distributed, in whole or in part, without the

Company's express written consent.

By transmitting information to Sika, you grant to the Company the unrestricted irrevocable license to use, reproduce,

display, modify, distribute and perform such information. Personal identity information is used by Sika only to process a

request for information by you or for marketing our products and services.

© Copyright Sika Services AG 2016

8.- ABOUT SIKA® CARBODUR® CALCULATION SOFTWARE

Engineered by:

Cype Software - Eusebio Sempere, 5 - 03003 Alicante (Spain)

www.cype.com

Sika Services AG Element: Главна греда - усилван... Date: 20/12/2019

Corporate Tech. Dept. Editor: Любомир Диев Project: Път III-906 - Мост при...

Tüffenwies 16 Remarks:

8048 Zürich (Switzerland)

www.sika.com

14/14

You might also like

- High Mast Design Calculation PDFDocument24 pagesHigh Mast Design Calculation PDFSandip Sengupta67% (6)

- Differences Between ASTM A706 and A615Document4 pagesDifferences Between ASTM A706 and A615อภิรักษ์ มานะกิจศิริสุทธิ100% (6)

- Design of PSC Cross Girder As Per IRC 112Document2 pagesDesign of PSC Cross Girder As Per IRC 112rrajdeep54100% (4)

- Fundamentals of Metal Forming - Wagoner ChenotDocument401 pagesFundamentals of Metal Forming - Wagoner Chenotthacal67% (3)

- Sika® Carbodur® Calculation Software: PROJECT: Pontilhão ELEMENT: Potilhão MRXDocument14 pagesSika® Carbodur® Calculation Software: PROJECT: Pontilhão ELEMENT: Potilhão MRXpauloNo ratings yet

- Sample Column RetrofittingDocument17 pagesSample Column RetrofittingVictor DlreyesNo ratings yet

- IndexDocument25 pagesIndexYLENGNo ratings yet

- Crack Width CalculationsDocument1 pageCrack Width CalculationsdfdgggNo ratings yet

- FlexuralCapacity-FRP - CNR-DT200-2013 - WIPDocument55 pagesFlexuralCapacity-FRP - CNR-DT200-2013 - WIPAlberto AraújoNo ratings yet

- Concrete Section Design For Flexure:: Input DataDocument12 pagesConcrete Section Design For Flexure:: Input DataSandesh KumarNo ratings yet

- B68 BeamDocument2 pagesB68 BeamPooja C PNo ratings yet

- BeamDocument10 pagesBeamdoggNo ratings yet

- ProkonDocument12 pagesProkonHoài Thương LêNo ratings yet

- Precast PlankDocument9 pagesPrecast PlankKalpanaNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKSanjeev SanjeevNo ratings yet

- ETABS Concrete Frame Design: ETABS 19.0.0 License # 1AVSJX3S5D5WKQEDocument2 pagesETABS Concrete Frame Design: ETABS 19.0.0 License # 1AVSJX3S5D5WKQEAastha AdhiakariNo ratings yet

- Unit: 1 Residential & Commercial Building: The Area of Project 348.87 m2Document58 pagesUnit: 1 Residential & Commercial Building: The Area of Project 348.87 m2Civil SanamNo ratings yet

- 1 Input Data: Profis Anchor 2.7.1Document6 pages1 Input Data: Profis Anchor 2.7.1Shafeeq KTNo ratings yet

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- 400mm THK Raft - T25-100Document2 pages400mm THK Raft - T25-100Ihab SorourNo ratings yet

- ETABS Concrete Frame DesignDocument2 pagesETABS Concrete Frame DesignRabi DhakalNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- 1 Input Data: Profis Anchor 2.6.4Document6 pages1 Input Data: Profis Anchor 2.6.4ihpeterNo ratings yet

- Pile DesignDocument9 pagesPile DesignAmit Kumar PaulNo ratings yet

- 19052018-QATAR-MAN-CEILING MOUNTED-SPACING 1.2mDocument6 pages19052018-QATAR-MAN-CEILING MOUNTED-SPACING 1.2mRamu DNo ratings yet

- Grade Beam DesignDocument2 pagesGrade Beam Designjohnstruct archNo ratings yet

- ETABS Concrete Frame Design: ETABS 20.1.0 License # 1PWEY5GKVXGJ5BPDocument1 pageETABS Concrete Frame Design: ETABS 20.1.0 License # 1PWEY5GKVXGJ5BPTamilselvi MNo ratings yet

- 1 Input Data: Profis Anchor 2.5.2Document6 pages1 Input Data: Profis Anchor 2.5.2jasekanNo ratings yet

- BeammDocument1 pageBeammBimalBhandariNo ratings yet

- Lecture 5 Worked Example-Shear-Torsion (Part 2) PDFDocument15 pagesLecture 5 Worked Example-Shear-Torsion (Part 2) PDFAnonymous apmOvzVzmjNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRADocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRARajib MaharjanNo ratings yet

- ATRUCTDocument75 pagesATRUCTRadu StratilaNo ratings yet

- Pier CapDocument2 pagesPier CapKapukets GreyNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRADocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRARajib MaharjanNo ratings yet

- Ilovepdf MergedDocument63 pagesIlovepdf MergedVignesh VenkatasubramanianNo ratings yet

- Deck Slab Design: CK Yk CT, EffDocument3 pagesDeck Slab Design: CK Yk CT, EffBlessyNo ratings yet

- LEDGE Beam DesignDocument1 pageLEDGE Beam DesignIrfan Ali100% (1)

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UR6WTN2QF4XGQ2Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UR6WTN2QF4XGQ2Samir RawatNo ratings yet

- Tie Beam DesignDocument2 pagesTie Beam Designjohnstruct archNo ratings yet

- SLABDocument6 pagesSLABLagnajit DasNo ratings yet

- Preliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesDocument4 pagesPreliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesIoana Codrea OrtelecanNo ratings yet

- Piling CaaaaapacitiDocument1 pagePiling Caaaaapacitiprompt consortiumNo ratings yet

- General Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)Document6 pagesGeneral Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)sumit_7285No ratings yet

- Prj03 Glass Canopy (Mepla)Document32 pagesPrj03 Glass Canopy (Mepla)Filip RisteskiNo ratings yet

- 1 Input Data: Profis Anchor 2.8.3Document6 pages1 Input Data: Profis Anchor 2.8.3Upendra WalinjkarNo ratings yet

- Langkah Model Rangka Portal 3d SAP 2000Document22 pagesLangkah Model Rangka Portal 3d SAP 2000janaNo ratings yet

- 1 Input Data: Profis Anchor 2.9.4Document4 pages1 Input Data: Profis Anchor 2.9.4MohMohkNo ratings yet

- Design, Supply, Installation, Testing and Commissioning of Extension For Sgr-1 220Kv Transmission Line From Kingolwira To Msamvu Sinohydro Corporation LimitedDocument23 pagesDesign, Supply, Installation, Testing and Commissioning of Extension For Sgr-1 220Kv Transmission Line From Kingolwira To Msamvu Sinohydro Corporation LimitedBAWA ALEXNo ratings yet

- PT8'' EdificioDocument2 pagesPT8'' EdificioIvan PorrasNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- LAGOS DORMITORY-BeamDesignDocument147 pagesLAGOS DORMITORY-BeamDesignadetokunbo fapuroNo ratings yet

- Dam I33Document47 pagesDam I33Trung ConNo ratings yet

- Kopaonik Oslonac Zatege 1Document7 pagesKopaonik Oslonac Zatege 1Dejan Deki MaticNo ratings yet

- 1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderDocument18 pages1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderManoj ChaudharyNo ratings yet

- Test Beam ReportDocument35 pagesTest Beam Reportkheang mengNo ratings yet

- Isolated Foundation Calculation (ACI 318M-95)Document6 pagesIsolated Foundation Calculation (ACI 318M-95)Benmark JabayNo ratings yet

- Design Calculation Sheet: FLEXURAL DESIGN of A Singly Reinforced Rectangular Section According ToDocument6 pagesDesign Calculation Sheet: FLEXURAL DESIGN of A Singly Reinforced Rectangular Section According ToMohammed HanafiNo ratings yet

- WiMAX Evolution: Emerging Technologies and ApplicationsFrom EverandWiMAX Evolution: Emerging Technologies and ApplicationsMarcos KatzNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Video and Multimedia Transmissions over Cellular Networks: Analysis, Modelling and Optimization in Live 3G Mobile CommunicationsFrom EverandVideo and Multimedia Transmissions over Cellular Networks: Analysis, Modelling and Optimization in Live 3G Mobile CommunicationsNo ratings yet

- Extradosed BridgeDocument174 pagesExtradosed Bridgemikoriz100% (1)

- Computational Simulations of The Cable-Stayed Brid PDFDocument8 pagesComputational Simulations of The Cable-Stayed Brid PDFmikorizNo ratings yet

- Diaphragm PDFDocument54 pagesDiaphragm PDFmikorizNo ratings yet

- Modele de BearingsDocument1 pageModele de BearingsmikorizNo ratings yet

- Elastic-Plastic Fracture Mechanics Assessment of Test Data For Circumferential Cracked PipesDocument19 pagesElastic-Plastic Fracture Mechanics Assessment of Test Data For Circumferential Cracked Pipesjhon ortizNo ratings yet

- Seismic Design of Precast Prestressed Concrete Structures - PampaninDocument14 pagesSeismic Design of Precast Prestressed Concrete Structures - PampaninLuis Pablo Ramirez ZavalaNo ratings yet

- Shear Jamming and Shear Melting in Mechanically Trained Frictionless ParticlesDocument10 pagesShear Jamming and Shear Melting in Mechanically Trained Frictionless Particles晨李No ratings yet

- ADA441366Document63 pagesADA441366ReggieNo ratings yet

- ElasticityDocument18 pagesElasticityMohd Azhari Mohd RodziNo ratings yet

- High Strength CGSTDocument15 pagesHigh Strength CGSTLeonardoNo ratings yet

- Mechanical Properties of Polyurethane FoamsDocument7 pagesMechanical Properties of Polyurethane FoamsRégis OngolloNo ratings yet

- 06 ES13 Axially Loaded MembersDocument22 pages06 ES13 Axially Loaded MembersMich Angeles100% (1)

- Structural Properties of High Strength Concrete and Its Implications For Precast Prestressed ConcreteDocument16 pagesStructural Properties of High Strength Concrete and Its Implications For Precast Prestressed ConcreteShamsul IslamNo ratings yet

- Formulation, Preparation, and Mechanical Characterization of Nitrile-Butadiene Rubber (NBR) CompositesDocument18 pagesFormulation, Preparation, and Mechanical Characterization of Nitrile-Butadiene Rubber (NBR) CompositesVijay AmirtharajNo ratings yet

- Lecture 9 Examples With SolutionsDocument6 pagesLecture 9 Examples With SolutionsゆかりNo ratings yet

- Characterization of Talahib (Saccharum Spontaneum) in Natural Fiber Reinforced Polymer (NFRP) Using Xylanase As Coupling Agent PDFDocument19 pagesCharacterization of Talahib (Saccharum Spontaneum) in Natural Fiber Reinforced Polymer (NFRP) Using Xylanase As Coupling Agent PDFDos Tumolva50% (2)

- Yohannes Kebede Kassa Final 1Document80 pagesYohannes Kebede Kassa Final 1Yohannes KebedeNo ratings yet

- Mec281 NotesDocument498 pagesMec281 NotesRasyidi AhmadNo ratings yet

- Lecture-II Basics of Reinforced Concrete DesignDocument61 pagesLecture-II Basics of Reinforced Concrete Designjs kalyana rama100% (1)

- Hardened Concrete (Lec 20)Document19 pagesHardened Concrete (Lec 20)vasu khandelwalNo ratings yet

- Technical Note: NasaDocument57 pagesTechnical Note: NasaRod GilesNo ratings yet

- On The Mechanisms of Ductile Failure in High-Strength Steels Subjected To Multi-Axial Stress-StatesDocument28 pagesOn The Mechanisms of Ductile Failure in High-Strength Steels Subjected To Multi-Axial Stress-Statessgssgs1No ratings yet

- Engineering Structures: Morteza Omidi, Farhad BehnamfarDocument23 pagesEngineering Structures: Morteza Omidi, Farhad BehnamfarKenaouia BahaaNo ratings yet

- Basics of Pipe Stress AnalysisDocument79 pagesBasics of Pipe Stress Analysisarjunprasannan7100% (1)

- Axial Loading: JU. Dr. Ibrahim Abu-AlshaikhDocument88 pagesAxial Loading: JU. Dr. Ibrahim Abu-AlshaikhqusayNo ratings yet

- Aircraftmaterialsandhardware 150922063901 Lva1 App6891Document131 pagesAircraftmaterialsandhardware 150922063901 Lva1 App6891atulkumargaur26No ratings yet

- IS 15756 - N ValueDocument11 pagesIS 15756 - N ValueSuvro ChakrabortyNo ratings yet

- Comparative Study of Architectural Textile Membranes: PTFE Coated Glass Fabric and ETFE FoilDocument28 pagesComparative Study of Architectural Textile Membranes: PTFE Coated Glass Fabric and ETFE FoilSamvida11100% (1)

- Mechanical Properties of Solids and Mechanical Properties of FluidsDocument19 pagesMechanical Properties of Solids and Mechanical Properties of FluidsSasidaran SasiNo ratings yet

- Creep Behavior of MaterialsDocument55 pagesCreep Behavior of Materialsgunapalshetty100% (2)

- M11 AceroDocument187 pagesM11 Aceroleocv_7No ratings yet

- Determination of N Value-Practical-5 PDFDocument7 pagesDetermination of N Value-Practical-5 PDFMatthew HaleNo ratings yet