Professional Documents

Culture Documents

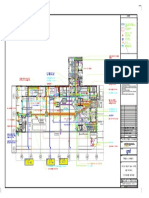

1.plan-Meghana Aac Blocks Industry-14082020

1.plan-Meghana Aac Blocks Industry-14082020

Uploaded by

technopreneurvizagOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.plan-Meghana Aac Blocks Industry-14082020

1.plan-Meghana Aac Blocks Industry-14082020

Uploaded by

technopreneurvizagCopyright:

Available Formats

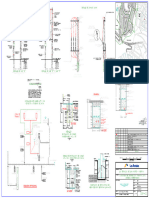

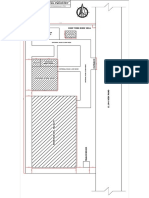

NOTES:

TO

1. STRUCTURE TO BE

TH

AN

DEM

VA

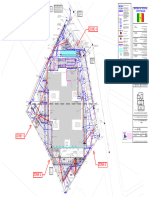

AGRICULTURAL FIELDS

LA SA

CONSTRUCTED IN ACCORDANCE

AGRICULTURAL FIELDS WITH IS 456-2000

M

AGRICULTURAL FIELDS

0

25

2. CONCRETE GRADE IS M20

R

AGRICULTURAL FIELDS

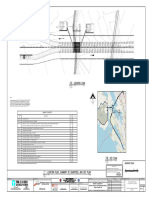

ONCE WE DECIDED THE UNIT LOCATION, SITE PLAN WOULD BE

AGRICULTURAL FIELDS

SAMPLE 3. STEEL GRADE IS Fe 415

DRAWN AS PER THE LAYOUT, BOUNDARIES AND FMB AGRICULTURAL FIELDS

AGRICULTURAL FIELDS

4. CLEAR COVER FOR FOOTING:

GRANITES AGRICULTURAL FIELDS 50MM, COLUMN: 40MM, PLINTH

P

LI

TU

AGRICULTURAL FIELDS

BEAM: 25MM

VIA

NH

HILLOCK

TO

AGRICULTURAL FIELDS

5. LAP LENGTH FOR COLUMN:

50 X Ø OF BAR, BEAM & SLAB: 60

SITE PLAN AGRICULTURAL FIELDS

TOPO PLAN

SCALE-1:400 NTS X Ø OF BAR

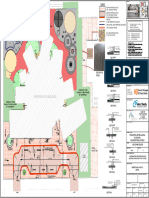

PLANT BUILDING

Turbo Ventilator, 2500 cfm cap.,8Nos

Galvalume Roofing Sheet

Purlin, 60X40 RHS

Metal Rafter, ISMB200

Galvalume Sheet cladding

6.80(RIDGE HT.)

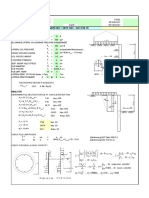

Metal Column, ISMB250 FOOTING DETAILS

6.00(EAVE HT.)

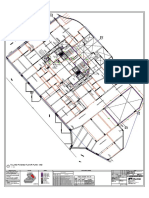

S.NO. TYPE A B D d PEDESTAL MIX NOs

1 F1 920 1220 600 250 500X400 M 20 16

14 14

Brick Work in CM 1:5 2 F2 920 920 500 200 400X300 M 20 10

5 Flooring Consists of 20 mm thick in

CM 1:4 over 100 mm CC Bed

Railing

Base Plate, 20 Thk.

0.76

GL SAND FILLING GL RCC Pedestal (1:2:4)

GL GL FFL

16.00 O/O OF STEEL LINE BASE PLATE

16.46 O/O OF CONCRETE LINE RR Masonry in CM 1:6

ANCHOR BOLTS

TO DETAILS

NGL NGL

ELEVATION SECTION ALONG GRID 'A-A' 8 Ø-200 C/C

2424

1524

2.00

UPTO HARD STRATA

2730

D

A TOP MAT

130

250

3.05 3.05 3.05 3.05 3.05 3.05 3.05 3.05 3.05 3.05 3.05 3.05 2.19 600 600 700

1830

W/V/W W/V/W W/V/W W/V/W W/V/W W/V/W W/V/W W/V/W W/V/W W/V/W W/V/W W/V/W BOTTOM MAT

0.61

CO2 F.E

4.5 KG

PCC 1:4:8, 150 THK

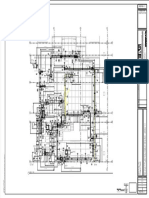

OFFICE, STORE ROOM & WORKERS' REST ROOM

2.75

SECTION B-B

D

WALK WAY TOP MAT

3.05

250

d

130

W/V/W

BOTTOM MAT

150

PCC 1:4:8, 150 THK

150 150

RCC Roof Slab 135 mm thick

A

SECTION A-A

2.00 2.00 with 12 weather proof course

150

2.75

150 150

A

CO2 F.E

1.00 2.40

4.5 KG

2.56

150

0.99

CO2 F.E

4.5 KG

RCC Sunshade

W/V/W

1.00

0.71

3.81

0.60

2.00

0.90

14

W/V/W

1.00

COL. PEDESTAL (400X300)

1.00

1950

BP (270X200)

ISMB150X75

Brick Masonry in CM 1:6

1.20

B

2.75

ISMB200X100

1.00

0.71

B

Flooring over 100 mm CC Bed A A B B

2.56

Sand Filling GL

1.00

GL

W/V/W

16.46

1.00

0.40

1st Footing (1:2:4)

W/V/W

2nd Footing (1:2:4)

1.00

ELEVATION

0.50

0.71

C.C Bed (1:4:8)

150

0.20

Levelling Course with Sand

150

2.40 0.10

2.75

2.56

1.07

FOUNDATION DETAILS FOR F1 FOUNDATION DETAILS FOR F2

SECTION AT 'D-D'

2.00

14 D

W/V/W

9.15

W/V/W

W W W

2.75

2.56

4.57

5 Office Room Store Room Rest Room

3.05

3

W

W

2.77x2.59 2768x2590 2947x2590

W/V/W

CO2 F.E

W/V/W

8 KG DCP F.E

10 KG

1

D D

4

D

2.71

2.00

2.56

4.57

1.22

1.22

1.22

1.22

CO2 F.E.

PLAN

CO2 F.E.

CO2 F.E

DCP F.E.

4.5 KG

DCP F.E.

10.0 KG

10.0 KG

8.0 KG

8.0 KG

LIST OF FIRE FIGHTING EQUIPMENT

3.05

W/V/W

3.05

W/V/W

3.05 3.05

W/V/W

3.05

W/V/W

3.05

W/V/W

3.05

W/V/W

3.05

W/V/W

3.05

W/V/W

3.05

W/V/W

3.05

W/V/W

3.05

W/V/W

3.05

W/V/W

3.05 SCALE-1:100

42.67

Item Symbol Description Qty.

A

PLAN CO2 F.E.

4.5 KG

DCP 10.0 Kg Fire Extenguisher 5

SCALE-1:100 CO2 F.E.

8.0 KG

CO2 4.5 Kg Fire Extenguisher 3

DCP F.E.

10.0 KG

CO2 8.0 Kg Fire Extenguisher 3

LIST OF MACHINERY & EQUIPMENT AREA STATEMENT (SQ.M)

BOILER SHED Natural Draft Stack; 1 Total Site Area 3520.89

CEMENT & LIME STORAGE SHED P.No. Description Power Rating

cross section 0.15m Ø, 18m Ht. 2 Prop. Plant Building Area 702.35

0.60

Galvolume Sheet Roofing 1 100 MT Cap. Fly Ash Storage Silo -

4.40 3 Prop. Boiler Shed Area 66.00

Purlin, 60X40 RHS

RCC Roof Slab 135 mm thick 2 60 MT Cap. Cement Storage Silo -

Metal Rafter, ISMB150

Metal Column, ISMB200

with 12 weather proof course 4 Prop. Lime & Cement storage Shed Area 32.00

Brick Masonry in CM 1:6 3 Screw Conveyor for Cement 7.5 HP

5 Prop. Office, Stores Area 27.91

Ventilator; 0.1m X 0.45m 4 Screw Conveyor for Flyash 7.5 HP

5.00

6 Total Built-up Area 828.26

4.50

150 mm Thick RCC Lintel (1:2:4)

RCC Sunshade RCC Sunshade 5 AAC Slurry Mixer 10 HP

0.60

7 Open Site Area 2692.63

1.45

Flooring Consists of 20 mm thick in Brick Masonry in CM 1:6 6 Mixer for Aluminum Powder 1 HP

REFERENCE

CM 1:4 over 100 mm CC Bed

0.90

Flooring over 100 mm CC Bed 7 Dust collectors for silo venting 1 HP

0.46

Door D 2.10X1.20 Window W 1.52X1.22

0.60

0.61

SAND FILLING RR Masonry in CM 1:6 SAND FILLING GL GL 8 Air Compressure 5 HP

GL GL GL GL Window W1 1.20X0.90 Ventilator V 1.00X0.45

RCC Pedestal (1:2:4) 0.40

1st Footing (1:2:4)

0.74

1st Footing (1:2:4) ELEVATION 2nd Footing (1:2:4) 9 AAC High Speed Mixer 10 HP

ELEVATION

0.50

C.C Bed (1:4:8)

0.48 2nd Footing (1:2:4) 0.20

0.10 Levelling Course with Sand

0.20

0.10 C.C Bed (1:4:8) 10 Water Discharge System 2 HP PLAN SHOWING THE DETAILS OF MANUFACTURING FACILITY OF

B Levelling Course with Sand SECTION ALONG MEGHANA AAC BLOCKS INDUSTRY

13.41 SECTION ALONG C 11 Screw Conveyor for Lime 5 HP

2.68 2.68 2.68 2.68 2.68 8.00 GRID 'C-C' Sy.No.XXXX, Situated within XXXX Revenue Village, XXXX Mandal,

2.66 3.88 1.46 Screw Conveyor for discharging Lime

W/V W/V W/V W/V

GRID 'B-B' W1 W1

12 7.5 HP

XXXX District, Andhrapradesh State.

1.25

Slurry Pump

10.0 KG

DCP F.E.

13 5 HP

CO2 F.E

4.5 KG

2.00

2.00

2.75

14 Wire Cutting Machine, 2 Sets 8 HP Scale 1:100; 1:400 Dwg.No.

1.50

4.00

W1

W1

15 De-Moulder, 2 Sets 4 HP

All Dimensions are in 'Mtrs' min/aac/2020/08/001

W/V

5.50

Base Moulds, 70 Nos

2.00

2.00

2.44 16 -

1.50 1.50 6

5 Upper Moulds, 30 Nos

17 - Signature of Proprietrix

1.22

5

3.25

1.00

2.75

W1 W1

0.53 1.23 1.76 1.23 1.46

1.00 18 FD Fan for Boiler 3 HP (RAMAVATH RAVI)

C

1.00

PLAN 19 ID Fan for Boiler 10 HP

CO2 F.E.

8.0 KG

Feed Pumps, 2 Nos

W/V W/V W/V W/V

2.68 2.68 2.68 2.68 2.68 SCALE-1:100 20 8 HP

Sign.of Licenced Engineer

B PLAN 21 Submersible Pump 2 HP

SCALE-1:100 22 Lighting Load 0.5 HP

Total 97 HP

You might also like

- Technical Feasibility Report-uPVC Windows & DoorsDocument158 pagesTechnical Feasibility Report-uPVC Windows & Doorstechnopreneurvizag100% (1)

- Technical Feasibility Report-uPVC Windows & DoorsDocument158 pagesTechnical Feasibility Report-uPVC Windows & Doorstechnopreneurvizag100% (1)

- DDP MSRDC Mumbai Pune ExpresswayDocument1 pageDDP MSRDC Mumbai Pune ExpresswayGodrej Construction100% (1)

- Dpr-Meghana Roofing Industries-From Page5Document20 pagesDpr-Meghana Roofing Industries-From Page5technopreneurvizagNo ratings yet

- Cma Data-414 Lacs-Aac Blocks Mfg. Unit.Document22 pagesCma Data-414 Lacs-Aac Blocks Mfg. Unit.technopreneurvizagNo ratings yet

- Reporting (PCD) - Chapter 2Document39 pagesReporting (PCD) - Chapter 2Cj BarcelonNo ratings yet

- Existing Floor Plan: Herminiano R. HuelgasDocument3 pagesExisting Floor Plan: Herminiano R. HuelgasMark Anthony TajonNo ratings yet

- Cnph001 262 03 DR MG 000005 Gases Medicinales Sector 01d Tercer NivelDocument1 pageCnph001 262 03 DR MG 000005 Gases Medicinales Sector 01d Tercer NivelTony Jimenez ChNo ratings yet

- Jkenneth - Thompson PortfolioDocument9 pagesJkenneth - Thompson PortfolioJ. Kenneth ThompsonNo ratings yet

- Ded Tubes p4 AccDocument36 pagesDed Tubes p4 AccLilya erviyana129 lilya erviyana129No ratings yet

- RONDOS ZonabajaDocument1 pageRONDOS Zonabaja2018111073No ratings yet

- Gab DSB Isometric Sanitary Works Plumbing PlanDocument1 pageGab DSB Isometric Sanitary Works Plumbing PlanTrisha Mae MaganteNo ratings yet

- Narrow Three Level HouseDocument3 pagesNarrow Three Level HouseDavid KisaluNo ratings yet

- 01-BWSS SITE Drainage System PLANDocument1 page01-BWSS SITE Drainage System PLANAsjad Rahim KhanNo ratings yet

- Cabida E01Document6 pagesCabida E01Fabian ArancibiaNo ratings yet

- Old PlumbingDocument8 pagesOld PlumbingfaizanNo ratings yet

- B.K.T Full Final DWG New-ModelDocument1 pageB.K.T Full Final DWG New-ModelATHARSBGNo ratings yet

- 8.5x11 Campus Map PDFDocument2 pages8.5x11 Campus Map PDFLedoNo ratings yet

- Harvard University CampusDocument2 pagesHarvard University CampustupesadillaNo ratings yet

- Red de Conecciones DomiciliariasDocument1 pageRed de Conecciones DomiciliariasAinhoa del carmen Llanos ulloaNo ratings yet

- Test - Logesh-EQPTDocument1 pageTest - Logesh-EQPTSenthilkumar KNo ratings yet

- Animal Incinerator: Site PlanDocument1 pageAnimal Incinerator: Site PlanNAHEEMA KPNo ratings yet

- Patapo ModelDocument1 pagePatapo ModelManuel Zuloaga CastellanosNo ratings yet

- 5° Piso 1° Piso 2°-4° PISO: Et HumDocument1 page5° Piso 1° Piso 2°-4° PISO: Et HumJavier SantillánNo ratings yet

- Planta 04 Sin ColorDocument1 pagePlanta 04 Sin ColorDIEGO FERNANDO GARCIA CARMONANo ratings yet

- Plano General-ClaveDocument1 pagePlano General-Clavealejandro chuquirimay mamaniNo ratings yet

- (RB6) OBANDO RIVER BRIDGE 3 - Structural Drawings - 10162023Document28 pages(RB6) OBANDO RIVER BRIDGE 3 - Structural Drawings - 10162023slvdrkdNo ratings yet

- FINAL HOUSING PROJECT Version 2Document1 pageFINAL HOUSING PROJECT Version 2Rogismar AlngogNo ratings yet

- External - SITE-WORK-PROCESS (002) - 1Document1 pageExternal - SITE-WORK-PROCESS (002) - 1verbat007No ratings yet

- Stfe de Antioquia: Puente-4 Popala IZQ 180m DER 180mDocument1 pageStfe de Antioquia: Puente-4 Popala IZQ 180m DER 180mMichell MorenoNo ratings yet

- CR Ingenieros: Limite de ProyectoDocument4 pagesCR Ingenieros: Limite de ProyectoJorge GutierrezNo ratings yet

- M O G A: Proposed Landuse Plan - 2031 LegendDocument1 pageM O G A: Proposed Landuse Plan - 2031 LegendRanaditaNo ratings yet

- Torre Marimar: Vestibulo Elevadores Vestibulo Elevadores Escaleras EmergenciaDocument1 pageTorre Marimar: Vestibulo Elevadores Vestibulo Elevadores Escaleras Emergenciajose mañanNo ratings yet

- Interlock Tile Phase 1 & 2Document1 pageInterlock Tile Phase 1 & 2amnaakmal070No ratings yet

- Ahmad City Al Khair GroupDocument1 pageAhmad City Al Khair Groupkamranqamar0099No ratings yet

- Plano Zonificacion Chilca Huancayo (2) - ZonasDocument1 pagePlano Zonificacion Chilca Huancayo (2) - ZonasDIANA GLADYS CARHUALLANQUI CACHUANNo ratings yet

- Reference Drawings: Key PlanDocument1 pageReference Drawings: Key PlanTalha BurnyNo ratings yet

- DEWA Water Network LayoutDocument1 pageDEWA Water Network Layoutabdullah fararjehNo ratings yet

- 9204-BP12A-MMJV-IFCD-ME-P1-000-00240-REV.000Document1 page9204-BP12A-MMJV-IFCD-ME-P1-000-00240-REV.000Abdulhamit KAYYALINo ratings yet

- A1103 - T3 1ST PODIUM FLOOR PLAN-Layout1Document1 pageA1103 - T3 1ST PODIUM FLOOR PLAN-Layout1nalini msNo ratings yet

- A1104 - T3 2ND PODIUM FLOOR PLAN Mesurment-Layout1Document1 pageA1104 - T3 2ND PODIUM FLOOR PLAN Mesurment-Layout1nalini msNo ratings yet

- ALD1 AllDocument1 pageALD1 AllBKVNo ratings yet

- CR Al ArDocument1 pageCR Al AramlaNo ratings yet

- Consultation Change Maps - AdelaideDocument6 pagesConsultation Change Maps - AdelaideMohammad Abram MaulanaNo ratings yet

- SDP-02 Rev 1 TLN-2 18.10.2021-SDP-02Document1 pageSDP-02 Rev 1 TLN-2 18.10.2021-SDP-02Harza Anaya MasNo ratings yet

- Los Nuncios Parcial 1Document1 pageLos Nuncios Parcial 1Antonio ChacónNo ratings yet

- GMF 4069-GS 010.2 SHT 1 Rev C4 - GRD Floor MEP Coordinated ServicesDocument1 pageGMF 4069-GS 010.2 SHT 1 Rev C4 - GRD Floor MEP Coordinated ServicesNitin SeenauthNo ratings yet

- SEBENTA Exisiting Features Drawing1-ISO A1 LayoutDocument1 pageSEBENTA Exisiting Features Drawing1-ISO A1 LayoutSizo MabilaNo ratings yet

- Fence Plan Part 03 01: CCTV System External FenceDocument1 pageFence Plan Part 03 01: CCTV System External FenceMicheal FawzyNo ratings yet

- Fence Plan Part 02 03: Lighting System External FenceDocument1 pageFence Plan Part 02 03: Lighting System External FenceMicheal FawzyNo ratings yet

- Ejecutivo Final 1.23Document1 pageEjecutivo Final 1.23Erick Almazan AvilaNo ratings yet

- ANEXO v. Proposta CicloviaDocument1 pageANEXO v. Proposta CicloviaDavi LelisNo ratings yet

- Soha Abathr Alameen ENA5 - 3Document2 pagesSoha Abathr Alameen ENA5 - 3yageen.alaaNo ratings yet

- MapalondresDocument1 pageMapalondresrzyoNo ratings yet

- 02 Singh GhatDocument1 page02 Singh GhatVinod Kumar GaurNo ratings yet

- Internet Undersea WorldDocument1 pageInternet Undersea Worldhoathinhdon100% (1)

- Haroli Jajon: Earthen Shoulder EdgeDocument13 pagesHaroli Jajon: Earthen Shoulder EdgeDushyant JadaunNo ratings yet

- MD-RA-1.1: Issued For ConstructionDocument1 pageMD-RA-1.1: Issued For ConstructionEmmanuel BahenaNo ratings yet

- MD-RA-1.1: Issued For ConstructionDocument1 pageMD-RA-1.1: Issued For ConstructionEmmanuel BahenaNo ratings yet

- Final Stitch Map-Shivaji Nagar-Model PDFDocument1 pageFinal Stitch Map-Shivaji Nagar-Model PDFsuper mageNo ratings yet

- PM210011 900 Es602 001Document1 pagePM210011 900 Es602 001Partha SundarNo ratings yet

- JR - Jose Carlos Mariategui: Jr. J. Cruz MontañoDocument1 pageJR - Jose Carlos Mariategui: Jr. J. Cruz MontañoFernando Quispe SinarahuaNo ratings yet

- Parking 8.5x11 0 PDFDocument1 pageParking 8.5x11 0 PDFuser5839No ratings yet

- 3.bom-Civil-Meghana Aac Blocks IndustryDocument15 pages3.bom-Civil-Meghana Aac Blocks IndustrytechnopreneurvizagNo ratings yet

- Plan-Meghana Engineering IndustryDocument1 pagePlan-Meghana Engineering IndustrytechnopreneurvizagNo ratings yet

- Product Portfolio-Disposable SyringesDocument7 pagesProduct Portfolio-Disposable SyringestechnopreneurvizagNo ratings yet

- Form No:: Date of Online Filing: 11 Mar 2013Document6 pagesForm No:: Date of Online Filing: 11 Mar 2013technopreneurvizagNo ratings yet

- State Wise Vacancy Information: Vacant Properties Summary For VISAKHAPATNAM Zone Property WiseDocument2 pagesState Wise Vacancy Information: Vacant Properties Summary For VISAKHAPATNAM Zone Property WisetechnopreneurvizagNo ratings yet

- Dpr-Meghana Roofing Industries-1to4 PagesDocument4 pagesDpr-Meghana Roofing Industries-1to4 PagestechnopreneurvizagNo ratings yet

- Details of Vacant Industrial Properties-Visakhapatnam Zone: Health City-ChinagadiliDocument6 pagesDetails of Vacant Industrial Properties-Visakhapatnam Zone: Health City-ChinagadilitechnopreneurvizagNo ratings yet

- Cma-Krishnaveni Upvc Profiles PDFDocument22 pagesCma-Krishnaveni Upvc Profiles PDFtechnopreneurvizagNo ratings yet

- Cma-Meghana SurgicalsDocument100 pagesCma-Meghana SurgicalstechnopreneurvizagNo ratings yet

- Tfr-Upvc Windows and Doors Fab. UnitDocument31 pagesTfr-Upvc Windows and Doors Fab. UnittechnopreneurvizagNo ratings yet

- Cross Section of Metal BuildingDocument1 pageCross Section of Metal BuildingtechnopreneurvizagNo ratings yet

- Product Portfolio-Aac BlocksDocument19 pagesProduct Portfolio-Aac BlockstechnopreneurvizagNo ratings yet

- Slab Design-ExcelDocument2 pagesSlab Design-ExceltechnopreneurvizagNo ratings yet

- Product Portfolio-Aac Blocks ManufactringDocument15 pagesProduct Portfolio-Aac Blocks ManufactringtechnopreneurvizagNo ratings yet

- Formworks & Falsework ManualDocument71 pagesFormworks & Falsework ManualWilfredo Lotino75% (4)

- Mumbai Metro Line 3: Cre Site Daily ReportDocument16 pagesMumbai Metro Line 3: Cre Site Daily Reportvansh chauhanNo ratings yet

- Is SP 16 1980 PDFDocument255 pagesIs SP 16 1980 PDFShaik Abdul RaheemNo ratings yet

- Axial Load Capacity of Columns: (Short) : N ST G ST G ST STDocument9 pagesAxial Load Capacity of Columns: (Short) : N ST G ST G ST STAurora VillalunaNo ratings yet

- Line-Up Expansion of Hat-Shaped Steel Sheet Pile (NS-SP-45H 50H)Document7 pagesLine-Up Expansion of Hat-Shaped Steel Sheet Pile (NS-SP-45H 50H)Thanh Dao BaNo ratings yet

- Foundation Loads 18Th SBML: Span 1 Span 2 Span 3 DLDocument1 pageFoundation Loads 18Th SBML: Span 1 Span 2 Span 3 DLShaileshRastogiNo ratings yet

- What Is An Expansion Joint?Document7 pagesWhat Is An Expansion Joint?PalakNo ratings yet

- CS 457 Revision 1 The Assessment of Composite Highway Bridges and Structures-WebDocument137 pagesCS 457 Revision 1 The Assessment of Composite Highway Bridges and Structures-Webasaad biqaiNo ratings yet

- Primary Chamber - Bending Moment, MXX (KNM/M) Automatic Direction Cases: 1 (Earth)Document3 pagesPrimary Chamber - Bending Moment, MXX (KNM/M) Automatic Direction Cases: 1 (Earth)afiqNo ratings yet

- Lecture 1 Introduction To Matrix Structural AnalysisDocument20 pagesLecture 1 Introduction To Matrix Structural AnalysisMuhammad Hassan IlyasNo ratings yet

- Rigid Versus Flexible Pavement DesignDocument3 pagesRigid Versus Flexible Pavement DesignAlbertJnBaptisteNo ratings yet

- Shear Resistance of RC Circular Members With FRP Discrete Hoops Versus SpiralsDocument16 pagesShear Resistance of RC Circular Members With FRP Discrete Hoops Versus Spiralser.praveenraj30No ratings yet

- Ain Shams University Faculty of Engineering Structural Engineering Dep. Structural Mechanics (1) Spring 2021 ReactionsDocument7 pagesAin Shams University Faculty of Engineering Structural Engineering Dep. Structural Mechanics (1) Spring 2021 Reactionsmohamed amerNo ratings yet

- Structural Design of Combined FootingsDocument6 pagesStructural Design of Combined Footingsselina100% (1)

- Tle First Quarter Drafting Technology 9Document4 pagesTle First Quarter Drafting Technology 9Ronel ConstantinoNo ratings yet

- Rate Analysis-IlyasDocument9 pagesRate Analysis-IlyasEr Bharat PrajapatiNo ratings yet

- General Notes: Makati - Mandaluyong BridgeDocument1 pageGeneral Notes: Makati - Mandaluyong BridgegregNo ratings yet

- Sheet Pile Wall Design Based On 2018 IBC / 2019 CBC / ACI 318-19Document3 pagesSheet Pile Wall Design Based On 2018 IBC / 2019 CBC / ACI 318-19afvilavilanoriegaNo ratings yet

- Bending in Beam 2: Reinforced Concrete DesignDocument16 pagesBending in Beam 2: Reinforced Concrete DesignlavyNo ratings yet

- Fire Damper WH25: DimensionsDocument11 pagesFire Damper WH25: DimensionsAncuta CosmanNo ratings yet

- Z Purlin DesignDocument22 pagesZ Purlin DesignGautam PaulNo ratings yet

- Self-Compacting Concrete GuidelinesDocument68 pagesSelf-Compacting Concrete GuidelinesJim Jackofalltrades Heffernan100% (1)

- Sloping Side Elevation: Base Slab PlanDocument1 pageSloping Side Elevation: Base Slab PlanMwesigwa DaniNo ratings yet

- PCI 6th Edition - Flexural Component DesignDocument127 pagesPCI 6th Edition - Flexural Component Designdeepa100% (1)

- Aci GFRP 440.11 Ma23Document7 pagesAci GFRP 440.11 Ma23DrSalehNo ratings yet

- Cirebon 2, 1X1000Mw Coal Fired Power PlantDocument8 pagesCirebon 2, 1X1000Mw Coal Fired Power PlantAnang RuwantoNo ratings yet

- IC WBS With Gantt ChartDocument1 pageIC WBS With Gantt ChartWarren DiwaNo ratings yet

- Beam Rebar ArrangementDocument10 pagesBeam Rebar Arrangementme_decent28457100% (2)

- Refresher. Roales 3. 2022 09 28Document27 pagesRefresher. Roales 3. 2022 09 28reneotejrboardexamNo ratings yet