Professional Documents

Culture Documents

Maximize The Efficiency of Your Additive

Maximize The Efficiency of Your Additive

Uploaded by

sriatul2006Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maximize The Efficiency of Your Additive

Maximize The Efficiency of Your Additive

Uploaded by

sriatul2006Copyright:

Available Formats

Maximize the efficiency

of your additive

STEPCOTE™ W-846: Multifunctional, APE-Free

Wetting Agent for Waterborne Coatings

STEPCOTE W-846 is an alternative to alkyl phenol ethoxylates (APE) for use in waterborne coatings. This

well-rounded, APE-free additive can provide benefits to gloss development, hiding, pigment dispersion and

temperature stability while preserving the wet scrub resistance of the coating.

Enhanced Gloss and Hiding

Improved gloss and hiding are indicative of optimized pigment dispersion. In Figure 1, STEPCOTE W-846

showed improved 20o and 60o gloss readings compared to a coating without an additive and comparable

performance to a commercial APE control (nonyl phenol 6-mole ethoxylate phosphate ester). When compared

to a coating without additive, STEPCOTE W-846 improved titanium dioxide (TiO2) dispersion that resulted in

enhanced hiding (Figure 2).

Figure 1. Gloss Development Figure 2. Hiding

80 0.99

20 Degree

60 Degree

60

Contrast Ratio

Gloss Reading

0.98

40 20 Degree

STEPCOTE 60 Degree 0.97

W-846 20

0 0.96

No APE STEPCOTE No APE STEPCOTE

Additive Control W-846 Additive Control W-846

ASTM D523: additive dosed at 3 lbs/100 gallons (active), all acrylic, ASTM D2805: additive dosed at 3 lbs/100 gallons (active), all acrylic,

29.8% PVC, <50 g/L VOC 29.8% PVC, <50 g/L VOC

Figure 3. TiO2 Dispersion Quality

800

The relative quality of the dispersion can be

-1, cps

700

1000

Failure

evaluated by change in viscosity. Lower viscosity 600

indicates efficient pigment wetting and better

Rate ofto10S

800

500

dispersion quality. When compared to a coating 400

Viscosity at ShearCycles

without additive and a commercial APE control, 600

300

STEPCOTE W-846 exhibited improved dispersion

200

400

quality of a 70% TiO2 pigment concentrate at a

dose of 0.5% (Figure 3). 100

200

0

No APE STEPCOTE STEPCOTE

0 Additive Control W-849 W-888

No APE STEPCOTE

Additive Control W-846

Additive tested at 0.5% use level with 70% TiO2 due to optimal

viscosity. Viscosity measured at Shear Rate of 10 S-1.

No APE STEPCOTE

Additive Control W-846

Maintained Durability Figure 4. Wet Scrub Resistance

The wet scrub resistance of a coating was 900

maintained after the addition of STEPCOTE W-846. 800

In Figure 4, STEPCOTE W-846 exhibits equivalent

Cycles to Failure

700

performance compared to a coating without 600

additive and a commercial APE control. 500

400

300

200

100

0

No APE STEPCOTE

Additive Control W-846

ASTM D2486: additive dosed at 3 lbs/100 gallons (active), all acrylic,

29.8% PVC, <50 g/L VOC

Improved Temperature Stability Table 1. Freeze/Thaw Stability

STEPCOTE W-846 can provide improved temperature KU Viscosity

stability to a coating. After three freeze/thaw cycles, Freeze/Thaw

Additive Change

the coating with STEPCOTE W-846 maintained Cycles Passed

After 3 Cycles

its viscosity in contrast to the commercial APE No Additive 0 N/A

control (Table 1). After high temperature evaluations,

APE Control 3 -9

STEPCOTE W-846 demonstrated the least amount

of viscosity loss and separation when compared to STEPCOTE W-846 3 -1

a coating without additive and a commercial APE ASTM D2243: additive dosed at 3 lbs/100 gallons (active), all acrylic,

control (Table 2). 29.8% PVC, <50 g/L VOC

Table 2. High Temperature Stability: 120oF

KU Viscosity

Additive Change Syneresis Settling

After 2 Weeks

No Additive -9 Moderate Moderate

APE Control -6 Slight Slight

STEPCOTE W-846 -4 None Slight

ASTM D1849: additive dosed at 3 lbs/100 gallons (active), all acrylic, 29.8% PVC, <50 g/L VOC

For more information visit go.stepan.com/CASEAdditives or contact us.

2020 © Stepan Company. All Rights Reserved.

STEPCOTE™ is a trademark of Stepan Company.

The information contained herein is based on the manufacturer’s own study and the works of others and is subject to change without prior notice. The information is not intended to be all-inclusive, including

as to the manner and conditions of use, handling, storage or disposal or other factors that may involve additional legal, environmental, safety or performance considerations. Nothing contained herein grants or

extends a license, express or implied, in connection with any patents issued or pending of the manufacturer or others, or shall be construed as a recommendation to infringe any patents. STEPAN COMPANY

MAKES NO PRODUCT WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR USE, EXPRESS OR IMPLIED, AND NO OTHER WARRANTY OR GUARANTY, EXPRESS OR IMPLIED, IS

MADE, INCLUDING AS TO INFORMATION REGARDING PERFORMANCE, SAFETY, SUITABILITY, STABILITY, ACCURACY, COMPLETENESS, OR ADEQUACY. Stepan Company (and its employees, subsidiaries

and affiliates) shall not be liable (regardless of fault) to the vendee, its employees, or any other party for any direct, indirect, special or consequential damages arising out of or in connection with the accuracy,

completeness, adequacy, furnishing, use, or reliance upon information provided herein. The vendee assumes and releases Stepan Company (and its employees, subsidiaries and affiliates) from all liability, whether

in tort, contract or otherwise to the fullest extent possible under the relevant law. July 2020

You might also like

- Sociological Analysis For The Joy Luck ClubDocument5 pagesSociological Analysis For The Joy Luck ClubNathan Doesitmatter100% (2)

- Oil Water Separator DrawingDocument1 pageOil Water Separator DrawingHazem Esam100% (1)

- 15KLD STP FBBR LayoutDocument1 page15KLD STP FBBR LayoutBiswajit SahooNo ratings yet

- Polyols & Aspartics For Reaction With Polyisocyanates Nonreactive ResinsDocument32 pagesPolyols & Aspartics For Reaction With Polyisocyanates Nonreactive Resinssriatul2006No ratings yet

- VOC Compliant 2K PUR Coatings in Low ... - Bayercoatings - deDocument32 pagesVOC Compliant 2K PUR Coatings in Low ... - Bayercoatings - desriatul2006No ratings yet

- OutlookDocument53 pagesOutlookAvi Kense100% (1)

- HA15321064 SignedDocument1 pageHA15321064 SignedSuyog GawandeNo ratings yet

- Petrosleeve PresentationDocument26 pagesPetrosleeve PresentationGerman Gonzalo RivasNo ratings yet

- 808-17-2HHDH 500 GPMDocument1 page808-17-2HHDH 500 GPMRafael ColinaNo ratings yet

- Thorlux HI19721 Hi-Style-Led 24WDocument3 pagesThorlux HI19721 Hi-Style-Led 24WravNo ratings yet

- Dryer Boost Fan - Reversomatic - TLD SeriesDocument2 pagesDryer Boost Fan - Reversomatic - TLD SeriesPamela De Melo-LangfordNo ratings yet

- 2 Whitgift Street Croydon NpsDocument35 pages2 Whitgift Street Croydon NpsravNo ratings yet

- Rheovis AT 120 - OPP & SpotlightDocument2 pagesRheovis AT 120 - OPP & SpotlightArvindNo ratings yet

- 600 800 Bowl Power:: Meta Petroleum: 18EKY/18EKH: EC-1460/1448: Agua Inyeccion: 5Document4 pages600 800 Bowl Power:: Meta Petroleum: 18EKY/18EKH: EC-1460/1448: Agua Inyeccion: 5willNo ratings yet

- Minimum Operating Envelope 2 Inch 18ppg Trim ChokesDocument1 pageMinimum Operating Envelope 2 Inch 18ppg Trim Chokescarlos angelNo ratings yet

- Astm G109Document6 pagesAstm G109AB Francisco JuanNo ratings yet

- k215-165b (15amp Trip Sel CB)Document1 pagek215-165b (15amp Trip Sel CB)Claudio DiazNo ratings yet

- Spray Droplet Size Standard S-572: Robert E. WolfDocument37 pagesSpray Droplet Size Standard S-572: Robert E. WolfIvana BaraćNo ratings yet

- 6922e SEPINOV EMT 10 E-LeafletDocument4 pages6922e SEPINOV EMT 10 E-LeafletVíctor Digón100% (1)

- Old Impeller Performance CurveDocument1 pageOld Impeller Performance CurveArjun ChouhanNo ratings yet

- LBZPC Carbopol-Silk Brochure TDS-947 2014 Hubcast FNLDocument4 pagesLBZPC Carbopol-Silk Brochure TDS-947 2014 Hubcast FNLOnesany TecnologiasNo ratings yet

- 25stg 862-18000-XA Shell Units New Curve 50HZ 100psiDocument2 pages25stg 862-18000-XA Shell Units New Curve 50HZ 100psiMohamed Ashraf SolimanNo ratings yet

- Pricelist 2022 Okt - Curl & ScalpDocument4 pagesPricelist 2022 Okt - Curl & ScalpTrio Bekti ImansahNo ratings yet

- Downstream MCCB - TCCDocument1 pageDownstream MCCB - TCCshrikanth5singhNo ratings yet

- CBR 04Document1 pageCBR 04DODI SOFYANNo ratings yet

- CPL - V2 Jan 2022Document4 pagesCPL - V2 Jan 2022Huzefa RangwalaNo ratings yet

- Allele 100bp DNA LadderDocument1 pageAllele 100bp DNA LadderAlleleBiotechNo ratings yet

- Pavement PerformanceDocument70 pagesPavement PerformanceAnonymous J9OnNRNo ratings yet

- Existing Computer Lab and Class Room: W W W WDocument1 pageExisting Computer Lab and Class Room: W W W WvijaykrishnaasacivilNo ratings yet

- IHHA2017 - Ebook Proceedings - Part 3Document50 pagesIHHA2017 - Ebook Proceedings - Part 3bremer090909No ratings yet

- TLD 300 InletDocument2 pagesTLD 300 Inletjacked19No ratings yet

- Minimum Operating Envelope 3 Inch 8ppg Trim ChokesDocument1 pageMinimum Operating Envelope 3 Inch 8ppg Trim Chokescarlos angelNo ratings yet

- Aslan™ 400 Carbon Fiber Reinforced Polymer (CFRP) Laminates Product SheetDocument1 pageAslan™ 400 Carbon Fiber Reinforced Polymer (CFRP) Laminates Product Sheet192113No ratings yet

- TDS SOFTILT AS-L Leaflet@20140721Document6 pagesTDS SOFTILT AS-L Leaflet@20140721Trần Yến NhiNo ratings yet

- 2 Speed Propulsion System Scana PropulsionDocument4 pages2 Speed Propulsion System Scana PropulsionMaurizio BernasconiNo ratings yet

- Section A - A, Scale 1:100: All Dimension Are in MilimeterDocument1 pageSection A - A, Scale 1:100: All Dimension Are in MilimetergadielNo ratings yet

- Ultrapure™ Agarose: Gel Strength Is Calculated at 1% ConcentrationDocument4 pagesUltrapure™ Agarose: Gel Strength Is Calculated at 1% ConcentrationDaniel Solís toroNo ratings yet

- Pump Curve 5M244Document3 pagesPump Curve 5M244Rachmad PascalNo ratings yet

- 9900-9245 00 GearboxappworksheetDocument1 page9900-9245 00 GearboxappworksheetDaniel MalfazNo ratings yet

- Multiples of Current Rating: Molded Case Circuit Breaker K 1000 LINEDocument2 pagesMultiples of Current Rating: Molded Case Circuit Breaker K 1000 LINEAmr AhmedNo ratings yet

- Godwin UHH250Document1 pageGodwin UHH250hendrynNo ratings yet

- Pressure vs. Temperature For PropaneDocument1 pagePressure vs. Temperature For Propanewerdna67No ratings yet

- BR CycloneDocument8 pagesBR CycloneRiegos Veracruz100% (1)

- Tds - 25 LPS, Head-150 MTRDocument4 pagesTds - 25 LPS, Head-150 MTRmukherjeemohul25No ratings yet

- Increase Your Production and Recovery With Improved Proppant Pack IntegrityDocument4 pagesIncrease Your Production and Recovery With Improved Proppant Pack Integrityarturo_partida_1No ratings yet

- Castrol HD Greases Brochure Aug 2019 LRDocument6 pagesCastrol HD Greases Brochure Aug 2019 LRDiego R. BettNo ratings yet

- DH GF HF Bio-X Vent AutoclaveDocument2 pagesDH GF HF Bio-X Vent AutoclaveOrlindo WagnerNo ratings yet

- Tech Docs Ksew Wss JJM Jmu Item3 RKBF 40 12l 15stg 37kc2 300m 22.73m3 07 09 2023Document1 pageTech Docs Ksew Wss JJM Jmu Item3 RKBF 40 12l 15stg 37kc2 300m 22.73m3 07 09 2023vivek dhadwalNo ratings yet

- Omega Introduction Letter Civil With Letter-1Document5 pagesOmega Introduction Letter Civil With Letter-1Velmurugan BalasubramanianNo ratings yet

- Concrete A2Document1 pageConcrete A2Darshan ShahNo ratings yet

- Baku Pembanding Ciprofloxacin HCL Pelarut Aquadest No. 1 2 3Document11 pagesBaku Pembanding Ciprofloxacin HCL Pelarut Aquadest No. 1 2 3kelas c 2016No ratings yet

- Gejayan CCTVDocument3 pagesGejayan CCTVsyaifudin zuhriNo ratings yet

- Drainase Pako FP Det 07-ModelDocument1 pageDrainase Pako FP Det 07-ModelHakasapra KonveksiNo ratings yet

- En - C100 EtaDocument1 pageEn - C100 EtaJosemaNo ratings yet

- Theta Catalog 2014 PMI Illuminazione LedDocument11 pagesTheta Catalog 2014 PMI Illuminazione LedFabio AriassiNo ratings yet

- Vistamaxx Waterproofing Membrane Factsheet enDocument2 pagesVistamaxx Waterproofing Membrane Factsheet enManoharan SundaramNo ratings yet

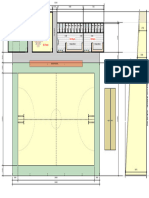

- DCP INFRA 08 2023 QEB Gym 5 Draft Concept DrawingsDocument1 pageDCP INFRA 08 2023 QEB Gym 5 Draft Concept DrawingsDon LalNo ratings yet

- DCP INFRA 08 2023 QEB Gym 5 Draft Concept DrawingsDocument1 pageDCP INFRA 08 2023 QEB Gym 5 Draft Concept DrawingsDon LalNo ratings yet

- Ultra-Arc™ Series: Metal Halide LampsDocument2 pagesUltra-Arc™ Series: Metal Halide LampsMilovan StaničićNo ratings yet

- Meyco FIB 500 PDFDocument2 pagesMeyco FIB 500 PDFFrancois-No ratings yet

- Idaku Pasuruan Lantai 2 Toko-ModelDocument1 pageIdaku Pasuruan Lantai 2 Toko-Modelfeniasaputri6No ratings yet

- Pac56 Mx13specsheet 2021 Final DigitalhiresDocument2 pagesPac56 Mx13specsheet 2021 Final Digitalhiresgaurao.pandeNo ratings yet

- MX 13 Spec SheetDocument2 pagesMX 13 Spec SheetHarish KumarNo ratings yet

- Technical Data Sheet: Rexin DP 127Document1 pageTechnical Data Sheet: Rexin DP 127sriatul2006No ratings yet

- Tomamine Inhibitor 60QDocument2 pagesTomamine Inhibitor 60Qsriatul2006No ratings yet

- Eucon VANDEX AM 10L TDS ME 0224-R2 PDFDocument2 pagesEucon VANDEX AM 10L TDS ME 0224-R2 PDFsriatul2006No ratings yet

- Trixene As TDSDocument2 pagesTrixene As TDSsriatul2006No ratings yet

- Ethacure® 90 - AlbemarleDocument2 pagesEthacure® 90 - Albemarlesriatul2006No ratings yet

- Amino Trimethylene Phosphonic Acid: (ATMP)Document2 pagesAmino Trimethylene Phosphonic Acid: (ATMP)sriatul2006No ratings yet

- Ethacryl GDocument2 pagesEthacryl Gsriatul2006No ratings yet

- Plastorit 0000 - Mica&Quartz PDFDocument1 pagePlastorit 0000 - Mica&Quartz PDFsriatul2006No ratings yet

- Basis 59 - TDSDocument2 pagesBasis 59 - TDSsriatul2006No ratings yet

- Basis 60 - TDSDocument2 pagesBasis 60 - TDSsriatul2006No ratings yet

- Wollatonite Powder Technical Data Sheet: Sr. No. Particulars ContentDocument1 pageWollatonite Powder Technical Data Sheet: Sr. No. Particulars Contentsriatul2006No ratings yet

- Luzenac10M0 - Talc PDFDocument1 pageLuzenac10M0 - Talc PDFsriatul2006No ratings yet

- Hydrophobic Poly - Etheramines For Moisture-Resistant Polyurea CoatingsDocument3 pagesHydrophobic Poly - Etheramines For Moisture-Resistant Polyurea Coatingssriatul2006No ratings yet

- Lime in ConstructionDocument7 pagesLime in Constructionsriatul2006No ratings yet

- Silane-Terminated Polyurethanes (STPS) For Sealants & AdhesivesDocument2 pagesSilane-Terminated Polyurethanes (STPS) For Sealants & Adhesivessriatul2006No ratings yet

- Boost Your Sustainability Profile: Sovermol - Natural Oil-Based, Performance Driven PolyolsDocument8 pagesBoost Your Sustainability Profile: Sovermol - Natural Oil-Based, Performance Driven Polyolssriatul2006No ratings yet

- Wax Emulsions CenterDocument7 pagesWax Emulsions Centersriatul2006No ratings yet

- How To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry PaintsDocument45 pagesHow To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry Paintssriatul2006No ratings yet

- Two Component Aliphatic Polyurea Coatings For High Productivity Applications PDFDocument6 pagesTwo Component Aliphatic Polyurea Coatings For High Productivity Applications PDFsriatul2006No ratings yet

- VOC CalculationDocument7 pagesVOC Calculationsriatul2006No ratings yet

- TDS BYK A 595 EquivalentDocument2 pagesTDS BYK A 595 Equivalentsriatul2006No ratings yet

- Titanium Dioxide RutileDocument1 pageTitanium Dioxide Rutilesriatul2006No ratings yet

- Product Data: CompositionDocument2 pagesProduct Data: Compositionsriatul2006No ratings yet

- Tannic Acid: SynonymsDocument1 pageTannic Acid: Synonymssriatul2006No ratings yet

- Tylovis SE7: Technical SalesDocument2 pagesTylovis SE7: Technical Salessriatul2006No ratings yet

- Taxanol PDFDocument47 pagesTaxanol PDFsriatul2006No ratings yet

- Georges A. Barrois, Jesus Christ and The Temple: Cărți Pentru TraducereDocument2 pagesGeorges A. Barrois, Jesus Christ and The Temple: Cărți Pentru TraducereAlin GogaNo ratings yet

- Internship Seminar On: Web Development (Epost Office)Document15 pagesInternship Seminar On: Web Development (Epost Office)sneha gnNo ratings yet

- Stonhard Color Sheet Stonclad Fnlrev-1Document1 pageStonhard Color Sheet Stonclad Fnlrev-1Anonymous aii1ilNo ratings yet

- Hand Hygiene and HandwashingDocument7 pagesHand Hygiene and HandwashingFaith Dianasas RequinaNo ratings yet

- Equivalence Above Word LevelDocument23 pagesEquivalence Above Word LevelHürü Nur DüzenliNo ratings yet

- HP Smart Update Firmware DVD 9.20 What's New and Release NotesDocument13 pagesHP Smart Update Firmware DVD 9.20 What's New and Release NotesDavid SaralidzeNo ratings yet

- Up A Pad A 1Document6 pagesUp A Pad A 1Ramesh MenonNo ratings yet

- Airport CAA JOBsDocument22 pagesAirport CAA JOBsRAM JAIPALNo ratings yet

- JaneEyre ExtendedEssayOutlineDocument3 pagesJaneEyre ExtendedEssayOutlineAnonymous w3Gji93No ratings yet

- WAGAN 8576 9 UserManualDocument24 pagesWAGAN 8576 9 UserManualNelly Cristina Rubio RodriguezNo ratings yet

- Maria Montessori and Her Educational Philosophy: Breaking Barriers in EducationDocument5 pagesMaria Montessori and Her Educational Philosophy: Breaking Barriers in EducationfreddyNo ratings yet

- Increasing Awareness of Future Teachers About Health, Health Preservation and Health Saving Technologies of Preschool ChildrenDocument4 pagesIncreasing Awareness of Future Teachers About Health, Health Preservation and Health Saving Technologies of Preschool ChildrenResearch ParkNo ratings yet

- Link - Chase Friction Material Test ReportDocument5 pagesLink - Chase Friction Material Test ReportEver MartínezNo ratings yet

- Clinical Considerations For Increasing Occlusal Vertical DimensionDocument9 pagesClinical Considerations For Increasing Occlusal Vertical DimensionAmar BhochhibhoyaNo ratings yet

- Cambridge International Examinations: Information Technology 9626/11 May/June 2017Document9 pagesCambridge International Examinations: Information Technology 9626/11 May/June 2017uma9sathiyakailashNo ratings yet

- Business Research DONEDocument63 pagesBusiness Research DONEJoven TemploNo ratings yet

- ExamplesDocument1 pageExamplesSwordhamza KyatNo ratings yet

- The Cube Roots of Unity: David Arnold February 25, 2003Document16 pagesThe Cube Roots of Unity: David Arnold February 25, 2003Rituraj BoruahNo ratings yet

- Pipework Components - Definition and Selection of DN (Nominal Size) (ISO 6708:1995) Rörledningar - Nominell Storlek, DN (ISO 6708:1995)Document6 pagesPipework Components - Definition and Selection of DN (Nominal Size) (ISO 6708:1995) Rörledningar - Nominell Storlek, DN (ISO 6708:1995)Aliraza AlirazaNo ratings yet

- ReflectionDocument5 pagesReflectionpau quitoNo ratings yet

- Design and Construction of Diaphragm Walls Embedded in Rock For A Metro ProjectDocument27 pagesDesign and Construction of Diaphragm Walls Embedded in Rock For A Metro ProjectCEG BangladeshNo ratings yet

- Local and Foreign Case StudiesDocument6 pagesLocal and Foreign Case StudiesYani FranzNo ratings yet

- Concept NoteDocument4 pagesConcept NoteAfanie Mae Romero EstepaNo ratings yet

- BasterLord - Network Manual v2.0Document24 pagesBasterLord - Network Manual v2.0xuxujiashuoNo ratings yet

- Labour Economics-1Document10 pagesLabour Economics-1Francis NyoniNo ratings yet

- Division - Memo - No. - 28s.2023 - CONTINUING FUNDDocument9 pagesDivision - Memo - No. - 28s.2023 - CONTINUING FUNDChard A. CañasNo ratings yet

- SM 4500 OdDocument8 pagesSM 4500 OdThainy BressanNo ratings yet

- JavaScript - Math - Random Method Example - DiraskDocument3 pagesJavaScript - Math - Random Method Example - DiraskKelve AragaoNo ratings yet