Professional Documents

Culture Documents

Licence: Tracey Hassell

Licence: Tracey Hassell

Uploaded by

Edward Carhuanina LescanoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Licence: Tracey Hassell

Licence: Tracey Hassell

Uploaded by

Edward Carhuanina LescanoCopyright:

Available Formats

Licence

Environmental Protection Act 1986, Part V

Licensee: City of Cockburn

Licence: L9159/2018/1

Registered office: 9 Colevill Crescent

SPEARWOOD WA 6163

Premises address: Henderson Waste Recovery Park

920 Rockingham Road

WATTLEUP WA 6166

Being Lot 202 on Plan 60443, Lot 2 on Diagram 17998 and Lot 235 on Plan

226117

Issue date: 23 October 2018

Expiry date: 22 October 2021

Prescribed premises category

Schedule 1 of the Environmental Protection Regulations 1987

Category Approved Premises

Category production or production or design

Category description

number design capacity

capacity

61 Liquid waste facility: premises on which liquid 100 tonnes or 120 tonnes per annual

waste produced on other premises (other than more per year period

sewage waste) is stored, reprocessed, treated or

irrigated.

62 Solid waste depot: premises on which waste is 500 tonnes or 50,000 tonnes per annual

stored, or sorted, pending final disposal or more per year period

re-use.

63 Class I inert landfill site: premises on which 500 tonnes or 15,000 tonnes per annual

waste (as determined by reference to the waste more per year period

type set out in the document entitled “Landfill

Waste Classification and Waste Definitions 1996”

published by the Chief Executive Officer and as

amended from time to time) is accepted for burial.

64 Class II or III putrescible landfill site: premises on 20 tonnes or 200,000 tonnes per

which waste (as determined by reference to the more per year annual period

waste type set out in the document entitled

“Landfill Waste Classification and Waste

Definitions 1996” published by the Chief Executive

Officer and as amended from time to time) is

accepted for burial.

This licence is granted to the licence holder, subject to the attached conditions, on 10 March 2020, by:

Tracey byHassell

Digitally signed

Tracey

Tracey Hassell

A/MANAGER WASTE INDUSTRIES

REGULATORY SERVICES

Hassell Date: 2020.03.10

16:30:55 +08'00'

an officer delegated under section 20 of the Environmental Protection Act 1986 (WA)

Environmental Protection Act 1986 Page 1 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Contents

Licence 1

Contents 2

Introduction 2

Licence conditions 5

1 General 5

2 Emissions 16

3 Monitoring 17

4 Improvements 21

5 Information 21

Schedule 1: Maps 24

Schedule 2: N1 – Notification form 33

Schedule 3: Minimum Specifications 35

Schedule 4: CQA Requirements 40

Introduction

This Introduction is not part of the Licence conditions.

DWER’s industry licensing role

The Department of Water and Environment Regulation (DWER) is a government department for the

state of Western Australia in the portfolio of the Minister for Environment. DWER’s purpose is to

advise on and implement strategies for a healthy environment for the benefit of all current and future

Western Australians.

DWER has responsibilities under Part V of the Environmental Protection Act 1986 (the Act) for the

licensing of prescribed premises. Through this process DWER works with the business owners,

community, consultants, industry and other representatives to prevent, control and abate pollution and

environmental harm to conserve and protect the environment. DWER also monitors and audits

compliance with works approvals and licence conditions, takes enforcement action as appropriate and

develops and implements licensing and industry regulation policy.

Licence requirements

This Licence is issued under Part V of the Act. Conditions contained within the Licence relate to the

prevention, reduction or control of emissions and discharges to the environment and to the monitoring

and reporting of them.

Where other statutory instruments impose obligations on the Premises/Licensee the intention is not to

replicate them in the licence conditions. You should therefore ensure that you are aware of all your

statutory obligations under the Act and any other statutory instrument. Legislation can be accessed

through the State Law Publisher website using the following link:

http://www.slp.wa.gov.au/legislation/statutes.nsf/default.html

For your Premises relevant statutory instruments include but are not limited to obligations under the:

Environmental Protection (Unauthorised Discharges) Regulations 2004 – these Regulations make

it an offence to discharge certain materials such as contaminated stormwater into the environment

other than in the circumstances set out in the Regulations.

Environmental Protection (Controlled Waste) Regulations 2004 - these Regulations place

obligations on you if you produce, accept, transport or dispose of controlled waste.

Environmental Protection (Noise) Regulations 1997 – these Regulations require noise emissions

from the Premises to comply with the assigned noise levels set out in the Regulations.

Environmental Protection Act 1986 Page 2 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

You must comply with your licence. Non-compliance with your licence is an offence and strict

penalties exist for those who do not comply.

Licence holders are also reminded of the requirements of section 53 of the Act which places

restrictions on making certain changes to prescribed premises unless the changes are in accordance

with a works approval, licence, closure notice or environmental protection notice.

Licence fees

If you have a licence that is issued for more than one year, you are required to pay an annual licence

fee prior to the anniversary date of issue of your licence. Non payment of annual licence fees will

result in your licence ceasing to have effect meaning that it will no longer be valid and you will need to

apply for a new licence for your Premises.

Ministerial conditions

If your Premises has been assessed under Part IV of the Act you may have had conditions imposed

by the Minister for Environment. You are required to comply with any conditions imposed by the

Minister.

Premises description and Licence summary

The City of Cockburn (CoC) has operated the Henderson Waste Recovery Park (HWRP) on

Rockingham Road, Henderson since 1990. HWRP consists of an inert landfill, a putrescible landfill, a

domestic transfer station, green waste mulching area, a household hazardous waste storage shed,

leachate ponds and a landfill gas power generation plant. The putrescible landfill includes Cells 1,2

and 3 which are capped, Cells 4,5 and 6 which are currently uncapped and Cell 7 where waste is

actively being deposited. In June 2016, a Landfill Closure Management Plan was submitted setting out

the activities to be undertaken as part of the progressive closure and rehabilitation of the site.

HRWP currently accepts municipal solid waste, commercial and industrial waste, construction and

demolition waste, inert waste and alternate daily cover. The domestic transfer station accepts and

sorts solid waste pending final disposal or re-use. The HWRP provides a service to the Kwinana

Industrial strip and many other commercial and domestic users where metropolitan landfill capacity is

limited. Greenwaste is removed from the domestic waste stream only and stockpiled onsite until it is

chipped into mulch.

The HWRP is located on the Swan Coast Plain, 3 kilometres inland from the Indian Ocean coastline.

The premises is underlain by limestone and calcrete and depth to groundwater varies on site from

approximately 5 – 18 metres below ground level. The HWRP is located within the Environmental

Protection (Kwinana) (Atmospheric Wastes) Policy 1999 (Kwinana EPP) area. The Beeliar Regional

Park (Bush Forever) is located to the west of the property, separated by Rockingham Road and

contains the conservation category wetlands, Lake Mount Brown, Brownman Swamp and Anderson

Swamp. The nearest residences are located adjacent to the south west boundary, on Rockingham

and Musson Roads. There are also numerous residences and market gardens located to the east of

Cell 7, separated by the railway line, on Moylan Road, west of Cell 6 on Rockingham Road and

adjacent to the premises boundary to the east of Cell 4.

This licence is the replacement licence issued for L6965/1997/14 under the EP Act.

Licence amendment summary

In October 2019, a licence amendment application was submitted to perform infrastructure works to

construct landfill capping to Cell 6. The cell was finally completed in 2011 and it was decided to leave

the cell uncapped to allow it to decompose and settle and reach its final approved post-settlement cell

height by the beginning of the 2019-2020 financial year. The purpose of a landfill cap is to provide a

long-term sustainable barrier between the waste and the environment. It is designed to limit the

ingress of moisture to 75% of the leakage rate through the base liner, so as not to accumulate

leachate within the landfill.

Environmental Protection Act 1986 Page 3 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

The licences and works approvals issued for the Premises since 13 December 2012 are:

Instrument log

Instrument Issued Description

L6965/1997/14 13/12/2012 Licence amendment to include Leachate Pond B.

L6965/1997/14 2/4/2015 Licence amendment to extend duration for two months.

L6965/1997/14 4/6/2015 Licence reissue in new format.

L6965/1997/14 29/04/2016 Licence duration was extended to 2021.

L6965/1997/14 28/03/2018 Amendment Notice 1 issued to include additional category 61.

L6965 licence ceased to have effect in 2018 due to non

payment of fees.

L9159/2018/1 23/10/2018 The new replacement licence issued for the ceased licence.

Also this licence includes amendments issued under the

previous licence.

L9159/2018/1 10/03/2020 Amendment issued for capping of landfill Cell 6.

Severance

It is the intent of these Licence conditions that they shall operate so that, if a condition or a part of a

condition is beyond the power of this Licence to impose, or is otherwise ultra vires or invalid, that

condition or part of a condition shall be severed and the remainder of these conditions shall

nevertheless be valid to the extent that they are within the power of this Licence to impose and are not

otherwise ultra vires or invalid.

END OF INTRODUCTION

Environmental Protection Act 1986 Page 4 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Licence conditions

1 General

1.1 Interpretation

1.1.1 In the Licence, definitions from the Environmental Protection Act 1986 apply unless the

contrary intention appears.

1.1.2 For the purposes of this Licence, unless the contrary intention appears:

‘AACR’ means Annual Audit Compliance Report, the current template for which can be found on the

DWER’s website www.dwer.wa.gov.au

‘ACM’ means asbestos containing material and has the meaning defined in the Guidelines for

Assessment, Remediation and Management of Asbestos Contaminated Sites, Western Australia,

(DOH, 2009);

‘Acceptance Criteria’ has meaning defined in Landfill Definitions;

‘Act’ means the Environmental Protection Act 1986;

AHD’ means the Australian height datum;

‘annual period’ means the inclusive period from 2 March until 1 March in the following year;

‘AQIS’ means Australian Quarantine and Inspection Service;

‘asbestos’ means the asbestiform variety of mineral silicates belonging to the serpentine or

amphibole groups of rock-forming minerals and includes actinolite, amosite, anthophyllite, chrysotile,

crocidolite, tremolite and any mixture containing 2 or more of those;

‘asbestos fibres’ has the meaning defined in the Guidelines for Assessment, Remediation and

Management of Asbestos Contaminated Sites, Western Australia, (DOH, 2009);

‘AS 2001.2.13’ means the Australian Standard AS 2001.2.13 Methods of tests for textiles Physical

tests – Determination of mass per unit area and mass per unit length of fabrics;

‘AS 2001.2.15’ means the Australian Standard AS 2001.2.15 Methods of test for textiles Physical tests

– Determination of thickness of textile fabrics;

‘AS 3706.2’ means the Australian Standard AS 3706.2 -2012 Geotextiles – Methods of Test. Method

2: Determination of tensile properties – Wide strip and grab method;

‘AS 3706-3’ means the Australian Standard AS 3706.3-2012 Geotextiles – Methods of test

Determination of tearing strength – Trapezoidal Method;

‘AS 3706.4’ means the Australian Standard AS 3706.4-2012 Geotextiles – Methods of test

Determination of burst strength – California bearing ratio (CBR) – Plunger method;

‘AS 3706.5’ means the Australian Standard AS 3706.5-2014 Geotextiles – Methods of test

Determination of puncture resistance – Drop cone Method;

‘AS/NZS 5667.1’ means the Australian Standard AS/NZS 5667.1 Water Quality – Sampling –

Guidance of the Design of sampling programs, sampling techniques and the preservation and

handling of samples;

‘AS/NZS 5667.4’ means the Australian Standard AS/NZS 5667.4 Water Quality – Sampling –

Guidance on sampling from lakes, natural and man-made;

Environmental Protection Act 1986 Page 5 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

‘AS/NZS 5667.10’ means the Australian Standard AS/NZS 5667.10 Water Quality – Sampling –

Guidance on sampling of waste waters;

‘AS/NZS 5667.11’ means the Australian Standard AS/NZS 5667.11 Water Quality – Sampling –

Guidance on sampling of groundwaters;

‘ASTM D1004’ means the ASTM International Standard ASTM D1004 Standard Test Method for Tear

Resistance (Graves Tear) of Plastic Film and Sheeting;

‘ASTM D1505’ means the ASTM International Standard ASTM D1505 Standard Test Method for

Density of Plastics by the Density-Gradient Technique;

‘ASTM D3895’ means the ASTM International Standard ASTM D3895 Standard Test Method for

Oxidative-Induction Time of Polyolefins by Differential Scanning Calorimetry;

‘ASTM D4218’ means the ASTM International Standard ASTM D4218 Standard Test Method for

Determination of Carbon Black Content in Polyethylene Compounds By the Muffle-Furnace

Technique;

‘ASTM D4833’ means the ASTM International Standard ASTM D4833 Standard Test Method for Index

Puncture Resistance of Geomembranes and Related Products;

‘ASTM D5199’ means the ASTM International Standard ASTM D5199 Standard Test Method for

Measuring the Nominal Thickness of Geosynthetics;

‘ASTM D5596’ means the ASTM International Standard ASTM D5596 Standard Test Method For

Microscopic Evaluation of the Dispersion of Carbon Black in Polyolefin Geosynthetics;

‘ASTM D5617’ means the ASTM International Standard ASTM D5617 Standard Test Method for Multi-

Axial Tension Test for Geosynthetics;

‘ASTM D5641’ means the ASTM International Standard ASTM D5641 Standard Practice for

Geomembrane Seam Evaluation by Vacuum Chamber;

‘ASTM D5820’ means the ASTM International Standard ASTM D5820 Standard Practice for

Pressurized Air Channel Evaluation of Dual-Seamed Geomembranes;

‘ASTM D5885’ means the ASTM International Standard ASTM D5885 Standard Test Method for

Oxidative Induction Time of Polyolefin Geosynthetics by High-Pressure Differential Scanning

Calorimetry;

‘ASTM D5887’ means the ASTM International Standard ASTM D5887 Standard Test Method for

Measurement of Index Flux Through Saturated Geosynthetic Clay Liner Specimens Using a Flexible

Wall Permeameter;

‘ASTM D5890’ means the ASTM International Standard ASTM D5890 Standard Test Method for Swell

Index of Clay Mineral Component of Geosynthetic Clay Liners;

‘ASTM D5891’ means the ASTM International Standard ASTM D5891 Standard Test Method for Fluid

Loss of Clay Component of Geosynthetic Clay Liners;

‘ASTM D5993’ means the ASTM International Standard ASTM D5993 Standard Test Method for

Measuring Mass Per Unit of Geosynthetic Clay Liners;

‘ASTM D5994’ means the ASTM International Standard ASTM D5994 Standard Test Method for

Measuring Core Thickness of Textured Geomembranes;

‘ASTM D6364’ means the ASTM International Standard ASTM D6364 Standard Test Method for

Determining Short-Term Compression Behavior of Geosynthetics;

Environmental Protection Act 1986 Page 6 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

‘ASTM D6392’ means the ASTM International Standard ASTM D6392 Standard Method for

Determining the Integrity of Nonreinforced Geomembrane Seams Produced Using thermos-Fusion

Methods;

‘ASTM D6496’ means the ASTM International Standard ASTM D6496 Standard Test Method for

Determining Average Bonding Peel Strength Between Top and Bottom Layers of Needle-Punched

Geosynthetic Clay Liners;

‘ASTM D6693’ means the ASTM International Standard ASTM D6693 Standard Test Method for

Determining Tensile Properties of Nonreinforced Polyethylene and Nonreinforced Flexible

Polypropylene Geomembrane;

‘ASTM D6768’ means the ASTM International Standard ASTM D6768 Standard Test Method for

Tensile Strength of Geosynthetic Clay Liners;

‘ASTM D7005’ means the ASTM International Standard ASTM D7005 Standard Test Method for

Determining the Bond Strength (Ply Adhesion) of Geocomposites;

‘ASTM D7179’ means the ASTM International Standard ASTM D7179 Standard Test Method for

Determining Geonet Breaking Force;

‘ASTM D792’ means the ASTM International Standard ASTM D792 Standard Test Methods for

Density and Specific Gravity (relative Density) of Plastics by Displacement;

‘averaging period’ means the time over which a limit or target is measured, or a monitoring result is

obtained;

‘Cell 6’ means the cell marked as ‘Cell 6’ in Schedule 1 of the Licence;

‘CEO’ means Chief Executive Officer of the Department of Water and Environmental Regulation;

‘CEO’ for the purpose of correspondence means;

Director General

Department administering the Environmental Protection Act 1986

Locked Bag 10

Joondalup DC WA 6919

Email: info@dwer.wa.gov.au

‘Clean Fill’ has the meaning defined in Landfill Definitions;

‘code of practice for the storage and handling of dangerous goods’ means the document titled

“Storage and handling of dangerous goods: Code of Practice“ published by the Department of Mines,

Industry Regulation and Safety, as amended from time to time;

‘Contaminated Solid Waste’ has the meaning defined in Landfill Definitions;

‘controlled waste’ has the definition in Environmental Protection (Controlled Waste) Regulations

2004;

‘dangerous goods’ has the meaning defined in the Dangerous Goods Safety (Storage and Handling

of Non-explosives) Regulations 2007;

‘environmentally hazardous material’ means material (either solid or liquid raw materials, materials

in the process of manufacture, manufactured products, products used in the manufacturing process,

by-products and waste) which if discharged into the environment from or within the premises may

cause pollution or environmental harm. Note: Environmentally hazardous materials include dangerous

goods where they are stored in quantities below placard quantities. The storage of dangerous goods

above placard quantities is regulated by the Department of Mines, Industry Regulation and Safety;

Environmental Protection Act 1986 Page 7 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

‘freeboard’ means the distance between the maximum water surface elevations and the top of

retaining banks or structures at their lowest point;

‘fugitive emissions’ means all emissions not arising from point sources;

‘‘Green Waste’ means waste that originates from flora and which does not contain or has not been

treated or coated with, preserving agents, biocides, fire retardants, paint, adhesives or binders;

‘Inert Waste Type 1’ has the meaning defined in Landfill Definitions;

‘Inert Waste Type 2’ has the meaning defined in Landfill Definitions;

‘Landfill Definitions’ means the document titled “Landfill Waste Classification and Waste Definitions

1996” published by the Chief Executive Officer of the Department of Environment as amended from

time to time.

‘Landfill Gas’ means gas generated from the decomposition of waste containing a mixture of

methane, carbon dioxide and other gases

‘leachate’ means liquid released by or water that has percolated through waste and which contains

some of its constituents;

‘Licence’ means this Licence numbered L9159/2018/1 and issued under the Act;

‘Licensee’ means the person or organisation named as Licensee on page 1 of the Licence;

‘mulched’ means greenwaste shredded by a mechanical process into small pieces;

‘NATA’ means the National Association of Testing Authorities, Australia;

‘NATA accredited’ means in relation to the analysis of a sample that the laboratory is NATA

accredited for the specified analysis at the time of the analysis;

‘Premises’ means the area defined in the Premises Map in Schedule 1 and listed as the Premises

address on page 1 of the Licence;

‘Putrescible’ has the meaning defined in Landfill Waste Classification and Waste Definitions 1996 (As

amended December 2009), published by the CEO and as amended from time to time;

‘quarantined storage area or container’ means a hardstand storage area or sealed-bottom

container that is separate and isolated from authorised waste disposal areas and is capable of

containing all non-conforming waste and its constituents, these areas must be clearly marked and their

access restricted to authorised personnel;

‘Qualified Geotechnical Engineer’ means a person who:

a) holds a Bachelor of Engineering recognised by the Institute of Engineers; and

b) has a minimum of five years of experience working in a supervisory area of geotechnical

engineering; and

c) Is employed by an independent third party external to the Works Approval Holder’s business;

or is otherwise approved in writing by the CEO to act in this capacity.

‘Quarantine Waste’ means material from a foreign region or country that is capable of being host to

insects, helminths or other parasites, diseases, weeds or any other organisms that are not existent or

prevalent in Australia and pose a potential threat to local ecosystems, people or local plant or animal

industries. Quarantine Waste may include:

Material used to pack and stabilise imported goods;

Galley food and any other waste from overseas vessels;

Human; animal or plant waste bought into Australia;

Refuse or sweepings from a hold of an overseas vessel;

Environmental Protection Act 1986 Page 8 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Any other waste or other material, which comes into contact with Quarantine Waste;

Contents of AQIS airport amnesty bins; and

Articles seized by AQIS and/or not collected by clients.

‘rehabilitation’ means the completion of the engineering of a landfill cell and includes capping and/or

final cover;

‘Schedule 1’ means Schedule 1 of this Licence unless otherwise stated;

‘Schedule 2’ means Schedule 2 of this Licence unless otherwise stated;

‘Schedule 3’ means Schedule 3 of this Licence unless otherwise stated;

‘Schedule 4’ means Schedule 4 of this Licence unless otherwise stated;

‘six monthly’ means the 2 inclusive periods from 2 March to 1 September and 2 September to 1

March in the following year;

‘Special Waste Type 1’ has the meaning defined in Landfill Definitions;

‘Special Waste Type 2’ has the meaning defined in Landfill Definitions;

‘spot sample’ means a discrete sample representative at the time and place at which the sample is

taken;

‘Temporary Transfer Station’ means facility designed to separate waste from domestic trailer traffic,

located on top of Cells 4 and 5 (as depicted in Schedule 1);

“tipping area” means the area of the landfill in which waste other than cover material is being

deposited;

‘usual working day’ means 0800 – 1700 hours, Monday to Friday excluding public holidays in

Western Australia;

‘vacuum box test’ means a non-destructive examination used when trying to locate weld seam leaks;

‘x-ray diffraction’ means a non-destructive test method used to analyse the structure of crystalline

materials;

‘µS/cm’ means microsiemens per centimetre.

1.1.3 Any reference to an Australian or other standard in the Licence means the relevant parts of

the standard in force from time to time during the term of this Licence.

1.1.4 Any reference to a guideline or code of practice in the Licence means the version of that

guideline or code of practice in force from time to time, and shall include any amendments or

replacements to that guideline or code of practice made during the term of this Licence.

1.2 General conditions

1.2.1 Nothing in the Licence shall be taken to authorise any emission that is not mentioned in the

Licence, where the emission amounts to:

(a) pollution;

(b) unreasonable emission;

(c) discharge of waste in circumstances likely to cause pollution; or

(d) being contrary to any written law.

1.2.2 The Licensee shall operate and maintain all pollution control and monitoring equipment to the

manufacturer’s specification or any relevant and effective internal management system.

Environmental Protection Act 1986 Page 9 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

1.2.3 The Licensee, except where storage is prescribed in section 1.3, shall ensure that

environmentally hazardous materials are stored in accordance with the code of practice for the

storage and handling of dangerous goods.

1.2.4 The Licensee shall immediately recover, or remove and dispose of spills of environmentally

hazardous materials outside an engineered containment system.

1.2.5 The Licensee shall:

(a) implement all practical measures to prevent stormwater run-off becoming

contaminated by the activities on the Premises; and

(b) treat contaminated or potentially contaminated stormwater as necessary prior to being

discharged from the Premises.1

Note1: The Environmental Protection (Unauthorised Discharges) Regulations 2004 make it an offence to

discharge certain materials into the environment.

1.2.6 The Licensee must construct/undertake capping works in accordance with the requirements in

Table 1.2.1.

Table 1.2.1: Capping Works specifications

Landfill cell/ Specifications Design Plan

Infrastructure Reference

Cell 6 – The Cell 6 capping subgrade must be designed to achieve Landfill capping

Sub-grade the following: details 1

Preparation Steel drum rolled to ensure no excessive Landfill capping

irregularities, depressions or obstructions that may details 2

affect the integrity of the synthetic liner; Landfill capping

Removal of unsuitable material2; details 3

Free from any sharp objects, stone, debris, water

and desiccation cracks;

All vegetation (weeds) removed from areas on

which synthetic liner is to be installed;

Filled with compacted material meeting the

following parameters on placement1:

o Moisture conditioned to +/- 2 % of optimum

and compacted to not less than 90% of the

Modified Maximum Dry Density (MMDD)

o Free of debris (<2% by weight organic

content)

o General fill material with a maximum

particle dimension no larger than 200mm;

and

o Sandy fill material with a maximum particle

dimension no larger than 40mm.

Cell 6 – The Cell 6 capping GCL must be designed and constructed Landfill capping

Geosynthetic to meet the following specifications: details 1

Clay Liner Reinforced, multi-layered system comprising two Landfill capping

(GCL) and layers of geotextile encapsulating a layer of dry details 2

coated GCL bentonite; material for the side slope shall also Landfill capping

incorporate a polyethylene coating, laminated GCL details 3

products are not acceptable; Cell 6 landfill

Laid in roof tile effect to allow continuous flow of capping layout

water in the downward slope direction, installed plan

such that the panels are continuous down side

slopes,;

No placement with folds or wrinkles in the overlap

zone;

The overlap zone shall be kept clean and shall not

be contaminated with loose soil or other debris;

Environmental Protection Act 1986 Page 10 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

The minimum longitudinal overlap shall be 300mm

and the minimum roll-end overlap shall be 1.5m on

the top of the landfill and an anchor trench and

1.5m overlap on the side slopes;

Panel overlaps must be sealed with bentonite paste

or powder/granules; and

GCL material properties meeting ‘minimum values’

defined in Schedule 3 Table 1.

No panel placement with folds or wrinkles in the

overlap zone;

GCL installed on slopes is to be fixed in anchor

trenches or extend a minimum of 5 m up onto the

top of the landfill;

Cell 6 – The Cell 6 LLDPE geomembrane must be designed and Landfill capping

LLDPE constructed to meet the following specifications: details 1

Geomembrane Overlying; and in intimate contact with GCL; Landfill capping

layer (above Manufacturer specified thickness of 2mm; details 2

the GCL) Textured on one side and installed with the textured Landfill capping

surface in contact with GCL; details 3

All LLDPE panels subject to copper wedge shall Cell 6 landfill

create two contact fusion areas of a minimum width capping layout

of 15mm and a 5mm minimum wide void between plan

each of the separate parallel weld zones;

All LLDPE panels subject to extrusion welding shall

have a minimum width of the surface extruded bead

of 30mm;

All LLDPE panels subject to hot wedge welding

must be overlapped by a minimum of 125mm and a

minimum of 75mm for extrusion welding; and

LLDPE material properties meeting ‘minimum

values’ defined in Schedule 3 Table 2.

Cell 6 - The Cell 6 non-woven protection geotextile must be Landfill capping

Nonwoven designed and constructed to meet the following details 1

geotextile specifications: Landfill capping

cushion layer Geotextile shall be 100 % polyester or details 2

polypropylene, non-woven needle-punched Landfill capping

geotextile fabric; details 3

Geotextile shall be placed overlying; and in contact

with the LLDPE geomembrane;

Geotextile shall be installed such that the sheets

are free of wrinkles and folds;

Geotextile panels shall be laid in roof tile effect to

allow continuous flow of water in the downward

slope direction;

Geotextile panel overlap must be a minimum of

150mm;

Joining of the sheets shall be conducted by

stitching or by heat bonding and joins shall be

continuous along the full join length; and

Geotextile material properties meeting ‘minimum

values’ defined in Schedule 3 Table 3.

Cell 6 - The Cell 6 geocomposite drainage layer must be designed Landfill capping

Geocomposite and constructed to meet the following specifications: details 1

Drainage Consisting of a HDPE resin geonet with non-woven Landfill capping

Layer 100% polyester or polypropylene, non-woven details 2

needle-punched geotextile fabric heat bonded on Landfill capping

both sides; details 3

Shall be placed overlying; and in contact with the

coated GCL;

Environmental Protection Act 1986 Page 11 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Geocomposite panels shall be laid to allow Cell 6 landfill

continuous flow of water within the geocomposite capping layout

drainage material; and plan

Geocomposite drainage material properties

meeting ‘minimum values’ defined in Schedule 3

Table 4.

Cell 6 – The Cell 6 gas collection pipework must be designed and Landfill capping

Gas Collection constructed to meet the following specifications: details 1

Pipework Installation of landfill gas collection pipes as Landfill capping

specified and to the extent shown in the detailed details 2

design drawings specified in Column 3 of this table; Landfill gas

Pipes must be placed so that no damage occurs to collection

the pipes; pipework layout

Joining of pipes shall be in accordance with the plan

pipe manufacturer’s recommendations; Cell 6 landfill

Perforated pipes are to be wrapped with a light capping layout

geotextile sheet or filter sock to prevent sand from plan

entering the cut or drilled holes; and

Landfill gas collection pipes shall be placed directly

into pipe trenches with side support material.

Cell 6 – The Cell 6 capping growing medium material shall: Landfill capping

Growing Comprise silty sandy or clayey sand soil which details 1

Medium have a maximum particle dimension no larger than Landfill capping

300mm; details 2

Placed in a single layer and not compacted; Landfill capping

Minimum layer thickness of 1.2m; and details 3

Have unsuitable material2 removed. Cell 6 landfill

Placement of growing medium material to be capping layout

carried out so as not to damage the liner materials plan

and negatively impact on the slope stability1;

Top of capping designed to 1V in 50H slope; and

Side batter designed to no steeper than 1V in 3H

slope.

Note 1: Determined in accordance with the Australian Standard AS 1289.5.2.1, Methods of testing soil for engineering

purposes

Note 2: The suitability of material is defined in the Australian Standard AS 3798, Guidelines on earthworks for

commercial and residential developments.

1.2.7 The Licensee shall undertake a minimum of two Material-Specific direct shear tests only for

side slope capping system of the Cell 6 capping system in accordance with ASTM D5321.

1.2.8 The Licensee shall undertake quality assurance including visual inspection, materials testing

and weld testing for GCL, LLDPE Geomembrane, Geotextile and Geocomposite layers in

accordance with the CQA tables in Schedule 4.

1.2.9 The Licensee must ensure that all laboratory samples taken in accordance with Condition

1.2.7 are submitted to and tested by a laboratory with current NATA accreditation for the

parameters being measured unless indicated otherwise in the relevant table.

1.2.10 Within 30 days of the completion of the Cell 6 Capping Works specified in Table 1.2.1, the

Licensee must provide to the CEO a compliance certification from a suitably qualified

professional confirming each item or component of infrastructure specified In Table 1.2.1 has

been constructed with no material defects and to the requirements specified in Column 2.

1.2.11 The compliance certification required by Condition 1.2.9 must be accompanied by a

Construction Quality Assurance Validation Report that:

(a) is written and certified by a Qualified Geotechnical Engineer (or equivalent) that

completed the construction quality assurance processes detailed in Schedule 4;

(b) assesses results against minimum values detailed in Schedule 3;

Environmental Protection Act 1986 Page 12 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

(c) documents all repairs to subgrade and resulting from non-destructive weld testing;

(d) certifies that the sub-grade and liner is free of fault or defect, built to the design

specification and fit for the intended purpose;

(e) includes copies of results of surveys and drawings of the final capping, inspections,

monitoring and testing for the sub-grade preparation, liner installation and extraction

systems; and

(f) demonstrates compliance with Condition 1.2.6.

1.2.12 Vegetation and rehabilitation of Cell 6 must commence within 6-months of the completion of the

Cell 6 capping works specified in Condition 1.2.6.

1.3 Premises operation

1.3.1 The Licensee shall only accept waste on to the Premises if:

(a) it is of a type listed in Table 1.3.1;

(b) the quantity accepted is below any quantity limit listed in Table 1.3.1;

(c) it meets any specification listed in Table 1.3.1; and

(d) in the case of contaminated solid waste is supported by documentation that

demonstrates compliance with the acceptance criteria for the relevant Class landfill.

Table 1.3.1: Waste acceptance

Waste Quantity Limit tonnes/annual period Specification 1

Cat 61 Cat 62 Cat 63 Cat 64

Green Waste N/A

Putrescible N/A None specified

Clean fill Combined

Inert Waste Type total of Waste containing visible

1 50,000 asbestos or ACM shall not be

tonnes accepted.

Inert Waste Type Combined Tyres and plastic only

2 total

Special Waste 15,000 Cement bonded asbestos only.

Combined

Type 1 N/A tonnes No fibrous asbestos shall be

total of

N/A accepted.

200,000

Contaminated tonnes Must meet the waste acceptance

solid waste criteria for Class I landfills

(Class I)

Special Waste Biomedical waste that is not

Type 2 radioactive2

Contaminated Must meet the waste acceptance

solid waste N/A criteria for Class II or III landfills

(Class II & III)

Quarantine As defined in condition 1.1.2

waste

Hazardous Liquid 120 NA Limited to paints and resins only

Waste tonnes

Note 1: Additional requirements for the acceptance of controlled waste (including asbestos and tyres) are set out

in the Environmental Protection (Controlled Waste) Regulations 2004.

Note 2: Information relating to the classification of radioactive waste can be found in the Western Australian

Radiation Safety Act 1975

1.3.2 The Licensee shall ensure that where waste does not meet the waste acceptance criteria set

out in condition 1.3.1 it is removed from the Premises by the delivery vehicle or, where that is

not possible, stored in a quarantined storage area or container and removed to an

appropriately authorised facility as soon as practicable.

1.3.3 The Licensee shall ensure that wastes accepted onto the Premises are only subjected to the

process(es) set out in Table 1.3.2 and in accordance with any process limits described in that

Table.

Environmental Protection Act 1986 Page 13 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 1.3.2: Waste processing

Waste type(s) Process Process limits 1,2

Shall only take place within the landfill area shown on the

Landfill Area Map in Schedule 1;

All in Table No waste shall be temporarily stored or landfilled within 35

1.3.1 (excluding Disposal of metres from the boundary of the premises; and

tyres) waste by The separation distance between the base of the landfill

landfilling and the highest groundwater level shall not be less than

2m.

Receipt,

handling,

Inert Waste storage prior to No more than 100 tyres stored at any one time.

Type 2 - Tyres

removal from

the premises

Only be stored and mulched in the Green Waste Storage

Area shown on the map prior to removal from the premises;

Not to be stored in dried state;

No more than 2000m3 of greenwaste and 6000m3 of

Storage prior to mulched greenwaste stored at any one time;

mulching, Mulched Green Waste to be stored in windrows no more

Green Waste mulching or than 3 metres high, 4 metres wide and be separated by at

disposal by least 5 metres;

landfilling Mulched Green Waste windrows with an internal

temperature exceeding 80 degrees Celsius shall be turned,

mixed or otherwise treated, to reduce the temperature; and

A 5 metre fire break shall be maintained around the Green

Waste Storage Area.

Clean Fill

Inert Waste

Type 1

Inert Waste

Type 2 None specified

(excluding

tyres)

Contaminated

Solid Waste

Only to be disposed of into a designated asbestos disposal

area within the landfill;

Special Waste Not to be deposited within 2m of the final tipping surface of

Type 1 Receipt, the landfill; and

handling and No works shall be carried out on the landfill that could lead

disposal by to a release of asbestos fibres.

landfilling Only to be disposed of into a designated biomedical waste

disposal area within the landfill;

Not to be deposited within 2m of the final tipping surface of

the landfill; and

Special Waste

Type 2 No works shall be carried out on the landfill that could lead

to biomedical wastes being excavated or uncovered.

During disposal access to the landfill area, where Special

Waste Type 2 is buried, shall be restricted to authorised

personnel only

Only to be disposed of into a designated quarantine waste

disposal area within the landfill;

Quarantine Not to be deposited within 2m of the final tipping surface of

Waste the landfill; and

No works shall be carried out on the landfill that could lead

to quarantine wastes being excavated or uncovered.

Environmental Protection Act 1986 Page 14 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 1.3.2: Waste processing

Waste type(s) Process Process limits 1,2

During disposal access to the landfill area, where

Quarantine Waste is buried, shall be restricted to authorised

personnel only.

All leachate from the landfill shall be collected and

Storage prior to

contained within lined Leachate Pond A or B prior to

disposal offsite,

removal from the premises or infiltration to the lined, waste

Leachate infiltration to

filled cells; and

lined, waste

Leachate or leachate contaminated water shall not be

filled cells

discharged to the environment.

Receipt, Paint and resins shall be stored in dedicated impermeable

Hazardous

handling and bunded storage containers (‘stillages’) provided by the

Liquid

and removal Paintback Scheme

Waste

offsite Paint shall not be decanted or treated on the Premises

Note 1: Requirements for landfilling tyres are set out in Part 6 of the Environmental Protection Regulations1987.

Note 2: Additional requirements for the acceptance and landfilling of controlled waste (including asbestos and

tyres) are set out in the Environmental Protection (Controlled Waste) Regulations 2004.

1.3.4 The Licensee shall ensure that waste is only disposed of in landfill cells or phases provided

with the infrastructure detailed in Table 1.3.3 for that Class of landfill cell or phase.

Table 1.3.3: Landfill infrastructure

Cell or Phase Class of Cell Infrastructure requirements

Number(s) or Phase

Lined to achieve a permeability of less than or equal to 1x10-

9 m/s.

Class III

7

(Putrescible) Leachate collection system

Landfill gas collection and management system.

1.3.5 The Licensee shall ensure that waste materials are only stored and/or treated within vessels

or compounds provided with the infrastructure detailed in Table 1.3.4.

Table 1.3.4: Containment infrastructure

Reference and Material Infrastructure requirements

location on

Premises map in

Schedule 1

Leachate Pond Leachate Lined to achieve a permeability of less than 1x10-9 m/s or

A&B equivalent; and

Maintain a freeboard of no less than 500mm.

Greenwaste Greenwaste Compacted limestone which has a minimum thickness of 300

Storage Area millimetres.

Washdown Bay Washwater Concrete bunded hardstand with grading to sealed tank via

screens to fully contained underground settlement tank.

1.3.6 The Licensee shall manage the landfilling activities to ensure:

(a) the size of the tipping face is kept to a minimum and not larger than 30 m long x 40 m

wide x 2 m high;

(b) waste is levelled and compacted as soon as practicable after is discharged;

(c) waste is placed and compacted to ensure all faces are stable and capable of retaining

rehabilitation material; and

(d) rehabilitation of a cell or phase takes place within 6 months after disposal in that cell or

phase has been completed.

1.3.7 The Licensee shall ensure that cover is applied to waste in accordance with Table 1.3.5 and

that sufficient stockpiles of cover are maintained on site at all times.

Environmental Protection Act 1986 Page 15 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 1.3.5: Cover requirements

Waste Type Material Depth Timescales

Inert waste type 1 300mm As soon as practicable and not later than

Special Waste or clean fill the end of the working day after deposit and

Type 1 prior to compaction.

Solid waste or soil 1000mm As soon as practicable after deposit

Inert waste type 1 As soon as practicable and no later than the

Special Waste 300mm

or clean fill end of the working day after deposit

Type 2

Solid waste or soil 1000mm As soon as practicable after deposit

Quarantine Waste

Non-Quarantine

(non Aircraft 2000mm

solid waste or soil

Galley Waste)

Immediately after deposit

Quarantine Waste Non-Quarantine

(Aircraft Galley solid waste or soil 1000mm

waste)

Putrescible Inert waste type 1, 150mm As soon as practicable and not later than

Wastes soil or clay the end of the working day.

Putrescible Inert waste type 1, 1000mm Within 3 months of achieving final waste

Wastes soil, or clay contours.

Inert waste type 1 100mm

Inert Waste Type 2 By the end of the working day after deposit

or soil

Note 1: As required by Department of Agriculture Fisheries and Forestry’s ‘Process Management System for the

Burial of Quarantine Waste’

1.3.8 The Licensee shall operate and maintain a system for controlling landfill gas generated on the

Premises to prevent lateral migration of landfill gas outside the boundary of the Premises.

1.3.9 The Licensee shall implement the following security measures at the site:

(a) erect and maintain suitable fencing to prevent unauthorised access to the site as far

as is practicable;

(b) ensure that any entrance gates to the premises are securely locked when the

premises are unattended; and

(c) undertake regular inspections of all security measures and repair damage as soon as

practicable

1.3.10 The Licensee shall ensure that no waste is burnt on the premises.

1.3.11 The Licensee shall ensure that wind-blown waste is contained within the boundary of the

Premises and that wind-blown waste is collected on at least a weekly basis to the tipping area

or appropriately contained.

1.3.12 The Licensee shall ensure that vermin, birds, flies and other insects do not give rise to

nuisance at the premises or in the immediate area of the premises. Any method used by the

licensee shall not cause environmental pollution.

1.3.13 The Licensee shall ensure that there is no excavation of areas of the premises where waste

has previously been buried.

1.3.14 The Licensee shall ensure all residual waste located in the waste recovery area of the

Temporary Transfer Station shall be removed by the close of each business day.

2 Emissions

2.1 General

2.1.1 The Licensee shall record and investigate the exceedance of any descriptive or numerical limit

or target specified in any part of section 2 of this Licence.

Environmental Protection Act 1986 Page 16 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

2.2-2.4 Point source emissions to air, surface water and groundwater

There are no specified conditions relating to point source emissions to air, surface water and

groundwater in this section.

2.5 Emissions to land

There are no specified conditions relating to emissions to land in this section.

2.6 Fugitive emissions

2.6.1 The Licensee shall ensure that no visible dust generated by the activities on the Premises

crosses the boundary of the Premises.

2.6.2 The Licensee shall provide and maintain suitable wheel cleaning facilities to ensure that no

waste or other debris is tracked beyond the boundary of the premises.

2.7 Odour

2.7.1 The Licensee shall ensure that odour emitted from the Premises does not unreasonably

interfere with the health, welfare, convenience, comfort or amenity of any person who is not on

the Premises.

2.8 Noise

There are no specified conditions relating to noise in this section.

3 Monitoring

3.1 General monitoring

3.1.1 The licensee shall ensure that:

(a) all water samples are collected and preserved in accordance with AS/NZS 5667.1;

(b) all groundwater sampling is conducted in accordance with AS/NZS 5667.11;

(c) all laboratory samples are submitted to and tested by a laboratory with current NATA

accreditation for the parameters being measured unless indicated otherwise in the

relevant table.

3.1.2 The Licensee shall ensure that:

(a) six monthly monitoring is undertaken at least 5 months apart; and

(b) annual monitoring is undertaken at least 9 months apart.

3.1.3 The Licensee shall ensure that all monitoring equipment used on the Premises to comply with

the conditions of this Licence is calibrated in accordance with the manufacturer’s

specifications.

3.1.4 The Licensee shall, where the requirements for calibration cannot be practicably met, or a

discrepancy exists in the interpretation of the requirements, bring these issues to the attention

of the CEO accompanied with a report comprising details of any modifications to the methods.

3.2-3.4 Monitoring of point source emissions to air, surface water and groundwater

There are no specified conditions relating to monitoring of point source emissions to air,

surface water or groundwater in this section.

3.5 Monitoring of emissions to land

There are no specified conditions relating to monitoring of emissions to land in this section.

Environmental Protection Act 1986 Page 17 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

3.6 Monitoring of inputs and outputs

3.6.1 The Licensee shall undertake the monitoring in Table 3.6.1 according to the specifications in

that table.

Table 3.6.1: Monitoring of inputs and outputs

Input/Output Parameter Units Averaging Frequency

period

Waste Inputs Clean fill, Inert Waste Each load arriving at

Type 1, Inert Waste the Premises

Type 2, Putrescible tonnes (where

waste, Contaminated a weighbridge

solid waste, Special is present on

N/A

Waste Type 1, Special the site)

Waste Type 2,

Quarantine Waste,

Hazardous Liquid

Waste

Waste Waste type as defined N/A Each load leaving or

Outputs in the Landfill rejected from the

Definitions Premises, after

acceptance

3.7 Process monitoring

3.7.1 The Licensee shall undertake the monitoring in Table 3.7.1 according to the specifications in

that table.

Table 3.7.1 Process monitoring

Monitoring Process description Parameter Units Frequency1

point

reference

Mulched Greenwaste Temperature °C Weekly

-

windrows

Volume of leachate m3 Whenever irrigated

irrigated over lined

cells

pH1 -

Leachate A Cadmium

Leachate Chloride

Leachate B

C4 Chromium

C5 Copper

Manganese mg/L Annual

Mercury

Nickel

Lead

Zinc

Ammonia-Nitrogen mg/L

Nitrate-Nitrogen

Total Nitrogen

Total Phosphorus

Total Potassium

Total Dissolved Solids

Electrical conductivity

Benzene

Ethylbenzene

Toluene

Xylenes

Environmental Protection Act 1986 Page 18 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 3.7.1 Process monitoring

Monitoring Process description Parameter Units Frequency1

point

reference

Total Petroleum

Hydrocarbons

Polycyclic aromatic

Hydrocarbons (PAHs)

Acenapthene

Anthracene µg/L

Benz(a)pyrene

Fluoranthene

Napthalene

Pyrene

Organochlorine

Pesticides (OCPs)

Leachate A Aldrin

Leachate B Leachate Chlordane and Annual

C4 metabolites

C5 DDT and metabolites

Dieldrin

HCB

Heptachlor and its

epoxide

Lindane

Organophosphate

Pesticides (OPPs)

Chlorpyrifos

Demeton-S-Methyl

Diazinon

Dimethoate µg/L

Fenamiphos

Fenthion

Maldison

Parathion

Other Pesticides and

Organic Compounds

Atrazine

PCB

TCE

PCE

Note 1: In field non-NATA accredited analysis permitted.

3.8 Ambient environmental quality monitoring

3.8.1 The Licensee shall undertake the monitoring in Table 3.8.1 according to the specifications in

that table and record and investigate results that do not meet any target specified.

Table 3.8.1: Monitoring of ambient groundwater quality

Monitoring point reference Parameter Units Averaging Frequency

and location period

Standing water level1 m bgl

and

m(AHD)

pH1 -

Cadmium

Chloride

Bore 1 – 4 Chromium

Environmental Protection Act 1986 Page 19 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 3.8.1: Monitoring of ambient groundwater quality

Monitoring point reference Parameter Units Averaging Frequency

and location period

Copper

MW4-S, MW4-I, MW4-D Manganese

MW5-S, MW5-I, MW5-D Six monthly

Mercury

MW6-S, MW6-I, MW6-D

MW7-S, MW7-I, MW7-D Nickel Spot

MW8-S, MW8-I, MW8-D Lead mg/L sample

MW9-S, MW9-I, MW9-D Zinc

MW10-S, MW10-I, MW10-D Ammonia-Nitrogen

MW11-S, MW11-I, MW11-D

Nitrate-Nitrogen

Total Nitrogen

Total Phosphorus

Total Potassium

Total Dissolved Solids

Electrical conductivity µS/cm

Benzene

Ethylbenzene

Toluene

Xylenes

Total Petroleum

Hydrocarbons

Polycyclic aromatic

Hydrocarbons (PAHs)

Bore 1 – 4 Acenapthene

Anthracene

MW4-S, MW4-I, MW4-D Benz(a)pyrene

MW5-S, MW5-I, MW5-D Fluoranthene

MW6-S, MW6-I, MW6-D Napthalene µg/L Spot Annual

MW7-S, MW7-I, MW7-D Pyrene sample

MW8-S, MW8-I, MW8-D Organochlorine Pesticides

MW9-S, MW9-I, MW9-D (OCPs)

MW10-S, MW10-I, MW10-D Aldrin

MW11-S, MW11-I, MW11-D Chlordane and

metabolites

DDT and metabolites

Dieldrin

HCB

Heptachlor and its

epoxide

Lindane

Organophosphate

Pesticides (OPPs)

Bore 1 – 4 Chlorpyrifos

Demeton-S-Methyl

MW4-S, MW4-I, MW4-D Diazinon

MW5-S, MW5-I, MW5-D Dimethoate µg/L Spot

MW6-S, MW6-I, MW6-D Fenamiphos sample Annual

MW7-S, MW7-I, MW7-D Fenthion

MW8-S, MW8-I, MW8-D Maldison

MW9-S, MW9-I, MW9-D Parathion

MW10-S, MW10-I, MW10-D Other Pesticides and

MW11-S, MW11-I, MW11-D Organic Compounds

Atrazine

PCB

Environmental Protection Act 1986 Page 20 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 3.8.1: Monitoring of ambient groundwater quality

Monitoring point reference Parameter Units Averaging Frequency

and location period

TCE

PCE

Note 1: In field non-NATA accredited analysis permitted.

Note 2: m bgl means metres below ground level

3.9 Meteorological monitoring

There are no specified conditions relating to meteorological monitoring in this section.

4 Improvements

4.1 Improvement program

4.1.1 The Licensee shall complete the improvements in Table 4.1.1 by the date of completion in

Table 4.1.1.

Table 4.1.1: Improvement program

Improvement Improvement Date of

reference completion

IR5 The Licensee shall submit to the CEO, a Geotechnical Within 28

Inspection Report prepared on behalf of the Licensee by a calendar days

GITA certified engineer that, through visual inspection, of the end of

assesses the stability of all landfill embankments, cut slopes the annual

and visual inspections to confirm integrity of final capping. period

5 Information

5.1 Records

5.1.1 All information and records required by the Licence shall:

(a) be legible;

(b) if amended, be amended in such a way that the original and subsequent amendments

remain legible or are capable of retrieval;

(c) except for records listed in 5.1.1(d) be retained for at least 6 years from the date the

records were made or until the expiry of the Licence or any subsequent licence; and

(d) for those following records, be retained until the expiry of the Licence and any

subsequent licence:

(i) off-site environmental effects; or

(ii) matters which affect the condition of the land or waters.

5.1.2 The Licensee shall ensure that:

(a) any person left in charge of the Premises is aware of the conditions of the Licence

and has access at all times to the Licence or copies thereof; and

(b) any person who performs tasks on the Premises is informed of all of the conditions of

the Licence that relate to the tasks which that person is performing.

5.1.3 The Licensee shall complete an Annual Audit Compliance Report indicating the extent to

which the Licensee has complied with the conditions of the Licence, and any previous licence

issued under Part V of the Act for the Premises for the previous annual period.

5.1.4 The Licensee shall:

Environmental Protection Act 1986 Page 21 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

(a) implement a complaints management system that shall record the following

information (if known or provided) about complaints received at the Premises

concerning any environmental impact of the activities undertaken at the Premises:

(i) name and address of the complainants (if consented);

(ii) date and time of complaint;

(iii) date and time of alleged incident;

(iv) alleged source of the incident;

(v) general description of the alleged incident, including any environmental or

health impacts reported by the complainant;

(vi) wind direction, wind speed and temperature at time of alleged incident;

(vii) likely source of the alleged incident; and

(viii) actions taken by licensee to address complaint, including the outcome of any

investigation(s) and action(s) to verify any impacts.

(b) complete an annual analysis and review of complaints recorded under 5.1.4(a) to

identify any common factors and root cause of complaints and proposals to address

these.

5.1.5 The Licensee shall maintain a register of Special Waste Type 1 (Asbestos waste), Special

Waste Type 2 (Biomedical and clinical waste) and Quarantine Waste disposed of at the

Premises which shall include:

(i) a plan showing the position of Special Waste Type 1(Asbestos waste), Special

Waste Type 2 (Biomedical and Clinical waste) and Quarantine Waste disposed

of at the Premises;

(ii) the date of the deposit; and

(iii) the name of the person that deposited the waste.

5.2 Reporting

5.2.1 The Licensee shall submit to the CEO an Annual Environmental Report within 28 calendar

days after the end of the annual period. The report shall contain the information listed in Table

5.2.1 in the format or form specified in that table.

Table 5.2.1: Annual Environmental Report

Condition or table Parameter Format or form1

(if relevant)

- Summary of any failure or malfunction of any pollution None specified

control equipment and any environmental incidents that

have occurred during the annual period and any action

taken

- Surveyed Topographic contour map depicted the area of At least A3 in size

the planned footprint including cross sections for cut in electronic format

slopes, filled areas and un-excavated areas

Table 3.6.1 Waste input and output data (including rejected loads)

None specified

Table 3.7.1 Process Monitoring

Table 3.8.1 Monitoring of ambient groundwater quality

5.1.3 Compliance Annual Audit

Compliance Report

(AACR)

5.1.4 Complaints summary None specified

Note 1: Forms are in Schedule 2

5.2.2 The Licensee shall ensure that the Annual Environmental Report also contains:

(a) any relevant process, production or operational data recorded under Condition 3.1.3;

and

(b) an assessment of the information contained within the report against previous

monitoring results and Licence limits and/or targets

5.2.3 The Licensee shall submit the information in Table 5.2.2 to the CEO according to the

specifications in that table.

Environmental Protection Act 1986 Page 22 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 5.2.2: Non-annual reporting requirements

Condition or table Parameter Reporting Reporting date Format or form1

(if relevant) period (after end of the

reporting period)

- Copies of original Not Within 14 days of As received by the

monitoring reports Applicable the CEOs request Licensee from third

submitted to the parties

Licensee by third

parties

5.3 Notification

5.3.1 The Licensee shall ensure that the parameters listed in Table 5.3.1 are notified to the CEO in

accordance with the notification requirements of the table.

Table 5.3.1: Notification requirements

Condition Parameter Notification requirement1 Format

or table or form2

(if relevant)

2.1.1 Breach of any limit specified Part A: As soon as practicable but no N1

in the Licence later than 5pm of the next usual working

- Any failure or malfunction of day.

any pollution control

equipment or any incident, Part B: As soon as practicable

which has caused, is causing

or may cause pollution

3.1.5 Calibration report As soon as practicable. None

specified

3.8.1 Any bores listed in Table Within 7 days None

3.8.1 are destroyed or specified

otherwise made unusable

Note 1: Notification requirements in the Licence shall not negate the requirement to comply with s72 of the Act

Note 2: Forms are in Schedule 2

Environmental Protection Act 1986 Page 23 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Schedule 1: Maps

Premises map

The Premises is shown in the map below. The grey line depicts the Premises boundary.

Environmental Protection Act 1986 Page 24 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Map of monitoring locations

The locations of the monitoring points defined in Tables 3.7.1 and 3.8.1 are shown below.

Environmental Protection Act 1986 Page 25 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Landfill and storage area map

The location of Cell 6 capping, the current landfilling area (depicted by the yellow polygon) and the

greenwaste area are shown below.

Environmental Protection Act 1986 Page 26 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

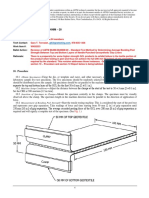

Detailed design plans - Landfill capping details 1

Environmental Protection Act 1986 Page 27 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Detailed design plans - Landfill capping details 2

Environmental Protection Act 1986 Page 28 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Detailed design plans - Landfill capping details 3

Environmental Protection Act 1986 Page 29 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Detailed design plans - Surface water discharge layout plan

Environmental Protection Act 1986 Page 30 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Detailed design plans - Landfill gas collection pipework layout plan

Environmental Protection Act 1986 Page 31 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Detailed design plans - Cell 6 landfill capping layout plan

Environmental Protection Act 1986 Page 32 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Schedule 2: N1 – Notification form

Licence: L9159/2018/1 Licensee: City of Cockburn

Form: N1 Date of breach:

Notification of detection of the breach of a limit or any failure or malfunction of any pollution

control equipment or any incident which has caused, is causing or may cause pollution.

These pages outline the information that the operator must provide.

Units of measurement used in information supplied under Part A and B requirements shall be

appropriate to the circumstances of the emission. Where appropriate, a comparison should be made

of actual emissions and authorised emission limits.

Part A

Licence Number

Name of operator

Location of Premises

Time and date of the detection

Notification requirements for the breach of a limit

Emission point reference/ source

Parameter(s)

Limit

Measured value

Date and time of monitoring

Measures taken, or intended to

be taken, to stop the emission

Notification requirements for any failure or malfunction of any pollution control equipment or

any incident which has caused, is causing or may cause pollution

Date and time of event

Reference or description of the

location of the event

Description of where any release

into the environment took place

Substances potentially released

Best estimate of the quantity or

rate of release of substances

Measures taken , or intended to

be taken, to stop any emission

Description of the failure or

accident

Environmental Protection Act 1986 Page 33 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Part B

Any more accurate information on the matters for

notification under Part A.

Measures taken, or intended to be taken, to

prevent a recurrence of the incident.

Measures taken, or intended to be taken, to rectify,

limit or prevent any pollution of the environment

which has been or may be caused by the emission.

The dates of any previous N1 notifications for the

Premises in the preceding 24 months.

Name

Post

Signature on behalf of

City of Cockburn

Date

Environmental Protection Act 1986 Page 34 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Schedule 3: Minimum Specifications

Table 1: GCL Material Specification

Value –

Landfill side slope

Value – capping (structured,

Property Test Frequency

Landfill top capping Coated GCL, not

laminated or glued

membrane)

Montmorillonite XRD (X-ray 50 tonnes of Greater than 70 wt% Greater than 70 wt%

content diffraction) GCL

Quantitative

Mineralogy

Analysis

Carbonate 50 tonnes of 1-2 wt% 1-2 wt%

content 1 GCL

Bentonite form 50 tonnes of Natural NA-bentonite Natural NA-bentonite or

GCL or >80 wt% Sodium >80 wt% Sodium as

as activated bentonite activated bentonite

Particle size AS 1289- 50 tonnes of Powdered (e.g. 80% Powdered (e.g. 80%

3.6.2 GCL passing 75 micron passing 75 micron

sieve) or Granulated sieve) or Granulated

(e.g. <1% passing 75 (e.g. <1% passing 75

micron) micron)

Cation Methylene 50 tonnes of Equal to or greater Equal to or greater than

exchange Blue Method GCL than 70 meq/100 g 70 meq/100 g (or

capacity (or cmol/kg) cmol/kg)

Free Swell ASTM D5890 50 tonnes of Equal to or greater Equal to or greater than

(bentonite) GCL than 24 mL/2g 24 mL/2g

(min. ave)

Moisture ASTM D5993 2,500 m2 Equal to or less than Equal to or less than

Content 25% at Manufacture 25% at Manufacture

(bentonite) 2

Equal to or less than Equal to or less than

35% Site Samples 35% Site Samples

Fluid Loss ASTM D5891 50 tonnes of Equal to or less than Equal to or less than 18

(bentonite) 2 GCL 18 ml max ml max

Polymer Coating ASTM D5261 4,000 m2 N/A Equal to or greater than

(min. ave) 500 g/m 2

Top Geotextile ASTM D5261 20,000 m2 Equal to or greater Equal to or greater than

Mass (min. ave) than 240 g/m2 200 g/m 2

3

Mass of GCL ASTM D5993 2,500 m2 Equal to or greater Equal to or greater than

(min. ave) 4 than 4,340 g/m2 4,500 g/m2

Mass of ASTM D5993 2,500 m2 Equal to or greater Equal to or greater than

Bentonite (min. than 4,000 g/m2 3,700 g/m2

ave) 4

Bottom ASTM D5261 20,000 m2 Equal to or greater Equal to or greater than

Geotextile Mass than 100 g/m2 100 g/m 2

(min. ave)

Environmental Protection Act 1986 Page 35 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Value –

Landfill side slope

Value – capping (structured,

Property Test Frequency

Landfill top capping Coated GCL, not

laminated or glued

membrane)

Composite layer ASTM D5199 2,500 m2 Equal to or greater Equal to or greater than

Thickness (Dry) than 6 mm 5.7 mm

(min. ave)

Elongation (MD) ASTM D4632 20,000 m2 Equal to or greater Equal to or greater than

(min. ave) than 10% 8%

Tensile Strength ASTM D6768 20,000 m2 Equal to or greater Equal to or greater than

(min. ave) than 8 kN/m 10 kN/m

Peel Strength ASTM D6496 2,500 m2 360 N/m 360 N/m

(min. ave)

Permeability 2 ASTM D5887 25,000 m2 Equal to or less than Equal to or less than 5 x

5 x 10-11 m/s 10-11 m/s

Permeability EN 14150 25,000 m2 N/A Equal to or less than 1 x

coating (10m 10-14 m/s

head)2

Note 1: Carbonate here implies calcite, calcium carbonate or other soluble or partially soluble carbonate minerals

Note 2: These values are maximum (all others are minimum). Coating 10 m head.

Note 3: For both cap and carrier fabrics for non-woven reinforced GCL’s; one, or the other, must contain a scrim

component of mass ≥ 100 g/m2 for dimensional stability. This only applies to GM/GCL composites, which are

exposed to the atmosphere for several months or longer so as to mitigate panel separation

Note 4: Mass of the GCL and bentonite is measured after oven drying as per the stated test method

Environmental Protection Act 1986 Page 36 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 2: LLDPE Geomembrane Material Specifications

LLDPE

Test Testing Frequency

Property Test Value – 2.00 mm

Method (minimum)

Smooth/Textured

Thickness (min. ave.)

nom. (-5%)

Lowest individual for 8 out of 10

-10%

values D 5994 Per roll

Lowest individual for any of the 10 -15%

values

Asperity Height (min. ave.) D 7466 0.40 mm Every 2nd roll 1

D 1505/

Sheet Density (max) 0.939 g/cc 90,000 kg

D 792

Tensile Properties (min. ave)2

D 6693 21 kN/m

break strength 9,000 kg

Type IV 250%

break elongation

2% Modulus (max) D 5323 840 kN/m Per formulation

Tear Resistance (min. ave.) D 1004 200 N 20,000 kg

Puncture Resistance (min. ave.) D 4833 400 N 20,000 kg

Axi-Symmetric Break Resistance

D 5617 30% Per formulation

Strain (min)

Carbon Black Content – Particle size

D 4218 3 2.0-3.0% 20,000 kg

~20 nm (range)

Carbon Black Dispersion D 5596 Note 4 20,000 kg

Oxidative Induction Time (OIT) (min.

ave.) 6

90,000 kg

(a) Standard OIT, or D 3895 100 min.

(b) High Pressure OIT D 5885 400 min.

Oven Aging at 85°C 5 and 6 D 5721

(a) Standard OIT (min. ave.) - % D 3895 35%

retained after 90 days, or Per each formulation

(b) High Pressure OIT (min. ave.)

- % retained after 90 days D 5885 60%

UV Resistance7 D 7238

(a) Standard OIT (min. ave.) or D 3895 N.R. 8

Per each formulation

(b) High Pressure OIT (min. ave.) 35%

- % retained after 1,600 hrs9 D 5885

Note 1: Alternate the measurement side for double sided texture sheet.

Note 2: Machine direction (MD) and cross machine direction (XMD) average values shall be on the basis of 5 test

specimens each direction: Break elongation is calculated using a gauge length of 50mm at 50mm/min.

Note 3: Other methods such as D 1603 (tube furnace) or D 6370 (TGA) are acceptable if an appropriate

correlation to D 4218 (muffle furnace) can be established.

Note 4: Carbon black dispersion (only near spherical agglomerates) for 10 different views: 9 in Categories 1 or 2

and 1 in Category 3.

Note 5: The manufacturer has the option to select either one of the OIT methods listed to evaluate the

antioxidant content in the geomembrane.

Note 6: It is also recommended to evaluate samples at 30 and 60 days to compare with the 90 day response.

Note 7: The condition of the test shall be 20 hr. UV cycle at 75°C followed by 4 hr condensation at 60°C.

Note 8: Not recommended since the high temperature of the Std-OIT test produces an unrealistic result for some

of the antioxidants in the UV exposed samples.

Note 9: UV resistance is based on percentage retained value regardless of the original HP-OIT value.

For notes, refer to GRI Test Method GM17

Min Average Roll Value (min. ave.) is defined as the Mean value less 2 standard deviations.

Environmental Protection Act 1986 Page 37 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 3: LLDPE Geomembrane Minimum Average Weld Properties

Property Test Method Unit Strength Sample Strength (N)

(kN/m)

Peel strength (fusion & ext.), ASTM D6392 18.0 450 N/25 mm test

kN/m sample

Shear strength (fusion & ext.), ASTM D 6392 27.6 690 N/25 mm test

kN/m sample

Table 4: Geotextile Material Specifications

Property Cushion Geotextile Test Method & Frequency

Thickness (min. ave) Equal to or greater than 4.0 mm AS 2001-2.15,

1 sample per 2,500 m2

Mass per Unit Area (min. ave) Equal to or greater than 450 AS 2001-2.13,

g/m2 1 sample per 2,500 m2

Wide Strip Tensile Strength 37.5 kN/m AS 3706-2,

(min. ave) 1 sample per 5,000 m2

Tear Strength (min. ave) Equal to or greater than 830 N AS 3706-3,

1 sample per 5,000 m2

CBR Burst Strength (min. ave) Equal to or greater than 6,400 N AS 3706-4,

1 sample per 5,000 m2

UV Strength Resistance after 70% ASTM D7238,

500 light hrs. exposure 1 sample per 5,000 m2

Environmental Protection Act 1986 Page 38 of 42

Licence: L9159/2018/1

File Number: DER2018/001433 IRLB_TI0672 v2.8

Table 5: Geocomposite Drainage Material Specifications

Property Value Test Method & Frequency

Geocomposite Drainage Material

Thickness (min. ave) Equal to or greater than 8.0 mm ASTM D 5199,

1 sample per 2,500 m2

Carbon Black (min. ave) 2% ASTM D 4218,

1 sample per 5,000 m2