Professional Documents

Culture Documents

Micro Automation Set

Micro Automation Set

Uploaded by

Passenger MedeamCopyright:

Available Formats

You might also like

- F04 Checklist of Tools, Equipment, Supplies and Materials, and Facilities NEW FORM CSSDocument13 pagesF04 Checklist of Tools, Equipment, Supplies and Materials, and Facilities NEW FORM CSSgillian marbebe100% (1)

- Brochure Telecontrol enDocument16 pagesBrochure Telecontrol enHari PrashannaNo ratings yet

- CEMAT - Process Control For The Cement Industry. Answers For Industry.Document20 pagesCEMAT - Process Control For The Cement Industry. Answers For Industry.ylebongoNo ratings yet

- Power System ControlDocument24 pagesPower System ControlСтоян БанчевNo ratings yet

- TM 1703Document78 pagesTM 1703waltdisneyyNo ratings yet

- Totally Integrated Power ProtectionDocument38 pagesTotally Integrated Power Protectionvthiseas100% (1)

- 3-Totally Integrated Automation ChemicalDocument30 pages3-Totally Integrated Automation ChemicalUmesh SNo ratings yet

- Thesis Reference 6 (Development of Feedback Mechanism For Microcontroller Based SMS Electronic Strolling Message Display Board)Document10 pagesThesis Reference 6 (Development of Feedback Mechanism For Microcontroller Based SMS Electronic Strolling Message Display Board)reyvin.constantinoNo ratings yet

- A Mobile Based Home Automation System and Energy Saving SystemDocument4 pagesA Mobile Based Home Automation System and Energy Saving SystemkarunamoorthiNo ratings yet

- Accessnet®-T Ip NMS: Network Management SystemDocument8 pagesAccessnet®-T Ip NMS: Network Management Systemarif budimanNo ratings yet

- GSM Based Device ControlDocument9 pagesGSM Based Device ControlsubucudNo ratings yet

- 05 # Wireless Signalling and SMSDocument4 pages05 # Wireless Signalling and SMSRaj ChavanNo ratings yet

- Efficiency Package For Solar TrackerDocument2 pagesEfficiency Package For Solar TrackerBoulos NassarNo ratings yet

- DDC Controller - Jci - XPMDocument15 pagesDDC Controller - Jci - XPMolingga92No ratings yet

- Mark ViesDocument32 pagesMark ViesMauricio GuanellaNo ratings yet

- Remote Monitoring Application PaperDocument4 pagesRemote Monitoring Application PaperOliver AlfaroNo ratings yet

- ABB E180 CatDocument24 pagesABB E180 CatPALANI MNo ratings yet

- Telecontrol - Efficient Telecontrol SolutionsDocument16 pagesTelecontrol - Efficient Telecontrol SolutionsJONATHAN FERNANDO VITON CASTAÑEDANo ratings yet

- The Sicas Electronic Interlocking enDocument6 pagesThe Sicas Electronic Interlocking enIgor BlanariNo ratings yet

- Cybersecurity Services - : That Fit Your NeedsDocument2 pagesCybersecurity Services - : That Fit Your NeedsIvan JeremicNo ratings yet

- Remote Mobile Control of Industry Appliances: AbstractDocument3 pagesRemote Mobile Control of Industry Appliances: AbstractkarunamoorthiNo ratings yet

- MonitorDocument86 pagesMonitorsabNo ratings yet

- GFT 870Document32 pagesGFT 870Ha NguyenNo ratings yet

- DFMC b10011 00sinamicsstartdrivedeenus 72Document10 pagesDFMC b10011 00sinamicsstartdrivedeenus 72Tun Myint OoNo ratings yet

- SICAM Navigator - ProfileDocument2 pagesSICAM Navigator - ProfileAldo Bona HasudunganNo ratings yet

- 07 - 001 - 254536-Power System Control and Energy ManagementDocument4 pages07 - 001 - 254536-Power System Control and Energy ManagementGabriel Apavaloaiei100% (1)

- Industrial Automation Using GSM: MBSG Lalitha, V Akshitha, Vs Vineeth K Soundara RajanDocument3 pagesIndustrial Automation Using GSM: MBSG Lalitha, V Akshitha, Vs Vineeth K Soundara RajanTanaka dzapasiNo ratings yet

- M2M Communication Based Wireless SCADA For Real-Time Industrial AutomationDocument3 pagesM2M Communication Based Wireless SCADA For Real-Time Industrial AutomationAutoyearNo ratings yet

- B11190 SUBNET PowerSYSTEM Center BrochureDocument4 pagesB11190 SUBNET PowerSYSTEM Center Brochureeduardo.honorato5586No ratings yet

- Modicon Quantum - SOE SystemDocument4 pagesModicon Quantum - SOE SystemAgis Rijal AtmawijayaNo ratings yet

- Sicam 230 Brochure enDocument8 pagesSicam 230 Brochure enLuis Enrique PariapazaNo ratings yet

- SICAM TM System Data Sheet - 018125328Document78 pagesSICAM TM System Data Sheet - 018125328jakelingonzalezNo ratings yet

- Substation MonitoringDocument6 pagesSubstation MonitoringManish TiwariNo ratings yet

- Siemens SEM3Document24 pagesSiemens SEM3Diego Dandolini PasiniNo ratings yet

- White Paper DMC enDocument31 pagesWhite Paper DMC enraider1eNo ratings yet

- Siemens A50 - Service ManualDocument39 pagesSiemens A50 - Service ManualHolografNo ratings yet

- ANSI LV MCC SIMOCODE EthernetDocument4 pagesANSI LV MCC SIMOCODE EthernetJaime PaizNo ratings yet

- 1.6 Catálogo Blokset Solution Guide 2013Document46 pages1.6 Catálogo Blokset Solution Guide 2013william andres pena castanoNo ratings yet

- ESBED297701EN Blockset Solution Guide 2014Document46 pagesESBED297701EN Blockset Solution Guide 2014Shailesh ChettyNo ratings yet

- Synopsis SMS Controlled Device Switching: University Institute of Engineering & TechnologyDocument9 pagesSynopsis SMS Controlled Device Switching: University Institute of Engineering & TechnologyNarayan Singh WaraichNo ratings yet

- Teleperm XP y Teleperm XS - ComunicaciónDocument12 pagesTeleperm XP y Teleperm XS - Comunicaciónkerusacba_2011No ratings yet

- Job Role-3 Part-3Document24 pagesJob Role-3 Part-3SENTHIL KUMARNo ratings yet

- Submitted To: Implementation of GSM Modem For Industrial Automation ApplicationsDocument79 pagesSubmitted To: Implementation of GSM Modem For Industrial Automation ApplicationsSireesh YeshwantapurNo ratings yet

- UMP BrochureDocument2 pagesUMP BrochureAmarsaikhan AmgalanNo ratings yet

- SIEMENS Embebido CatDocument264 pagesSIEMENS Embebido Catbad boysNo ratings yet

- SIPROTEC Processbus - ProfileDocument2 pagesSIPROTEC Processbus - ProfileVladimir TomicNo ratings yet

- Ficha de Especificaciones inDocument2 pagesFicha de Especificaciones inRodolfo Antonio Cardenas FernandezNo ratings yet

- 3M Volition: Intelligent Management SystemDocument12 pages3M Volition: Intelligent Management SystemFlorin FlorinNo ratings yet

- Final Report FinalDocument67 pagesFinal Report FinalMATHANKUMAR.SNo ratings yet

- GSM Based DC Motor ControlDocument8 pagesGSM Based DC Motor ControlK IsmailNo ratings yet

- 1 Data Sheet Nokia Assurance CenterDocument2 pages1 Data Sheet Nokia Assurance CenterThorNo ratings yet

- Sinumerik 840D SLDocument8 pagesSinumerik 840D SLDinn WahabNo ratings yet

- K-Chief: All Control Requirements Fulfilled - in A Uniform SystemDocument16 pagesK-Chief: All Control Requirements Fulfilled - in A Uniform Systemdnse90900No ratings yet

- A6V10062647 enDocument26 pagesA6V10062647 enSaber MarzoukNo ratings yet

- Machine Monitoring System Based On Mtconnect TechnologyDocument6 pagesMachine Monitoring System Based On Mtconnect TechnologyChiragPhadkeNo ratings yet

- Siemens A52 A55 A56 Service Manual Lvl2Document34 pagesSiemens A52 A55 A56 Service Manual Lvl2topogigio240No ratings yet

- SIMATIC Automation Tool Mit NAT Routing enDocument10 pagesSIMATIC Automation Tool Mit NAT Routing enmaussan El reptilianoNo ratings yet

- Building Management SystemsDocument7 pagesBuilding Management SystemsArman Ul NasarNo ratings yet

- Industrial Training Seminar On BSNL: Submitted ByDocument33 pagesIndustrial Training Seminar On BSNL: Submitted ByShivam ParasharNo ratings yet

- Mastering Siemens S7: A Comprehensive Guide to PLC ProgrammingFrom EverandMastering Siemens S7: A Comprehensive Guide to PLC ProgrammingNo ratings yet

- A5E36695225-ABen SIWAREX WP521 WP522 M en-USDocument176 pagesA5E36695225-ABen SIWAREX WP521 WP522 M en-USPassenger MedeamNo ratings yet

- 104 0661 Abc PDP - 2 - 52Document72 pages104 0661 Abc PDP - 2 - 52Passenger MedeamNo ratings yet

- Hq-EnDocument36 pagesHq-EnPassenger MedeamNo ratings yet

- Keyboard Filter Driver For Intouch 7.0/7.1/7.11: Tech Note 255Document7 pagesKeyboard Filter Driver For Intouch 7.0/7.1/7.11: Tech Note 255Passenger MedeamNo ratings yet

- Profinet ModuleDocument2 pagesProfinet ModulePassenger MedeamNo ratings yet

- BS SHINOHAWA PDFDocument258 pagesBS SHINOHAWA PDFPassenger MedeamNo ratings yet

- Promotional File PAC4200 002136 - ENDocument4 pagesPromotional File PAC4200 002136 - ENPassenger MedeamNo ratings yet

- Interface Module - UM 45-FLKS50/ZFKDS - 2298506: Key Commercial DataDocument1 pageInterface Module - UM 45-FLKS50/ZFKDS - 2298506: Key Commercial DataPassenger MedeamNo ratings yet

- P7PRW03B en-USDocument210 pagesP7PRW03B en-USPassenger MedeamNo ratings yet

- Tech Note 99 Determining SPCPro Alarm Types With SQL QueriesDocument2 pagesTech Note 99 Determining SPCPro Alarm Types With SQL QueriesPassenger MedeamNo ratings yet

- Basic Installation and Start-Up Guide For MASTERDRIVES MC and GMC Software PackagesDocument25 pagesBasic Installation and Start-Up Guide For MASTERDRIVES MC and GMC Software PackagesPassenger MedeamNo ratings yet

- Tech Note 222configuring OPCLink Using TCPIP and A Standard Network Card For Windows NT 4.0 To Access S7-400 PLCs Via The Siemens S7 OPC ServerDocument16 pagesTech Note 222configuring OPCLink Using TCPIP and A Standard Network Card For Windows NT 4.0 To Access S7-400 PLCs Via The Siemens S7 OPC ServerPassenger MedeamNo ratings yet

- Tech Note 154 Configuring InTouch To Query Data From IndustrialSQL ServerDocument11 pagesTech Note 154 Configuring InTouch To Query Data From IndustrialSQL ServerPassenger MedeamNo ratings yet

- Tech Note 79 Creating InTouch Tagnames To Read InControl Local SymbolsDocument7 pagesTech Note 79 Creating InTouch Tagnames To Read InControl Local SymbolsPassenger MedeamNo ratings yet

- Tech Note 88 Configuring InTouch To Communicate With Oracle7Document8 pagesTech Note 88 Configuring InTouch To Communicate With Oracle7Passenger MedeamNo ratings yet

- Using Supertags in Intouch 7.X: What Is A Supertag?Document7 pagesUsing Supertags in Intouch 7.X: What Is A Supertag?Passenger MedeamNo ratings yet

- Security Features in Intouch 8.X: Tech Note 295Document6 pagesSecurity Features in Intouch 8.X: Tech Note 295Passenger MedeamNo ratings yet

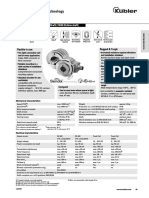

- Rotary Measuring Technology: Incremental EncodersDocument7 pagesRotary Measuring Technology: Incremental EncodersPassenger MedeamNo ratings yet

- Tech Note 61 Building Queries in Crystal Reports With IndustrialSQL ServerDocument8 pagesTech Note 61 Building Queries in Crystal Reports With IndustrialSQL ServerPassenger MedeamNo ratings yet

- Siemens S7 PLC and VLT 5000 ProfibusDocument6 pagesSiemens S7 PLC and VLT 5000 ProfibusPassenger MedeamNo ratings yet

- IOSrv ABCIPDocument64 pagesIOSrv ABCIPPassenger MedeamNo ratings yet

- 8000 BR 0826Document8 pages8000 BR 0826Passenger MedeamNo ratings yet

- Waygate Technologies Mentor Visual IQDocument8 pagesWaygate Technologies Mentor Visual IQWilliamNo ratings yet

- Easytek: User GuideDocument120 pagesEasytek: User GuideaxisNo ratings yet

- Led TV: Service ManualDocument99 pagesLed TV: Service Manualloc nguyen100% (1)

- College of Management: Case Analysis: Logitech: The Little Mouse That RoarsDocument4 pagesCollege of Management: Case Analysis: Logitech: The Little Mouse That RoarsEmy Rose DiosanaNo ratings yet

- ITE 6.0 Pre-Test Answers 2018 2019 100% ITE 6.0 Pre-Test Answers 2018 2019 100%Document8 pagesITE 6.0 Pre-Test Answers 2018 2019 100% ITE 6.0 Pre-Test Answers 2018 2019 100%Egy RenataNo ratings yet

- SMT 585Document109 pagesSMT 585Cesar MessiasNo ratings yet

- Frequency Allocation - 1800Mhz Band: Mobitel 2G Airtel 2G Mobitel - 4G Lte Mobitel 2GDocument1 pageFrequency Allocation - 1800Mhz Band: Mobitel 2G Airtel 2G Mobitel - 4G Lte Mobitel 2GSudheera IndrajithNo ratings yet

- Tmob NitherlandsDocument1 pageTmob NitherlandsAmine AminovichNo ratings yet

- Evolution DMS-1004HD-CA (HD - DTA - CA - Slick - 5.5.11 - MX)Document3 pagesEvolution DMS-1004HD-CA (HD - DTA - CA - Slick - 5.5.11 - MX)Alx_doeth0% (1)

- Introduction To GSMDocument52 pagesIntroduction To GSMapi-3717973100% (2)

- Cs - TC - Datasheet - RF 7400e VP Tactical Video ProcessorDocument2 pagesCs - TC - Datasheet - RF 7400e VP Tactical Video Processorjuan camilo cardona SánchezNo ratings yet

- ИКТ алфавит (копия)Document18 pagesИКТ алфавит (копия)Dancho KZNo ratings yet

- Leica Geosystems TPS Comparison ChartDocument1 pageLeica Geosystems TPS Comparison ChartBirdNo ratings yet

- Home What MobileDocument2 pagesHome What MobilemuhsanshakeelNo ratings yet

- Advantages & Disadvantages of Social Media (TwitterDocument3 pagesAdvantages & Disadvantages of Social Media (Twitterpronab sarkerNo ratings yet

- STPCS7 IPC647C-IPC847C English 2011-12Document22 pagesSTPCS7 IPC647C-IPC847C English 2011-12Federico DiazNo ratings yet

- Architecture of A Computer SystemDocument6 pagesArchitecture of A Computer SystemJohn VibarNo ratings yet

- Nokia 2013 Annual ReportDocument96 pagesNokia 2013 Annual ReportMvk ChaitanyaNo ratings yet

- BR01 iNAND Embedded Integrated Solutions 0217Document4 pagesBR01 iNAND Embedded Integrated Solutions 0217potatoNo ratings yet

- Pengenalan Teknologi Rangkaian Terintegrasi: Eka Maulana, ST, MT, Meng. Adharul Muttaqin, S.T., M.TDocument35 pagesPengenalan Teknologi Rangkaian Terintegrasi: Eka Maulana, ST, MT, Meng. Adharul Muttaqin, S.T., M.TMuhammad FauzanNo ratings yet

- 006 0584 00 LidarCam BrochureDocument2 pages006 0584 00 LidarCam BrochureTịnh TrầnNo ratings yet

- Practical Task 2Document2 pagesPractical Task 2Tiniey NadlanNo ratings yet

- Stryker 26 Vision Elect BrochureDocument2 pagesStryker 26 Vision Elect BrochureRicardo SalazarNo ratings yet

- Unit4 - Components of A Computer SystemDocument74 pagesUnit4 - Components of A Computer SystemJaren QueganNo ratings yet

- Tarea de Cruso de Contabilidad y InglkesDocument2 pagesTarea de Cruso de Contabilidad y Inglkeskarin trinidad villanuevaNo ratings yet

- Ufone StakeholdersDocument7 pagesUfone StakeholdersArslan NawazNo ratings yet

- Brosura EBS 260Document4 pagesBrosura EBS 260Cocis MirceaNo ratings yet

- Konftel 70 Data Sheet - ENG-LOWDocument2 pagesKonftel 70 Data Sheet - ENG-LOWRavi sontakkeNo ratings yet

- H3509 User-Manual enDocument25 pagesH3509 User-Manual enYaseen QariNo ratings yet

Micro Automation Set

Micro Automation Set

Uploaded by

Passenger MedeamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Micro Automation Set

Micro Automation Set

Uploaded by

Passenger MedeamCopyright:

Available Formats

MAS_Fernwirktechnik_EN.book Seite 1 Mittwoch, 27.

August 2008 11:21 11

© Siemens AG 2008

Micro Automation Sets

For Remote Control

Brochure · July 2008

MICRO AUTOMATION SET

MAS_Fernwirktechnik_EN.book Seite 2 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Micro Automations Sets

Compact Solutions for your success

Micro Automation Sets are carefully matched combina-

tions of automation components from the Siemens port-

folio. They are tailored to solve various automation issues

and can be used for applications in the fields of industry,

machine building and building services technology –

simple, inexpensive and tested.

Lots of value added:

• You can solve small automation tasks faster and easier. Micro Automation Sets can be used for applications in indus-

• An integrated, tested solution package is available which try, machine building and building services technology – with

you can fully rely on. the most varied of products from our wide-ranging portfolio.

• You receive all information and data from one source.

• By combining standard components in one network, you • Drive Technology

safely can solve your automation task whilst making inter- Starting, controlling and positioning with standard drives

esting cost saving.

• Building Automation

Our Micro Automation Sets not only help you to find the right Controlling, monitoring and signaling in building applica-

product quickly – we also supportyou in using them with our tions

"plug-and-play" tools for a fast start-up:

• Remote Control

Functions in detail – Micro Application Examples Remote monitoring and control of distributed plants

The Micro Application Examples show you what a concrete • Communication

application can look like. All Sets are based on real-world Human machine interfacing in industrial applications and

applications as well as extensive tests and simulations. In this simple networking

way, you benefit from detailed documentation and perfectly

matched products. • Measuring & Sensor Technology

Recording, measuring and evaluation of non-electrical

Plug and Play for every phase – values

free start-up software examples

We offer codes and parameter sets for programming the

application. This means "plug and play" at your ease – whether

at the planning, engineering or commissioning.

www.siemens.com/microset

2 Micro Automations Sets

MAS_Fernwirktechnik_EN.book Seite 3 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Remote Control Content

Remote monitoring and control of distributed plants

text

Micro Automation Sets for Remote Control

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Remote control is often understood as being the central moni-

toring and control of remote processes over long distances. MAS 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Wireless signaling and switching per SMS

The service personnel can thus be informed of failures and

service intervals systematically and in time. MAS 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Remote control and telemonitoring via

Current operating data can easily be transmitted from substa- dedicated modem

tions to a control room.

MAS 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Owing to the possibility of remote programming, the necessi- Wireless Data Communication based

ty of local troubleshooting is dramatically reduced. on GPRS

Application areas Support via Internet . . . . . . . . . . . . . . . . . . . . . . . . . . 10

• Oil and gas industry (pipeline, drill head controlling,

pump stations)

• Water and waste water supply (pumping systems, well

stations)

• Power distribution/generation

(district heating, transformer stations)

• Transportation systems (signaling systems)

• Infrastructure (tunnel/street lighting)

• Open pit/ underground mining

• Facility Management

• Agriculture (Material supply/disposal for silos and/

or tanks, irrigation systems)

• Outdoor advertising (billboards)

• Vending machines (material supply)

Remote control is subdivided into remote maintenance, re-

mote measurement, remote control and remote monitoring.

Telecontrol installations use virtually all communication op-

tions capable of transmitting data, such as:

• Dedicated lines – networking of distributed automation

stations via private leased lines.

• SMS – remote maintenance and remote diagnosis simply

via mobile phone, for service cases via SMS with included

current process values.

• Via mobile telephone system (GPRS) – GMS providers with

GPRS networks can be used worldwide. GPRS provides

prompt transmission, only the transmitted data volume is

charged.

3 Micro Automations Sets

MAS_Fernwirktechnik_EN.book Seite 4 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Micro Automation Set 5

Wireless signaling and switching per SMS

Wireless messaging and controlling of plant conditions via

.

SMS with SIMATIC S7-200 and GSM modem TC65 Terminal

• SIMATIC S7-200 wirelessly sends fault and operating

messages via SMS message, e-mail or fax via TC65T GSM

modem.

• Maintenance and service personnel are appropriately

informed with process values that are integrated within the

message.

• S7-200 receives SMS messages. Fault and operating

messages can be acknowledgeable and processes can be

operated remotely.

• Controller connection to the GSM network can also be used

for teleservice purposes. Therefore the current plant status

can be remotely monitored and the controller program can

be optimized remotely.

• The TC65T modem can be used in nearly all GSM networks MAS 5 Hardware components

worldwide thanks to the quad-band technology.

E mail SMS

N L1 Fax Teleservice Antenna

LOGO! Power SIMATIC S7-200 TC65 Terminal

4 Micro Automation Set 5

MAS_Fernwirktechnik_EN.book Seite 5 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Application areas

This Micro Automation Set is especially suitable for simple controlling and monitoring

functions in decentralized plants, in which operating and fault messages will

occasionally have to be transferred to a control room or maintenance personnel, e. g.:

• Monitoring of gas pipes

• Pump stations in water distribution and waste water plants

• Small ventilation systems

• Transformer stations in power distribution systems

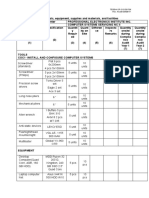

Technical specification

Product

LOGO! Power (24 V/1.3 A), primary switched power supply 6EP1 3ÕÓ–ÓîãÒÔ

Supply voltage 85 … 264 V AC

Output voltage 24 V DC

Output current 1.3 A

SIMATIC S7-200 (CPU 221) 6ES7 2ÓÓ–ÒÜÜÔÕ–ÒóÁÒ

Supply voltage 20.4 … 28.8 V DC

Current consumption 450 mA

Interfaces 1 x RS485 communication interface

TC65 Terminal - Modem 6AG1 011-1CC00-0AA0

Supply voltage 24 V (8 … 30 V) DC

Current consumption 600 mA

Output power Kl.4 (2 W) with EGSM 850/900, Kl. 1 (1 W) with GSM 1800/1900

Frequency range GSM 850/900/1800/1900 MHz

Provided Accessories Adapter for rail mounting, antenna with magnetic base, data cable and power

supply adapter

Accessories

SIM cards Available from your mobile service provider

RS232/PPI- cable 6ES7 901-3CB30-0XA0

Miniature circuit-breaker 5SX2 116-6

Configuring software/tools

STEP 7 Micro/WIN 6ES7 810-2CC03-0YX0

ÜÁ–ÓÔÕ:

You can find ordering information for variants in the Mall.

Micro Automation Set 5 5

MAS_Fernwirktechnik_EN.book Seite 6 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Micro Automation Set 17

Remote control and telemonitoring via dedicated modem

Simple remote operation with SIMATIC S7-200,

MD2 dedicated modem and WinCC flexible RT

• Networking of distributed automation stations, e.g. pump

stations or wells via private dedicated lines.

• Communication is parameterized instead of being

programmed.

• Remote maintenance of the stations is also possible via the

dedicated line; you don't need any other tools,

STEP 7 Micro/WIN is enough here.

• Thanks to WinCC flexible, remote control and tele-

monitoring are especially low in cost.

• Plant sections can be networked even across long

distances.

• The MD2 dedicated modem is connected to the SIMATIC

S7-200 simply via standard cable; additional modules or

inverters are superfluous. MAS 17 Hardware components

Central control room Station n e.g.

pump1

Station 2

e.g.

pump1

Station 1

e.g.

Standard-PC with pump1

WinCC flexible RT

LOGO! SIMATIC

Power S7-200

LOGO! SIMATIC

Power S7-200

LOGO! SIMATIC

Power S7-200

LTOP MD2

LTOP MD2

LTOP MD2

LOGO! Power MD2 LTOP

Dedicated line (max distance 10 km)

6 Micro Automation Set 17

MAS_Fernwirktechnik_EN.book Seite 7 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Application areas

The Micro Automation Set is especially suited for networking of simple and distributed

stations.

Simple automation tasks are solved decentralized and the data are transmitted via

dedicated line, e.g.:

• Pumping systems

• Well stations

• Silos

• Tanks

Technical specification

Product

LOGO! Power (24 V/1.3 A), primary switched power supply 6EP1 3ÕÓ–ÓîãÒÔ

Supply voltage 85 … 264 V AC

Output voltage 24 V DC

Output current 1.3 A

WinCC flexible RT

WinCC flexible Advanced 6AV6 613-0AA51-3CA5

WinCC flexible RT 128 6AV6 613-1BA51-3CA0

WinCC flexible RT Archive 6AV6 618-7ED01-3AB0

MD2 dedicated modem 6NH7 810-0AA20

Supply voltage, rated value 24 V DC

Current consumption typ. 100 mA

Max. cable length approx. 10 km

LTOP: lightning protection and overvoltage protection

LTOP 1 6NH9 821-0BC11

LTOP 2 6NH9 821-0BC12

SIMATIC S7-200 CPU 222 6ES7 2ÓÔ–ÓÜÁÔÕ–ÒóÁÒ

Supply voltage 20.4 … 28.8 V DC

Interfaces 1 x RS485 communication interface

Accessories

CP5611, MPI-compatible interface (if not yet available on PC) 6GK1 561-1AA01

PROFIBUS cable, delivery unit: up to 1000 m, minimum order quantity: 20 m 6XV1 830-0EH10

(ordered by the meter)

PROFIBUS switch with programming device connection 6ES7 972-0BB12-0XA0

PROFIBUS switch without programming device connection 6ES7 972-0BA12-0XA0

Adapter for securing the MD2s on the DIN rail 6NH7 760-0AA

Spare part for LTOP, overvoltage protection module OPM, plug-in (optional) 6NH9 821-0BB00

Connecting cable for serial interface 6ES7 901-3CB30-0XA0

Connecting cable for USB port 6ES7 901-3DB30-0XA0

Configuring software/tools

STEP 7 Micro/WIN 6ES7 810-2CC03-0YX0

Micro Automation Set 17 7

MAS_Fernwirktechnik_EN.book Seite 8 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Micro Automation Set 21

Wireless Data Communication based on GPRS

Wireless monitoring and controlling of distributed plants

with SIMATIC S7-200

• Economically realizing bidirectional data communication

between all stations with SINAUT Micro SC.

• The OPC server integrated in SINAUT Micro SC transpar-

ently provides all process data of the remote station; the

general interrogation of the data can be realized by the

central station.

• All remote stations feature teleservice functionality for ser-

vice purposes, messages are automatically transferred to

the service staff by SMS.

• Thanks to quad-band modem, GSM mobile service provid-

ers with GPRS network can be taken advantage of world-

wide.

• GPRS and Internet secure short transmission times, are

always online and only the transferred data volume is MAS 21 Hardware components

charged.

Teleservice Central Station

Micro/WIN

GSM Modem

SIMATIC Microbox

SINAUT MicroSC

WinCC flexible

Remote Station 1 Remote Station n

WAN

GPRS

SMS

MD720-3 SIMATIC S7-200 MD720-3 SIMATIC S7-200

8 Micro Automation Set 21

MAS_Fernwirktechnik_EN.book Seite 9 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Application areas

The Micro Automation Set is especially suitable for the use in geographically distributed

plants. Simple automation tasks are solved using decentralized concepts. Operating

statuses can be monitored and controlled by data transfer via mobile radio (GPRS) fast

and cost-effectively, e.g.:

• Pump stations in water distribution and waste water plants

• Controlling and monitoring of street light systems

• Monitoring of gas pipes

• Irrigation sytems

Technical specification

Product

SIMATIC MicroBox PC 427B 6ES7 647-7AA20-0QA0

2GB Compact-Flash accessible

Operating System: Windows XP Embedded

SINAUT Micro SC (License for 8 stations) 6NH9 910-0AA10-0AA3

WinCC flexible

Runtime 6AV6 613-1BA51-3CA0

Advanced 6AV6 613-0AA51-3CA5

SIMATIC S7-200 CPU 224 *) 6ES7 2ÓÖ–ÓÁßÔÕ–ÒóÁÒ

Supply voltage 85 ... 264 V AC

Interfaces 1 x RS485 communication interface

MD720-3 (GPRS-Modem) 6NH9 720-3AA00

Quadband GSM 850, EGSM 900, DCS 1800 and PCS 1900

Output Power 2 W/Klasse 4 with GSM 850 and EGSM 900; 1 W/Klasse 1 with DCS 1800 and

PCS 1900

Connection management Autonomous establishment and maintenance of the GPRS connection to

SINAUT Micro SC

ANT794-4MR (not identical with the picture) 6NH9 860-1AA00

PPI - Modem cable 6NH9 701-0AD

Accessories

SIM cards Available from your mobile service provider

Configuring software/tools

STEP 7 Micro/WIN 6ES7 810-2CC03-0YX0

*) For simple applications also CPU221 and 222 are applicable.

Micro Automation Set 21 9

MAS_Fernwirktechnik_EN.book Seite 10 Mittwoch, 27. August 2008 11:21 11

© Siemens AG 2008

Get more information

Infoservice – via Post or Fax:

Siemens AG, Infoservice, AD/Z 1306

Postfach 23 48, 90713 Fürth

Fax: 0911 978-3321

Visit us:

www.siemens.com/microset

E-Mail:

microautomation.aud@siemens.com

Ordering via Internet:

www.siemens.com/automation/mall

Discuss your issues on Micro Automation Sets over the internet:

www.siemens.com/forum-microset

Technical support:

www.siemens.com/automation/support-request

The information provided in this brochure contains descriptions

Siemens AG Subject to change without prior notice or characteristics of performance which in case of actual use do

Industry Sector Order No.: 6ZB5310-0PF02-0BA0 not always apply as described or which may change as a result of

Competence Center Micro Automation Dispo 26101 further development of the products. An obligation to provide

Postfach 48 48 BS 0908 10. ROT 10 En / 801598 the respective characteristics shall exist only if expressly agreed

90026 NÜRNBERG Printed in Germany in the terms of contract. Availability and technical specifications

GERMANY © Siemens AG 2008 are subject to change without prior notice.

Any product names mentioned may be trademarks or product

designations of Siemens AG or their suppliers, whose use by third

www.siemens.com/microset parties for their own purposes may infringe the rights of the

trademark owners.

You might also like

- F04 Checklist of Tools, Equipment, Supplies and Materials, and Facilities NEW FORM CSSDocument13 pagesF04 Checklist of Tools, Equipment, Supplies and Materials, and Facilities NEW FORM CSSgillian marbebe100% (1)

- Brochure Telecontrol enDocument16 pagesBrochure Telecontrol enHari PrashannaNo ratings yet

- CEMAT - Process Control For The Cement Industry. Answers For Industry.Document20 pagesCEMAT - Process Control For The Cement Industry. Answers For Industry.ylebongoNo ratings yet

- Power System ControlDocument24 pagesPower System ControlСтоян БанчевNo ratings yet

- TM 1703Document78 pagesTM 1703waltdisneyyNo ratings yet

- Totally Integrated Power ProtectionDocument38 pagesTotally Integrated Power Protectionvthiseas100% (1)

- 3-Totally Integrated Automation ChemicalDocument30 pages3-Totally Integrated Automation ChemicalUmesh SNo ratings yet

- Thesis Reference 6 (Development of Feedback Mechanism For Microcontroller Based SMS Electronic Strolling Message Display Board)Document10 pagesThesis Reference 6 (Development of Feedback Mechanism For Microcontroller Based SMS Electronic Strolling Message Display Board)reyvin.constantinoNo ratings yet

- A Mobile Based Home Automation System and Energy Saving SystemDocument4 pagesA Mobile Based Home Automation System and Energy Saving SystemkarunamoorthiNo ratings yet

- Accessnet®-T Ip NMS: Network Management SystemDocument8 pagesAccessnet®-T Ip NMS: Network Management Systemarif budimanNo ratings yet

- GSM Based Device ControlDocument9 pagesGSM Based Device ControlsubucudNo ratings yet

- 05 # Wireless Signalling and SMSDocument4 pages05 # Wireless Signalling and SMSRaj ChavanNo ratings yet

- Efficiency Package For Solar TrackerDocument2 pagesEfficiency Package For Solar TrackerBoulos NassarNo ratings yet

- DDC Controller - Jci - XPMDocument15 pagesDDC Controller - Jci - XPMolingga92No ratings yet

- Mark ViesDocument32 pagesMark ViesMauricio GuanellaNo ratings yet

- Remote Monitoring Application PaperDocument4 pagesRemote Monitoring Application PaperOliver AlfaroNo ratings yet

- ABB E180 CatDocument24 pagesABB E180 CatPALANI MNo ratings yet

- Telecontrol - Efficient Telecontrol SolutionsDocument16 pagesTelecontrol - Efficient Telecontrol SolutionsJONATHAN FERNANDO VITON CASTAÑEDANo ratings yet

- The Sicas Electronic Interlocking enDocument6 pagesThe Sicas Electronic Interlocking enIgor BlanariNo ratings yet

- Cybersecurity Services - : That Fit Your NeedsDocument2 pagesCybersecurity Services - : That Fit Your NeedsIvan JeremicNo ratings yet

- Remote Mobile Control of Industry Appliances: AbstractDocument3 pagesRemote Mobile Control of Industry Appliances: AbstractkarunamoorthiNo ratings yet

- MonitorDocument86 pagesMonitorsabNo ratings yet

- GFT 870Document32 pagesGFT 870Ha NguyenNo ratings yet

- DFMC b10011 00sinamicsstartdrivedeenus 72Document10 pagesDFMC b10011 00sinamicsstartdrivedeenus 72Tun Myint OoNo ratings yet

- SICAM Navigator - ProfileDocument2 pagesSICAM Navigator - ProfileAldo Bona HasudunganNo ratings yet

- 07 - 001 - 254536-Power System Control and Energy ManagementDocument4 pages07 - 001 - 254536-Power System Control and Energy ManagementGabriel Apavaloaiei100% (1)

- Industrial Automation Using GSM: MBSG Lalitha, V Akshitha, Vs Vineeth K Soundara RajanDocument3 pagesIndustrial Automation Using GSM: MBSG Lalitha, V Akshitha, Vs Vineeth K Soundara RajanTanaka dzapasiNo ratings yet

- M2M Communication Based Wireless SCADA For Real-Time Industrial AutomationDocument3 pagesM2M Communication Based Wireless SCADA For Real-Time Industrial AutomationAutoyearNo ratings yet

- B11190 SUBNET PowerSYSTEM Center BrochureDocument4 pagesB11190 SUBNET PowerSYSTEM Center Brochureeduardo.honorato5586No ratings yet

- Modicon Quantum - SOE SystemDocument4 pagesModicon Quantum - SOE SystemAgis Rijal AtmawijayaNo ratings yet

- Sicam 230 Brochure enDocument8 pagesSicam 230 Brochure enLuis Enrique PariapazaNo ratings yet

- SICAM TM System Data Sheet - 018125328Document78 pagesSICAM TM System Data Sheet - 018125328jakelingonzalezNo ratings yet

- Substation MonitoringDocument6 pagesSubstation MonitoringManish TiwariNo ratings yet

- Siemens SEM3Document24 pagesSiemens SEM3Diego Dandolini PasiniNo ratings yet

- White Paper DMC enDocument31 pagesWhite Paper DMC enraider1eNo ratings yet

- Siemens A50 - Service ManualDocument39 pagesSiemens A50 - Service ManualHolografNo ratings yet

- ANSI LV MCC SIMOCODE EthernetDocument4 pagesANSI LV MCC SIMOCODE EthernetJaime PaizNo ratings yet

- 1.6 Catálogo Blokset Solution Guide 2013Document46 pages1.6 Catálogo Blokset Solution Guide 2013william andres pena castanoNo ratings yet

- ESBED297701EN Blockset Solution Guide 2014Document46 pagesESBED297701EN Blockset Solution Guide 2014Shailesh ChettyNo ratings yet

- Synopsis SMS Controlled Device Switching: University Institute of Engineering & TechnologyDocument9 pagesSynopsis SMS Controlled Device Switching: University Institute of Engineering & TechnologyNarayan Singh WaraichNo ratings yet

- Teleperm XP y Teleperm XS - ComunicaciónDocument12 pagesTeleperm XP y Teleperm XS - Comunicaciónkerusacba_2011No ratings yet

- Job Role-3 Part-3Document24 pagesJob Role-3 Part-3SENTHIL KUMARNo ratings yet

- Submitted To: Implementation of GSM Modem For Industrial Automation ApplicationsDocument79 pagesSubmitted To: Implementation of GSM Modem For Industrial Automation ApplicationsSireesh YeshwantapurNo ratings yet

- UMP BrochureDocument2 pagesUMP BrochureAmarsaikhan AmgalanNo ratings yet

- SIEMENS Embebido CatDocument264 pagesSIEMENS Embebido Catbad boysNo ratings yet

- SIPROTEC Processbus - ProfileDocument2 pagesSIPROTEC Processbus - ProfileVladimir TomicNo ratings yet

- Ficha de Especificaciones inDocument2 pagesFicha de Especificaciones inRodolfo Antonio Cardenas FernandezNo ratings yet

- 3M Volition: Intelligent Management SystemDocument12 pages3M Volition: Intelligent Management SystemFlorin FlorinNo ratings yet

- Final Report FinalDocument67 pagesFinal Report FinalMATHANKUMAR.SNo ratings yet

- GSM Based DC Motor ControlDocument8 pagesGSM Based DC Motor ControlK IsmailNo ratings yet

- 1 Data Sheet Nokia Assurance CenterDocument2 pages1 Data Sheet Nokia Assurance CenterThorNo ratings yet

- Sinumerik 840D SLDocument8 pagesSinumerik 840D SLDinn WahabNo ratings yet

- K-Chief: All Control Requirements Fulfilled - in A Uniform SystemDocument16 pagesK-Chief: All Control Requirements Fulfilled - in A Uniform Systemdnse90900No ratings yet

- A6V10062647 enDocument26 pagesA6V10062647 enSaber MarzoukNo ratings yet

- Machine Monitoring System Based On Mtconnect TechnologyDocument6 pagesMachine Monitoring System Based On Mtconnect TechnologyChiragPhadkeNo ratings yet

- Siemens A52 A55 A56 Service Manual Lvl2Document34 pagesSiemens A52 A55 A56 Service Manual Lvl2topogigio240No ratings yet

- SIMATIC Automation Tool Mit NAT Routing enDocument10 pagesSIMATIC Automation Tool Mit NAT Routing enmaussan El reptilianoNo ratings yet

- Building Management SystemsDocument7 pagesBuilding Management SystemsArman Ul NasarNo ratings yet

- Industrial Training Seminar On BSNL: Submitted ByDocument33 pagesIndustrial Training Seminar On BSNL: Submitted ByShivam ParasharNo ratings yet

- Mastering Siemens S7: A Comprehensive Guide to PLC ProgrammingFrom EverandMastering Siemens S7: A Comprehensive Guide to PLC ProgrammingNo ratings yet

- A5E36695225-ABen SIWAREX WP521 WP522 M en-USDocument176 pagesA5E36695225-ABen SIWAREX WP521 WP522 M en-USPassenger MedeamNo ratings yet

- 104 0661 Abc PDP - 2 - 52Document72 pages104 0661 Abc PDP - 2 - 52Passenger MedeamNo ratings yet

- Hq-EnDocument36 pagesHq-EnPassenger MedeamNo ratings yet

- Keyboard Filter Driver For Intouch 7.0/7.1/7.11: Tech Note 255Document7 pagesKeyboard Filter Driver For Intouch 7.0/7.1/7.11: Tech Note 255Passenger MedeamNo ratings yet

- Profinet ModuleDocument2 pagesProfinet ModulePassenger MedeamNo ratings yet

- BS SHINOHAWA PDFDocument258 pagesBS SHINOHAWA PDFPassenger MedeamNo ratings yet

- Promotional File PAC4200 002136 - ENDocument4 pagesPromotional File PAC4200 002136 - ENPassenger MedeamNo ratings yet

- Interface Module - UM 45-FLKS50/ZFKDS - 2298506: Key Commercial DataDocument1 pageInterface Module - UM 45-FLKS50/ZFKDS - 2298506: Key Commercial DataPassenger MedeamNo ratings yet

- P7PRW03B en-USDocument210 pagesP7PRW03B en-USPassenger MedeamNo ratings yet

- Tech Note 99 Determining SPCPro Alarm Types With SQL QueriesDocument2 pagesTech Note 99 Determining SPCPro Alarm Types With SQL QueriesPassenger MedeamNo ratings yet

- Basic Installation and Start-Up Guide For MASTERDRIVES MC and GMC Software PackagesDocument25 pagesBasic Installation and Start-Up Guide For MASTERDRIVES MC and GMC Software PackagesPassenger MedeamNo ratings yet

- Tech Note 222configuring OPCLink Using TCPIP and A Standard Network Card For Windows NT 4.0 To Access S7-400 PLCs Via The Siemens S7 OPC ServerDocument16 pagesTech Note 222configuring OPCLink Using TCPIP and A Standard Network Card For Windows NT 4.0 To Access S7-400 PLCs Via The Siemens S7 OPC ServerPassenger MedeamNo ratings yet

- Tech Note 154 Configuring InTouch To Query Data From IndustrialSQL ServerDocument11 pagesTech Note 154 Configuring InTouch To Query Data From IndustrialSQL ServerPassenger MedeamNo ratings yet

- Tech Note 79 Creating InTouch Tagnames To Read InControl Local SymbolsDocument7 pagesTech Note 79 Creating InTouch Tagnames To Read InControl Local SymbolsPassenger MedeamNo ratings yet

- Tech Note 88 Configuring InTouch To Communicate With Oracle7Document8 pagesTech Note 88 Configuring InTouch To Communicate With Oracle7Passenger MedeamNo ratings yet

- Using Supertags in Intouch 7.X: What Is A Supertag?Document7 pagesUsing Supertags in Intouch 7.X: What Is A Supertag?Passenger MedeamNo ratings yet

- Security Features in Intouch 8.X: Tech Note 295Document6 pagesSecurity Features in Intouch 8.X: Tech Note 295Passenger MedeamNo ratings yet

- Rotary Measuring Technology: Incremental EncodersDocument7 pagesRotary Measuring Technology: Incremental EncodersPassenger MedeamNo ratings yet

- Tech Note 61 Building Queries in Crystal Reports With IndustrialSQL ServerDocument8 pagesTech Note 61 Building Queries in Crystal Reports With IndustrialSQL ServerPassenger MedeamNo ratings yet

- Siemens S7 PLC and VLT 5000 ProfibusDocument6 pagesSiemens S7 PLC and VLT 5000 ProfibusPassenger MedeamNo ratings yet

- IOSrv ABCIPDocument64 pagesIOSrv ABCIPPassenger MedeamNo ratings yet

- 8000 BR 0826Document8 pages8000 BR 0826Passenger MedeamNo ratings yet

- Waygate Technologies Mentor Visual IQDocument8 pagesWaygate Technologies Mentor Visual IQWilliamNo ratings yet

- Easytek: User GuideDocument120 pagesEasytek: User GuideaxisNo ratings yet

- Led TV: Service ManualDocument99 pagesLed TV: Service Manualloc nguyen100% (1)

- College of Management: Case Analysis: Logitech: The Little Mouse That RoarsDocument4 pagesCollege of Management: Case Analysis: Logitech: The Little Mouse That RoarsEmy Rose DiosanaNo ratings yet

- ITE 6.0 Pre-Test Answers 2018 2019 100% ITE 6.0 Pre-Test Answers 2018 2019 100%Document8 pagesITE 6.0 Pre-Test Answers 2018 2019 100% ITE 6.0 Pre-Test Answers 2018 2019 100%Egy RenataNo ratings yet

- SMT 585Document109 pagesSMT 585Cesar MessiasNo ratings yet

- Frequency Allocation - 1800Mhz Band: Mobitel 2G Airtel 2G Mobitel - 4G Lte Mobitel 2GDocument1 pageFrequency Allocation - 1800Mhz Band: Mobitel 2G Airtel 2G Mobitel - 4G Lte Mobitel 2GSudheera IndrajithNo ratings yet

- Tmob NitherlandsDocument1 pageTmob NitherlandsAmine AminovichNo ratings yet

- Evolution DMS-1004HD-CA (HD - DTA - CA - Slick - 5.5.11 - MX)Document3 pagesEvolution DMS-1004HD-CA (HD - DTA - CA - Slick - 5.5.11 - MX)Alx_doeth0% (1)

- Introduction To GSMDocument52 pagesIntroduction To GSMapi-3717973100% (2)

- Cs - TC - Datasheet - RF 7400e VP Tactical Video ProcessorDocument2 pagesCs - TC - Datasheet - RF 7400e VP Tactical Video Processorjuan camilo cardona SánchezNo ratings yet

- ИКТ алфавит (копия)Document18 pagesИКТ алфавит (копия)Dancho KZNo ratings yet

- Leica Geosystems TPS Comparison ChartDocument1 pageLeica Geosystems TPS Comparison ChartBirdNo ratings yet

- Home What MobileDocument2 pagesHome What MobilemuhsanshakeelNo ratings yet

- Advantages & Disadvantages of Social Media (TwitterDocument3 pagesAdvantages & Disadvantages of Social Media (Twitterpronab sarkerNo ratings yet

- STPCS7 IPC647C-IPC847C English 2011-12Document22 pagesSTPCS7 IPC647C-IPC847C English 2011-12Federico DiazNo ratings yet

- Architecture of A Computer SystemDocument6 pagesArchitecture of A Computer SystemJohn VibarNo ratings yet

- Nokia 2013 Annual ReportDocument96 pagesNokia 2013 Annual ReportMvk ChaitanyaNo ratings yet

- BR01 iNAND Embedded Integrated Solutions 0217Document4 pagesBR01 iNAND Embedded Integrated Solutions 0217potatoNo ratings yet

- Pengenalan Teknologi Rangkaian Terintegrasi: Eka Maulana, ST, MT, Meng. Adharul Muttaqin, S.T., M.TDocument35 pagesPengenalan Teknologi Rangkaian Terintegrasi: Eka Maulana, ST, MT, Meng. Adharul Muttaqin, S.T., M.TMuhammad FauzanNo ratings yet

- 006 0584 00 LidarCam BrochureDocument2 pages006 0584 00 LidarCam BrochureTịnh TrầnNo ratings yet

- Practical Task 2Document2 pagesPractical Task 2Tiniey NadlanNo ratings yet

- Stryker 26 Vision Elect BrochureDocument2 pagesStryker 26 Vision Elect BrochureRicardo SalazarNo ratings yet

- Unit4 - Components of A Computer SystemDocument74 pagesUnit4 - Components of A Computer SystemJaren QueganNo ratings yet

- Tarea de Cruso de Contabilidad y InglkesDocument2 pagesTarea de Cruso de Contabilidad y Inglkeskarin trinidad villanuevaNo ratings yet

- Ufone StakeholdersDocument7 pagesUfone StakeholdersArslan NawazNo ratings yet

- Brosura EBS 260Document4 pagesBrosura EBS 260Cocis MirceaNo ratings yet

- Konftel 70 Data Sheet - ENG-LOWDocument2 pagesKonftel 70 Data Sheet - ENG-LOWRavi sontakkeNo ratings yet

- H3509 User-Manual enDocument25 pagesH3509 User-Manual enYaseen QariNo ratings yet