Professional Documents

Culture Documents

Warp and Fill Breaking Load at Room Temperature: 3M Nextel Woven Fabrics 312 and 440

Warp and Fill Breaking Load at Room Temperature: 3M Nextel Woven Fabrics 312 and 440

Uploaded by

ninatenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warp and Fill Breaking Load at Room Temperature: 3M Nextel Woven Fabrics 312 and 440

Warp and Fill Breaking Load at Room Temperature: 3M Nextel Woven Fabrics 312 and 440

Uploaded by

ninatenaCopyright:

Available Formats

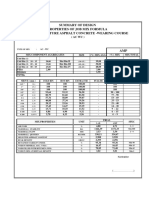

Warp and Fill Breaking Load at Room Temperature

Nextel

3M Woven Fabrics 312 and 440

Warp and fill breaking loads were measured The tensile tester was set up with a 3 inch

at room temperature using the following (7.62 cm) gauge length and a crosshead speed

procedure, based upon ASTM D-5035: of 0.5 inch (1.27 cm) per minute.

Fabric samples were cut into 1.5 inch x 6 inch Fabric was placed into the jaws fitted with

(3.81 cm x 15.24 cm) strips in the warp and fill 1 inch (2.54 cm) pads. Air pressure was set

directions, respectively. Strips were placed in at 60-80 psi (4.14 x 105 – 5.51 x 105 Pa).

a 1472°F (800°C) oven for one hour to remove

the sizing. Each sample was loaded until failure. Five

samples of each fabric were tested at room

Edges were unraveled to 1 inch (2.54 cm). temperature. The averages are shown below.

Masking tape was placed at each end with 3

inches (7,62 cm) test area exposed between

taped areas.

TM TM

3M Nextel Woven Fabric 312 and 440

Warp and Fill Strength

350 (62.6)

350

Warp Fill

300 (53.6)

300

250 (44.7)

250

Tensile Strength, lbs/in (kg/cm)

200 (35.7)

200

150 (26.8)

150

100 (17.9)

100

50 (8.9)

50

00

AF-10 AF-11 AF-12 AF-14 AF-20 AF-30 AF-40 AF-62 BF-20 BF-30 BF-40

Fabric Type

Typical property data is for engineering use only. Contact a 3M representative before developing a specification. 29

See Important Notice to Purchaser for details.

You might also like

- SITXFSA008 - Unit Assessment Tool (UAT) V3Document71 pagesSITXFSA008 - Unit Assessment Tool (UAT) V3Stacy ParkerNo ratings yet

- Grade 6 Weekly Spelling WordsDocument6 pagesGrade 6 Weekly Spelling WordsJessie OcadoNo ratings yet

- Adidas ST-02 Tear StrengthDocument7 pagesAdidas ST-02 Tear StrengthHenry Chao-Jen WangNo ratings yet

- Huawei HCIA-IoT v. 2.5 Evaluation QuestionsDocument77 pagesHuawei HCIA-IoT v. 2.5 Evaluation Questionstest oneNo ratings yet

- Meril Suture Catalogue Final Pages Deleted (1 24.40 44.50 64)Document44 pagesMeril Suture Catalogue Final Pages Deleted (1 24.40 44.50 64)threwaway75% (4)

- Preformed Expansion Joint Filler For Concrete (Bituminous Type)Document2 pagesPreformed Expansion Joint Filler For Concrete (Bituminous Type)Katerin HernandezNo ratings yet

- 1.01 The Updated Tex-248-F Test ProcedureDocument13 pages1.01 The Updated Tex-248-F Test ProcedureDavid Vaca OyolaNo ratings yet

- B.C - Nadanghat - Ballah PilingDocument2 pagesB.C - Nadanghat - Ballah PilingAlok Sarkar100% (1)

- Tensile Test Report - COMPLETEDocument9 pagesTensile Test Report - COMPLETEJasanta Jinor50% (2)

- KM Instructor Course Phase 1aDocument22 pagesKM Instructor Course Phase 1anozza_1No ratings yet

- Compressive PropertiesDocument3 pagesCompressive PropertiesSh.nasirpurNo ratings yet

- 120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVDocument2 pages120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVMuhammad Shabbir AwanNo ratings yet

- Flexural PropertiesDocument2 pagesFlexural PropertiesSh.nasirpurNo ratings yet

- Bharat Engineering Construction Company (P) LTD Sieve Analysis of Fine Aggregate For ConcreteDocument1 pageBharat Engineering Construction Company (P) LTD Sieve Analysis of Fine Aggregate For ConcretemohamedNo ratings yet

- Concrete Mix Design Aci 211 - Workshop 2017 PRDP PDFDocument39 pagesConcrete Mix Design Aci 211 - Workshop 2017 PRDP PDFChuckie EntocNo ratings yet

- Qualitative Examination: Table 1Document1 pageQualitative Examination: Table 1VimalNo ratings yet

- List of Tests in Geotechnical EngineeringDocument4 pagesList of Tests in Geotechnical EngineeringJulian KitingNo ratings yet

- Preformed Expansion Joint Filler For Concrete (Bituminous Type)Document2 pagesPreformed Expansion Joint Filler For Concrete (Bituminous Type)mjgutierrezperaltaNo ratings yet

- Bending Tests: 3-Point and 4-Point BendingDocument20 pagesBending Tests: 3-Point and 4-Point BendingTuấn NguyễnNo ratings yet

- PRC-II Lab ManualDocument41 pagesPRC-II Lab ManualRana Asad AliNo ratings yet

- Verification of Working Tapes With A Master TapeDocument14 pagesVerification of Working Tapes With A Master TapeTauseef Aamere RoseNo ratings yet

- Fane HP ClassicDocument1 pageFane HP ClassicferdinandNo ratings yet

- Die Cut PartsDocument2 pagesDie Cut PartsAbdelrhman ElsayedNo ratings yet

- Seive Analysis of Coarse Aggregate OnlyDocument3 pagesSeive Analysis of Coarse Aggregate OnlyYasirNo ratings yet

- Material Testing Laboratory ManualDocument22 pagesMaterial Testing Laboratory ManualSamirHashimNo ratings yet

- Shear PropertiesDocument1 pageShear PropertiesSh.nasirpurNo ratings yet

- ComFlor 80 Load Span Tables PDFDocument4 pagesComFlor 80 Load Span Tables PDFAkhil VNNo ratings yet

- Brochure Sieve Shakers enDocument4 pagesBrochure Sieve Shakers enjesusNo ratings yet

- O o Fig. 4 - Stress-Strain Curves For Steel ReinforcementDocument1 pageO o Fig. 4 - Stress-Strain Curves For Steel ReinforcementRonal J Clavijo RNo ratings yet

- AASHTO T19-00 Bulk Density ("Unit Weight") & Voids in Aggregate ApparatusDocument2 pagesAASHTO T19-00 Bulk Density ("Unit Weight") & Voids in Aggregate ApparatusNguyễn Văn MinhNo ratings yet

- Siewe Analiysis of Course SandDocument1 pageSiewe Analiysis of Course SandAkash katiyarNo ratings yet

- Bursting Strength of Leather by The Ball Method: Standard Test Method ForDocument4 pagesBursting Strength of Leather by The Ball Method: Standard Test Method ForSTAFFORDNo ratings yet

- CMT QuizDocument3 pagesCMT QuizCHARLES LEJANONo ratings yet

- Material Properties CheckDocument10 pagesMaterial Properties CheckNikkiNo ratings yet

- Ashcroft ThermometerDocument2 pagesAshcroft ThermometerjlcegarraNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- Lec 3 and 4 Properties and Uses of AggregatesDocument45 pagesLec 3 and 4 Properties and Uses of Aggregatespurple9440No ratings yet

- LR Magna Comp BPDocument2 pagesLR Magna Comp BPherbster28No ratings yet

- Astm c578Document1 pageAstm c578Nicole Campos CastroNo ratings yet

- Elastomer I C Bearings PDFDocument8 pagesElastomer I C Bearings PDFMiguel Belda DiezNo ratings yet

- (Joint Size at Mean T F) (Closes To) (Opens To) : (See "Performance" For Movement Capabilities & Limitations)Document1 page(Joint Size at Mean T F) (Closes To) (Opens To) : (See "Performance" For Movement Capabilities & Limitations)Erickzelaya2014No ratings yet

- Sizes of Aggregate For Road and Bridge ConstructionDocument3 pagesSizes of Aggregate For Road and Bridge ConstructionRicardoNo ratings yet

- 8 SFRS PerfromanceDocument11 pages8 SFRS PerfromancePavel TelloNo ratings yet

- SEFAR Specification 3A03-0300-153-00Document1 pageSEFAR Specification 3A03-0300-153-00Alex MtzNo ratings yet

- Aggregate: Testing EquipmentsDocument12 pagesAggregate: Testing EquipmentsMorched TounsiNo ratings yet

- Investigation of The Performance of Sewing Thread: Department of Clothing Science, Nara Women's University, JapanDocument8 pagesInvestigation of The Performance of Sewing Thread: Department of Clothing Science, Nara Women's University, JapanAshish GuptaNo ratings yet

- SolidreportDocument7 pagesSolidreportDarshit GadhiyaNo ratings yet

- D 448 - 03 Rdq0oc1sruqDocument4 pagesD 448 - 03 Rdq0oc1sruqel kevinsio el kevinsoNo ratings yet

- 3M Nextel Woven Ceramic FabricsDocument3 pages3M Nextel Woven Ceramic FabricsninatenaNo ratings yet

- 185 Betonpalen TestenDocument16 pages185 Betonpalen TestenMarko PopovicNo ratings yet

- Pure 50Document9 pagesPure 50Carlos LagosNo ratings yet

- JMF Pertamina 2Document18 pagesJMF Pertamina 2Erda Adyatma SamtiarikoNo ratings yet

- ASTM A333 GR.6 Seamless Low Temperature Pipes PDFDocument7 pagesASTM A333 GR.6 Seamless Low Temperature Pipes PDFraditya putraNo ratings yet

- Effect of Changing Arm Pressure of Drafting Zone of A Roving Frame On Yarn QualityDocument11 pagesEffect of Changing Arm Pressure of Drafting Zone of A Roving Frame On Yarn QualityMd. Humayun KabirNo ratings yet

- Glued Laminated Timber: Shear Test of Gluelines: René SteigerDocument10 pagesGlued Laminated Timber: Shear Test of Gluelines: René SteigerAlronavee MambajeNo ratings yet

- Concrete and Soil Test ProceduresDocument5 pagesConcrete and Soil Test ProceduresMohammad Rabnawaz imamNo ratings yet

- HPSM08030FU1Document9 pagesHPSM08030FU1Bhaumik DaveNo ratings yet

- Penetration Test On BituminousDocument3 pagesPenetration Test On BituminousM Zeeshan Haider100% (2)

- Dynamic Test - Method StatementDocument4 pagesDynamic Test - Method StatementNilay Gandhi100% (1)

- CE305 C 136Document3 pagesCE305 C 136Laiyee YeowNo ratings yet

- Cushion-Mount Plus Plate Mounting Tapes With Easy Mount Adhesive High Plateside AdhesionDocument6 pagesCushion-Mount Plus Plate Mounting Tapes With Easy Mount Adhesive High Plateside AdhesionSerhan ÜnverNo ratings yet

- TDS-US-Terramesh GalMac & PVC, July17Document2 pagesTDS-US-Terramesh GalMac & PVC, July17edson_vladimirNo ratings yet

- Effect of Thickness and Grain Size On Flow Stress of Very Thin Brass Anand2014Document7 pagesEffect of Thickness and Grain Size On Flow Stress of Very Thin Brass Anand2014Abichou IssaNo ratings yet

- Etag 001 Annex ADocument19 pagesEtag 001 Annex AEmmanuel Dupuy100% (1)

- Gríma, You and Ása Ride Back With MeDocument20 pagesGríma, You and Ása Ride Back With MeninatenaNo ratings yet

- (Over Radio) Einar To Gríma. - (Over Radio) Gríma HereDocument26 pages(Over Radio) Einar To Gríma. - (Over Radio) Gríma HereninatenaNo ratings yet

- Enct. - : - Ref. 01..:.. '. MS TotDocument2 pagesEnct. - : - Ref. 01..:.. '. MS TotninatenaNo ratings yet

- Katla S01E03 The Mother 1080p NF WEB-DL SDHDocument22 pagesKatla S01E03 The Mother 1080p NF WEB-DL SDHninatenaNo ratings yet

- (Automated Voice) The NumberDocument21 pages(Automated Voice) The NumberninatenaNo ratings yet

- Om Under The Glacier 1080p NF WEB-DL SDHDocument23 pagesOm Under The Glacier 1080p NF WEB-DL SDHninatenaNo ratings yet

- Aws D1.1/D1.1M:2015Document6 pagesAws D1.1/D1.1M:2015ninatenaNo ratings yet

- Welding Processes and ProceduresDocument6 pagesWelding Processes and ProceduresninatenaNo ratings yet

- Enct. - : - Ref. 01..:.. '. MS TotDocument2 pagesEnct. - : - Ref. 01..:.. '. MS TotninatenaNo ratings yet

- Stell 2011specificDocument7 pagesStell 2011specificninatenaNo ratings yet

- TTBDocument1 pageTTBninatenaNo ratings yet

- Enct. - : - Ref. 01..:.. '. MS TotDocument2 pagesEnct. - : - Ref. 01..:.. '. MS TotninatenaNo ratings yet

- But I Guess I Missed All The FunDocument2 pagesBut I Guess I Missed All The FunninatenaNo ratings yet

- B: - (R T) × B - B: B: - (R T) × B - BDocument2 pagesB: - (R T) × B - B: B: - (R T) × B - BninatenaNo ratings yet

- But I Guess I Missed All The FunDocument2 pagesBut I Guess I Missed All The FunninatenaNo ratings yet

- Mateaq11235V2Bbrials: Sl. WQQQQQQQQ Materials Qqqwetwetgsd W352v33r Wuiuo Etty 7745nldrdyrzdyriogDocument1 pageMateaq11235V2Bbrials: Sl. WQQQQQQQQ Materials Qqqwetwetgsd W352v33r Wuiuo Etty 7745nldrdyrzdyriogninatenaNo ratings yet

- Ksfkds LGK:DSKG LGK FLG DGKSDG Kf:Laskl:Fkjhpthw (G Lgkwe'Gj'EgsdgldsDocument2 pagesKsfkds LGK:DSKG LGK FLG DGKSDG Kf:Laskl:Fkjhpthw (G Lgkwe'Gj'EgsdgldsninatenaNo ratings yet

- Transmittal NutDocument2 pagesTransmittal NutninatenaNo ratings yet

- L KDVLCK GDSK Glkopddfpijoho (TRRT RWRLWQKR KW:LRWDocument2 pagesL KDVLCK GDSK Glkopddfpijoho (TRRT RWRLWQKR KW:LRWninatenaNo ratings yet

- Elklke TK Epl ZLK Fdhar (Eahprepoay Oskp Yvy Yvsjttt: Sl. Ryq4Lklk:Gk Ek TK Oetw Tegswe2R24Cd Materials Grade OriginDocument1 pageElklke TK Epl ZLK Fdhar (Eahprepoay Oskp Yvy Yvsjttt: Sl. Ryq4Lklk:Gk Ek TK Oetw Tegswe2R24Cd Materials Grade OriginninatenaNo ratings yet

- Qeqeqrtrw5 PCS, Ba DKJFQJWKJRKWJRJJR CQWQJLJFJKFJKXFH KjwhfjheqkfwfwkjlejqrkDocument2 pagesQeqeqrtrw5 PCS, Ba DKJFQJWKJRKWJRJJR CQWQJLJFJKFJKXFH KjwhfjheqkfwfwkjlejqrkninatenaNo ratings yet

- ELLNA iMPLEMENTER FINALDocument22 pagesELLNA iMPLEMENTER FINALGina HerraduraNo ratings yet

- Solar PV Water Pumping SystemDocument7 pagesSolar PV Water Pumping SystemAastha JoshiNo ratings yet

- Double Wedding Ring Size Fabric Requirements EditedDocument3 pagesDouble Wedding Ring Size Fabric Requirements EditedfrapatchNo ratings yet

- Master Part ListDocument4 pagesMaster Part ListMATHIVANNANNo ratings yet

- Ethan Mollick TechTrendsDocument6 pagesEthan Mollick TechTrendsnsansaturninoNo ratings yet

- Recruitment and Selection Kamini-200Document98 pagesRecruitment and Selection Kamini-200Mohammad ShoebNo ratings yet

- Muhammad Alauddin Nur, S.PD., GR.: Arranged byDocument75 pagesMuhammad Alauddin Nur, S.PD., GR.: Arranged byNo HikariNo ratings yet

- FlowDocument8 pagesFlowAnasBahariNo ratings yet

- The Myth of The Neronian Persecution. Brent D. ShawDocument28 pagesThe Myth of The Neronian Persecution. Brent D. ShawDolores MonteroNo ratings yet

- Liebert - CRV Series Air Conditioner User Manual: V1.4 Revision Date May 28, 2012 BOM 31011886Document79 pagesLiebert - CRV Series Air Conditioner User Manual: V1.4 Revision Date May 28, 2012 BOM 31011886Dam Ngoc KienNo ratings yet

- Fermi LevelDocument13 pagesFermi LevelArchit P. MeshramNo ratings yet

- Chapter 75Document2 pagesChapter 75Quranic ResourcesNo ratings yet

- Analyzing The Internal Environment of The FirmDocument7 pagesAnalyzing The Internal Environment of The FirmRegine Balaan Anua100% (1)

- Catalogue Product M-Plus FilterDocument40 pagesCatalogue Product M-Plus FilterAdrian Samuel ThenochNo ratings yet

- Unstructured Data ClassificationDocument2 pagesUnstructured Data ClassificationAyush GargNo ratings yet

- 503 Acetic Acid in PeptidesDocument2 pages503 Acetic Acid in PeptidesGOGETTONo ratings yet

- 151-Enablon Orm - Permit To WorkDocument2 pages151-Enablon Orm - Permit To WorkRishikesh GunjalNo ratings yet

- Territory Management Decision GuideDocument5 pagesTerritory Management Decision GuideIoana AlexandraNo ratings yet

- Family EngagementDocument8 pagesFamily Engagementapi-559316869No ratings yet

- HR Practices NTPCDocument16 pagesHR Practices NTPCRuchika SinhaNo ratings yet

- Case Study in Safety ManagementDocument37 pagesCase Study in Safety ManagementVernie SorianoNo ratings yet

- Guía Didáctica - Profesionalización Inglés A1Document60 pagesGuía Didáctica - Profesionalización Inglés A1Fernanda AndradeNo ratings yet

- Form 16: Warora Kurnool Transmission LimitedDocument10 pagesForm 16: Warora Kurnool Transmission LimitedBHASKAR pNo ratings yet

- Tutorial (Equlibrium) AnswersDocument4 pagesTutorial (Equlibrium) Answersoh khang chiangNo ratings yet

- Foward Reverse StarterDocument5 pagesFoward Reverse StarterCahayaKeasLiaN67% (6)